The global acrylic sheets market is experiencing steady expansion, driven by rising demand across construction, signage, automotive, and retail sectors. According to Grand View Research, the global acrylic sheet market size was valued at USD 14.2 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030. This growth is fueled by the material’s superior properties—such as high transparency, impact resistance, and lightweight characteristics—making it a preferred alternative to glass. With increasing customization needs, particularly for perspex acrylic sheets cut to size, manufacturers are investing in precision cutting technologies and on-demand production capabilities. As demand for tailored solutions surges across industries, a new wave of manufacturers has emerged, combining advanced fabrication techniques with scalable operations to serve diverse applications—from architectural glazing to point-of-sale displays. The following list highlights the top 10 manufacturers excelling in delivering precision-cut perspex acrylic sheets, evaluated based on production capacity, technological innovation, geographic reach, and customer-centric service models.

Top 10 Perspex Acrylic Sheet Cut To Size Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

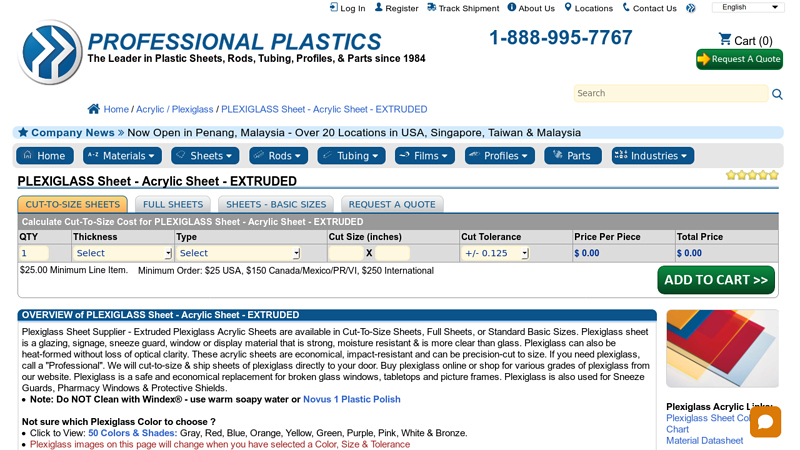

#1 Plexiglass Sheet

Domain Est. 1997

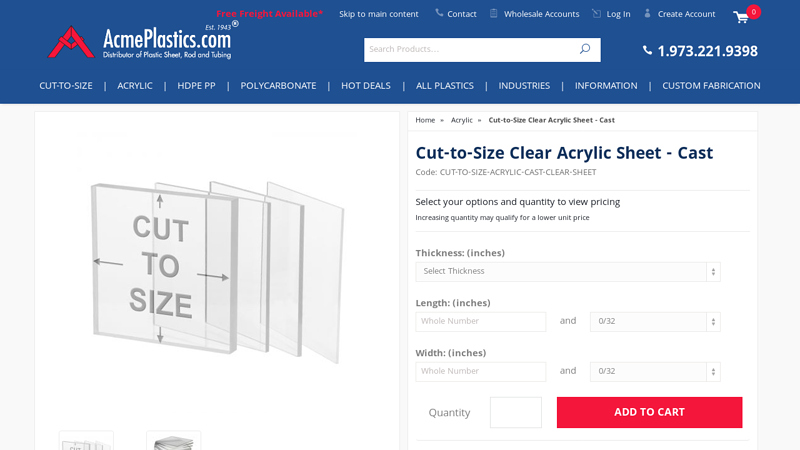

#2 Cut

Domain Est. 1997

Website: acmeplastics.com

Key Highlights: Free delivery 15-day returnsChoose from a range options for custom cut-to-size clear acrylic plexiglass sheets. We offer a variety of customization options and edge polishing metho…

#3 Plastic, Acrylic & Polycarbonate Sheet Supplier

Domain Est. 1997

Website: acplasticsinc.com

Key Highlights: Our offering includes acrylic sheeting, plexiglass sheeting, polycarbonate sheeting, multiwall sheeting, abs plastic sheeting, HDPE and much more….

#4 Perspex

Domain Est. 1998

Website: perspex.co.uk

Key Highlights: UK’s largest range of Perspex® Acrylic Sheet. Also Perspex® extruded acrylic, aluminium composite, PVC Foam, Polycarbonate and more cut to size from stock….

