The global fastener market, a critical enabler of modern manufacturing, is experiencing robust growth driven by rising demand across automotive, construction, and industrial equipment sectors. According to Grand View Research, the market was valued at USD 112.67 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 4.8% from 2024 to 2030. A key segment within this landscape—pitch screw manufacturers—is benefiting from increased automation, precision engineering requirements, and advancements in machine tool technology. Pitch screws, essential for linear motion control in CNC machines, robotics, and aerospace systems, are seeing heightened demand in high-precision applications. As industries prioritize efficiency and accuracy, the competitive field among manufacturers is intensifying. Based on production capabilities, innovation in thread rolling and grinding technologies, global reach, and industry certifications, the following ten companies have emerged as leaders shaping the future of pitch screw manufacturing.

Top 10 Pitch Screw Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

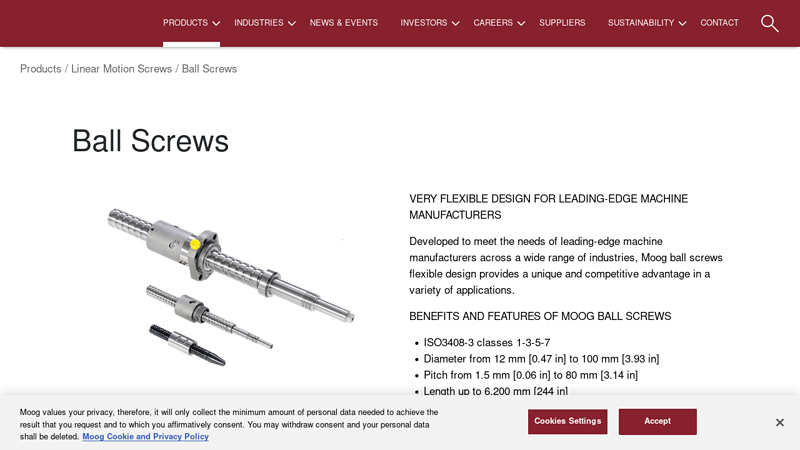

#1 Ball Screws

Domain Est. 1990

Website: moog.com

Key Highlights: A ball screw is a rolling system consisting of a threaded shaft (screw) and a nut that, internally threaded as well, contains a determined number of balls….

#2 Steinmeyer

Domain Est. 1997

Website: steinmeyer.com

Key Highlights: Steinmeyer is one of the world’s leading manufacturers of precision ball screws. … – Fully customized specs: pitch, diameter, nut type, lubrication, preload etc ……

#3 Portland Bolt

Domain Est. 1998 | Founded: 1912

Website: portlandbolt.com

Key Highlights: Portland Bolt has manufactured and distributed the highest-quality anchor bolts and nonstandard construction fasteners since 1912….

#4 Ball Screw Manufacturers

Domain Est. 2002

Website: ball-screws.net

Key Highlights: Instantly locate the leading ball screw manufacturers and suppliers in the United States whose products are made with premium materials and are ……

#5 Global Leader in Fastening Technology

Domain Est. 2012

Website: stanleyengineeredfastening.com

Key Highlights: As the world’s #1 fastening systems provider, Stanley® Engineered Fastening builds on over 100 years of experience and the strength of legacy brands like Nelson ……

