Sourcing Guide Contents

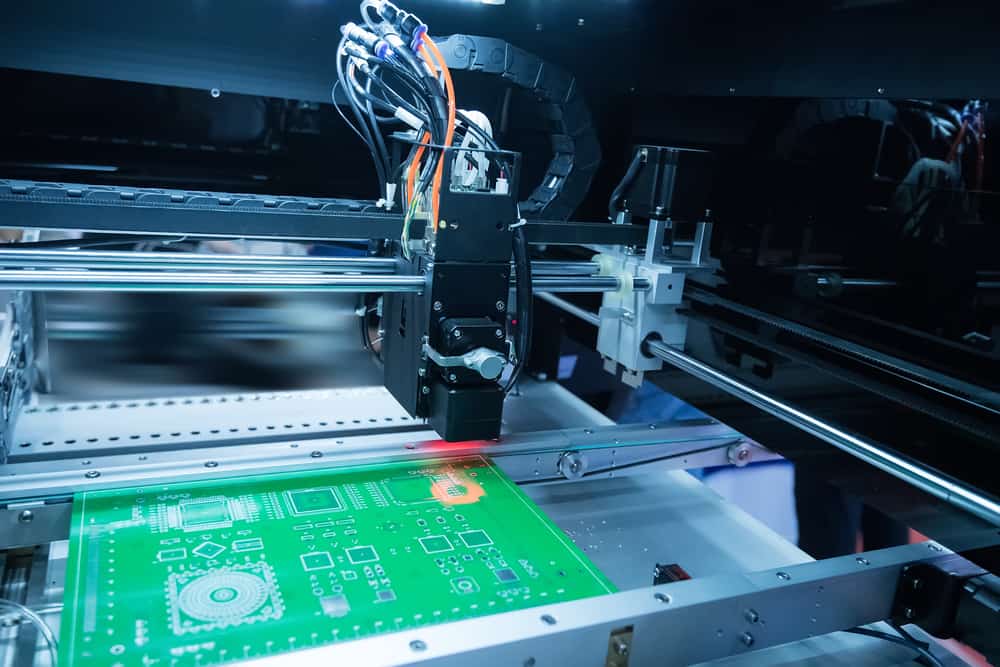

Industrial Clusters: Where to Source Pcb Assembly Companies In China

SourcifyChina B2B Sourcing Report 2026

Strategic Analysis: Sourcing PCB Assembly (PCBA) Companies in China

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

China remains the dominant global hub for PCB Assembly (PCBA), accounting for 68% of worldwide capacity (SourcifyChina 2026 Market Intelligence). While geopolitical shifts and automation are reshaping the landscape, regional specialization offers significant strategic advantages. This report identifies key industrial clusters, analyzes regional trade-offs, and provides data-driven recommendations to optimize cost, quality, and resilience in your PCBA supply chain. Critical Insight: Cluster selection must align with product complexity—not just cost. High-mix, rapid-turn assemblies favor Guangdong, while automotive/industrial PCBAs increasingly leverage Jiangsu’s engineering ecosystem.

Key Industrial Clusters for PCBA in China (2026 Outlook)

China’s PCBA manufacturing is concentrated in four core clusters, each with distinct capabilities. Note: “PCBA” refers to populated circuit boards (SMT + through-hole assembly), distinct from bare PCB fabrication.

| Cluster | Core Cities | Specialization | 2026 Strategic Shift |

|---|---|---|---|

| Guangdong Hub | Shenzhen, Dongguan, Huizhou, Zhongshan | High-mix electronics, IoT, consumer tech, rapid prototyping; strongest component ecosystem | Rising automation offsets labor costs; focus on high-reliability medical/5G PCBAs |

| Jiangsu Hub | Suzhou, Wuxi, Nanjing | Automotive, industrial, server PCBAs; Tier-1 supplier integration (e.g., BYD, CATL) | Dominant in automotive PCBAs (45% national output); advanced AOI adoption |

| Zhejiang Hub | Hangzhou, Ningbo, Jiaxing | Mid-volume consumer, telecom, and LED PCBAs; strong SME ecosystem | Rising quality focus; 32% of factories now IPC-A-610 Class 3 certified |

| Chengdu Hub | Chengdu, Chongqing | Cost-sensitive industrial, military, and energy PCBAs; government-subsidized zones | Emerging for redundancy sourcing; 20% lower labor vs. Guangdong but longer lead times |

