The global pendulum machine market is experiencing steady growth, driven by rising demand for precise impact testing in industries such as automotive, aerospace, and construction materials. According to Mordor Intelligence, the global impact testing equipment market—which includes pendulum impact testers—is projected to grow at a CAGR of over 4.8% from 2023 to 2028. This expansion is fueled by stringent quality control standards and regulatory requirements for material safety and performance. As industries prioritize reliability in material testing, pendulum machines, particularly Charpy and Izod impact testers, have become essential tools in evaluating fracture resistance. With increasing industrialization and infrastructure development, especially in Asia-Pacific and Latin America, the demand for high-accuracy testing equipment continues to rise. Based on market presence, technological innovation, global reach, and compliance with international standards, the following nine manufacturers stand out as leaders in the pendulum machine industry.

Top 9 Pendulum Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Plate Loaded Pendulum-X Squat

Domain Est. 1995

Website: lifefitness.com

Key Highlights: Engineered for elite athletes, this machine builds stronger legs, powerful hips, and next-level performance. Dimensions (L x W x H): 97 x 45 x 81 in (246 x 114 ……

#2 Weight Room Equipment

Domain Est. 1996

Website: rogersathletic.com

Key Highlights: Achieve maximum results on Pendulum Strength machines thanks to the precision strength curve. Lifters can be confident knowing they’re lifting safely….

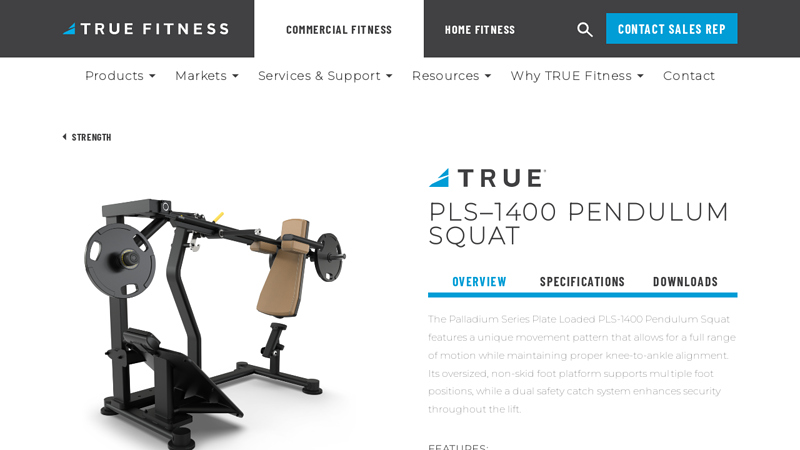

#3 PLS–1400 Pendulum Squat

Domain Est. 1996

Website: truefitness.com

Key Highlights: The Palladium Series Plate Loaded PLS-1400 Pendulum Squat features a unique movement pattern that allows for a full range of motion while maintaining proper ……

#4 Super pendulum squat

Domain Est. 1999

Website: panattasport.com

Key Highlights: The Super Pendulum Squat is ideal for the complete training of the entire thigh muscles, with main emphasis on the quads and Buttoks….

#5 On

Domain Est. 2003

Website: pendulum-instruments.com

Key Highlights: On-line product registration. 1. Please identify your product. Product group. Frequency Counters/Analyzers. Microwave Counters. Frequency & Time Standards….

#6 Pendulum squat (C212)

Domain Est. 2011

Website: atlantisstrength.com

Key Highlights: Large non-skid foot platform provides proper positioning for all users. · The foot platform is fixed to 45°. · Counterbalanced for lower starting resistance….

