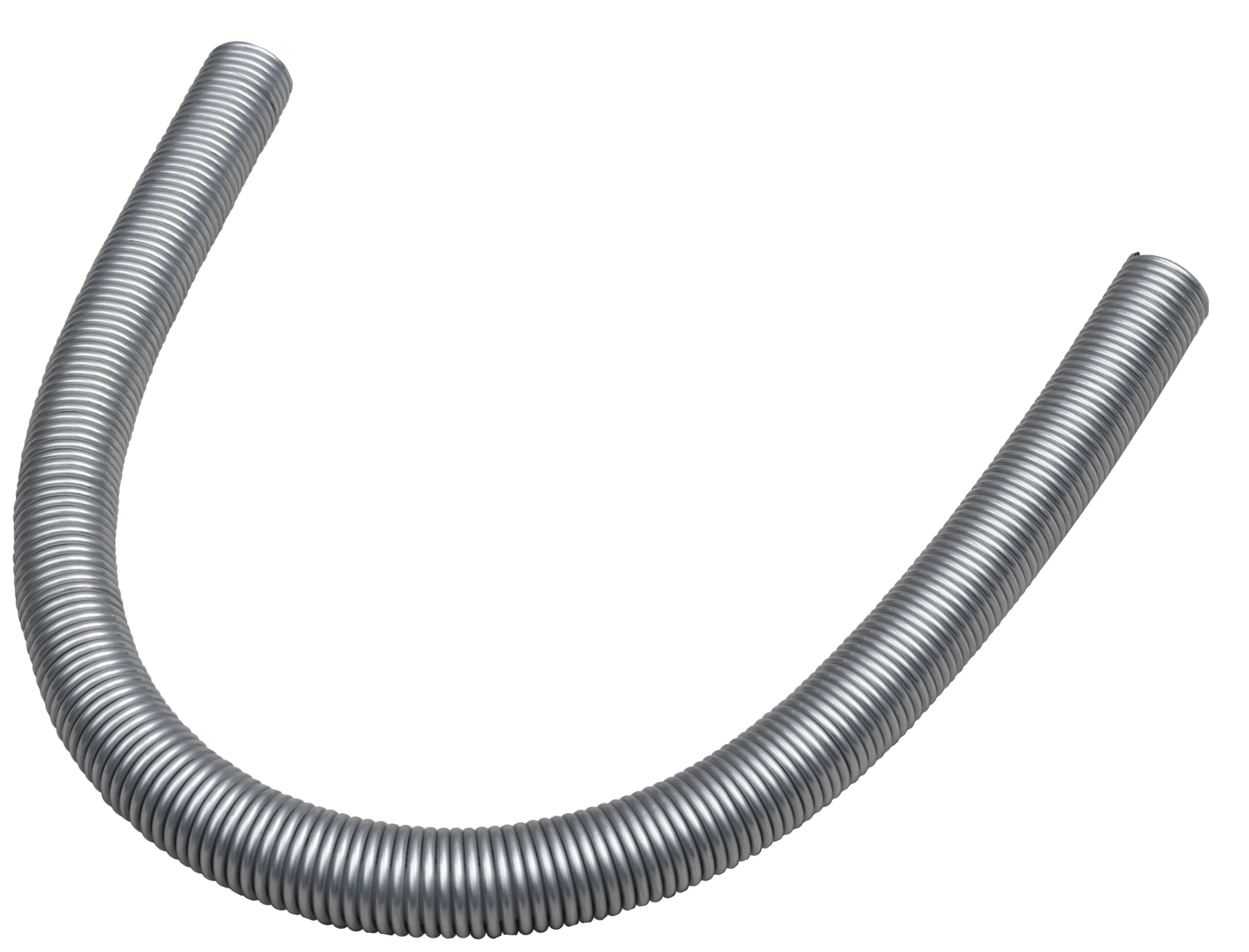

The global pipe bending spring market is experiencing steady growth, driven by increasing demand across plumbing, HVAC, automotive, and manufacturing industries. According to Mordor Intelligence, the global pipe bending tools market—which includes bending springs—was valued at approximately USD 1.2 billion in 2023 and is projected to grow at a CAGR of over 5.3% from 2024 to 2029. This expansion is fueled by rising industrial construction activities, infrastructure development, and the need for precision in tubing and piping systems. As manufacturers prioritize efficiency and material durability, the demand for high-quality pipe bending springs made from stainless steel and other resilient alloys continues to climb. In this competitive landscape, a select group of manufacturers have emerged as leaders, combining innovation, scalability, and product reliability. Based on performance metrics, market presence, and customer reviews, here are the top 9 pipe bending spring manufacturers shaping the industry in 2024.

Top 9 Pipe Bending Spring Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

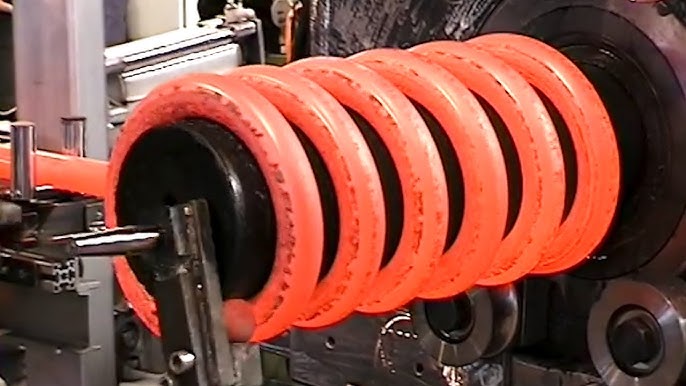

#1 Spiral spring, wire · tube bending processing Nagoya

Domain Est. 2003

Website: hayashi-spring.com

Key Highlights: Hayashi Spring Co., Ltd is a spring factory with pioneer technology, we are producing the comprehensive evaluation of the ‘highest benchmark’ spiral spring, ……

