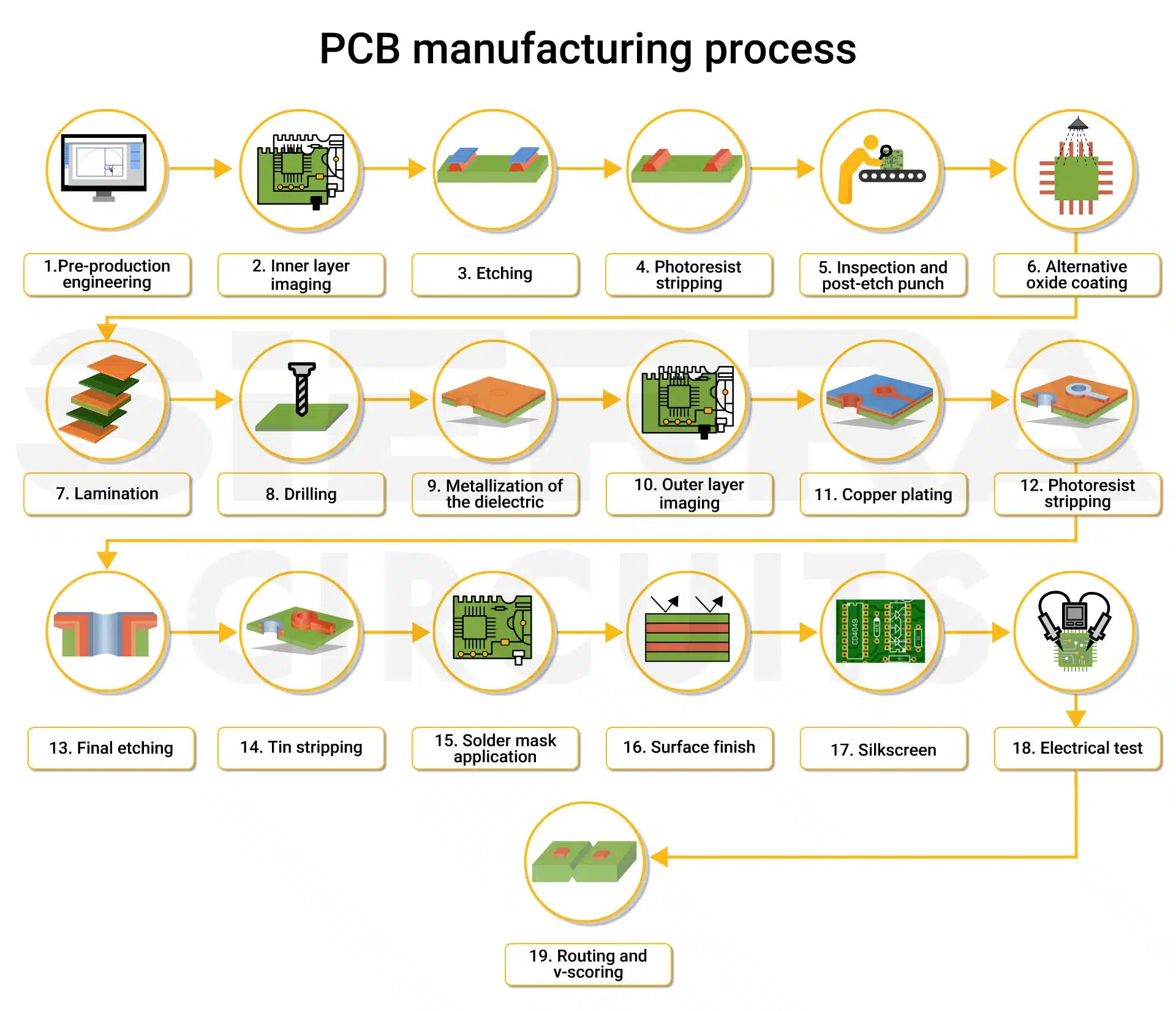

The global printed circuit board (PCB) market is experiencing robust growth, driven by rising demand across consumer electronics, automotive, and industrial sectors. According to a report by Mordor Intelligence, the PCB market was valued at USD 76.9 billion in 2023 and is projected to reach USD 101.8 billion by 2029, growing at a CAGR of approximately 4.7% during the forecast period. This expansion reflects increasing miniaturization of electronic devices and the proliferation of IoT-enabled products—trends that have also fueled niche innovations such as PCB-based business cards. Once a novelty, these functional, tech-forward cards have become a strategic branding tool for engineers, startups, and tech companies alike. As demand for high-quality, miniaturized circuitry grows, so does the number of manufacturers capable of producing sophisticated, small-batch PCB business cards. Based on production capabilities, lead times, material quality, customer reviews, and technological precision, the following nine manufacturers have emerged as leaders in this specialized segment.

