The global livestock water systems market, including specialized solutions for swine production, is experiencing steady expansion driven by rising demand for efficient and hygienic animal husbandry practices. According to a 2023 report by Mordor Intelligence, the global livestock farming market is projected to grow at a CAGR of 5.8% from 2023 to 2028, with increasing adoption of automated watering systems in commercial piggeries as a key growth driver. This trend is further supported by Grand View Research, which noted that advancements in precision livestock farming and the push for biosecurity are accelerating investments in closed-loop, nipple-based watering systems that minimize water wastage and reduce disease transmission. As large-scale swine operations prioritize animal health, sustainability, and operational efficiency, the demand for high-performance piggery water systems has intensified—fueling innovation among manufacturers worldwide. In this evolving landscape, nine leading companies have emerged at the forefront, combining engineering excellence with data-informed design to meet modern swine production challenges.

Top 9 Piggery Water System Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Fancom

Domain Est. 1997

Website: fancom.com

Key Highlights: Fancom is leading in helping poultry and pig producers and mushroom growers to improve processes in their farms. We stand for superior housing conditions….

#2 Hog & Pig Water Drinking

Domain Est. 1995

#3 Pig Drinking Water Cleaning and Disinfection Solutions

Domain Est. 1996

Website: ecolab.com

Key Highlights: Ecolab provides cleaning and disinfecting solutions for pig drinking water. We can help you safeguards your investment and maintain animal health….

#4 Impex drinking water solutions for pigs

Domain Est. 1997

Website: impex.nl

Key Highlights: Impex supplies drinking nipples for piglets, porkers, lactating sows, and boars. Our range consists of bite nipples, spray nipples, and wet feeding nipples….