#2 Custom Springs and Wire Forms

Domain Est. 1997

Website: newcombspring.com

Key Highlights: Newcomb Spring is one of North America’s largest and most experienced custom spring and wire form manufacturers. We pride ourselves in producing quality ……

#3 TUBE BENDING SPECIALISTS TUBE AND PIPE BENDING …

Domain Est. 2000

Website: tubebendingspecialists.com

Key Highlights: Tube Bending Specialists provides commercial and industrial manufacturing services focusing on pipe bending, tube bending, steel fabrication, roll forming and ……

#4 Bending Springs

Domain Est. 2022

Website: gl-metal.com

Key Highlights: GL Metal is a specialist in the design and production of best-in-class stock and custom bending springs of multiple sizes and configurations….

#5 Spring

Domain Est. 1995

Website: ridgid.com

Key Highlights: RIDGID’s Spring-Type Tube Benders provide fast free-form bending of soft copper and aluminum tube. Shop now….

#6 Stainless Steel Strip

Domain Est. 1997

Website: gibbswire.com

Key Highlights: We stock a large inventory of wire products with a special focus on the spring industry; providing stainless steel, carbon, and red metals in various tempers….

#7 Automation Solutions

Domain Est. 1999

Website: wafios.com

Key Highlights: We work with you to develop modular solutions for automating bending, spring coiling, and CNC tube bending machines – tailored precisely to your needs….