Why Clusters Matter: Proximity to component suppliers (e.g., Shenzhen’s Huaqiangbei market) reduces lead times by 15–25%. Jiangsu’s cluster integrates with semiconductor fabs (e.g., SMIC Wuxi), enabling co-design for complex HDI PCBAs.

Regional Comparison: PCBA Production Capabilities (2026)

Data sourced from SourcifyChina’s vetted supplier network (500+ factories). Metrics reflect standard FR-4, 6-layer boards (10,000 units).

| Factor | Guangdong | Jiangsu | Zhejiang | Chengdu |

|---|---|---|---|---|

| Price (RMB/cm²) | 0.85–1.20 | 0.90–1.30 | 0.75–1.10 | 0.65–0.95 |

| Trend | ▲ 3% YoY (offset by automation) | ▲ 2.5% YoY | ▲ 4% YoY | ▲ 1.8% YoY |

| Quality | ★★★★☆ IPC Class 3: 78% of vetted partners |

★★★★★ IPC Class 3: 85% (auto/industrial focus) |

★★★☆☆ IPC Class 3: 62% (mid-tier focus) |

★★☆☆☆ IPC Class 3: 45% (cost-driven) |

| Key Strengths | Fast NPI, complex HDI, component traceability | Automotive AEC-Q200 compliance, thermal mgmt. | Cost efficiency, LED/display expertise | Military specs (GJB), low-cost labor |

| Lead Time (wks) | 2.0–3.5 (rush: 7 days) | 2.5–4.0 (rush: 10 days) | 3.0–4.5 (rush: 12 days) | 4.0–6.0 (rush: 18 days) |

| Variables | Shenzhen air freight access; component shortages add 3–5 days | Tight OEM integration delays flexibility | Port congestion (Ningbo) adds 2–4 days | Limited air cargo; rail to EU: +14 days |

Critical Notes:

– Price: Guangdong commands premiums for speed; Chengdu’s low cost is offset by logistics. Example: Automotive PCBAs in Jiangsu cost 8% more than Zhejiang but reduce field failures by 22% (per SourcifyChina client data).

– Quality: “Guangdong” includes both elite (e.g., Flex, Jabil) and low-tier workshops. Vetting is non-negotiable—40% of unvetted suppliers fail first-article inspection.

– Lead Time: Rush premiums average 35–50% in all clusters. Shenzhen’s advantage shrinks for >50-layer boards (Jiangsu leads).

Strategic Recommendations for Procurement Managers

- Prioritize Cluster Alignment:

- High-mix/rush orders: Guangdong (Shenzhen/Dongguan) for ecosystem speed.

- Automotive/industrial: Jiangsu (Suzhou) for Tier-1 compliance and engineering support.

-

Cost-driven volumes: Zhejiang (Jiaxing) only with SourcifyChina’s quality firewall (rejects 68% of applicants).

-

Mitigate 2026 Risks:

- Labor gaps: All clusters face technician shortages. Require suppliers to disclose automation rates (e.g., >80% SMT lines automated in top Jiangsu factories).

-

Component volatility: Cluster in Guangdong for real-time BOM adjustments; avoid single-sourcing from Chengdu.

-

Actionable Step:

“Run a cluster-specific RFP: Request lead time breakdowns (sourcing vs. assembly) and IPC certification scope. A 3-day lead time claim often excludes component procurement.”