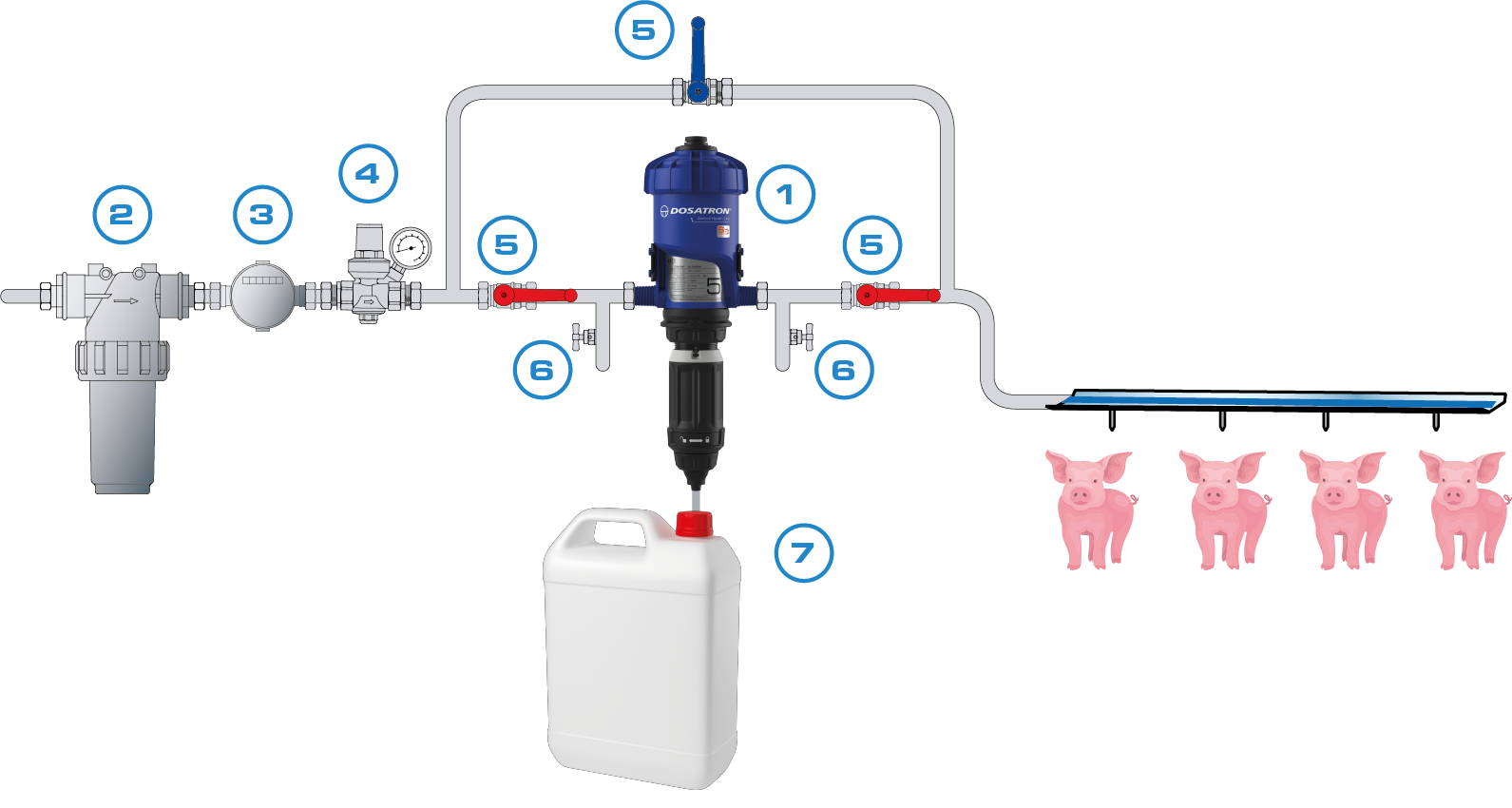

#5 Dosatron Pig Breeding

Domain Est. 1997

Website: dosatron.com

Key Highlights: Improve pig breeding health & efficiency with Dosatron’s precise, reliable dosing solutions….

#6 Pig waterer

Domain Est. 2000

Website: skiold.com

Key Highlights: High quality automatic pig waterer, water nipples, drinkers, valves, drinking cups and water through. Ensure animal welfare and wellbeing….

#7 Pig Farm Equipment

Domain Est. 2004

Website: acofunki.com

Key Highlights: We develop and produce products for new or existing farms, including penning equipment, intelligent feeding systems, flooring, water systems, and components….

#8 Pig Farming & Pork Industry

Website: integrawater.com.au

Key Highlights: We offer a comprehensive range of water treatment and hygiene solutions specifically designed to elevate your farm’s biosecurity and operational efficiency….

#9 Drinking Water for Piggery

Website: makwater.com.au

Key Highlights: Custom skid mounted Brackish Water Reverse Osmosis (BWRO) plant to produce potable water from bore water for intensive pig farming. MAK Water Key Solutions. In- ……

Expert Sourcing Insights for Piggery Water System

H2: Projected 2026 Market Trends for Piggery Water Systems

The global piggery water system market is poised for significant transformation by 2026, driven by technological innovation, rising demand for sustainable livestock practices, and increasing regulatory pressures. As the swine industry modernizes to meet food security and animal welfare standards, water delivery systems are becoming central to operational efficiency and herd health. The following are key market trends expected to shape the piggery water system landscape in 2026:

1. Integration of Smart Water Management Technologies

By 2026, smart water systems leveraging IoT (Internet of Things) sensors, real-time monitoring, and data analytics will be increasingly adopted. These systems enable precise control of water flow, detect leaks, monitor pig drinking patterns, and identify health anomalies early. Automated systems linked to farm management software will allow producers to optimize water use, reduce waste, and enhance biosecurity.

