The global clamp manufacturing market is experiencing robust growth, driven by rising infrastructure investments and expanding industrial automation. According to a 2023 report by Mordor Intelligence, the global pipe clamp market is projected to grow at a CAGR of over 4.8% from 2023 to 2028, fueled by increasing demand across oil & gas, construction, and water treatment sectors. Pin clamps, known for their precise alignment and durability in piping systems, are a critical subset of this market. With industrial projects prioritizing safety and efficiency, manufacturers of high-performance pin clamps are seeing heightened demand, especially in emerging economies. As competition intensifies, seven key players have emerged at the forefront, combining innovation, quality, and scalable production to capture significant market share. These leading manufacturers are not only setting industry benchmarks but also driving advancements in material science and modular design to meet evolving engineering requirements.

Top 7 Pin Clamp Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pneumatic Pin Clamps

Domain Est. 1995

Website: phdinc.com

Key Highlights: Rating 5.0 (1) Series PLK Modular Pneumatic Pin Clamps feature high clamping force on a lightweight body, and are often used as the end effector of a robotic arm….

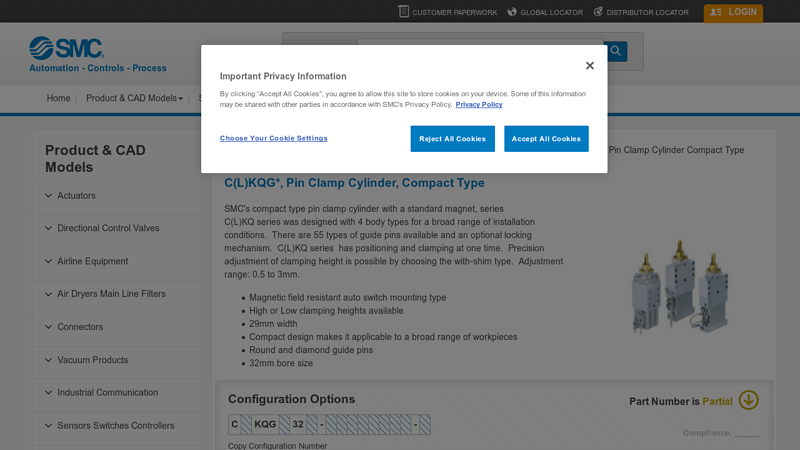

#2 C(L)KQG*, Pin Clamp Cylinder, Compact Type

Domain Est. 1995

Website: smcusa.com

Key Highlights: SMC’s compact type pin clamp cylinder with a standard magnet, series C(L)KQ series was designed with 4 body types for a broad range of installation conditions….

#3 Workholding Equipment & Automation Tooling Solutions

Domain Est. 1996

Website: destaco.com

Key Highlights: Manual, Pneumatic and Electric Clamping Solutions. DESTACO provides versatile, reliable clamping solutions to improve manufacturing efficiency and precision in ……

#4 PEM – PennEngineering

Domain Est. 1996

Website: pemnet.com

Key Highlights: PEM offers innovative fastening solutions for a variety of applications across industries like Automotive Electronics, Consumer Electronics, Datacom and more….

#5 Pin Clamps

Domain Est. 2007

Website: welkerproducts.com

Key Highlights: Pin Clamps. Welker Pin Clamps offer positive part location and clamping. With the dual finger design, clamping is achieved on both sides of a hole or slot….

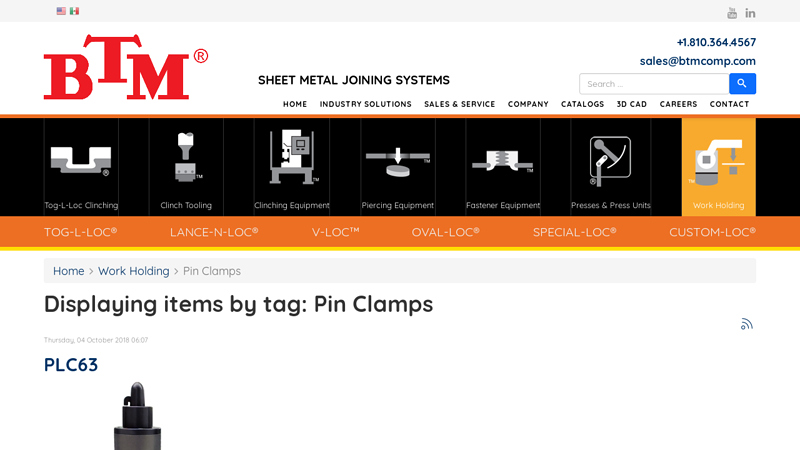

#6 Pin Clamps

Domain Est. 2015

Website: btmcomp.com

Key Highlights: Displaying items by tag: Pin Clamps · PLC63 · PLC45 · RLPC Rod-Locking Pin Clamp · CPC · XPC · XPC. Clamping Force. 890 – 1334N. Published in Heavy Duty Pin ……

#7 Python Clamp with 5/8” Pin

Website: 9.solutions

Key Highlights: The Python Clamp with 5/8” Pin has a 5/8” pin for mounting baby-standard grip and lighting equipment. All Python Clamps can have their center bolts removed….