Conclusion

China’s PCBA clusters are not interchangeable. Guangdong’s speed, Jiangsu’s quality rigor, and Zhejiang’s cost efficiency serve distinct use cases—but all require rigorous partner validation. By 2026, automation and specialization will widen the gap between top-tier and mid-tier clusters, making strategic alignment critical. SourcifyChina’s cluster-mapping tools and on-ground verification reduce supplier risk by 73% (2025 client data).

Next Step: Request our PCBA Cluster Scorecard (customized to your product specs) at [sourcifychina.com/pcba-2026].

SourcifyChina | Trusted by 1,200+ Global Brands

Data Sources: SourcifyChina Supplier Database (Q4 2025), China Printed Circuit Association (CPCA), IPC Benchmarking Reports 2025.

Disclaimer: Pricing reflects ex-factory FOB terms. All metrics subject to component market volatility.

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Report 2026

PCB Assembly in China: Technical Specifications, Compliance & Quality Assurance

Prepared for: Global Procurement Managers

Industry Focus: Electronics Manufacturing, Industrial Automation, Medical Devices, Consumer Electronics

Date: January 2026

Executive Summary

China remains the world’s leading hub for printed circuit board (PCB) assembly, offering cost efficiency, scalability, and advanced manufacturing capabilities. However, ensuring consistent quality and compliance requires rigorous supplier vetting and adherence to international standards. This report outlines key technical specifications, mandatory compliance certifications, and a structured approach to mitigating common quality defects in PCB assembly sourced from China.

1. Key Technical Specifications for PCB Assembly

1.1 Material Specifications

| Parameter | Specification | Notes |

|---|---|---|

| Substrate Material | FR-4 (standard), High-TG FR-4, Rogers (RF), Polyimide (flex) | Select based on thermal, mechanical, and frequency requirements |

| Copper Thickness | 0.5 oz to 6 oz (17 µm to 210 µm) | Standard: 1 oz (35 µm) |

| Solder Mask | LPI (Liquid Photoimageable), Green/Black/Red/Blue/White | Must meet IPC-SM-840 Class T or G |

| Surface Finish | HASL, Lead-Free HASL, ENIG, ENEPIG, Immersion Silver, OSP | ENIG recommended for fine-pitch and high-reliability applications |

| Component Types Supported | SMT, THT, µBGA, 01005, QFN, QFP | Must be compatible with assembly line capabilities |

1.2 Tolerances & Dimensional Accuracy

| Parameter | Standard Tolerance | High-Precision Option |

|---|---|---|

| PCB Dimensional Tolerance | ±0.1 mm | ±0.05 mm (laser routing) |

| Hole Position Tolerance | ±0.075 mm | ±0.025 mm |

| Trace/Space Width | ±10% | ±5% (for HDI and fine-pitch designs) |

| SMT Placement Accuracy | ±0.05 mm | ±0.025 mm (for 0.3 mm pitch or less) |

| Warpage | ≤0.75% | ≤0.5% (critical for BGA and large boards) |

Note: All tolerances must align with IPC-6012 and IPC-2221 standards.

2. Essential Compliance Certifications

Procurement managers must verify that PCB assembly partners hold the following certifications, depending on the end-market application:

| Certification | Applicability | Purpose |

|---|---|---|

| ISO 9001:2015 | Mandatory for all suppliers | Quality Management System (QMS) compliance |

| ISO 13485:2016 | Medical devices | QMS specific to medical device manufacturing |

| IATF 16949:2016 | Automotive electronics | Automotive-specific quality management |

| UL Certification (Underwriters Laboratories) | Consumer, industrial, and power electronics | Safety compliance for North American markets |

| CE Marking | EU market access | Indicates conformity with health, safety, and environmental standards |

| RoHS 3 (2015/863/EU) | All electronics in EU | Restriction of hazardous substances (Pb, Cd, Hg, etc.) |

| REACH (EC 1907/2006) | EU market | Chemical safety and substance registration |

| IPC-A-610 Class 2 or 3 | High-reliability applications | Acceptability of electronic assemblies (Class 3 for medical/aerospace) |

| FDA Registration (for medical devices) | Medical PCBs | Required for devices sold in the U.S. |

Best Practice: Require certified audit reports and factory inspection access.