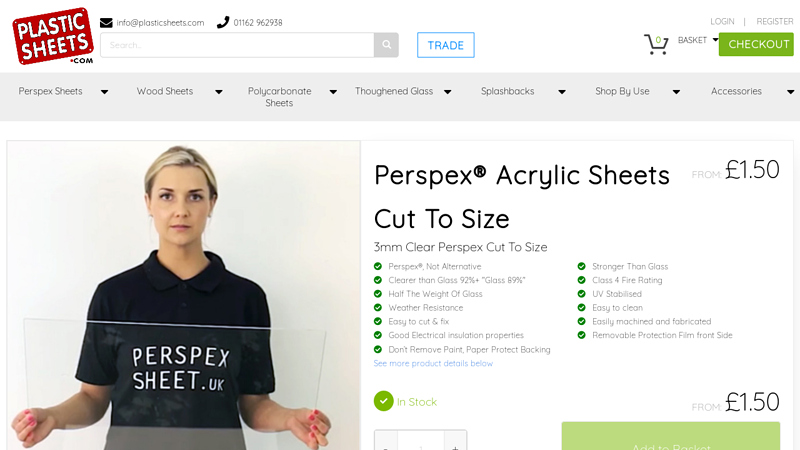

#5 Perspex Acrylic Sheet Cut To Size

Domain Est. 1999

Website: plasticsheets.com

Key Highlights: 30-day returnsCut to size Plastic Acrylic sheets and blocks. 85 options to choose from. Full sheets, shapes and discs, bespoke cutting. Fast delivery, amazing prices….

#6 Min Plastics

Domain Est. 2000

Website: minplastics.com

Key Highlights: Official distributor of PLEXIGLAS®, Polycarbonate, Expanded/Foamed PVC, HDPE, Starboard, and Laser-Engraveable sheets. Supporting projects from cut-to-size ……

#7 Delvie’s Plastics

Domain Est. 2002

#8 PERSPEX®

Domain Est. 2010

Website: display.3acomposites.com

Key Highlights: Cast Acrylic sheet with limitless colour and texture options. PERSPEX® acrylic sheet is recognised as a premium product, one of the best quality acrylic ……

#9 Simply Plastics

Domain Est. 2011

Website: simplyplastics.com

Key Highlights: Simply Plastics are an online supplier of cut to size plastic sheet, tube and rod, all of which are available in various styles, colours, sizes and thicknesses….

#10 RuudraScott Plastic

Domain Est. 2015

Website: ruudrascottplastics.com

Key Highlights: 14-day returnsCut to size plastics, just buy what you need. Stunning kitchen splashbacks, wetwalls, hygienic cladding & floor panels at wholesale price….

Expert Sourcing Insights for Perspex Acrylic Sheet Cut To Size

H2: 2026 Market Trends for Perspex Acrylic Sheet Cut To Size

The global market for Perspex (acrylic) sheets cut to size is projected to experience steady growth through 2026, driven by increasing demand across construction, signage, retail displays, and residential applications. Key trends shaping the market include technological advancements in precision cutting, sustainability initiatives, regional industrial expansion, and the rising adoption of customized solutions.

-

Growth in Customization and On-Demand Manufacturing

Consumers and businesses increasingly favor bespoke dimensions and finishes, fueling demand for acrylic sheets cut to size. Digital fabrication tools—such as CNC routers and laser cutters—enable faster, more accurate production, reducing waste and lead times. Online configurators allow customers to input exact dimensions, accelerating e-commerce adoption in the sector. -

Expansion in Construction and Architectural Applications

The construction industry is embracing acrylic sheets as lightweight, shatter-resistant alternatives to glass in skylights, partitions, and façades. Urbanization in Asia-Pacific and the Middle East, coupled with green building standards, will boost demand for energy-efficient, transparent materials like Perspex. -

Sustainability and Recyclability Focus

As environmental regulations tighten, manufacturers are investing in recyclable and bio-based acrylic alternatives. Brands are promoting eco-friendly production processes and closed-loop recycling systems to appeal to environmentally conscious buyers. This shift enhances the material’s appeal in regulated markets like the EU and North America. -