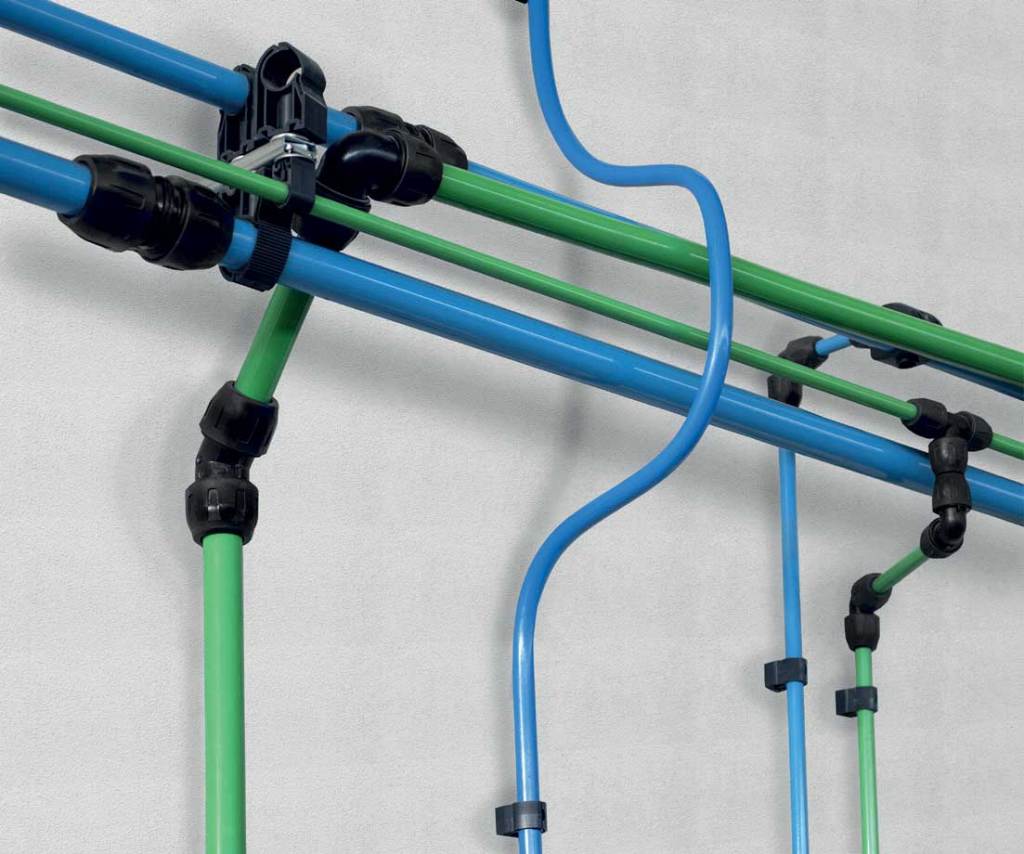

#8 External Bending Spring

Domain Est. 2013

Website: mtspain.net

Key Highlights: External bending spring for multilayer pipe. Model 6402 allows the pipe to be safely bent manually to the required angle and with precision….

#9 Multi

Domain Est. 2020

Expert Sourcing Insights for Pipe Bending Spring

H2: 2026 Market Trends for Pipe Bending Springs

The global market for pipe bending springs is poised for steady growth and transformation by 2026, driven by advancements in manufacturing technologies, increasing demand from key end-use industries, and evolving material preferences. Several key trends are expected to shape the landscape of this niche yet essential segment of the pipe and tube processing industry.

1. Rising Demand in Construction and HVAC Sectors

The construction and HVAC (Heating, Ventilation, and Air Conditioning) industries are projected to be primary drivers of market growth. With urbanization accelerating across Asia-Pacific, the Middle East, and Africa, there is a growing need for efficient and precise pipe installation in residential, commercial, and industrial buildings. Pipe bending springs, used to prevent kinking during manual tube bending, remain vital in small-scale and on-site applications where powered bending equipment is impractical.

2. Shift Toward Lightweight and Corrosion-Resistant Materials

Manufacturers are increasingly focusing on producing pipe bending springs from high-grade stainless steel and coated alloys to enhance durability and resistance to corrosion. This trend aligns with the broader industry shift toward longer-lasting, low-maintenance tools. Additionally, the use of composite materials in certain spring designs is being explored to reduce weight without compromising strength, particularly for applications involving softer tubing materials like copper and aluminum.