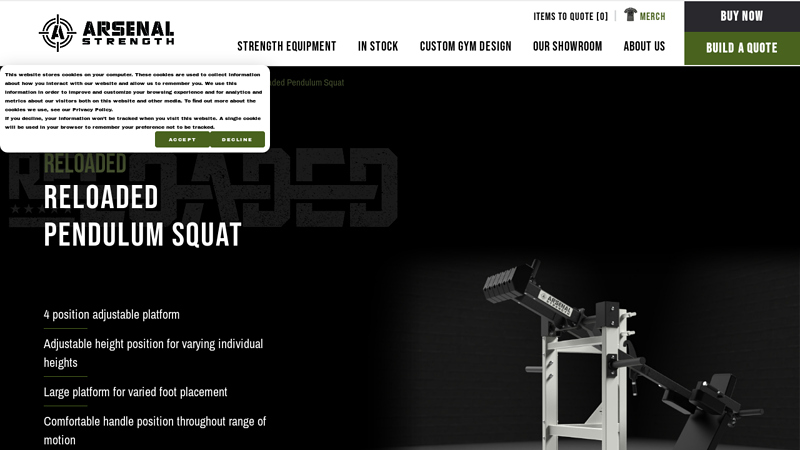

#7 Reloaded Pendulum Squat

Domain Est. 2014

Website: myarsenalstrength.com

Key Highlights: Our Reloaded Pendulum Squat features a large range of motion, a large back pad to secure body placement, and 7 gauge uprights for unit stability….

#8 Skelcore Pro Plus Series Pendulum Squat

Domain Est. 2020

Website: skelcore.com

Key Highlights: The Pendulum Squat is a premium plate-loaded strength machine designed to target the quads, glutes, and hamstrings with an optimal range of motion and reduced ……

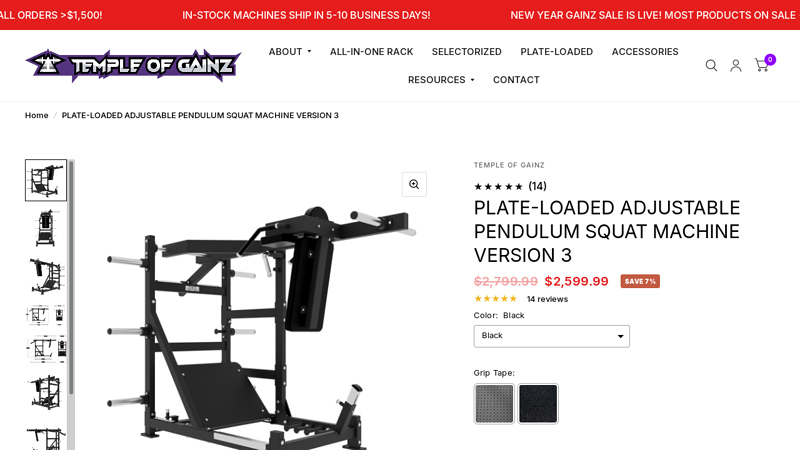

#9 PLATE

Domain Est. 2023

Website: templeofgainz.com

Key Highlights: In stock Rating 5.0 (14) Pendulum Squat V3 machines are in stock in black and white! Orders placed now ship within 5-10 business days, with free freight shipping included!…

Expert Sourcing Insights for Pendulum Machine

H2: Projected 2026 Market Trends for Pendulum Machines

As the global industrial and fitness equipment sectors evolve, the market for pendulum machines—devices that utilize controlled swinging motion for strength training, rehabilitation, or mechanical applications—is expected to experience notable shifts by 2026. Driven by advancements in biomechanics, digital integration, and demand for functional fitness solutions, the following trends are projected to shape the pendulum machine landscape.

1. Rising Demand in Functional and Rehabilitation Fitness

Pendulum machines are increasingly being adopted in physical therapy clinics, sports performance centers, and functional training facilities. Their ability to mimic natural human movement patterns makes them ideal for injury prevention, post-rehabilitation conditioning, and athletic development. By 2026, the growing emphasis on holistic health and injury mitigation is expected to expand market penetration, particularly in North America and Europe.

2. Integration with Smart Technology

A key trend shaping the 2026 market is the integration of IoT (Internet of Things) and AI-driven analytics into pendulum machines. Manufacturers are incorporating sensors, real-time performance tracking, and mobile app connectivity to provide users with data on force output, range of motion, and workout progression. This digital transformation enhances user engagement and personalization, appealing to tech-savvy consumers and professional training environments.