Rise of Digital Signage and Retail Displays

The retail and advertising sectors are major end-users of cut-to-size acrylic sheets. With the resurgence of physical retail post-pandemic and the need for eye-catching point-of-sale displays, demand for durable, glossy, and customizable acrylic solutions is rising. UV-printable and anti-reflective variants are gaining popularity. -

E-commerce and Direct-to-Consumer (DTC) Models

Online platforms offering made-to-measure acrylic sheets have expanded rapidly. Companies leveraging digital marketing, 3D visualization tools, and same-day dispatch services are capturing market share. This trend is particularly strong in North America and Western Europe, where DIY culture and small business needs drive demand. -

Regional Market Dynamics

- Asia-Pacific: Fastest-growing region due to industrialization, infrastructure development, and rising disposable incomes. China and India are key production and consumption hubs.

- North America & Europe: Mature markets focusing on innovation, sustainability, and high-precision applications in healthcare and transportation.

-

Latin America and Africa: Emerging opportunities as construction and advertising sectors modernize.

-

Price Volatility and Supply Chain Adjustments

Fluctuations in raw material (e.g., methyl methacrylate) prices and logistical challenges may affect margins. However, localized production and inventory optimization strategies are helping suppliers maintain competitiveness.

In summary, the 2026 outlook for Perspex acrylic sheets cut to size is positive, with innovation, customization, and sustainability acting as primary growth drivers. Companies that invest in digital manufacturing, eco-friendly materials, and responsive supply chains are poised to lead the evolving market landscape.

Common Pitfalls When Sourcing Perspex Acrylic Sheet Cut To Size (Quality & IP)

Sourcing Perspex® acrylic sheet cut to size offers convenience and precision, but it comes with potential pitfalls related to material quality and intellectual property (IP) concerns. Being aware of these risks helps ensure you receive a product that meets your specifications and legal requirements.

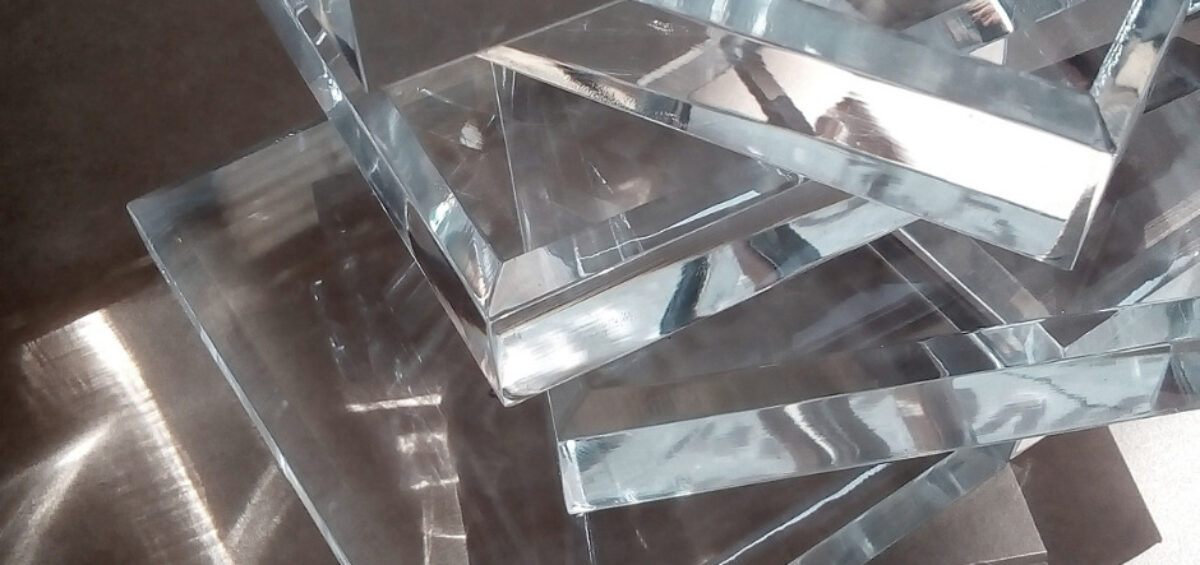

Poor Material Quality and Inconsistent Specifications

One of the most frequent issues when ordering cut-to-size acrylic is receiving material that doesn’t meet expected quality standards. Suppliers may use lower-grade acrylic—such as regrind, off-spec, or non-branded alternatives—instead of genuine Perspex®, leading to inconsistencies in clarity, color, UV resistance, or mechanical strength. Scratches, surface haze, or internal stress marks introduced during cutting can also compromise the final product, especially for applications requiring optical clarity or structural integrity.

