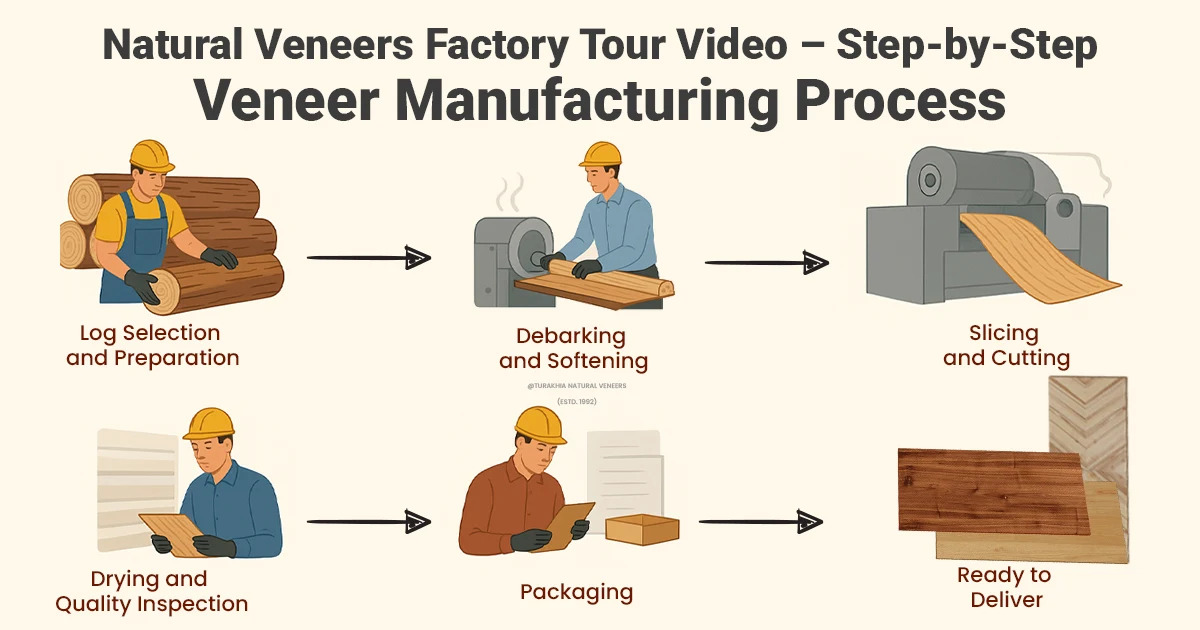

The global veneer market is experiencing steady expansion, driven by rising demand for sustainable and cost-effective decorative surfaces in furniture, interior design, and architectural applications. According to Grand View Research, the global wood veneer market size was valued at USD 2.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 6.2% from 2024 to 2030. This growth is fueled by increasing construction activities, a shift toward eco-friendly materials, and the versatility of engineered wood products. Among these, paper backed veneer has emerged as a preferred choice due to its enhanced stability, ease of application, and reduced risk of warping during installation. As demand surges, manufacturers are investing in advanced laminating technologies and sustainable sourcing practices to meet evolving industry standards. In this competitive landscape, the following nine companies have distinguished themselves as leaders in innovation, quality, and market reach—setting the benchmark for excellence in paper backed veneer production.

Top 9 Paper Backed Veneer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Paperbacked Veneer

Domain Est. 2004

Website: mghinc.ca

Key Highlights: The maximum dimensions of a sheet of flexible veneer is 5’x12′. Sanding. The standard sanding is done at the factory using 180 grit paper or as you choose….

#2 Paper Backed Wood Veneer Basics

Domain Est. 2017

Website: wood-veneer-factory-outlet.com

Key Highlights: Wood Veneer, paper backed. How to buy, use, finish. Wood Veneer Sheets Deals and Wood Veneer Tutorials, Videos, FAQ at Veneer Factory Outlet.com….

#3 Hardwood Veneer Paper

Domain Est. 1996

Website: formwood.com

Key Highlights: Our finely matched, paper-backed veneer is consistently chosen because of our high grading standards and attention to overall veneer quality….