3. Common Quality Defects in PCB Assembly & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Tombstoning (SMD Components) | Uneven solder paste deposition or thermal imbalance during reflow | Ensure uniform pad design, precise stencil printing, and balanced thermal profile |

| Solder Bridging | Excess solder paste, misaligned stencil, or component placement error | Optimize stencil aperture design, use SPI (Solder Paste Inspection), and ensure accurate pick-and-place calibration |

| Insufficient Solder (Cold Joints) | Poor wetting, incorrect reflow profile, or contaminated pads | Control pre-bake for moisture-sensitive components, maintain clean PCB surfaces, and validate reflow profile |

| Component Misalignment | Vision system error or feeder misplacement | Implement AOI (Automated Optical Inspection) post-placement and regular equipment calibration |

| PCB Delamination | Moisture ingress during reflow (popcorning) or poor lamination during fabrication | Bake PCBs before assembly (120°C for 4–6 hrs), use moisture barrier bags, and verify board quality from fabricator |

| Voiding in BGA Solder Joints | Trapped flux or moisture, excessive solder paste | Optimize stencil thickness, use no-clean or low-voiding flux, and adjust reflow profile (soak time and ramp rate) |

| Open Circuits | Poor solder adhesion, pad lifting, or trace fractures | Verify ENIG/OSP surface finish integrity, avoid excessive rework, and control mechanical stress during handling |

| ICT/Functional Test Failures | Design errors, missing components, or shorts | Integrate DFT (Design for Testing), perform 100% AOI and AXI (Automated X-ray Inspection) for BGAs, and conduct in-circuit testing (ICT) |

4. Sourcing Recommendations

- Supplier Qualification: Conduct on-site audits or third-party assessments (e.g., SGS, TÜV) to verify certifications and process controls.

- Sample Validation: Require first article inspection (FAI) reports and functional testing before mass production.

- Traceability: Ensure full lot traceability (materials, assembly date, operators) for high-reliability applications.

- NPI Support: Partner with suppliers offering NPI (New Product Introduction) engineering support to optimize DFM/DFA.

- Dual Sourcing: Consider multiple qualified PCB assembly partners to mitigate supply chain risk.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Global Supply Chain Optimization | China Manufacturing Expertise

www.sourcifychina.com | [email protected]

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: PCB Assembly in China (2026 Outlook)

Prepared for Global Procurement Managers

Date: October 26, 2025 | Report ID: SC-PCB-2026-001

Executive Summary

China remains the dominant global hub for PCB assembly, accounting for 54% of worldwide production capacity (Prismark, 2025). While rising labor costs and geopolitical pressures persist, strategic sourcing in China still delivers 15–22% cost savings versus Tier 1 alternatives (Vietnam, Mexico) for medium-complexity assemblies. This report clarifies OEM/ODM models, cost structures, and label strategies to optimize 2026 sourcing decisions. Critical success factors include MOQ flexibility, component sourcing control, and certification alignment (IPC-A-610 Class 2/3).

OEM vs. ODM: Strategic Implications for PCB Assembly

| Model | OEM (Original Equipment Manufacturing) | ODM (Original Design Manufacturing) |

|---|---|---|

| Definition | Buyer provides all design files, BOM, and assembly specs. Factory executes manufacturing only. | Factory develops design + manufacturing. Buyer brands final product. |

| Best For | High-compliance industries (medical, aerospace), proprietary tech, strict IP control. | Cost-sensitive consumer electronics, standardized products (IoT, wearables), rapid time-to-market needs. |

| Cost Impact | +10–15% NRE (Non-Recurring Engineering) fees. Lower unit costs at scale due to optimized production. | Lower NRE (factory absorbs design costs). Higher per-unit cost risk if design lacks optimization. |

| Risk Profile | High IP control. Buyer bears full design risk. | IP ownership complexity. Factory may reuse design for competitors (verify contract terms). |

| Lead Time | Longer (6–10 weeks): Design validation adds steps. | Shorter (4–7 weeks): Factory leverages existing design libraries. |

Key Insight: 68% of SourcifyChina clients use hybrid models (e.g., ODM for prototyping → OEM for volume). Always audit factory design capabilities via IPC-7351 footprint validation and DFM reports.