Inaccurate or Inconsistent Cutting Tolerances

Even if the base material is high quality, poor fabrication practices can undermine results. Some suppliers may lack precision cutting equipment or fail to maintain it properly, resulting in dimensional inaccuracies, uneven edges, or warping. This is particularly problematic in applications requiring tight tolerances or seamless assembly. Always confirm the supplier’s cutting capabilities and adherence to industry tolerances (e.g., ±0.5mm) before placing an order.

Misuse of Brand Names and Trademark Infringement

“Perspex®” is a registered trademark owned by Mitsubishi Chemical Group for a specific range of acrylic sheet products. Many suppliers incorrectly use “Perspex” generically to describe any acrylic sheet, which can mislead buyers into believing they are purchasing the branded product. This misuse not only affects quality expectations but can also pose IP risks—especially in commercial or retail applications where trademark compliance is essential. Always verify whether you’re receiving genuine Perspex® or a generic acrylic alternative.

Lack of IP Compliance in Custom Designs

When providing custom designs for cutting (e.g., logos, branded shapes), ensure your supplier respects intellectual property rights. Reputable suppliers should have policies to confirm that the buyer holds the rights to the design or has appropriate licensing. Failure to do so can expose both you and the supplier to IP infringement claims, particularly if the design incorporates copyrighted or trademarked elements.

Inadequate Traceability and Certification

For regulated industries (e.g., medical, aerospace, or food-contact applications), material traceability and certification are critical. Generic or low-cost suppliers may not provide batch certifications, material data sheets (MSDS), or proof of compliance with relevant standards (e.g., ISO, REACH, RoHS). Without these documents, you risk non-compliance, especially when using the material in sensitive environments.

Hidden Costs and Minimum Order Constraints

Some suppliers advertise competitive pricing but impose hidden costs for cutting, handling, or delivery—particularly for small or complex orders. Others may enforce minimum order quantities or charge disproportionately for intricate cuts. Always request a detailed quote that includes all potential fees and confirm whether small-batch or prototype orders are supported.

By being vigilant about these common pitfalls, you can select a reliable supplier that delivers high-quality, accurately cut acrylic while respecting brand integrity and intellectual property standards.

Logistics & Compliance Guide for Perspex Acrylic Sheet Cut To Size

Product Overview

Perspex® Acrylic Sheets cut to size are precision-manufactured thermoplastic panels used in signage, displays, protective barriers, architectural glazing, and industrial applications. These sheets are custom-cut to customer specifications from standard or large-format acrylic stock. Proper logistics and compliance handling ensures product integrity and regulatory adherence.

Packaging & Handling

Proper packaging is essential to prevent scratches, warping, and edge damage during transit.

- Protective Films: All cut sheets are supplied with factory-applied low-adhesion masking films on both sides to protect surfaces.

- Edge Protection: Fragile edges are safeguarded using foam corner guards or edge trims, especially for larger or thicker sheets.

- Stacking & Separation: Sheets are stacked with interleaving paper or foam to prevent marring. Avoid direct contact between bare acrylic surfaces.

- Palletization: Large orders are secured on wooden or recyclable plastic pallets using stretch wrap and edge boards. Overhang must not exceed 10% of sheet length.

- Labeling: Each package is labeled with handling instructions (e.g., “This Side Up,” “Fragile,” “Protect from Sunlight”).

Transportation & Shipping

Ensure safe and efficient delivery through appropriate transport methods and handling protocols.

- Mode of Transport: Suitable for road, sea, and air freight. Air shipping requires compliance with IATA regulations if applicable.

- Environmental Controls: Avoid prolonged exposure to high temperatures (>40°C) or humidity, which can cause warping or film adhesion issues.

- Loading/Unloading: Use mechanical aids (e.g., forklifts, suction lifters) to handle large or heavy sheets. Never drag or drop packages.