3. Growth in DIY and Small-Scale Fabrication Markets

The do-it-yourself (DIY) and small workshop segments are expanding, especially in North America and Europe, due to increased accessibility to fabrication tools and online tutorials. Pipe bending springs are favored in these settings for their affordability, ease of use, and minimal equipment requirements. This consumer-driven demand is prompting manufacturers to develop user-friendly, multi-size spring kits tailored to hobbyists and small contractors.

4. Regional Market Expansion and Localization

Asia-Pacific is expected to dominate the market by 2026, supported by rapid industrialization in countries like India, Vietnam, and Indonesia. Local production of pipe bending springs is increasing to meet domestic demand and reduce reliance on imports. Meanwhile, North America and Europe will continue to see moderate growth, with emphasis on product innovation and compliance with safety and environmental standards.

5. Sustainability and Circular Economy Considerations

Environmental concerns are influencing product design and manufacturing practices. Companies are exploring recyclable materials and energy-efficient production methods to align with sustainability goals. Some manufacturers are introducing take-back programs or offering refurbished tools, contributing to the circular economy and appealing to environmentally conscious buyers.

6. Integration with Digital Tools and Enhanced Product Labeling

While pipe bending springs are inherently mechanical, digital support is becoming more common. By 2026, leading suppliers are expected to offer augmented reality (AR) guides, mobile apps, and QR-coded packaging to assist users in selecting the correct spring size and bending technique. This digital integration enhances user experience and reduces errors in application.

In conclusion, the pipe bending spring market in 2026 will be characterized by innovation in materials, expanding end-user applications, and strategic regional growth. While facing competition from automated bending solutions, pipe bending springs will maintain relevance in niche and manual operations, supported by their cost-effectiveness and versatility.

Common Pitfalls When Sourcing Pipe Bending Springs (Quality, IP)

Sourcing pipe bending springs may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to performance issues, safety risks, and legal complications. Here are common pitfalls to avoid:

Poor Material Quality and Inadequate Specifications

Many suppliers offer pipe bending springs made from inferior-grade stainless steel or improperly heat-treated alloys. This can result in reduced elasticity, premature fatigue, or failure during use—especially when bending harder materials or smaller radii. Always verify material specifications (e.g., ASTM standards) and ensure the springs are designed for the intended pipe material and diameter. Avoid suppliers who cannot provide traceable material certifications.

Inaccurate Dimensional Tolerances

Low-cost or generic springs often suffer from inconsistent inner/outer diameters and pitch, leading to poor fit within the pipe. This can cause kinking, uneven bending, or difficulty inserting and removing the spring. Confirm dimensional tolerances match your application requirements and test sample units before bulk procurement.

Lack of IP Due Diligence

Some suppliers may offer springs that replicate patented designs—especially those with specialized geometry or anti-slip features. Sourcing such products can expose your company to intellectual property infringement claims. Always verify that the product design does not violate existing patents, and request documentation from suppliers confirming IP compliance.

Insufficient Corrosion Resistance

In environments exposed to moisture or chemicals, using springs with substandard corrosion resistance can lead to rust, contamination, and failure. Ensure the spring’s finish and alloy (e.g., 304 or 316 stainless steel) are appropriate for the operating environment. Be wary of suppliers who do not specify corrosion resistance ratings.

Inadequate Packaging and Handling

Poor packaging can result in deformed or tangled springs upon delivery, affecting usability and safety. Springs should be individually protected or coiled properly to maintain shape. Confirm packaging standards with the supplier to prevent damage during shipping.

Overlooking Application-Specific Needs

Not all pipe bending springs are interchangeable. Using a spring designed for soft copper on harder materials like PEX or PVC can lead to cracking. Ensure the spring is rated for the specific pipe type, wall thickness, and bend radius required. Avoid one-size-fits-all solutions without technical validation.