3. Expansion in Commercial and Institutional Sectors

Gyms, collegiate athletic programs, and military training centers are investing in pendulum machines due to their efficiency in building explosive strength and core stability. By 2026, institutional procurement is expected to rise, driven by evidence-based results in performance enhancement and reduced injury rates among athletes.

4. Focus on Customization and Modular Design

To meet diverse user needs, manufacturers are developing modular pendulum systems that allow for adjustable resistance, pivot points, and attachment options. This flexibility supports scalable training for individuals across fitness levels and rehabilitation stages, making the machines more versatile and cost-effective for commercial buyers.

5. Sustainability and Manufacturing Efficiency

Environmental concerns are influencing material selection and production methods. Companies are exploring recycled materials and energy-efficient manufacturing processes to align with global sustainability goals. This shift is expected to appeal to eco-conscious buyers and support long-term brand loyalty.

6. Emerging Markets and Global Reach

While North America currently dominates the pendulum machine market, regions such as Asia-Pacific and Latin America are anticipated to show significant growth by 2026. Increasing health awareness, urbanization, and investments in fitness infrastructure will drive demand in these emerging economies.

In conclusion, the 2026 market for pendulum machines is poised for innovation and expansion, fueled by technological advancements, healthcare integration, and evolving consumer preferences. Stakeholders who prioritize smart features, adaptability, and global accessibility will be best positioned to capitalize on this upward trajectory.

Common Pitfalls When Sourcing a Pendulum Machine: Quality and Intellectual Property Risks

Sourcing a pendulum machine—whether for testing, calibration, or research—can present significant challenges, particularly in ensuring product quality and protecting intellectual property (IP). Overlooking these aspects can lead to performance issues, legal disputes, or compromised project integrity.

Quality-Related Pitfalls

Inconsistent Manufacturing Standards

Suppliers, especially those in regions with less stringent quality controls, may produce pendulum machines that vary significantly between units. Differences in materials, machining tolerances, or assembly processes can undermine repeatability and accuracy, leading to unreliable test results or measurement drift over time.

Lack of Calibration and Certification

Many low-cost suppliers fail to provide traceable calibration certificates from accredited laboratories. Without proper certification, it becomes difficult to validate the machine’s performance against international standards (e.g., ISO, ASTM, or NIST traceability), potentially invalidating data collected during use.

Poor Material Selection and Durability

Substandard materials—such as low-grade metals or plastics—can degrade under repeated mechanical stress or environmental exposure. This not only reduces the machine’s lifespan but can also introduce measurement errors due to wear, deformation, or friction inconsistencies.

Inadequate Documentation and Support

Incomplete technical documentation, unclear operating manuals, or lack of supplier responsiveness can hinder proper installation, maintenance, and troubleshooting. This is especially problematic for complex pendulum systems requiring precise alignment or regular servicing.

Intellectual Property-Related Pitfalls

Risk of Infringing on Patented Designs

Pendulum mechanisms, especially those used in precision testing (e.g., impact testers or gravimeters), may incorporate patented technologies. Sourcing from suppliers who replicate protected designs without licensing can expose the buyer to legal liability, including cease-and-desist orders or infringement lawsuits.

Ambiguous Ownership of Customizations

When working with suppliers to modify or co-develop a pendulum machine, failure to define IP ownership in writing can lead to disputes. Suppliers may claim rights over design improvements or software integrations, limiting your ability to reproduce, modify, or commercialize the technology.

Exposure of Proprietary Processes

Sharing detailed specifications or application requirements with unvetted suppliers may inadvertently disclose sensitive R&D information. Without robust non-disclosure agreements (NDAs) and IP protection clauses, your proprietary methods or innovations could be exploited or reverse-engineered.

Use of Open-Source or Unverified Components

Some suppliers integrate open-source hardware or software into their systems without proper licensing compliance. This can create downstream legal risks for the buyer, particularly if the end application involves commercial use or distribution.