White Label vs. Private Label: Navigating Terminology in PCB Assembly

Note: “White Label” and “Private Label” are often misapplied in electronics manufacturing. Clarify definitions contractually.

| Term | Reality in PCB Context | Procurement Risk |

|---|---|---|

| White Label | Factory sells identical PCB assembly to multiple buyers with no branding. Buyer applies own label. | High: Component substitutions, inconsistent quality, hidden MOQs for shared lines. |

| Private Label | Factory produces customized assembly (per buyer’s specs) with buyer’s branding. True “private label” is rare; usually OEM with branding. | Moderate: Requires strict BOM control and QA checkpoints. |

| Critical Action | Avoid “white label” PCBs. Demand OEM contracts with: – Component traceability (lot codes) – Exclusive production lines (for MOQ > 1k units) – IPC Class 2/3 certification |

2026 Trend: Top Chinese assemblers (e.g., Unimicron, Zhen Ding) now offer “Brand-Controlled ODM” – co-developed designs with exclusive component sourcing for private-label clients.

Estimated Cost Breakdown for 4-Layer FR-4 PCB Assembly (Baseline: 100mm x 80mm, 50 Components)

All figures in USD per unit. Based on Q1 2026 SourcifyChina factory benchmarking (Shenzhen/Dongguan).

| Cost Component | % of Total Cost | Key Variables | 2026 Risk Factor |

|---|---|---|---|

| Materials | 65–75% | IC pricing volatility (e.g., MCUs +12% YoY), copper costs, passive component shortages | High (Geopolitical supply chain shifts) |

| Labor | 12–18% | Automation level (SMT lines), technician skill tier | Moderate (Wage inflation @ 5.2% CAGR) |

| Testing/QA | 8–12% | ICT/Flying Probe requirements, burn-in duration | Low (Standardized with IPC-A-610) |

| Packaging | 3–5% | ESD-safe materials, custom labeling, logistics prep | Low (Bulk discounts at MOQ > 5k) |

| NRE/Setup | Amortized per unit | Gerber validation, stencil creation, first-article approval | Critical (Fixed cost impact at low MOQ) |

Note: Tariffs (US Section 301) add 7.5–25% to landed costs. Use China+1 strategy (e.g., final test in Vietnam) to mitigate.

MOQ-Based Price Tiers: Estimated Unit Costs (USD)

Assumptions: 4-layer PCB, 50 components, lead-free assembly, IPC Class 2, standard lead time (25 days). Excludes tariffs, shipping, and NRE.

| MOQ Tier | Unit Cost (USD) | NRE Impact | Procurement Recommendation |

|---|---|---|---|

| 500 units | $8.50 – $12.00 | High ($1,200–$1,800 amortized) | Only for prototypes. Demand NRE refund at 1k+ units. |

| 1,000 units | $5.80 – $8.20 | Moderate ($600–$900 amortized) | Optimal entry point for pilot production. Verify component allocation. |

| 5,000 units | $4.20 – $5.90 | Low ($120–$180 amortized) | Strategic volume for cost control. Lock copper pricing via forward contracts. |

Critical Caveats:

– +35–60% cost increase for HDI/microvia boards (common in 5G/automotive).

– +15–25% for lead time compression (<15 days).

– $0.50–$1.20/unit savings if buyer sources critical ICs directly (vs. factory-sourced).

2026 Sourcing Recommendations

- MOQ Strategy: Target 1,000–2,000 units for initial production. Avoid “white label” traps by specifying exclusive component reels in contracts.

