The global pearl setting machine market is experiencing steady growth, driven by rising demand in the textile, packaging, and apparel industries for precision fastening solutions. According to a report by Mordor Intelligence, the global snap button and fasteners market—which includes pearl setting machines—is projected to grow at a CAGR of over 4.5% from 2023 to 2028. This growth is fueled by increasing automation in garment manufacturing, rising consumer preference for durable and stylish fastenings, and the expansion of the ready-to-wear fashion sector, particularly in Asia-Pacific. As manufacturers seek reliable, high-efficiency machinery, the need for advanced pearl setting solutions has never been sharper. In this evolving landscape, six key manufacturers stand out for their innovation, global reach, and technological expertise—shaping the future of automated pearl and snap button application across industries.

Top 6 Pearl Setting Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 China Plastic Pearl Attaching Machine Factory and Manufacturers

Domain Est. 2020

Website: chinatopsew.com

Key Highlights: Plastic Pearl Attaching Machine Manufacturers, Factory, Suppliers From China, We promise to try our greatest to deliver you with high quality and economical ……

#2 Swisspearl Group

Domain Est. 2003

Website: swisspearl.com

Key Highlights: With headquarters in Switzerland, Swisspearl is manufacturer of premium fibre cement products for facade, roofing, interior wall cladding and garden ……

