The global plastic pallet market is experiencing robust growth, driven by increasing demand for durable, lightweight, and hygienic material handling solutions across logistics, automotive, pharmaceutical, and food & beverage industries. According to a 2023 report by Mordor Intelligence, the plastic pallet market was valued at USD 5.8 billion in 2022 and is projected to grow at a CAGR of 6.8% from 2023 to 2028, reaching an estimated USD 8.7 billion by the end of the forecast period. This expansion is fueled by the rising adoption of plastic pallets in automated warehouses, their reusability, and compliance with stringent sanitation and sustainability standards. Additionally, Grand View Research highlights that innovations in resin technology and closed-loop leasing models are further accelerating market penetration. As demand surges, a select group of manufacturers has emerged as leaders, setting benchmarks in product quality, innovation, and global reach—shaping the future of supply chain efficiency.

Top 10 Plastic Palette Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Plastic Pallets

Domain Est. 2001

Website: orbiscorporation.com

Key Highlights: ORBIS manufactures all types of plastic pallets for industrial & retail supply chains. Contact us to get a quote or to discuss custom pallet solutions….

#2 Reliable Pallet Suppliers for Your Operations

Domain Est. 1998

Website: chep.com

Key Highlights: Unmatched global network of consistent quality pallets and containers that enable suppliers, manufacturers and retailers to reliably move goods….

#3 Plastic Pallet Manufacturers

Domain Est. 2012

Website: plasticpalletmanufacturers.org

Key Highlights: Explore the list of plastic pallet suppliers listed on this site. Their pallets are nestable, and can be bought for the best prices possible….

#4 Rehrig Pacific Plastic Pallets

Domain Est. 1997

Website: rehrigpacific.com

Key Highlights: Explore Rehrig Pacific’s range of durable, sustainable plastic pallets designed to enhance supply chain efficiency. From nestable to rackable options, ……

#5 RM2

Domain Est. 1997

Website: rm2.com

Key Highlights: REUSABLE PALLET MANUFACTURING, LOGISTICS, AND CLEANING. With nationwide pallet cleaning and logistics infrastructure and sophisticated manufacturing ……

#6 Plastic Pallets

Domain Est. 1999

Website: cabka.com

Key Highlights: Find high-quality plastic pallets for your business needs. Choose from a wide range of sustainable, durable and custom solutions. Contact us today!…

#7 Industry-Leading Plastic Pallets & Bottled Water Racks

Domain Est. 1999

Website: prostack.com

Key Highlights: PSI provides durable plastic pallets and bottled water racks for food, beverage, and pharma. Improve efficiency and sustainability with reusable HDPE ……

#8 Gorilla Pallets

Domain Est. 2004

Website: gorillapallets.com

Key Highlights: Gorilla Pallets offers durable plastic pallets for various industries. Explore our selection of high-quality, long-lasting pallet solutions….

#9 Greystone Logistics – 100% Recycled Plastic Pallets

Domain Est. 2023

Website: greystonepallets.com

Key Highlights: Greystone Logistics is a manufacturing company that designs, manufactures, and sells high quality plastic pallets that provide logistical solutions needed by a ……

#10 Plastic Pallets: Your Definitive Guide

Domain Est. 2003

Website: igps.net

Key Highlights: A plastic pallet is a flat platform made from durable plastic, used for transporting, storing, and handling goods. Unlike wooden pallets, plastic pallets ……

Expert Sourcing Insights for Plastic Palette

2026 Market Trends for Plastic Pallets: A H2 Analysis

The plastic pallet market in 2026 is poised for significant evolution, driven by sustainability mandates, technological advancements, supply chain resilience demands, and shifting regulatory landscapes. Here’s a breakdown of key trends shaping the industry:

1. Sustainability & Circular Economy Dominance (H2 Focus):

* Regulatory Pressure (H2): Expect stringent regulations (e.g., extended producer responsibility – EPR, plastic taxes, carbon border adjustments) to accelerate in H2 2026, particularly in the EU and North America. This will force manufacturers and users towards pallets with higher recycled content (PCR) and full recyclability.

* Closed-Loop Systems (H2): Investment in and adoption of closed-loop rental/pooling models will surge. Companies will prioritize partners offering take-back programs and guaranteed recycling, minimizing waste and lifecycle costs. H2 will see consolidation and scaling of these models.

* Advanced Recycling (H2): Chemical recycling technologies (e.g., depolymerization) will move beyond pilot stages, enabling the use of mixed or contaminated plastic waste to create virgin-quality resin for pallets. This addresses feedstock limitations and enhances circularity credentials by H2.

* Carbon Footprint Transparency (H2): Demand for verifiable lifecycle assessment (LCA) data will be critical. Suppliers offering low-carbon footprint pallets (using renewable energy, bio-based plastics, efficient logistics) will gain significant competitive advantage, especially for ESG-conscious clients.