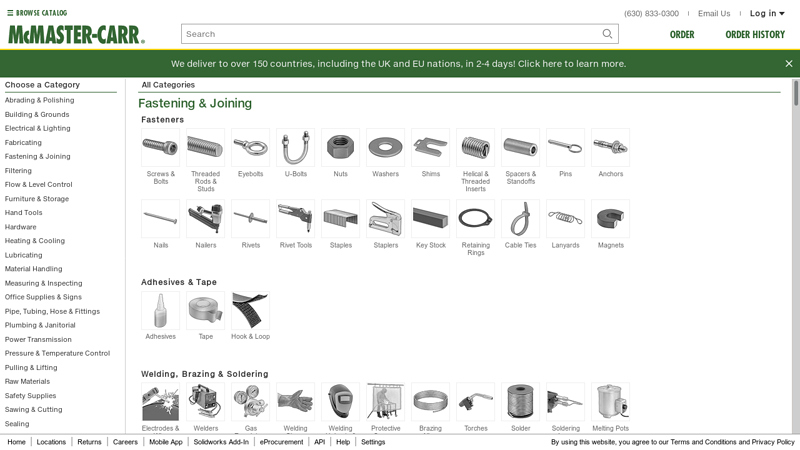

#6 McMaster

Domain Est. 1994

Website: mcmaster.com

Key Highlights: McMaster-Carr is the complete source for your plant with over 700000 products. 98% of products ordered ship from stock and deliver same or next day….

#7 Ball Screw|Product Information|THK Official Web Site [India]

Domain Est. 1995

Website: thk.com

Key Highlights: Ball screws are feed screws that provide high efficiency due to the rolling motion of the balls between the screw shaft and nut….