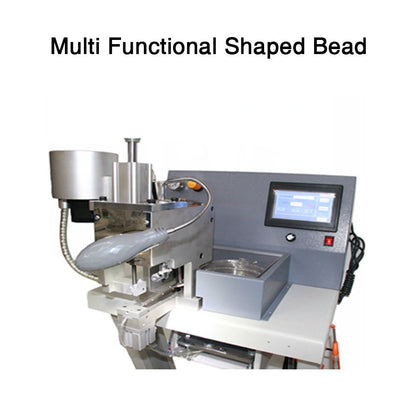

#3 Garment beads attaching pearl Setting Machine

Domain Est. 2014

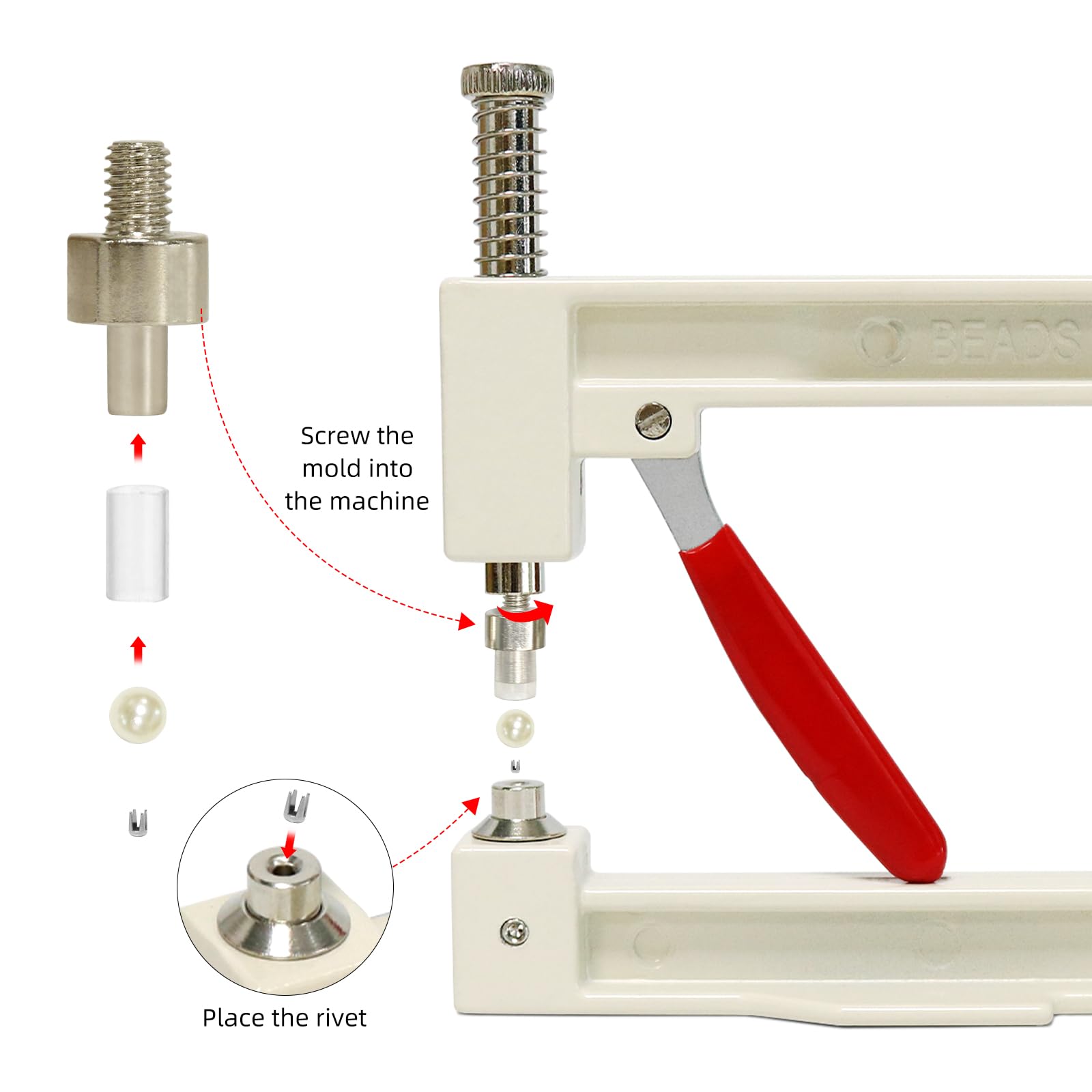

#4 Wokape Pearl Setting Machine (Including 5Pcs Molds) with 630 Pcs …

Domain Est. 2014

Website: gosupps.com

Key Highlights: $19.99 deliveryBuy Wokape Pearl Setting Machine Kit with 630 Colorful ABS Pearls & 700 Nailheads Studs – Includes 5 Molds | Pearl Setting Tools from GoSupps.com – Express ……

#5 L Press Troyune Pearl Setting Machine, Hand Press Tools With …

Domain Est. 2019

Website: bellagreymedspa.com

Key Highlights: VERSATILE TOOL: Hand press tool designed for attaching pearls and studs to clothing, bags, hair accessories, and various DIY craft projects Whether you’re a ……

#6 Pearl Setting Machine

Domain Est. 2020

Website: embroidery-equip.com

Key Highlights: Pearl setting machine is used to decorate underwear, children’s clothing, T-shirts, embroidery patterns, leather, handbags, hair accessories, hats and other ……

Expert Sourcing Insights for Pearl Setting Machine

H2: 2026 Market Trends for Pearl Setting Machines

The global market for pearl setting machines is poised for significant transformation by 2026, driven by technological innovation, shifting consumer preferences, and evolving manufacturing demands in the jewelry and fashion industries. As automation and precision become increasingly critical in gemstone and pearl processing, pearl setting machines are expected to experience renewed growth and diversification. Below are the key market trends anticipated in 2026:

-

Increased Automation and AI Integration

By 2026, pearl setting machines are expected to incorporate more advanced automation and artificial intelligence (AI) capabilities. These enhancements will improve precision, reduce human error, and increase production speeds. AI-driven vision systems will allow machines to detect pearl size, shape, and quality in real time, ensuring optimal placement and reducing material waste. -

Growing Demand in the Fashion and Luxury Jewelry Sectors

The rising popularity of pearl-based jewelry—driven by sustainable fashion trends and cultural revivals—will fuel demand for efficient and reliable pearl setting solutions. Luxury brands and independent designers alike are expected to invest in high-end pearl setting machines to meet consumer demand for intricate, handmade-quality designs at scalable production levels. -

Miniaturization and Precision Engineering

As designers experiment with smaller, more delicate pearl settings (such as micro-pearl inlays and nano-settings), machine manufacturers will respond with compact, high-precision models. These next-generation machines will support ultra-fine settings on a range of materials, including gold, silver, and alternative alloys, while maintaining durability and consistency. -

Expansion in Asian Manufacturing Hubs

Countries like China, India, and Thailand—already major players in jewelry manufacturing—are expected to lead adoption of automated pearl setting machines by 2026. Government incentives for industrial automation, coupled with rising labor costs, will accelerate the shift from manual setting to mechanized processes. -