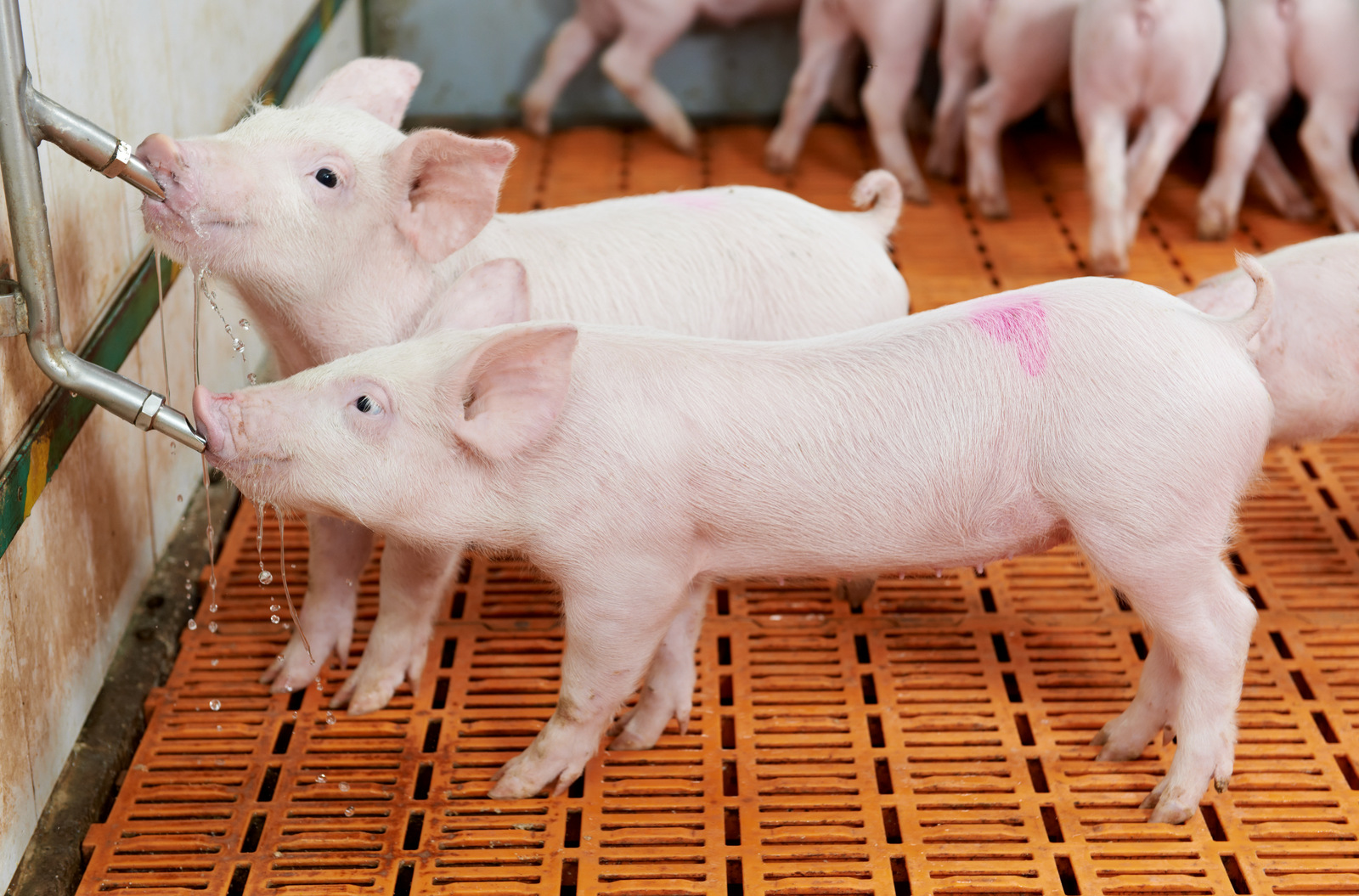

2. Focus on Water Conservation and Sustainability

With growing concerns over water scarcity and environmental impact, especially in regions like Asia-Pacific and Africa, there will be heightened demand for water-efficient systems. Recirculation and filtration technologies, low-flow nipple drinkers, and closed-loop water systems will gain traction. Producers will prioritize systems that minimize water wastage while maintaining animal hydration and performance.

3. Expansion in Emerging Markets

Countries such as China, India, Vietnam, and Brazil are expected to drive market growth due to increasing pork consumption and large-scale commercial pig farming. Government initiatives promoting modernized agriculture and biosecure farming practices will boost investments in advanced piggery water infrastructure.

4. Rising Emphasis on Animal Health and Welfare

Clean, reliable water access is directly linked to pig health, growth rates, and disease prevention. By 2026, water systems with built-in sanitization features—such as UV treatment, automatic chlorination, and self-cleaning mechanisms—will become standard in high-health-status farms. These features support antibiotic reduction strategies and comply with animal welfare certifications.