#4 Paper Back Veneer Sheets

Domain Est. 1997

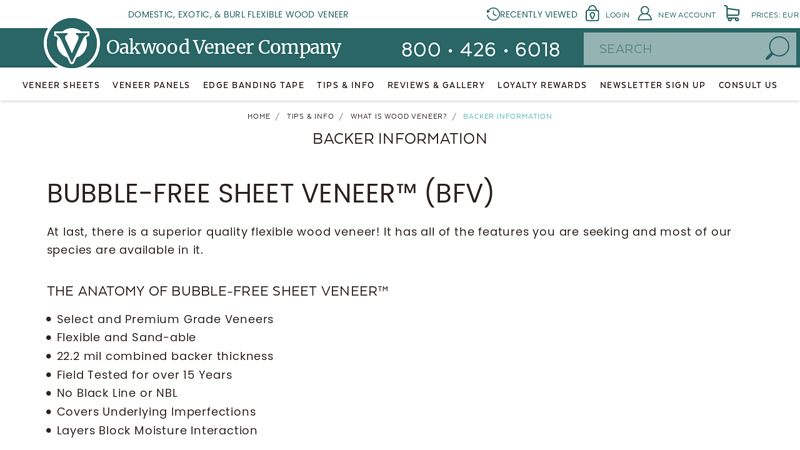

#5 Wood Veneer Backer Information

Domain Est. 1998

Website: oakwoodveneer.com

Key Highlights: A quality wood veneer with a single 10 mil paper backing. Economical to use yet delivers beautiful results. Available in all species….

#6 Paper Backed Veneer

Domain Est. 2002

Website: tsukiita.jp

Key Highlights: Paper backed veneer is an extremely thin material referred to as Japanese paper or (Teflon paper), it is a thin material which is easy to handle….

#7 Supporting Woodworkers for 22 Years!

Domain Est. 2003

Website: veneersupplies.com

Key Highlights: We make veneering easy and affordable with 280000 square feet of high-end burl, quilted, curly and birds eye exotic wood veneer sheets in stock and ready to ……

#8 Paper Back Veneer

Domain Est. 2011

#9 Wood Veneer. Paper Backed Wood Veneer, 10 mil, 20 mil, 30 mil

Domain Est. 2013

Website: veneer-factory-outlet.com

Key Highlights: Paper Backed Wood Veneers Are The Most Economical Choice; 10 mil Paper Backed Veneer is “stock”, Available On This Website; 20 mil and 30 mil Paper Backed ……

Expert Sourcing Insights for Paper Backed Veneer

2026 Market Trends for Paper Backed Veneer

The paper backed veneer market is poised for notable transformation by 2026, driven by evolving consumer preferences, sustainability demands, and advancements in manufacturing technologies. This analysis explores key trends shaping the industry in the coming years.

Growing Demand for Sustainable Interior Solutions

A primary driver of the paper backed veneer market is the rising demand for eco-friendly and sustainable interior materials. As consumers and businesses increasingly prioritize environmental responsibility, paper backed veneer—being a thin layer of real wood bonded to a paper backing—offers a resource-efficient alternative to solid wood. Its production consumes less timber and generates lower waste, aligning with green building certifications such as LEED and BREEAM. By 2026, this product is expected to gain traction in residential, commercial, and hospitality interiors, particularly in markets with strong environmental regulations like Europe and North America.

Expansion in Emerging Economies

Emerging markets in Asia-Pacific, Latin America, and Africa are witnessing rapid urbanization and growth in the construction and furniture sectors. Countries such as India, Vietnam, and Brazil are seeing increased adoption of cost-effective and aesthetically pleasing materials like paper backed veneer. As mid-tier housing and commercial projects expand, demand for affordable yet high-quality finishes will boost market growth. Local manufacturers are also investing in veneer processing capabilities, reducing reliance on imports and stimulating regional supply chains.

Technological Advancements in Adhesive and Application Methods

Advancements in adhesive technology are enhancing the durability and ease of application of paper backed veneers. Innovations such as water-based, low-VOC adhesives and pressure-sensitive backings are improving installation efficiency and indoor air quality. Furthermore, digital printing integration allows for consistent grain patterns and custom designs, increasing design flexibility. By 2026, automated lamination systems and robotics in production lines are expected to improve precision and reduce labor costs, making paper backed veneer more competitive against other surface materials.

Shift Toward Design Flexibility and Customization

Interior designers and architects are increasingly favoring customizable materials that offer unique visual appeal. Paper backed veneer provides a natural wood aesthetic with greater versatility in pattern matching and finishing options. With digital scanning and CNC cutting, manufacturers can produce bespoke veneer panels tailored to specific project requirements. This trend toward personalization is particularly strong in high-end residential and boutique commercial spaces, contributing to market differentiation and premium pricing opportunities.

Competitive Pressure from Alternatives

Despite its advantages, paper backed veneer faces competition from alternative surfacing materials such as laminate, HPL (high-pressure laminate), and wood-based composites. These materials often offer superior moisture resistance and durability in high-traffic areas. However, the authentic look and feel of real wood veneer continue to give paper backed options a distinct advantage in premium applications. By 2026, hybrid products combining veneer with protective coatings may emerge to close the performance gap and expand application scope.