2. Technological Integration & Smart Pallets:

* IoT & Track-and-Trace (H2): While growing, widespread adoption of smart pallets with embedded sensors (RFID, GPS, temperature/humidity) will face cost hurdles. However, H2 2026 will see targeted use cases expand in high-value, regulated (pharma, food), or critical logistics where real-time visibility and condition monitoring justify the investment.

* Digitalization & Data (H2): Integration of pallet data into supply chain management platforms (SCM, WMS) will become standard. Analytics on pallet utilization, location, and condition will drive optimization, reduce losses, and improve asset management efficiency.

3. Supply Chain Resilience & Material Innovation:

* Reshoring & Nearshoring (H2): Geopolitical instability and supply chain disruptions will continue pushing companies to regionalize manufacturing. H2 2026 will see increased demand for regionally produced plastic pallets to reduce lead times and logistical complexity.

* Alternative Materials (H2): Research and limited commercialization of bio-based polymers (e.g., from agricultural waste) will progress. While cost and scalability remain challenges, H2 may see niche premium pallets using these materials, appealing to specific sustainability goals.

* Performance & Durability Focus (H2): Demand for longer-lasting, high-performance pallets (e.g., for automated warehouses, heavy loads, extreme temperatures) will grow, reducing total cost of ownership (TCO) despite higher initial cost.

4. Market Dynamics & Competition:

* Consolidation (H2): The market will likely see further M&A activity, particularly among rental/pooling providers and larger manufacturers seeking scale, technology, or geographic reach to compete effectively.

* Cost Pressures (H2): Volatility in virgin polymer prices and energy costs will persist. This will intensify competition on efficiency and drive innovation in design (lighter pallets) and recycling processes to control input costs.

* E-commerce & Warehousing Growth (H2): The continued expansion of e-commerce fulfillment centers will drive demand for plastic pallets suitable for automated handling systems (AS/RS) and offering hygiene benefits, especially in food and consumer goods.

Conclusion (H2 Outlook):

By H2 2026, the plastic pallet market will be fundamentally reshaped by sustainability imperatives. Success will hinge on embracing the circular economy through closed-loop systems, advanced recycling, and transparent low-carbon production. While smart pallets offer potential, their impact will be selective. Resilience, regionalization, and performance will be key differentiators. Companies failing to adapt to regulatory demands and circular economy principles will face significant challenges, while innovators and integrated service providers will capture substantial market share. The focus will shift decisively from just cost to total value, including environmental impact and supply chain security.

Common Pitfalls in Sourcing Plastic Pallets: Quality and Intellectual Property Issues

Logistics & Compliance Guide for Plastic Pallets

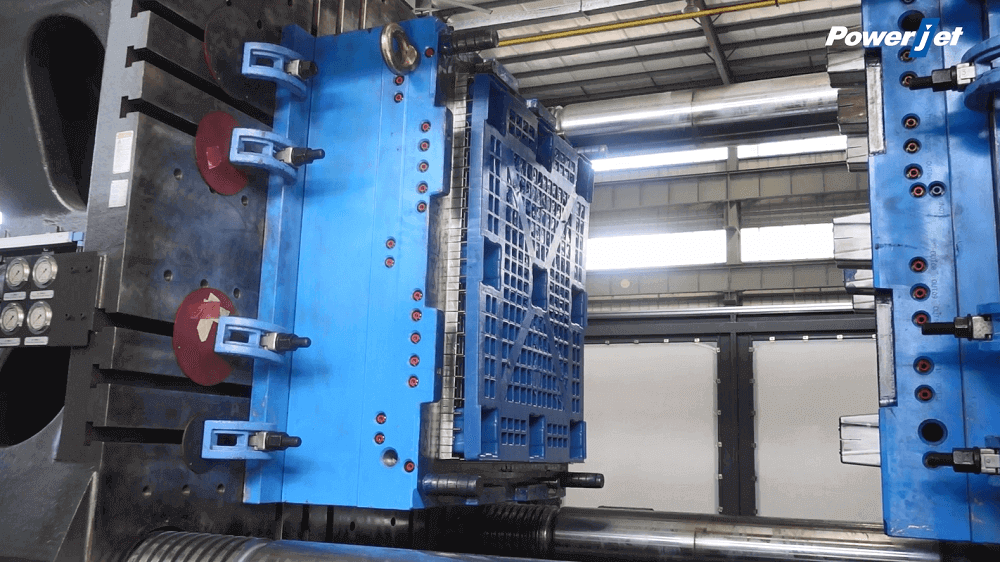

Plastic pallets offer durability, hygiene, and sustainability advantages over traditional wooden pallets. However, their use involves specific logistics considerations and compliance requirements. This guide outlines key aspects to ensure efficient handling, transportation, and regulatory adherence when using plastic pallets in supply chain operations.

Material Specifications and Standards

Plastic pallets are commonly made from high-density polyethylene (HDPE) or polypropylene (PP), both of which are recyclable and resistant to moisture, chemicals, and pests. To ensure compatibility and safety, pallets should conform to international standards such as:

- ISO 8611 – Specifies performance requirements and test methods for pallets.