Top 9 Pcb Business Card Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Summit Interconnect leads Complex Circuits and Rigid Flex PCB

Domain Est. 2016

Website: summitinterconnect.com

Key Highlights: Summit Interconnect is a manufacturer of advanced technology printed circuit boards focused on complex rigid, flex and rigid-flex PCBs….

#2 Printed Circuit Board Manufacturer

Domain Est. 1998

Website: pcbnet.com

Key Highlights: Imagineering is a trusted printed circuit board manufacturer, offering precision PCB assembly, fabrication, & protoype services with quick turnaround….

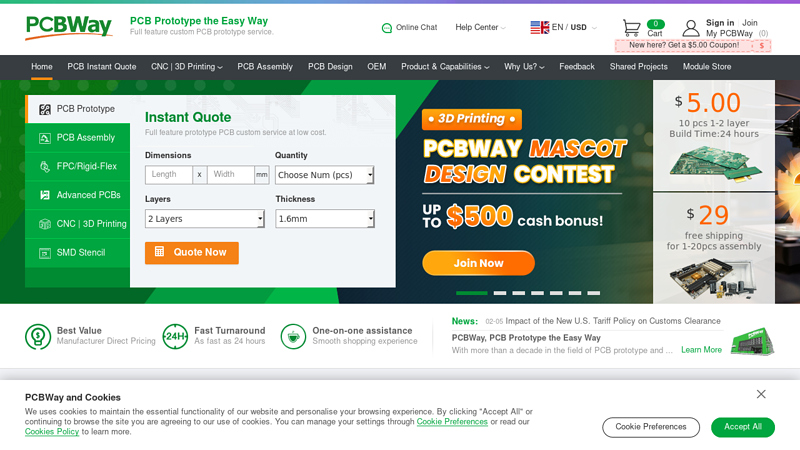

#3 China PCB Prototype & Fabrication Manufacturer

Domain Est. 2012

Website: pcbway.com

Key Highlights: $29 deliveryFull feature prototype PCB custom service at low cost. … SMD-Stencils. Online calculation and order of your precision SMD-Stencils. … Assembly Enquiry. PCB ……