5. Consolidation and Innovation Among Suppliers

The market will see increased consolidation among equipment manufacturers, with larger players acquiring niche technology firms to offer integrated solutions. Innovation will focus on modular, scalable systems adaptable to both smallholder farms and mega-commercial operations. Partnerships between agricultural tech companies and water system providers will accelerate product development.

6. Regulatory and Food Safety Compliance

Stringent regulations on water quality, waste management, and farm emissions—particularly in the EU and North America—will compel producers to upgrade their water systems. Traceability and documentation of water usage and hygiene practices will become integral, promoting adoption of digitally monitored systems.

7. Shift Toward Automated and Labor-Saving Solutions

Labor shortages and rising operational costs will drive adoption of fully automated water systems. These systems reduce manual oversight, improve consistency, and integrate seamlessly with automated feeding and climate control systems in smart barns.

In conclusion, the 2026 piggery water system market will be defined by intelligence, sustainability, and integration. Producers who invest in advanced water technologies will gain competitive advantages through improved productivity, reduced environmental footprint, and enhanced compliance—positioning water systems as a cornerstone of modern swine production.

Common Pitfalls in Sourcing Piggery Water Systems: Quality and Intellectual Property Risks

Sourcing piggery water systems involves critical considerations beyond cost and availability. Overlooking quality assurance and intellectual property (IP) can lead to operational failures, financial losses, and legal complications. Below are key pitfalls to avoid:

Poor Quality Control and Materials

One of the most frequent issues is receiving systems constructed with substandard materials or poor workmanship. Cheaply made drinkers, pipelines, or valves may corrode, leak, or fail under farm conditions. This leads to inconsistent water delivery, increased maintenance costs, animal stress, and potential disease spread due to stagnant water. Always verify supplier certifications, request material specifications, and inspect samples before bulk orders.

Lack of Compliance with Agricultural Standards

Many suppliers—especially offshore or non-specialized ones—offer systems that do not meet regional agricultural or animal welfare regulations. For example, water flow rates, hygiene features, and durability standards may fall short of requirements in the EU, USDA, or other bodies. Non-compliant systems may result in rejected installations or fines during inspections.

Inadequate System Design for Specific Herd Needs

A common quality-related pitfall is sourcing a one-size-fits-all system that doesn’t match the farm’s pig size, growth stage, or housing layout. Mismatched nipple drinkers or troughs can lead to water wastage, dehydration, or aggressive behavior among pigs. Always ensure the supplier provides a tailored design backed by technical expertise in swine nutrition and behavior.

Intellectual Property Infringement Risks

Sourcing from manufacturers that replicate patented designs—such as advanced nipple drinkers or automated flow regulators—can expose your operation to legal liability. Using counterfeit or IP-infringing components may lead to cease-and-desist orders, product recalls, or damage to your farm’s reputation. Always verify that the supplier owns or legally licenses the technology they provide.

Limited Warranty and After-Sales Support

Low-cost suppliers often offer minimal or voidable warranties, leaving you responsible for repairs or replacements. Additionally, lack of technical support or spare parts availability can halt operations during breakdowns. Prioritize suppliers with clear IP ownership, robust warranties, and accessible customer service to ensure long-term system reliability.

Failure to Verify IP Ownership in Custom Solutions

When commissioning custom water systems, ensure that any new designs or modifications are properly documented and that IP rights are assigned to your organization or appropriately licensed. Ambiguity in contracts can result in disputes or prevent future modifications without the original supplier’s permission.

By addressing these quality and IP pitfalls during the sourcing process, pig producers can ensure reliable, compliant, and legally secure water delivery systems that support animal health and operational efficiency.

Logistics & Compliance Guide for Piggery Water System

System Design and Installation Requirements

When establishing a water system for a piggery, compliance with local agricultural and environmental regulations is essential. The system must be designed to deliver clean, potable water consistently to pigs at all growth stages. Key components include water sources (e.g., municipal supply, borewell, or protected reservoir), filtration units, pressure regulators, troughs or nipple drinkers, and storage tanks.

All materials used in the plumbing—such as PVC, stainless steel, or food-grade polyethylene—must meet national safety standards (e.g., NSF/ANSI 61 for drinking water system components). The layout should minimize dead legs and stagnation points to prevent bacterial growth. Systems must be installed by certified technicians and inspected prior to commissioning.