Sustainability and Ethical Production Focus

The jewelry industry’s push toward sustainable and traceable sourcing will influence machine design. Pearl setting machines may integrate IoT sensors and digital logging features to provide data on material usage, energy consumption, and production efficiency—helping manufacturers meet ESG (Environmental, Social, and Governance) standards. -

Customization and On-Demand Manufacturing

With the rise of personalized and made-to-order jewelry, pearl setting machines will increasingly support flexible configurations and rapid changeovers. Modular designs and user-friendly software interfaces will allow jewelers to switch between different pearl types and setting styles with minimal downtime. -

Integration with Digital Design Platforms

By 2026, seamless integration between CAD/CAM software and pearl setting machines is expected to become standard. Designers will be able to create 3D models that are directly translated into machine instructions, enabling end-to-end digital workflows from concept to finished product. -

Rising Investment in R&D and Startups

Venture capital and industry players are likely to increase funding for startups developing innovative pearl setting technologies. This includes robotic arms with tactile feedback, hybrid manual-automated systems, and machines capable of handling irregular or baroque pearls with minimal human intervention.

In conclusion, the 2026 landscape for pearl setting machines will be defined by smarter, faster, and more adaptable technology. As the jewelry market embraces digital transformation and sustainability, pearl setting machines will play a pivotal role in enabling efficient, scalable, and high-quality production across global supply chains.

Common Pitfalls When Sourcing Pearl Setting Machines (Quality and Intellectual Property)

Sourcing a pearl setting machine—especially from international suppliers—can present several challenges, particularly concerning product quality and intellectual property (IP) protection. Being aware of these pitfalls helps mitigate risks and ensures a reliable, legally sound procurement process.

Quality Inconsistencies and Lack of Standardization

One of the most frequent issues is receiving machines that do not meet promised performance or durability standards. Some suppliers may provide prototypes or demo units that perform well, but mass-produced versions often suffer from subpar materials, poor craftsmanship, or inconsistent assembly. Without clear quality control benchmarks or third-party inspections, buyers risk acquiring equipment that breaks down quickly, requires frequent maintenance, or fails to handle delicate pearl-setting tasks accurately.

Misrepresentation of Technical Specifications

Suppliers may exaggerate or falsify machine capabilities, such as setting speed, precision tolerance, or compatibility with different pearl sizes and settings. This can lead to operational inefficiencies or the need for costly retrofits. Always verify specifications through independent testing or on-site demonstrations before finalizing purchases.

Absence of After-Sales Support and Spare Parts

Many low-cost suppliers, particularly from regions with less stringent service standards, offer limited technical support, training, or access to replacement parts. This can result in prolonged downtime and increased long-term costs. Ensure the supplier provides a clear service agreement, maintenance guides, and a reliable supply chain for critical components.

Intellectual Property Infringement Risks

Pearl setting machines often incorporate proprietary mechanisms, software, or design elements protected by patents or copyrights. Sourcing from manufacturers that replicate branded designs without authorization exposes buyers to legal liability, including shipment seizures, fines, or reputational damage. Always conduct due diligence on the supplier’s IP compliance, request documentation of design rights, and avoid machines that appear to be knockoffs of well-known models.

Lack of Transparency in Manufacturing Origins

Some suppliers act as intermediaries, rebranding machines produced by unknown or unverified OEMs. This obscurity makes it difficult to assess true manufacturing quality or trace IP ownership. Demand transparency about the actual manufacturer, factory audits, and proof of original design or licensing agreements.

Inadequate Compliance with Safety and Industry Standards

Machines that don’t comply with international safety regulations (e.g., CE, UL) or jewelry manufacturing standards may pose hazards to operators or fail to integrate smoothly into existing production lines. Confirm that the machine meets relevant certifications and has undergone proper safety testing.

By proactively addressing these pitfalls—through detailed vetting, contractual safeguards, and third-party verification—buyers can secure a high-quality, legally compliant pearl setting machine that supports long-term production goals.

Logistics & Compliance Guide for Pearl Setting Machine

Overview

This guide outlines the essential logistics and compliance considerations for the international shipment, import, and operation of a Pearl Setting Machine. Adhering to these guidelines ensures smooth delivery, regulatory compliance, and safe deployment of the equipment.