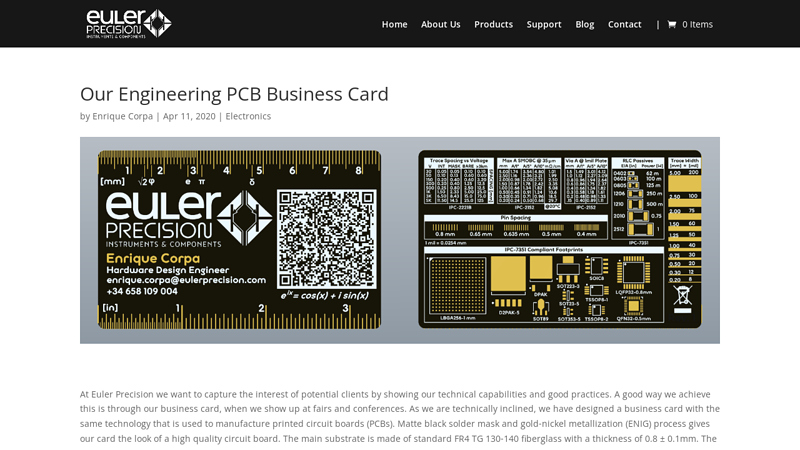

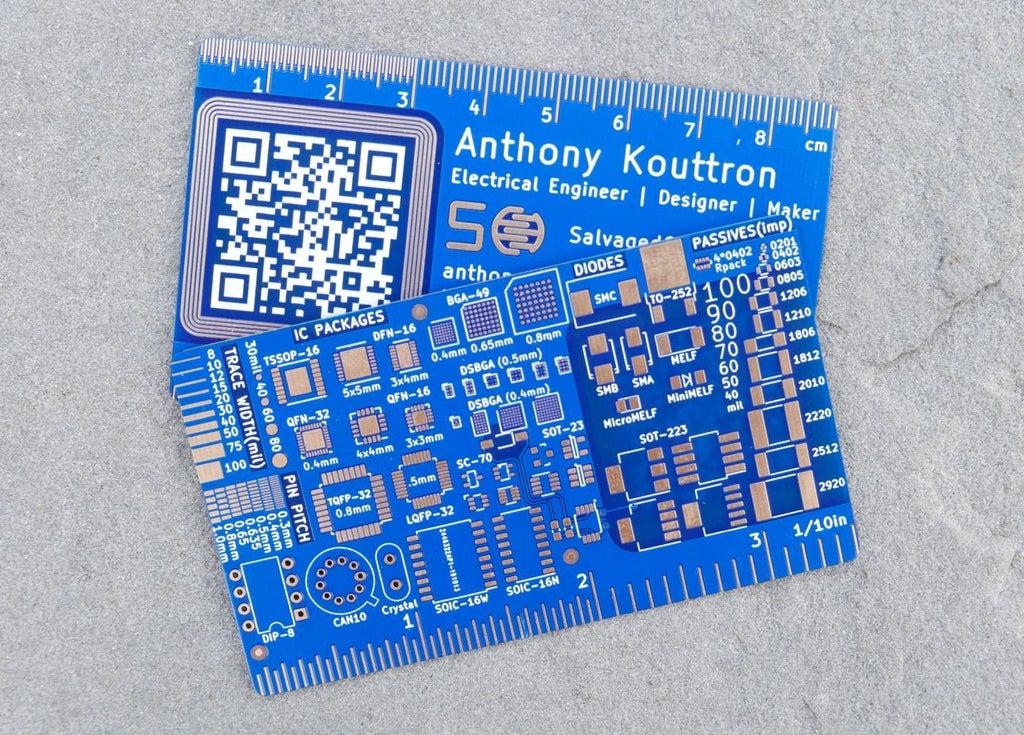

#4 Our Engineering PCB Business Card

Domain Est. 2019

Website: eulerprecision.com

Key Highlights: We have designed a business card with the same technology that is used to manufacture printed circuit boards (PCBs). Matte black solder mask and gold-nickel ……

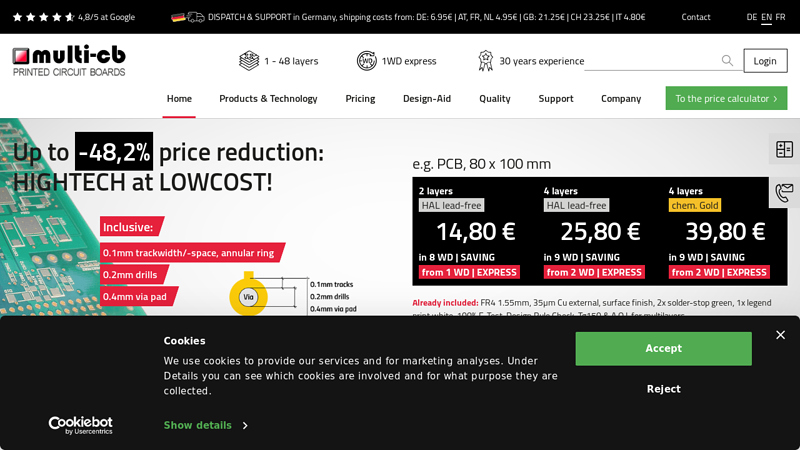

#5 Multi Circuit Boards

Website: multi-circuit-boards.eu

Key Highlights: Multi Circuit Boards (Multi-CB) is a leading European supplier of high-tech low-cost PCB / multilayer boards with up to 48 layers, from 1WD production time….