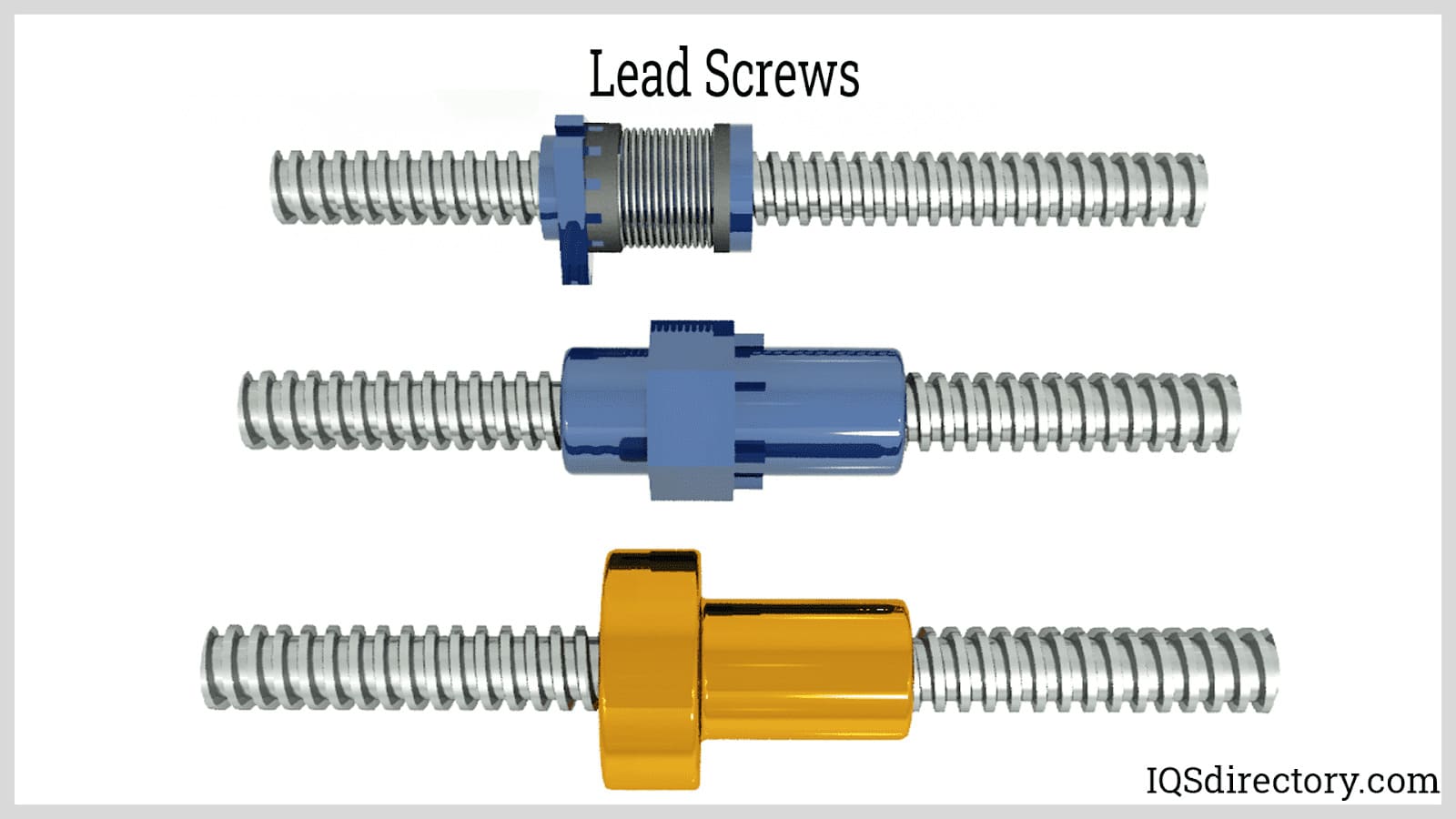

#8 Lead Screws

Domain Est. 2008

Website: thomsonlinear.com

Key Highlights: For more than 25 years, Thomson BSA has designed and manufactured the highest quality leadscrew assemblies in the industry….

#9 ParsPitch Co

Domain Est. 2009

Website: parspitch.com

Key Highlights: We specialize in manufacturing all kinds of inch and metric screws from M6 to M20 with various hex, Allen, hex, flange wrenches, and all kinds of hex, flange, ……

#10 Efficient and Effective Lead Screws

Domain Est. 2012

Website: helixlinear.com

Key Highlights: $20 delivery 30-day returnsLead screws are available in both metric and imperial sizes, with diameters ranging from 2mm to 25mm. Crafted from high-quality stainless steel or durabl…

Expert Sourcing Insights for Pitch Screw

H2: Market Trends for Pitch Screws in 2026

The pitch screw market in 2026 is poised for significant evolution, driven by technological advancements, shifting industrial demands, and global macroeconomic forces. Here’s an analysis of the key trends shaping this critical mechanical component sector:

1. Increased Demand in Automation and Robotics

- Growth Driver: The global push toward smart manufacturing (Industry 4.0) and robotic automation will continue to fuel demand for high-precision pitch screws.

- Application Expansion: Collaborative robots (cobots), automated guided vehicles (AGVs), and precision assembly systems rely on pitch screws for accurate linear motion control.

- Regional Impact: Asia-Pacific, particularly China, Japan, and South Korea, will lead adoption due to aggressive automation investments.

2. Shift Toward High-Precision and Miniaturization

- Accuracy Demands: Sectors such as semiconductor manufacturing, medical devices, and aerospace require pitch screws with micron-level precision and minimal backlash.

- Miniaturization: Compact and lightweight pitch screw systems are gaining traction in consumer electronics and portable medical equipment.

- Material Innovation: Use of advanced alloys and composite materials to enhance strength-to-weight ratios and thermal stability.

3. Integration with Smart Technologies

- Smart Components: Embedded sensors for real-time monitoring of load, temperature, and wear are being integrated into pitch screw assemblies.

- Predictive Maintenance: IoT-enabled pitch screws support condition-based maintenance, reducing downtime and improving system reliability.

- Digital Twins: Manufacturers are leveraging digital twin technology for performance simulation and optimization during design and operation.

4. Sustainability and Energy Efficiency

- Eco-Design: Growing emphasis on energy-efficient motion systems is pushing demand for low-friction, high-efficiency pitch screws.

- Lifecycle Management: Focus on recyclable materials and modular designs for easier repair and reuse.

- Regulatory Influence: Stricter environmental regulations in Europe and North America are encouraging greener manufacturing practices.

5. Supply Chain Resilience and Localization

- Geopolitical Impact: Ongoing trade tensions and supply chain disruptions are prompting companies to localize production.

- Nearshoring Trends: Increased investment in regional manufacturing hubs (e.g., Mexico for North America, Eastern Europe for Western Europe) to reduce dependency on single-source suppliers.