Water Quality Standards and Testing Protocols

Water supplied to pigs must meet livestock drinking water quality guidelines established by regulatory bodies such as the U.S. Environmental Protection Agency (EPA) or equivalent national agencies. Key parameters include:

- Microbiological safety: Absence of coliforms and E. coli

- Chemical composition: Nitrate levels below 100 ppm, iron less than 0.3 ppm, and pH between 6.0 and 8.5

- Turbidity: Less than 5 NTU

Routine testing—at minimum quarterly, or monthly in high-risk areas—is required. Records of water quality tests must be maintained for audit and compliance purposes. On-farm testing kits supplemented by certified laboratory analysis ensure accuracy.

Biosecurity and Contamination Control

The water system must be integrated into the piggery’s overall biosecurity plan. All storage tanks should be covered to prevent contamination from birds, rodents, and airborne pathogens. In-line filters and UV sterilizers or chlorination systems should be installed where necessary to mitigate microbial risks.

Cross-connection between potable water lines and waste or chemical systems is strictly prohibited. Backflow prevention devices must be installed at all connection points to non-potable systems. Regular cleaning and sanitization of tanks, pipes, and drinkers (at least quarterly or after disease outbreaks) are mandatory.

Maintenance and Operational Logging

A preventive maintenance schedule must be established and followed to ensure system reliability. This includes:

- Monthly inspection of drinkers and troughs for leaks or blockages

- Quarterly flushing of pipelines

- Annual pressure testing and integrity checks

All maintenance activities, repairs, and part replacements must be documented in a centralized log. Digital logging systems are encouraged for easy access during audits.

Regulatory Compliance and Recordkeeping

Piggeries are subject to agricultural, environmental, and animal welfare regulations that include water supply standards. Operators must comply with:

- Local environmental protection laws (e.g., preventing runoff contamination)

- Animal welfare codes requiring constant access to clean water

- Organic certification standards (if applicable), which may impose additional restrictions on water treatment chemicals

Inspection reports, water test results, maintenance logs, and system schematics must be retained for a minimum of three years and made available upon request by regulatory authorities.

Emergency Preparedness and Backup Systems

To ensure uninterrupted water supply during power outages or equipment failure, backup systems are required. These may include:

- Secondary water storage tanks with capacity for 48–72 hours of demand

- Generator-powered pumps

- Manual fill options for critical pens

Emergency procedures must be documented and staff trained to respond swiftly. Contingency plans should be reviewed annually and updated as needed.

Staff Training and Responsibility Assignment

Personnel responsible for water system management must receive training in:

- Daily inspection routines

- Water testing procedures

- Biosecurity protocols

- Emergency response

Designate a Water System Manager accountable for compliance, maintenance, and reporting. Training records should be kept and refreshed annually or when system upgrades occur.

Conclusion on Sourcing a Piggery Water System

Establishing an efficient and reliable water system is crucial for the success and sustainability of any piggery operation. After evaluating various sourcing options—such as municipal water supply, groundwater (boreholes/wells), surface water (rivers, dams), and rainwater harvesting—it is evident that each method comes with its own advantages and limitations. Groundwater typically offers the most consistent and hygienic water quality, making it a preferred choice for many pig farms, especially when supplemented with proper filtration and storage systems. Municipal supply ensures regulated quality but may be costly and subject to availability constraints. Surface water, while accessible, requires extensive treatment to ensure safety for livestock consumption, and rainwater harvesting serves as a useful supplementary source in regions with adequate rainfall.

Ultimately, the ideal water system for a piggery should prioritize water quality, reliability, cost-effectiveness, and scalability. A combined approach—such as using borehole water as the primary source with rainwater or stored treated surface water as backup—often provides the best resilience against seasonal variations and droughts. Additionally, integrating proper plumbing, automatic drinkers, and regular water quality testing ensures the health and productivity of the pigs while promoting efficient water use.

In conclusion, careful planning and investment in a well-designed water sourcing and delivery system are essential steps toward achieving optimal pig health, welfare, and farm profitability. Sustainable water management not only supports daily operations but also enhances the long-term viability of the piggery enterprise.