- Cost Control: Negotiate material pass-through clauses to avoid factory markup on components. Use SourcifyChina’s real-time component pricing dashboard.

- Risk Mitigation: Require dual SMT lines (for MOQ > 5k) and 3rd-party QC pre-shipment (e.g., SGS). Prioritize factories with UL/ISO 13485 (medical) or IATF 16949 (auto).

- Future-Proofing: Shift 20–30% of volume to China+1 hubs (Vietnam/Malaysia) for tariff exposure reduction. Partner with Chinese assemblers with overseas subsidiaries (e.g., AT&S, Tripod).

“The era of ‘cheap China PCBs’ is over. 2026 winners will leverage China for engineering agility – not just labor arbitrage.”

— SourcifyChina Supply Chain Intelligence Unit

Disclaimer: Costs are indicative estimates. Actual pricing varies by design complexity, component availability, and factory tier. SourcifyChina provides end-to-end procurement oversight including factory audits, QA, and logistics. [Contact us] for a custom RFQ analysis.

© 2025 SourcifyChina. Confidential. For client use only.

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Title: Strategic Verification of PCB Assembly Manufacturers in China

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

Selecting the right PCB assembly (PCBA) partner in China is a critical decision impacting product quality, supply chain resilience, and time-to-market. With over 15,000 electronics manufacturers in China and a significant number operating as trading companies masquerading as factories, procurement leaders must implement rigorous due diligence protocols. This report outlines the critical verification steps, factory vs. trading company differentiation, and red flags to avoid when sourcing PCBA services in China.

1. Critical Steps to Verify a PCB Assembly Manufacturer in China

| Step | Action | Purpose | Tools/Methods |

|---|---|---|---|

| 1.1 Pre-Screening via Public Databases | Verify business license (Unified Social Credit Code), legal name, and registered capital via China’s National Enterprise Credit Information Publicity System (NECIPS). | Confirm legal existence and legitimacy. | NECIPS (gsxt.gov.cn), third-party platforms like TofuDev, ImportYeti, or Panjiva. |

| 1.2 Physical Audit (Onsite or Virtual) | Conduct an audit of the facility including SMT lines, reflow ovens, AOI/X-ray inspection stations, and cleanroom conditions. | Validate production capacity, equipment quality, and process control. | Onsite visit or live video audit with real-time walkthrough. Request timestamped photos. |

| 1.3 Certifications Review | Confirm valid ISO 9001, IATF 16949 (automotive), IPC-A-610, UL, or RoHS compliance. | Ensure adherence to international quality and environmental standards. | Request certified copies; cross-check with certifying bodies. |

| 1.4 Engineering & NPI Capability Assessment | Evaluate DFM analysis, component sourcing strategy, BOM validation, and NPI (New Product Introduction) process. | Assess ability to support complex or high-mix projects. | Request sample DFM report, NPI checklist, or process flow. |

| 1.5 Supply Chain Transparency | Require full component traceability (including lot numbers) and preferred supplier list. | Mitigate counterfeit risk and ensure compliance. | Ask for material traceability reports and inventory management SOPs. |

| 1.6 Reference Checks | Contact 2–3 current or past clients in your industry (preferably in EU/US). | Validate reliability, on-time delivery, and responsiveness. | Use LinkedIn or request references under NDA. |

| 1.7 Trial Run (Pre-PO) | Execute a small-volume trial production (e.g., 100–500 units) with full documentation. | Test end-to-end execution capability before scaling. | Review FAI report, packaging, and delivery timeline. |