- Inventory Strategies: Adoption of just-in-case inventory models to mitigate component shortages.

6. Competition from Alternative Technologies

- Challenges: Linear motors and belt-driven systems are competing in high-speed, low-load applications.

- Response: Pitch screw manufacturers are enhancing performance (e.g., higher speeds, reduced noise) and offering hybrid solutions to maintain competitiveness.

7. R&D Focus on Advanced Lubrication and Durability

- Extended Lifespan: Development of self-lubricating coatings and improved sealing technologies to enhance reliability in harsh environments.

- Low Maintenance: Demand for maintenance-free pitch screws is rising, especially in inaccessible or cleanroom applications.

Conclusion

By 2026, the pitch screw market will be characterized by innovation in precision, intelligence, and sustainability. Companies that invest in R&D, embrace digital integration, and adapt to regional supply chain dynamics will lead the market. While competition from alternative motion technologies persists, the unique advantages of pitch screws—especially in high-load, high-precision applications—ensure their continued relevance in advanced industrial ecosystems.

Common Pitfalls in Sourcing Pitch Screws: Quality and Intellectual Property Risks

When sourcing pitch screws—critical components in precision motion systems—organizations often encounter significant challenges related to quality inconsistencies and intellectual property (IP) vulnerabilities. Overlooking these aspects can lead to performance failures, legal disputes, and increased total cost of ownership.

Quality-Related Pitfalls

Sourcing pitch screws without rigorous quality validation exposes projects to mechanical failure and system downtime. Common quality pitfalls include:

-

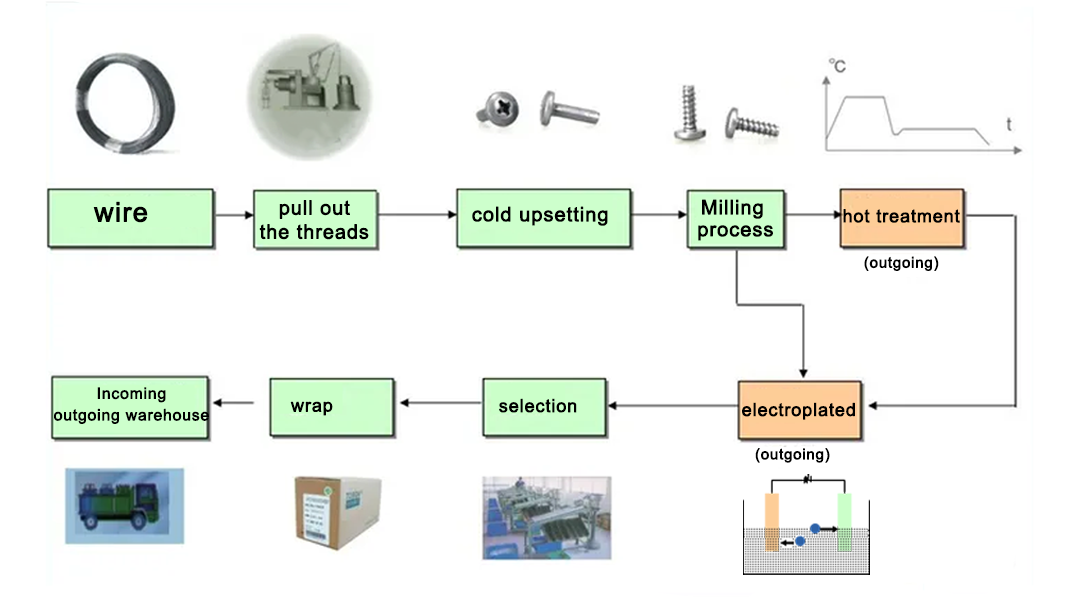

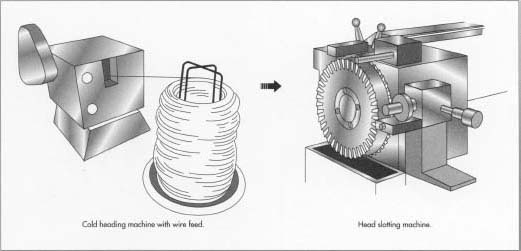

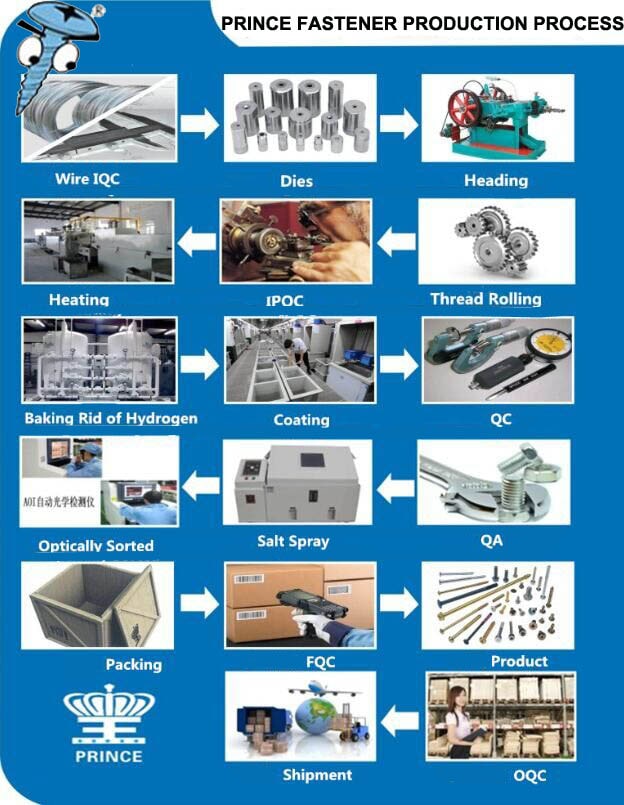

Inconsistent Thread Accuracy: Poorly manufactured pitch screws suffer from deviations in lead accuracy and thread geometry, resulting in positioning errors, vibration, and reduced system repeatability. Suppliers lacking precision grinding capabilities often fail to meet ISO or DIN standards.

-

Substandard Material Selection: Some vendors use inferior-grade materials or skip proper heat treatment processes, leading to premature wear, deformation, or fatigue failure under load. This is especially problematic in high-duty-cycle applications.

-

Lack of Traceability and Certification: Absence of material test reports (MTRs), process documentation, or compliance certifications (e.g., ISO 9001) makes it difficult to verify quality claims or troubleshoot field failures.

-

Inadequate Surface Finish and Hardness: Improper surface treatments or insufficient hardness reduce wear resistance and increase friction, affecting efficiency and lifespan. Poor finishes can also accelerate nut wear in ball or roller screw assemblies.

-

Insufficient Testing Protocols: Suppliers may skip functional testing such as preload verification, backlash measurement, or thermal stability checks, allowing defective units to reach end users.

Intellectual Property (IP) Risks

Sourcing from certain regions or unverified suppliers can expose companies to significant IP-related legal and reputational risks:

-

Counterfeit or Reverse-Engineered Designs: Some low-cost suppliers replicate patented screw designs, thread profiles, or nut configurations without authorization. Using such components may inadvertently involve the buyer in IP infringement claims.

-

Unclear Design Ownership: In custom or modified pitch screw applications, ambiguous contracts may fail to assign IP rights clearly, leading to disputes over design ownership or reuse rights.

-

Geopolitical and Compliance Exposure: Sourcing from jurisdictions with weak IP enforcement increases the risk of unauthorized replication and limits legal recourse. It may also conflict with export control regulations or corporate compliance policies.

-

Lack of IP Indemnification: Many suppliers, especially smaller or offshore vendors, do not offer IP indemnification clauses, leaving the buyer liable for infringement lawsuits even if unaware of the violation.

To mitigate these risks, organizations should conduct thorough supplier audits, require full compliance documentation, perform independent quality inspections, and include robust IP protection terms in procurement agreements.