- GS1 standards – Define dimensions and barcode placement for global interoperability.

- EUR/EPAL specifications – Common European pallet sizes (e.g., EUR 1: 1200 x 800 mm).

- FDA and EU Food Contact Regulations – Required if used in food, pharmaceutical, or healthcare supply chains (e.g., EC 1935/2004 in the EU).

Ensure that pallets are marked with relevant identification, including manufacturer details, material type (e.g., HDPE), and load capacity.

Load Capacity and Handling

Understanding load ratings is essential for safety and efficiency:

- Static Load – Maximum weight the pallet can support when stationary.

- Dynamic Load – Maximum weight when being moved (e.g., by forklift).

- Rack Load – Maximum weight when stored on pallet racking systems.

Always match the pallet’s load rating to the application. Overloading can lead to structural failure, product damage, or workplace injury. Use appropriate handling equipment—plastic pallets may require different forklift tine settings than wooden pallets due to solid decks or unique entry points (e.g., 2-way vs. 4-way entry).

Transportation and Intermodal Compatibility

Plastic pallets must be compatible with various modes of transport:

- Containerization – Ensure pallet dimensions allow for optimal cube utilization in shipping containers (e.g., 20′ or 40′ containers).

- Intermodal Freight – Pallets should be stackable and stable during rail, road, and sea transport.

- Air Freight – Consider weight savings; though heavier than some wood pallets, plastic models are often more durable for repetitive use.

Use slip sheets or stretch wrap appropriately to secure loads. Avoid mixing plastic and wooden pallets in the same shipment unless compatible in height and strength.

Sanitation and Hygiene Compliance

A major advantage of plastic pallets is their cleanability and resistance to contamination:

- Washable and Reusable – Pallets can be sanitized using high-pressure washing, steam, or chemical cleaning.

- IPPC/ISPM 15 Exemption – Unlike wood, plastic pallets do not require heat treatment or fumigation for international shipping, simplifying customs clearance.

- HACCP & GMP Compliance – Critical in food and pharma sectors; ensure pallets are non-porous and meet hygiene standards.

Maintain cleaning logs and inspection records to demonstrate compliance during audits.

Sustainability and Regulatory Compliance

Plastic pallets support circular economy goals when properly managed:

- Recyclability – At end-of-life, most plastic pallets can be recycled into new products.

- REACH and RoHS – Ensure materials comply with EU chemical regulations if operating in or exporting to Europe.

- Carbon Footprint – Consider lifecycle analysis (LCA); reusable plastic pallets often have lower environmental impact over time versus single-use wood.

Implement a pallet pooling or asset tracking system (e.g., RFID tags) to monitor usage, reduce loss, and support sustainability reporting.

Customs and International Trade Considerations

When shipping across borders:

- No ISPM 15 Requirements – Plastic pallets are exempt from wood packaging regulations, reducing delays.

- Country-Specific Rules – Verify local regulations; some countries may have import restrictions on certain plastics or require material declarations.

- Documentation – Include pallet material type in shipping manifests and commercial invoices.

Partner with logistics providers experienced in plastic pallet handling to avoid compliance issues.

Maintenance and Lifecycle Management

To maximize ROI and safety:

- Inspect Regularly – Check for cracks, warping, or structural damage before each use.

- Retire Damaged Units – Remove compromised pallets from circulation to prevent accidents.

- Inventory Tracking – Use barcodes or RFID for real-time visibility and loss prevention.

- Repair Programs – Some manufacturers offer refurbishment services to extend lifespan.

Conclusion

Plastic pallets enhance supply chain efficiency, hygiene, and sustainability when managed correctly. By adhering to material standards, load specifications, sanitation protocols, and international regulations, businesses can leverage the full benefits of plastic pallets while ensuring compliance and operational safety. Regular training and vendor collaboration are key to successful implementation.

Conclusion for Sourcing Plastic Pallets

In conclusion, sourcing plastic pallets presents a strategic advantage for businesses seeking durability, cost-efficiency, and sustainability in their supply chain operations. Unlike traditional wooden pallets, plastic pallets offer superior strength, resistance to moisture and chemicals, and a longer lifespan, reducing the total cost of ownership over time. Their consistent quality and hygienic properties make them ideal for industries such as food and beverage, pharmaceuticals, and clean manufacturing environments.

Furthermore, the availability of recyclable and recyclable content in plastic pallets supports environmental sustainability goals and aligns with increasing regulatory and consumer demands for eco-friendly practices. While the initial investment may be higher than wood, the long-term benefits—lower maintenance, reduced product damage, and compatibility with automated handling systems—justify the cost.

To ensure optimal results, it is essential to partner with reputable suppliers that offer certified, high-quality plastic pallets tailored to specific logistical needs. Conducting a thorough evaluation of load requirements, usage environment, and return on investment will guide effective decision-making.

Ultimately, sourcing plastic pallets is a forward-thinking choice that enhances operational efficiency, supports sustainability initiatives, and contributes to a more resilient and modern supply chain.