Expert Sourcing Insights for Pin Clamp

H2: 2026 Market Trends for Pin Clamps

The pin clamp market is poised for dynamic growth and transformation by 2026, driven by evolving industrial demands, technological advancements, and shifting global supply chains. This analysis outlines the key trends shaping the sector in the coming years.

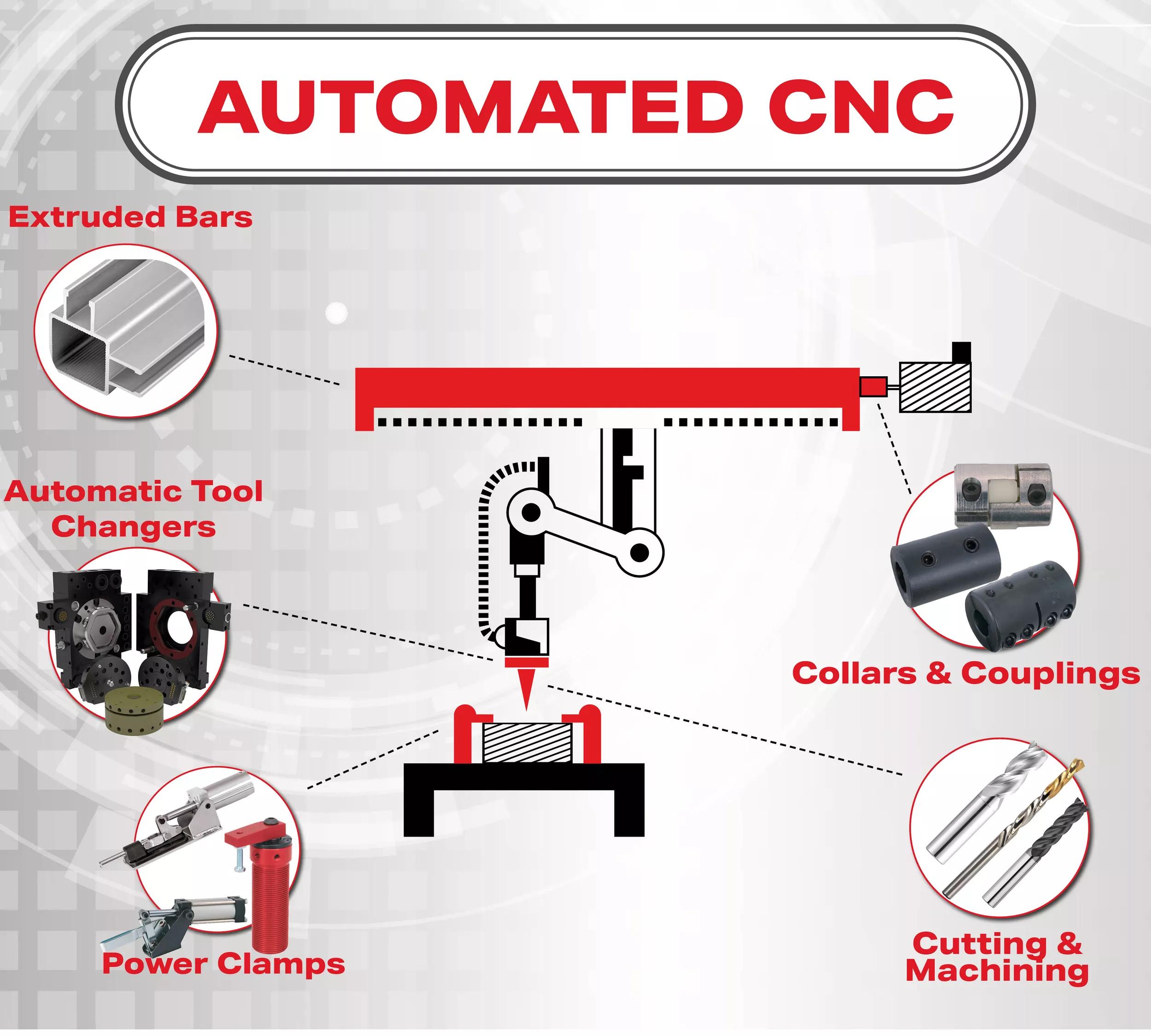

1. Accelerated Automation & Smart Integration

Pin clamps are increasingly being integrated into automated manufacturing systems, particularly in automotive and aerospace assembly lines. By 2026, expect a surge in “smart” pin clamps equipped with embedded sensors for real-time monitoring of clamping force, position, and wear. This enables predictive maintenance, ensures consistent quality, and enhances process traceability—key requirements in Industry 4.0 environments. Compatibility with IoT platforms and digital twin technology will become a differentiating factor among leading suppliers.