Shipping & Packaging Requirements

- Secure Packaging: The machine must be packed in a robust, wooden export crate with internal foam or foam-in-place cushioning to prevent movement during transit.

- Moisture Protection: Include desiccant packs and use moisture barrier bags to protect sensitive electronic and mechanical components.

- Labeling: Clearly label the package with “Fragile,” “This Side Up,” and “Do Not Stack,” along with the consignee and shipper information.

- Weight & Dimensions: Confirm machine weight and dimensions for accurate freight classification and to avoid additional handling fees.

Export Documentation

- Commercial Invoice: Include detailed description of the machine, value, quantity, HS code (e.g., 8479.89 – machines of a kind used in industrial processes), country of origin, and Incoterms (e.g., FOB, DDP).

- Packing List: Provide a detailed list of contents, box numbers, gross/net weights, and dimensions.

- Certificate of Origin: Required by many countries for tariff determination; may need chamber of commerce certification.

- Export License: Verify if export controls apply (e.g., dual-use technology). Most standard pearl setting machines do not require a license, but confirm based on destination and technical specifications.

Import Regulations by Destination

- Tariff Classification: Confirm the correct HS code in the destination country. Misclassification may result in delays or penalties.

- Import Duties & Taxes: Research applicable import duties, VAT, and customs processing fees. Duties vary by country (e.g., typically 0–5% in the EU for industrial machinery).

- Import License: Some countries may require an import permit for industrial equipment. Check with local customs authorities.

- Product Standards & Certification: Ensure the machine complies with local electrical (e.g., CE in EU, UL in USA) and safety standards. Include technical specifications and conformity declarations.

Electrical & Safety Compliance

- Voltage & Frequency: Verify compatibility with local power supply (e.g., 110V/60Hz vs. 220V/50Hz). Include a voltage converter if necessary.

- Certifications: Provide evidence of compliance with relevant standards:

- CE Marking (EU): Machinery Directive 2006/42/EC and Low Voltage Directive.

- UL/CSA (North America): For electrical safety.

- RoHS and REACH: Environmental compliance for restricted substances.

- User Manual: Supply a multilingual manual including safety instructions, maintenance guidelines, and emergency shutdown procedures.

Customs Clearance Process

- Appoint a Customs Broker: Use a licensed broker in the destination country to handle documentation and duties.

- Pre-Arrival Submission: Submit documents electronically before shipment arrival to minimize delays.

- Inspection Readiness: Be prepared for customs inspections; ensure the machine is easily accessible and documentation is complete.

After-Sales & Warranty Compliance

- Warranty Registration: Provide instructions for registering the machine with the manufacturer or distributor.

- Spare Parts Logistics: Maintain a supply of critical spare parts locally or regionally to minimize downtime.

- Service & Support: Confirm availability of technical support and qualified service personnel in the region.

Environmental & Disposal Regulations

- End-of-Life Management: Comply with local WEEE (Waste Electrical and Electronic Equipment) directives for proper disposal or recycling.

- Hazardous Materials: Declare any hazardous components (e.g., batteries, lubricants) per transport regulations (e.g., IATA/ADR).

Summary

Proper planning around packaging, documentation, regulatory standards, and local compliance ensures timely delivery and legal operation of the Pearl Setting Machine. Always consult with logistics providers and legal experts in the destination country to address specific requirements.

Conclusion for Sourcing a Pearl Setting Machine:

Sourcing a pearl setting machine is a strategic investment that can significantly enhance the efficiency, consistency, and quality of jewelry production, particularly for businesses specializing in pearl jewelry. After evaluating various suppliers, machine types, and technical specifications, it is clear that selecting the right machine requires a careful balance of precision, durability, ease of use, and cost-effectiveness. Automated and semi-automated machines offer improved accuracy and reduced labor costs, while reliable brands with strong after-sales support ensure long-term performance and minimal downtime.

It is recommended to prioritize machines with adjustable settings to accommodate different pearl sizes and mounting styles, as well as those constructed with high-quality materials to withstand continuous use. Additionally, considering future scalability and integration with existing production processes will maximize return on investment.

Ultimately, thorough research, supplier evaluation, and, where possible, machine testing will lead to an informed decision that supports craftsmanship excellence and operational efficiency in pearl jewelry manufacturing.