Mitigation Strategies

To avoid these pitfalls, conduct thorough due diligence on suppliers, request third-party quality certifications, verify IP status through patent searches, and establish clear contractual terms regarding IP ownership and confidentiality. Engaging legal and technical experts during the sourcing process can help safeguard both performance expectations and intellectual property rights.

Logistics & Compliance Guide for Pendulum Machine

This guide provides essential information for the safe, efficient, and compliant transportation, handling, and operation of the Pendulum Machine. Adherence to these guidelines ensures regulatory compliance, minimizes risks, and supports smooth logistics operations.

Packaging and Handling Requirements

The Pendulum Machine must be packed securely to prevent damage during transit. Use a robust wooden crate or reinforced cardboard container with internal foam or custom inserts to immobilize the unit. Clearly label the package with “Fragile,” “This Side Up,” and “Do Not Stack.” Avoid exposing the packaged machine to extreme temperatures, moisture, or direct sunlight during storage and transit.

Shipping and Transportation

Ship via a certified freight carrier experienced in handling precision equipment. For international shipments, ensure compliance with IATA/IMDG regulations if applicable. Use lift-gates or forklifts for loading/unloading due to the unit’s weight. Secure the machine on pallets with straps during transport to prevent shifting. Maintain a clean transport environment free from dust, vibrations, and contaminants.

Import/Export Compliance

Verify export control classifications (ECCN) under the Export Administration Regulations (EAR). The Pendulum Machine may be subject to dual-use regulations due to its engineering applications. Complete required documentation, including commercial invoice, packing list, and certificate of origin. For exports outside your home country, consult local customs authorities and ensure adherence to destination country import standards.

Regulatory and Safety Standards

The Pendulum Machine complies with ISO 12100 (Safety of Machinery) and relevant CE marking directives when applicable. Ensure all safety guards, emergency stops, and warning labels are intact and visible. Operators must follow OSHA (or local equivalent) safety protocols during installation and use. Electrical components must meet IEC 60204-1 standards for safety in machinery.

Installation and Site Preparation

Install the machine on a level, vibration-free surface with adequate clearance for maintenance and operation. Confirm power supply meets specified voltage and grounding requirements. Verify that the site has sufficient ventilation and is free from excessive dust or electromagnetic interference. Conduct a pre-installation inspection to ensure no damage occurred during shipping.

Documentation and Recordkeeping

Maintain all compliance documentation, including user manuals, calibration certificates, conformity declarations, and service logs. Retain shipping records, customs filings, and import/export licenses for a minimum of five years. Provide operators with up-to-date safety data sheets (SDS) if the machine involves any hazardous components or materials.

Maintenance and Compliance Audits

Perform scheduled maintenance per the manufacturer’s recommendations to ensure continued compliance and operational integrity. Document all maintenance activities and calibration checks. Conduct annual compliance audits to verify adherence to safety, environmental, and transport regulations. Update procedures promptly in response to regulatory changes.

Disposal and End-of-Life Management

Dispose of the Pendulum Machine in accordance with local environmental regulations, particularly concerning electronic waste (WEEE) and hazardous materials. Partner with certified e-waste recyclers. Remove and properly dispose of batteries or lubricants separately if applicable. Retain disposal certificates for audit purposes.

Conclusion for Sourcing a Pendulum Impact Testing Machine:

After thorough evaluation of technical specifications, supplier reliability, cost-effectiveness, and compliance with international standards (such as ISO 148, ASTM E23, etc.), sourcing a pendulum impact testing machine is a strategic investment to enhance material quality control and ensure product reliability. The selected machine meets the required energy capacity, accuracy, and safety standards necessary for consistent and repeatable Charpy or Izod impact testing. Additionally, considerations such as after-sales service, calibration support, and operator training have been addressed to ensure long-term operational efficiency. By procuring a high-quality pendulum machine from a reputable supplier, the organization strengthens its testing capabilities, supports regulatory compliance, and reinforces confidence in material performance under dynamic loading conditions.