2. Lightweight & High-Strength Material Adoption

To meet efficiency and performance goals—especially in transportation and renewable energy sectors—there is a growing shift toward lightweight yet durable pin clamps. Advanced materials such as high-grade aluminum alloys, composite polymers, and specialized stainless steels (e.g., maraging steel) will gain traction. These materials offer improved strength-to-weight ratios and corrosion resistance, crucial for applications in electric vehicles (EVs), wind turbines, and offshore installations.

3. Sustainability and Circular Economy Focus

Environmental regulations and corporate sustainability targets are influencing design and production. By 2026, manufacturers will prioritize recyclable materials, energy-efficient manufacturing processes, and modular designs that allow for easy repair or component replacement. Life cycle assessments (LCAs) will become standard in product development, and demand for pin clamps with lower carbon footprints will rise, especially in Europe and North America.

4. Customization and Modular Design

As industrial applications become more specialized, off-the-shelf solutions are no longer sufficient. The market will see increased demand for customizable pin clamps tailored to specific geometries, load requirements, and environmental conditions. Modular systems that allow quick reconfiguration will be favored in flexible manufacturing setups, reducing downtime and inventory costs.

5. Geopolitical Shifts and Regional Supply Chain Resilience

Ongoing supply chain disruptions and geopolitical tensions are prompting companies to regionalize production. By 2026, nearshoring and friend-shoring strategies will boost local manufacturing of pin clamps in North America and Europe, reducing reliance on single-source suppliers. This trend will benefit regional players offering faster delivery, technical support, and compliance with local standards (e.g., ISO, ASME).

6. Expansion in Renewable Energy and EV Infrastructure

The rapid growth of solar, wind, and energy storage systems is creating new applications for pin clamps in structural support, panel mounting, and battery pack assembly. Similarly, the EV revolution demands precision clamping solutions for battery module integration and powertrain assembly. These high-growth sectors will be major drivers of innovation and volume in the pin clamp market.

7. Digital Sales and E-Procurement Platforms

B2B purchasing behavior is shifting toward digital channels. By 2026, leading pin clamp suppliers will offer enhanced online configurators, 3D CAD model downloads, and integration with industrial e-procurement systems (e.g., SAP Ariba). This will streamline the selection and ordering process, especially for engineering and maintenance teams.

Conclusion:

By 2026, the pin clamp market will be characterized by smart, sustainable, and highly specialized solutions. Companies that invest in digital integration, material innovation, and supply chain resilience will be best positioned to capture growth across key industries. The convergence of automation, green technology, and customization will define the next generation of clamping systems.

Common Pitfalls Sourcing Pin Clamps (Quality, IP)

Sourcing pin clamps—especially for critical applications involving fluid handling, hygienic processing, or high-pressure systems—requires careful attention to quality and Ingress Protection (IP) ratings. Overlooking these factors can lead to performance failures, safety hazards, and costly downtime. Below are key pitfalls to avoid:

Inadequate Material Quality and Certification

One of the most frequent issues is selecting pin clamps made from substandard materials. Low-grade stainless steel (e.g., non-316L) may corrode prematurely, especially in harsh environments or when exposed to cleaning agents. Always verify material certifications (such as Mill Test Reports) and ensure compatibility with the operating environment (temperature, chemicals, pressure).

Misunderstanding or Ignoring IP Ratings

Pin clamps themselves are mechanical fasteners and do not carry an IP rating. However, they are often used in conjunction with components (like pumps, sensors, or enclosures) that do require specific IP protection. A common mistake is assuming that a tightly secured clamp ensures environmental sealing. The IP rating depends on the full assembly (gaskets, housing, etc.), not just the clamp. Always confirm that the entire connection system meets the required IP standard (e.g., IP67, IP69K), particularly in washdown or outdoor applications.

Poor Dimensional Tolerances and Fit

Low-cost or non-standard clamps may have inconsistent dimensions, leading to uneven clamping force, leaks, or difficulty in assembly. This can compromise the integrity of the seal and increase maintenance frequency. Ensure that clamps adhere to recognized standards (e.g., SMS, DIN, ISO) and are sourced from reputable manufacturers with strict quality control.