Logistics & Compliance Guide for Pitch Screw

Overview

This guide outlines the essential logistics and compliance considerations for the manufacturing, shipping, handling, and distribution of pitch screws—a critical mechanical component used in precision motion systems. Adherence to these guidelines ensures product integrity, regulatory compliance, and operational efficiency across the supply chain.

International Shipping & Customs Compliance

Ensure all pitch screws are shipped in accordance with international trade regulations. Accurate HS (Harmonized System) codes must be assigned—typically under 7316.00 for screw threads or similar metal components. Provide complete commercial invoices, packing lists, and certificates of origin. Confirm compliance with export controls, especially if components contain materials or technologies subject to ITAR or EAR restrictions.

Packaging & Handling Standards

Pitch screws must be protected against mechanical damage, corrosion, and contamination during transit. Use anti-corrosion packaging such as VCI (Vapor Corrosion Inhibitor) paper and sealed moisture-barrier bags. Secure components in rigid containers with cushioning material to prevent movement. Clearly label packages with handling instructions, including “Fragile,” “This Side Up,” and “Protect from Moisture.”

Regulatory Compliance

Comply with regional and industry-specific regulations, including:

– RoHS (Restriction of Hazardous Substances): Ensure materials used in pitch screws (e.g., plating, coatings) meet RoHS requirements, particularly for EU markets.

– REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): Declare any Substances of Very High Concern (SVHC) if present above threshold levels.

– ISO Standards: Follow relevant standards such as ISO 3408 for ball screw drives, covering tolerances, accuracy classes, and performance testing.

Documentation & Traceability

Maintain full traceability of pitch screws through batch or serial number tracking. Documentation must include material certifications (e.g., mill test reports), inspection reports, and compliance statements. Digital records should be securely stored and accessible for audits or recalls.

Storage Conditions

Store pitch screws in a controlled environment: temperature between 15°C and 25°C, relative humidity below 60%. Keep components off the floor on racks and away from direct sunlight or sources of vibration. Long-term storage requires additional protective wrapping and periodic inspection for corrosion.

Transportation Modes & Carrier Selection

Choose transportation methods based on delivery timelines, cost, and environmental controls. For high-precision pitch screws, air freight may be preferred to minimize transit time and handling risks. Partner with carriers experienced in handling industrial precision components and capable of providing real-time tracking and secure delivery.

Import/Export Licensing

Verify whether pitch screws or their constituent materials require export licenses based on destination country and end-use. Consult national trade authorities (e.g., BIS in the U.S.) to determine licensing needs, particularly for high-accuracy or dual-use components.

End-of-Life & Environmental Responsibility

Plan for end-of-life management in accordance with WEEE (Waste Electrical and Electronic Equipment) directives where applicable. Facilitate recycling by designing for disassembly and providing material composition data to customers and recyclers.

Audit & Continuous Improvement

Conduct regular internal audits of logistics and compliance processes. Address non-conformities promptly and update procedures to reflect changes in regulations or operational practices. Train staff annually on compliance requirements and handling protocols.

Contact & Support

For compliance inquiries, logistics support, or documentation requests, contact the Logistics & Compliance Department at [email protected] or +1-800-555-0199.

Conclusion for Sourcing Pitch Screw:

In conclusion, sourcing a high-quality pitch screw is a critical step in ensuring the precision, reliability, and longevity of linear motion systems. By carefully evaluating factors such as material composition, lead accuracy, surface finish, manufacturer reputation, and cost-effectiveness, we can identify a supplier that meets both performance requirements and budget constraints. A well-sourced pitch screw not only enhances system efficiency and repeatability but also reduces maintenance downtime and operational costs over time. Through strategic supplier selection and strong supply chain partnerships, we position the project for long-term success, delivering optimal performance across its lifecycle.

![Ball Screw|Product Information|THK Official Web Site [India]](https://www.fobsourcify.com/wp-content/uploads/2026/01/ball-screwproduct-informationthk-official-web-site-india-748.jpg)