#6 Sunstone Circuits Printed Circuit Boards

Domain Est. 1995

Website: sunstone.com

Key Highlights: Sunstone Offers Expert Service In High Quality Printed Circuit Board Manufacturing & PCB Assembly, Including Prototype & Production PCBs….

#7 Sierra Circuits

Domain Est. 1997

Website: protoexpress.com

Key Highlights: Sierra Circuits can manufacture your PCB and have it expedited to you within 24 hours. Full turnkey boards, with assembly and components in as fast as 5 days….

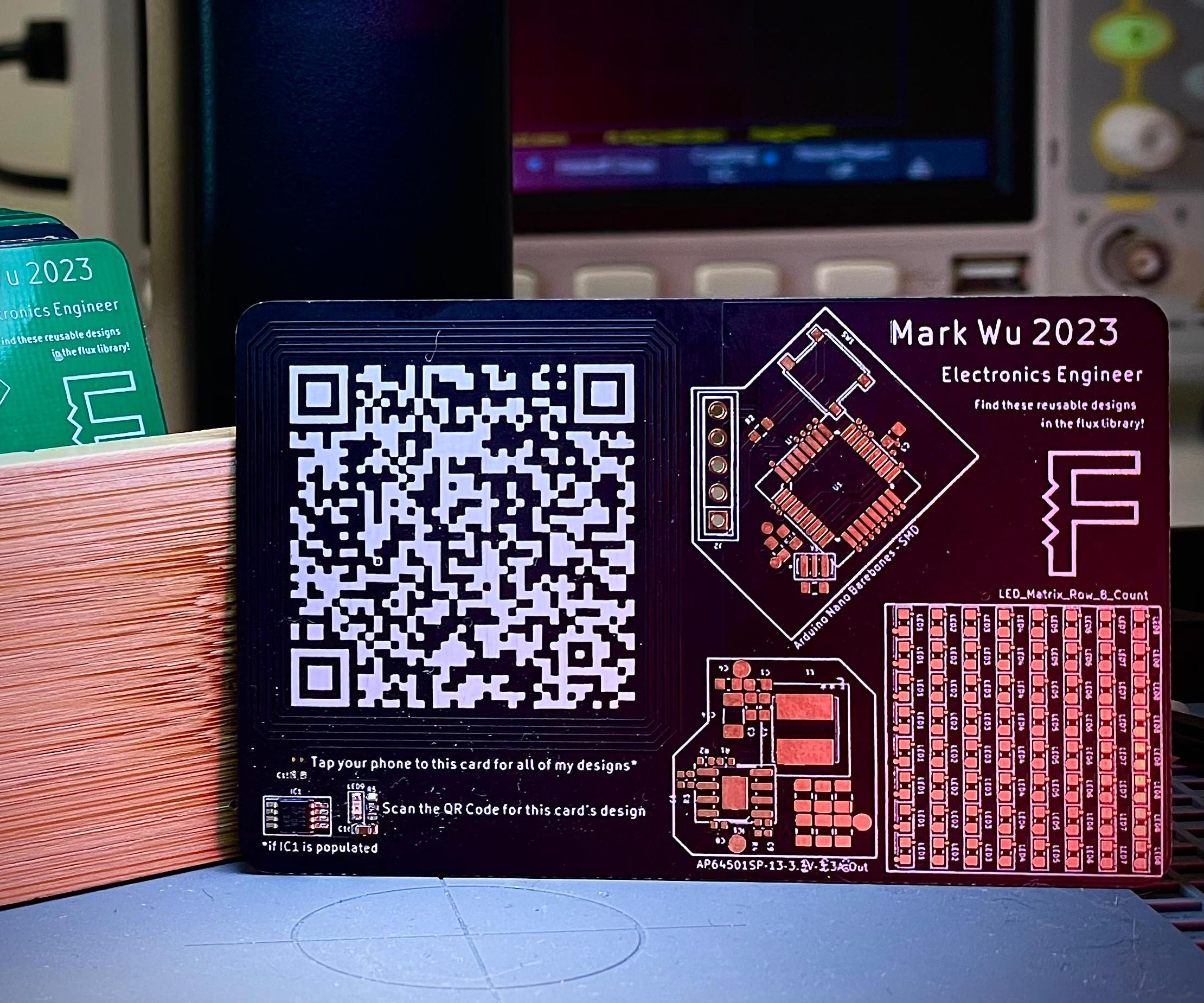

#8 Pro Electronic PCB Printed Circuit Board (QR Code) Business Card

Domain Est. 1999

#9 PCBCart

Domain Est. 2005

Website: pcbcart.com

Key Highlights: Expert of PCB manufacturing, we proudly offer PCB making & assembly services with certified quality standards for all your needs. Free online quote!…

Expert Sourcing Insights for Pcb Business Card

H2: 2026 Market Trends for PCB Business Cards

The market for PCB (Printed Circuit Board) business cards is poised for notable transformation by 2026, driven by technological innovation, evolving consumer preferences, and the increasing convergence of marketing and electronics. These unique, tech-infused business cards—featuring functional circuitry, LED displays, buttons, or even Bluetooth connectivity—are transitioning from niche novelties to strategic branding tools, particularly in the tech, engineering, and creative industries.

-

Growing Demand in Tech-Centric Industries

By 2026, demand for PCB business cards is expected to rise significantly among startups, electronics firms, and design studios seeking to differentiate themselves. As competition intensifies in sectors like IoT, robotics, and AI, professionals are leveraging PCB cards as both a functional and symbolic representation of their technical expertise. This trend is especially pronounced among engineers, hardware developers, and product designers who view the card as an extension of their innovation mindset. -

Advancements in Miniaturization and Energy Efficiency