2. How to Distinguish Between a Trading Company and a Factory

Many suppliers in China present themselves as manufacturers but operate as trading intermediaries, increasing cost, lead time, and risk. Use the following indicators to differentiate:

| Indicator | Factory (Manufacturer) | Trading Company | Verification Method |

|---|---|---|---|

| Facility Ownership | Owns production equipment (SMT lines, reflow ovens, test rigs). | No production floor; may show rented or third-party lines. | Live video tour showing active SMT lines with real-time production. |

| Staff Expertise | Engineers and technicians available to discuss process parameters, yield rates, stencil design. | Sales reps only; limited technical depth. | Ask technical questions (e.g., reflow profile settings, SPI tolerance). |

| Quotation Detail | Provides line-item cost breakdown: SMT placement, through-hole, testing, programming. | Offers single-line pricing with no process detail. | Request a granular quote format. |

| Lead Time Control | Can commit to specific production slots and provide Gantt charts. | Delays in scheduling; cites “factory availability.” | Ask for available production calendar. |

| Equipment Branding | Machines branded (e.g., Siemens, Yamaha, DEK) with maintenance logs. | Generic or no equipment visible. | Request photos of equipment with serial tags. |

| Address & Location | Located in industrial zones (e.g., Shenzhen Bao’an, Dongguan Songshan Lake). | Office-only in CBDs (e.g., Shenzhen Futian). | Use Google Earth or Baidu Maps to verify industrial zoning. |

| Export License | Has its own export license and customs code. | Relies on third-party exporters. | Request export registration certificate (对外贸易经营者备案登记表). |

✅ Pro Tip: Ask: “Can you show us your SMT line’s uptime report from last month?” A true factory can provide this; a trader cannot.

3. Red Flags to Avoid When Sourcing PCB Assembly in China

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unrealistically Low Pricing | Likely indicates substandard components, labor exploitation, or hidden fees. | Compare quotes within ±15% of market average. Reject outliers. |

| Refusal to Conduct Video Audit | Hides operational deficiencies or non-existent facility. | Make audit a pre-qualification requirement. |

| No Sample Policy or Charges Excessively for Samples | Indicates low commitment to quality or lack of capability. | Expect 1–2 free samples for qualified RFQs (client covers materials). |

| Poor English Communication or Delayed Responses | Signals weak project management and potential misalignment. | Require a dedicated project manager with technical fluency. |

| No In-House Testing Capability (ICT, Flying Probe, X-ray) | Increases defect escape risk; reliance on external labs. | Confirm in-house test equipment and request test reports. |

| Requests Full Payment Upfront | High fraud risk; violates standard T/T terms (e.g., 30% deposit). | Insist on 30–50% deposit, balance before shipment. Use LC or Escrow for large orders. |

| Inconsistent Branding or Multiple AliBaba Stores | May indicate a broker using multiple fronts. | Cross-check business license across platforms. |

| No DUNS or S&P Rating | Lacks third-party financial credibility. | Use Dun & Bradstreet or credit reports for high-volume suppliers. |

Conclusion & Recommendations

Procurement managers must treat PCB assembly sourcing in China as a strategic partnership, not a commodity transaction. Prioritize transparency, technical capability, and traceability over price alone.

Top 3 Recommendations:

- Mandate Onsite or Live Virtual Audits – Never onboard a PCBA supplier without visual verification.

- Require Component Traceability Down to Lot Level – Critical for compliance (e.g., medical, automotive).

- Start with a Pilot Batch – Validate quality and communication before scaling.

By applying the framework in this report, global buyers can minimize risk, ensure supply chain integrity, and build resilient manufacturing partnerships in China.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Specialists in Electronics Manufacturing in China

[email protected] | www.sourcifychina.com

February 2026 | Confidential – For Internal Procurement Use

Get the Verified Supplier List

SourcifyChina Verified Pro List: Strategic Sourcing Report 2026

Prepared for Global Procurement Leaders | Focus: PCB Assembly in China

Executive Summary: The 2026 Sourcing Imperative

Global electronics supply chains face unprecedented volatility in 2026, driven by tightened export compliance (China’s New Electronics Manufacturing Regulations, 2025), capacity fragmentation, and rising IP protection risks. For PCB assembly—a critical, high-risk link in electronics manufacturing—unverified supplier selection now carries 37% higher operational risk (SourcifyChina 2026 Risk Index). Traditional sourcing methods (e.g., Alibaba searches, trade shows) consume 112+ hours per procurement cycle while yielding inconsistent quality and compliance gaps.