- Transit Time: Expedited shipping recommended for temperature-sensitive environments.

Storage Requirements

Proper storage prevents deformation and surface degradation prior to installation.

- Location: Store indoors in a clean, dry, well-ventilated area away from direct sunlight and heat sources.

- Orientation: Store vertically in racks with support along the full height, or horizontally on flat, level surfaces with adequate support to prevent sagging.

- Stacking Limits: Do not stack horizontally beyond 1 meter in height to avoid pressure deformation.

- Shelf Life: Masking film should be removed within 6 months of delivery to prevent adhesion residue.

Regulatory Compliance

Adherence to international and regional standards ensures safety and legal conformity.

- REACH & RoHS Compliance: Perspex acrylic sheets are free from SVHCs (Substances of Very High Concern) under REACH and comply with RoHS directives for restricted hazardous substances.

- Fire Safety: Meets fire performance standards such as ASTM E84 (Class 1/Class A rating for flame spread) and BS 476 Part 7. Not suitable for applications requiring non-combustible materials.

- Food Contact: Standard acrylic is not certified for direct food contact unless specifically treated and certified (e.g., FDA 21 CFR 177.1010).

- Waste & Recycling: Classified as plastic code #7 (“Other”). Fully recyclable via mechanical recycling processes. Dispose of in accordance with local waste regulations.

Import & Export Documentation

For international shipments, ensure accurate documentation to avoid customs delays.

- HS Code: 3920.51 (Polymers of methyl methacrylate, in primary forms).

- Certificates: Provide Material Safety Data Sheet (MSDS/SDS), Certificate of Conformance (CoC), and origin declaration upon request.

- Customs Declarations: Accurate product description, dimensions, weight, and value must be declared.

- Duty & Tariff Information: Duty rates vary by country; consult local customs authorities for up-to-date classifications.

Safety & Handling Precautions

Protect personnel and maintain product quality during handling.

- Personal Protective Equipment (PPE): Use cut-resistant gloves, safety glasses, and masks when handling or machining cut edges.

- Cut Edge Hazards: Edges may be sharp; handle with care and provide warnings on packaging.

- Ventilation: When machining (drilling, routing), use adequate ventilation to avoid inhalation of fine dust particles.

- Static Control: Acrylic generates static; use anti-static wipes or ionizers in cleanroom environments.

Returns & Damage Claims

Clear procedures for addressing logistics-related issues.

- Inspection on Delivery: Customers must inspect goods immediately upon receipt for damage or discrepancies.

- Documentation: Report damages within 24 hours with photographic evidence and delivery note annotations.

- Return Authorization: Returns require prior approval. Custom-cut items are non-returnable unless defective or incorrectly manufactured.

- Liability: Carrier liability applies for transit damage if proper packaging and handling guidelines were followed.

Sustainability & Environmental Responsibility

Support eco-friendly practices throughout the supply chain.

- Recyclability: Perspex acrylic is 100% recyclable; encourage customers to return offcuts or obsolete panels for recycling.

- Packaging Materials: Use recyclable or biodegradable packaging components (e.g., cardboard, paper, recyclable stretch film).

- Carbon Reporting: Provide carbon footprint data upon request for logistics and production processes.

Contact & Support

For logistics inquiries, compliance documentation, or shipment tracking:

Contact: [email protected] | +1 (800) XXX-XXXX

Available Monday–Friday, 9:00 AM – 5:00 PM local time.

In conclusion, sourcing Perspex (acrylic) sheets cut to size offers a practical, cost-effective, and time-saving solution for a wide range of applications—from signage and displays to architectural features and DIY projects. Custom-cut acrylic ensures precision fitting, reduces material waste, and eliminates the need for extensive in-house fabrication. With advancements in laser and CNC cutting technologies, suppliers can deliver high-quality, accurately sized sheets with clean edges and professional finishes. When selecting a supplier, it is important to consider factors such as material thickness, color, UV resistance, lead times, and customer service. By partnering with a reputable provider, businesses and individuals can achieve superior results while streamlining their production processes. Overall, opting for pre-cut Perspex acrylic sheets combines convenience, quality, and efficiency, making it an ideal choice for both small-scale and large-scale projects.