Ongoing improvements in microelectronics are enabling slimmer, more energy-efficient PCB business cards. By 2026, expect widespread adoption of ultra-thin flexible PCBs, low-power microcontrollers, and energy-harvesting technologies (such as solar cells or kinetic charging). These innovations will reduce production costs and extend battery life, making sophisticated designs more accessible to small businesses and independent professionals. -

Integration with Digital Networking Platforms

PCB business cards are increasingly being designed to interface with digital ecosystems. By 2026, a significant portion of high-end PCB cards will feature NFC (Near Field Communication), QR code displays, or Bluetooth Low Energy (BLE) to enable seamless transfer of contact details, portfolio links, or social media profiles. This integration bridges physical and digital networking, aligning with hybrid work models and contactless communication preferences. -

Sustainability and Ethical Manufacturing Concerns

As environmental awareness grows, the PCB business card market faces pressure to adopt sustainable practices. By 2026, brands offering eco-friendly options—such as recyclable substrates, lead-free soldering, and modular designs that allow battery replacement—will gain competitive advantage. Regulatory scrutiny and consumer demand for green electronics will drive innovation in biodegradable PCB materials and circular economy models. -

Rise of Customization and On-Demand Production

Advances in automated PCB fabrication and AI-driven design tools will allow for rapid, cost-effective customization. By 2026, online platforms offering real-time PCB business card design and same-week shipping are expected to proliferate. This shift supports personalization at scale, enabling professionals to tailor not just aesthetics but also functionality (e.g., lighting patterns, interactive elements) to their brand identity. -

Expansion Beyond Niche Markets

While currently dominant in tech circles, PCB business cards are projected to expand into creative industries such as architecture, industrial design, and high-end fashion by 2026. As production costs decline and design tools become more user-friendly, broader professional adoption will follow, especially in markets that value experiential branding and tactile engagement.