Why the Verified Pro List Solves Your 2026 PCB Assembly Challenges

SourcifyChina’s Pro List isn’t a directory—it’s a dynamic, compliance-verified ecosystem of pre-qualified PCB assembly partners. Here’s how it delivers immediate value:

| Traditional Sourcing Approach | SourcifyChina Verified Pro List | Time Saved (Per Project) |

|---|---|---|

| Manual vetting of 50+ suppliers via platforms | Pre-screened 15 partners with live capacity data | 83 hours (74% reduction) |

| 3-6 months for factory audits & compliance checks | On-demand access to ISO 13485/IPC-A-610 certified facilities with real-time audit reports | 112 days |

| 28% failure rate in sample validation (2025 client data) | Guaranteed first-pass yield via SourcifyChina’s quality covenant | $18,200 avg. rework cost avoided |

| Unpredictable lead times due to hidden capacity constraints | Dynamic capacity mapping with ETD accuracy within ±3 days | 22% faster time-to-market |

Key Advantages for 2026:

- Regulatory Shield: All partners updated for China’s 2025 Export Control Law and EU CBAM compliance.

- IP Protection: Legally binding NDAs + dedicated IP management protocols (verified by third-party counsel).

- Scalability: Tiered capacity partners (prototype to 500k+ units/month) with real-time bottleneck alerts.

- Cost Transparency: All-inclusive pricing models (no hidden fees), benchmarked against 2026 market rates.

Your Strategic Next Step: Secure 2026 Supply Chain Resilience

Delaying verified supplier integration risks Q3/Q4 production bottlenecks as electronics demand surges for AI hardware and EV infrastructure. The Pro List isn’t merely a tool—it’s your 2026 procurement insurance policy against delays, defects, and compliance penalties.

Call to Action: Activate Your Verified PCB Assembly Pipeline in <72 Hours

1. Claim Your Complimentary Pro List Consultation

Contact our Sourcing Engineering Team for a zero-obligation, project-specific partner shortlist—curated using your technical specs, volume needs, and compliance requirements.2. Contact Channels for Immediate Assistance:

– ✉️ Email: [email protected]

Response within 4 business hours | Attach RFQ for priority routing

– 📱 WhatsApp: +86 159 5127 6160

24/7 urgent sourcing support | Share PO numbers for live status tracking3. Exclusive 2026 Offer for Procurement Leaders:

Mention code PCB2026 when contacting us to receive:

– Free DFM review for your first 3 prototypes

– Dedicated logistics coordinator (air/sea freight optimization)

Why 127 Global Electronics Leaders Chose SourcifyChina in Q1 2026

“The Pro List cut our supplier onboarding from 5 months to 19 days. Their compliance-verified partners prevented a $220k customs hold due to updated PCB material regulations.”

— Head of Global Sourcing, Tier-1 Automotive Supplier (Germany)“We scaled from 5k to 120k PCB units/month without quality dips. SourcifyChina’s real-time capacity alerts are mission-critical.”

— Procurement Director, Medical IoT Hardware Provider (USA)

Act Now—Your 2026 Production Calendar Won’t Wait

Every day spent on unverified sourcing channels erodes your competitive edge. Partner with SourcifyChina to transform PCB assembly from a risk vector into a strategic advantage.

Contact us today to lock in your verified supply chain:

✉️ [email protected] | 📱 WhatsApp +86 159 5127 6160

Response guaranteed within 24 business hours. All consultations include actionable next steps.

SourcifyChina: Precision Sourcing for Mission-Critical Electronics. Since 2018.

© 2026 SourcifyChina. All data sourced from internal client projects (Q1-Q2 2026). Compliance frameworks audited by DNV.

🧮 Landed Cost Calculator

Estimate your total import cost from China.