Skipping Supplier Qualification

Sourcing from unverified or offshore suppliers without quality audits increases the risk of receiving non-compliant or counterfeit products. Conduct supplier assessments, request samples, and verify compliance with relevant industry standards before committing to long-term contracts.

By addressing these pitfalls proactively, you can ensure reliable performance, regulatory compliance, and protection from legal exposure when sourcing pipe bending springs.

Logistics & Compliance Guide for Pipe Bending Springs

Product Overview

Pipe bending springs are precision tools used to prevent kinking and deformation when manually bending soft metal or plastic pipes. They are typically made from high-tensile steel or stainless steel and come in various sizes to match specific pipe diameters and wall thicknesses. Proper logistics handling and compliance adherence are essential to ensure product integrity and regulatory conformity.

Packaging Requirements

Pipe bending springs must be packaged to prevent mechanical damage, corrosion, and tangling. Individual springs should be wrapped in anti-corrosion paper or heat-shrink tubing. For bulk shipments, use compartmentalized plastic trays or corrugated cardboard dividers within sturdy export-grade cartons. Clearly label each package with product specifications, quantity, and handling instructions (e.g., “Fragile,” “Do Not Stack”).

Storage Conditions

Store pipe bending springs in a dry, temperature-controlled environment with low humidity (ideally below 60% RH) to prevent rust and degradation. Keep containers sealed and elevate pallets off the floor to avoid moisture absorption. Avoid exposure to corrosive chemicals or salt-laden air, especially for carbon steel variants. Implement a first-in, first-out (FIFO) inventory system to minimize prolonged storage.

Transportation Guidelines

Use enclosed, climate-controlled vehicles for long-distance or international shipping to protect against weather and contamination. Secure loads with straps or dunnage to prevent shifting during transit. For air freight, comply with IATA packaging standards; for ocean freight, adhere to IMDG Code requirements if applicable. Document all shipments with detailed packing lists and material specifications.

Regulatory Compliance

Ensure pipe bending springs comply with relevant regional and international standards. In the EU, adhere to CE marking requirements under the Machinery Directive (2006/42/EC) if sold as part of a toolset. In the U.S., follow OSHA and ANSI safety standards for hand tools. Materials must conform to RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) when applicable. Provide a Declaration of Conformity upon request.

Import/Export Documentation

Prepare accurate documentation for cross-border shipments, including commercial invoices, packing lists, certificates of origin, and material test reports (if required). Verify HS codes—typically 8205.59 (other hand tools) or 7326.90 (other articles of steel)—with customs authorities. Comply with export control regulations, especially when shipping to sanctioned regions.

Quality Assurance & Traceability

Implement a traceability system where each batch of pipe bending springs is assigned a unique lot number. Conduct periodic quality checks for tensile strength, surface finish, and dimensional accuracy. Maintain records for at least five years to support compliance audits and customer inquiries.

Environmental & Disposal Considerations

Dispose of damaged or obsolete pipe bending springs in accordance with local waste management regulations. Recycle steel components through certified metal reprocessing facilities. Avoid landfill disposal when possible. Provide end-of-life guidance in product documentation to support environmental compliance.

Supplier & Certification Management

Source materials only from suppliers with ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) certifications. Require mill test certificates for raw materials to confirm chemical composition and mechanical properties. Conduct periodic supplier audits to ensure ongoing compliance.

In conclusion, sourcing pipe bending springs requires careful consideration of factors such as material compatibility, spring size and diameter, durability, and intended application. Choosing the right spring ensures clean, accurate bends without damaging the pipe, especially when working with softer materials like copper, aluminum, or plastic. It is essential to purchase from reliable suppliers who provide high-quality, well-specified products to maintain efficiency and safety in plumbing, HVAC, or DIY projects. Additionally, evaluating cost versus performance and considering reusable options can lead to long-term savings and improved workflow. Proper selection and sourcing of pipe bending springs ultimately contribute to professional results and reduced material waste.