In conclusion, the 2026 market for PCB business cards will be shaped by technological sophistication, digital integration, and sustainability imperatives. As these cards evolve from gimmicks to strategic communication tools, businesses that embrace innovation and user-centric design will lead the market, redefining professional identity in the digital age.

Common Pitfalls When Sourcing PCB Business Cards (Quality, IP)

Sourcing printed circuit board (PCB) business cards offers a high-tech, memorable way to stand out. However, without careful consideration, businesses risk compromising on quality, design integrity, and intellectual property. Here are key pitfalls to avoid:

Poor Manufacturing Quality

One of the most frequent issues is receiving PCB business cards with subpar manufacturing. This includes inconsistent solder mask application, rough or uneven edges, misaligned components, or non-functional LEDs and circuits. Low-cost manufacturers may cut corners on materials and processes, resulting in cards that look unprofessional or fail prematurely.

Inadequate Component Sourcing

Using low-grade or counterfeit electronic components (e.g., LEDs, resistors) can affect both performance and longevity. Sourcing from unreliable suppliers may lead to inconsistent brightness, early burnout, or even short circuits. Ensure your manufacturer uses reputable component distributors and provides specifications for all parts used.

Design File Compatibility and Errors

Many suppliers accept design files but may not support advanced or non-standard formats, leading to translation errors. Miscommunication about layer alignment, silkscreen placement, or board thickness can result in a final product that deviates from the original design. Always confirm file format requirements and request a prototype or 3D preview before mass production.

Intellectual Property Risks

Sharing detailed PCB design files (such as Gerber or Eagle files) with third-party manufacturers exposes sensitive IP. Unscrupulous suppliers may replicate or resell your design, especially in regions with weak IP enforcement. Always work with trusted manufacturers, use non-disclosure agreements (NDAs), and consider watermarking or obfuscating non-essential design details when sharing pre-production files.

Lack of Prototyping and Testing

Skipping the prototyping phase to save time or money often leads to costly mistakes. Without testing functionality, durability, and fit, you risk mass-producing defective cards. A functional prototype allows you to verify electrical performance, component placement, and overall aesthetics before full-scale production.

Overlooking Environmental and Safety Standards

Some PCB business cards include active electronics, which may be subject to regulations like RoHS or REACH. Using hazardous materials or non-compliant components can lead to legal issues or rejection in certain markets. Confirm that your supplier adheres to relevant environmental and safety standards.

Misaligned Expectations on Minimum Order Quantities and Lead Times

Suppliers may offer attractive pricing but require high minimum order quantities (MOQs) or have extended lead times. Failing to plan for these constraints can result in excess inventory or missed deadlines. Clarify MOQs, production timelines, and shipping options early in the sourcing process.

By anticipating these common pitfalls—prioritizing quality control, protecting intellectual property, and verifying supplier credibility—you can ensure your PCB business cards make a lasting impression without unintended consequences.

Logistics & Compliance Guide for PCB Business Cards

Overview

PCB (Printed Circuit Board) business cards are innovative, tech-centric networking tools that combine functionality with aesthetic appeal. However, their unique composition—incorporating metals, electronic components, and circuitry—introduces specific logistical and regulatory challenges. This guide outlines key considerations for the safe, legal, and efficient handling of PCB business cards from production to delivery.

Material Composition & Environmental Compliance

PCB business cards typically contain copper, solder, FR-4 (fiberglass-reinforced epoxy), and occasionally surface-mounted components. These materials are subject to environmental regulations:

– RoHS Compliance (Restriction of Hazardous Substances): Ensure your PCB cards comply with EU RoHS directives, which restrict lead, mercury, cadmium, and other hazardous materials. Use lead-free solder and compliant substrates.