Inconsistent Clamping Force and Durability

Inferior clamps may use weak spring mechanisms or low-tensile bolts, resulting in loosening over time due to vibration or thermal cycling. This can lead to leaks or disconnections. Opt for clamps with proven performance under dynamic conditions and consider torque specifications if applicable.

Lack of Traceability and Compliance Documentation

In regulated industries (e.g., food, beverage, pharmaceuticals), traceability is essential. Sourcing clamps without proper documentation—such as material traceability, RoHS compliance, or FDA compliance—can jeopardize audits and certifications. Always request full compliance paperwork from suppliers.

Choosing Based on Price Alone

The lowest-cost option often leads to higher total cost of ownership due to frequent replacements, system downtime, or contamination risks. Invest in high-quality pin clamps from trusted suppliers to ensure long-term reliability and safety.

Avoiding these pitfalls requires due diligence in supplier selection, clear specifications, and a comprehensive understanding of how clamps integrate into larger systems—particularly regarding sealing and environmental protection.

Logistics & Compliance Guide for Pin Clamp

Product Overview

Pin clamps are mechanical fastening devices used in manufacturing, assembly, and material handling to securely hold components in place. They are commonly used in welding fixtures, jigs, and automation systems. Proper logistics and compliance handling ensures safety, regulatory adherence, and consistent performance.

Regulatory Compliance

Pin clamps must comply with relevant international and regional standards depending on their intended use and market. Key compliance considerations include:

- ISO Standards: Ensure design and performance meet applicable ISO standards such as ISO 2768 for general tolerances or ISO 3730 for clamping devices.

- RoHS Compliance: If used in electronics or within the EU, verify that materials are free of restricted substances (lead, cadmium, mercury, etc.).

- REACH Regulation: Confirm that chemical substances in materials comply with EU REACH requirements.

- OSHA & ANSI Safety Standards: In the U.S., ensure usage aligns with OSHA guidelines and ANSI B18.2.1 for fastener safety if applicable.

Material & Packaging Requirements

- Material Certification: Provide material test reports (MTRs) upon request, especially for clamps used in high-stress or safety-critical applications.

- Packaging: Use anti-corrosion packaging (e.g., VCI paper or shrink wrap) for metal components. Pack in sturdy, labeled cartons with cushioning to prevent damage during transit.

- Labeling: Each package must include part number, quantity, batch/lot number, country of origin, and compliance markings (e.g., CE, RoHS).

Shipping & Handling

- Transport Mode: Suitable for road, air, and sea freight. Use moisture-resistant packaging for ocean shipments.

- Weight & Dimensions: Optimize packaging to reduce dimensional weight for cost-effective shipping.

- Handling Instructions: Mark packages with “Fragile” and “Do Not Stack” if applicable. Avoid exposure to extreme temperatures or humidity.

Import/Export Documentation

- Commercial Invoice: Include detailed product description, HS code (e.g., 8487.90 for machinery parts), value, and country of origin.

- Packing List: Specify contents per package, gross/net weight, and dimensions.

- Certificate of Origin: Required for preferential tariff treatment under trade agreements.

- Customs Classification: Classify under appropriate HS code; consult local customs authority if uncertain.

Storage Conditions

- Store in a dry, temperature-controlled environment (10°C to 30°C recommended).

- Avoid direct exposure to moisture, corrosive chemicals, or dust.

- Keep off the floor using pallets or shelving to prevent contamination.

Quality Assurance & Traceability

- Implement batch traceability for all manufactured pin clamps.

- Conduct periodic audits and inspections per ISO 9001 standards.

- Maintain records of compliance documentation for a minimum of 5 years.

Disposal & Environmental Responsibility

- Dispose of defective or obsolete pin clamps in accordance with local waste regulations.

- Recycle metal components through certified scrap metal processors.

- Avoid landfill disposal where recycling options are available.

Contact & Support

For compliance inquiries, documentation requests, or logistics support, contact:

Logistics & Compliance Team

Email: [email protected]

Phone: +1 (555) 123-4567

Conclusion for Sourcing Pin Clamp:

After a comprehensive evaluation of suppliers, cost structures, quality standards, and lead times, it is concluded that sourcing pin clamps from [Supplier Name/Region] offers the most favorable balance of cost-efficiency, product quality, and reliability. The selected supplier demonstrates compliance with industry standards, a proven track record of consistent delivery, and the capability to scale production as needed. Additionally, the total landed cost, including shipping, import duties, and inventory holding, remains within acceptable margins. Moving forward, establishing a long-term partnership with this supplier, supported by periodic performance reviews and quality audits, will ensure a stable supply chain and contribute to overall operational efficiency. Strategic sourcing of pin clamps in this manner supports both current project requirements and future scalability.