– REACH Regulation: Verify that no substances of very high concern (SVHCs) are present above threshold levels.

– WEEE Directive: Although small in scale, PCBs fall under Waste Electrical and Electronic Equipment guidelines. Provide end-of-life disposal guidance to recipients, such as electronic waste recycling.

Packaging & Handling

Due to their rigid, conductive nature, proper packaging is critical:

– Use anti-static bags or clamshell packaging to prevent electrostatic discharge (ESD) damage and protect surface finishes.

– Include cushioning (e.g., foam inserts or cardboard dividers) to avoid chipping or breakage during transit.

– Label packages with “Fragile” and “Electrostatic Sensitive Device” warnings where applicable.

– Avoid moisture exposure; consider desiccant packs for long-term storage or humid climates.

Shipping & Customs Considerations

PCB business cards may be classified differently depending on their complexity:

– HS Code Classification: Typically falls under 8534.00 (Printed Circuits), which may attract duties in certain countries. Confirm the correct HS code with your freight forwarder.

– Commercial Invoice Requirements: Clearly declare contents as “Non-functional Printed Circuit Board Samples – Business Cards” to avoid misclassification as electronic components. Include material composition and value (usually low for promotional use).

– Export Controls: While standard PCBs are not restricted, verify that designs do not include controlled technologies (e.g., encryption circuits, military-spec features). Most business cards are exempt, but documentation should reflect their non-functional nature.

Import Regulations by Region

- United States: No special restrictions for non-functional PCBs; declared under HTS code 8534.00. Low-value shipments (<$800) may qualify for Section 321 entry.

- European Union: Subject to RoHS and REACH; no import duties for non-functional PCBs used as promotional items. VAT may apply based on country of destination.

- China: Requires import license for certain electronic goods; non-functional PCBs generally allowed but may require customs declaration.

- Canada, Australia, and Others: Typically permit low-value promotional PCB items with standard commercial documentation.

Safety & Liability

- Sharp Edges: Ensure board edges are smoothed or routed to prevent injury.

- Electrical Safety: Even if non-powered, avoid exposed conductive traces that could cause short circuits if inserted into devices. Include a disclaimer: “Not an electronic device—do not insert into any port.”

- Product Liability: Include disclaimers on packaging or accompanying inserts stating the item is a novelty or promotional product with no functional electrical purpose.

Sustainability & End-of-Life

Promote responsible disposal:

– Encourage recipients to recycle through e-waste programs.

– Partner with recycling organizations to offer take-back options for bulk corporate clients.

– Consider using recyclable or bio-based PCB substrates where feasible.

Best Practices Summary

- Confirm RoHS and REACH compliance with your manufacturer.

- Use ESD-safe, protective packaging.

- Accurately declare items on shipping documents to avoid customs delays.

- Educate recipients on proper handling and disposal.

- Maintain documentation for compliance audits.

By proactively addressing logistics and compliance, PCB business card providers can deliver a cutting-edge product while minimizing risk and ensuring global market accessibility.

Conclusion for Sourcing PCB Business Cards:

Sourcing PCB (Printed Circuit Board) business cards offers a unique and innovative way to stand out in a competitive professional environment. These tech-enhanced cards combine functionality, durability, and modern aesthetics, making them ideal for individuals and companies in the electronics, engineering, and tech industries. While the initial cost is higher than traditional paper cards and production timelines may be longer, the impact and memorability they create often justify the investment.

When sourcing PCB business cards, it is essential to partner with a reliable PCB manufacturer that offers quality assurance, design support, and reasonable minimum order quantities. Attention to design details—such as LED integration, component placement, and connectivity—ensures both visual appeal and functionality. Additionally, considering sustainability and end-use purpose can further enhance the value of the cards.

In conclusion, PCB business cards are more than just a contact tool—they are a statement of innovation and professionalism. With careful planning, the right supplier, and a creative design approach, sourcing PCB business cards can significantly elevate personal or brand identity in the technology-driven world.