Conclusion

The paper backed veneer market in 2026 will be shaped by sustainability, technological innovation, and growing demand in developing regions. As manufacturers adapt to environmental standards and consumer expectations, the product is likely to occupy a strategic niche in the global decorative surfaces industry. Companies that invest in R&D, sustainable sourcing, and digital customization will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing Paper-Backed Veneer (Quality and Intellectual Property)

Sourcing paper-backed veneer can be a cost-effective and efficient solution for manufacturers and designers seeking high-quality wood finishes. However, several pitfalls related to quality and intellectual property (IP) can arise if due diligence is not exercised. Understanding these risks helps ensure reliable supply, product integrity, and legal compliance.

Quality-Related Pitfalls

Inconsistent Veneer Thickness and Grain Matching

One of the most frequent quality issues is inconsistency in veneer thickness and grain patterns. Poorly sorted or graded veneer can lead to visible mismatches in appearance, especially in large panel applications. This often stems from suppliers using lower-grade stock or inadequate sorting procedures.

Adhesive Failure and Delamination

Paper-backed veneer relies on a strong bond between the wood and the paper substrate. Low-quality adhesives or improper application can lead to delamination during handling, pressing, or in end-use environments with temperature or humidity fluctuations.

Poor Moisture Resistance

Some paper-backed veneers are not adequately treated for moisture resistance. This can result in warping, bubbling, or adhesive breakdown when used in humid environments or in applications like kitchen cabinetry or bathroom furniture.

Inadequate Backing Paper Strength

The paper carrier must be strong enough to withstand handling and pressing processes. Thin or low-tensile-strength backing paper can tear during application, leading to production delays and material waste.

Lack of Certification and Traceability

Reputable suppliers provide certifications for sustainable sourcing (e.g., FSC or PEFC). Sourcing from uncertified vendors risks using illegally harvested or environmentally harmful materials, which can damage brand reputation and lead to regulatory penalties.

Intellectual Property (IP) Pitfalls

Unauthorized Use of Branded or Patented Designs

Some paper-backed veneers replicate the appearance of proprietary wood patterns or designer finishes protected by trademarks or design patents. Sourcing from suppliers who produce unauthorized copies can expose buyers to legal liability for IP infringement.

Supplier Misrepresentation of Origin or Brand

Unscrupulous suppliers may falsely claim that veneer is from a specific region (e.g., “Italian Walnut”) or associated with a well-known brand. This misrepresentation not only affects quality expectations but can also constitute false advertising or trademark violations.

Lack of IP Clarity in Custom Designs

When working with custom veneer patterns or unique finishes, buyers may assume ownership of the design. However, without explicit contractual agreements, the supplier may retain IP rights, limiting the buyer’s ability to use or reproduce the design.

Grey Market and Counterfeit Products

Paper-backed veneer from unauthorized distribution channels may include counterfeit or diverted products. These often lack quality control and may infringe on the original manufacturer’s IP, exposing the purchaser to legal and reputational risks.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Vet suppliers thoroughly, including site audits and sample testing.

– Request material certifications and chain-of-custody documentation.

– Establish clear contracts addressing IP ownership and usage rights.

– Work with reputable, legally compliant suppliers who respect design and trademark laws.

– Test samples under real-world conditions before large-scale procurement.

By being aware of these common quality and IP pitfalls, businesses can make informed sourcing decisions that protect both product performance and legal compliance.

Logistics & Compliance Guide for Paper Backed Veneer

Overview

Paper backed veneer (PBV) is a thin layer of real wood bonded to a paper backing for enhanced stability and ease of application. Due to its composite nature and wood content, PBV is subject to specific logistics handling requirements and international trade regulations. This guide outlines key considerations for safe transportation, import/export compliance, and regulatory adherence.

Packaging & Handling Requirements

Proper packaging is essential to prevent damage during transit.

– Roll Protection: PBV is typically supplied in rolls. Rolls must be wrapped in moisture-resistant film and placed in robust cardboard or wooden cores to prevent crushing.

– Palletization: Secure rolls on pallets using stretch wrap or banding. Avoid stacking excessive weight on top.

– Labeling: Clearly label packages with handling instructions such as “Fragile,” “This Side Up,” and “Protect from Moisture.” Include product details, batch number, and country of origin.

– Environmental Control: Store and transport in dry, temperature-controlled environments. Avoid exposure to humidity, direct sunlight, or extreme temperatures to prevent warping or delamination.

Transportation & Storage

- Mode of Transport: PBV can be shipped via road, sea, or air freight. For ocean freight, use ventilated containers to reduce moisture buildup.

- Stacking: Limit vertical stacking to prevent deformation. Use dunnage between layers if necessary.

- Storage Conditions: Maintain indoor storage at 18–25°C (64–77°F) and 40–60% relative humidity. Keep rolls off the floor on pallets and away from exterior walls.

Regulatory Compliance

Paper backed veneer may be subject to international standards and import regulations due to its wood component.

ISPM 15 (Wood Packaging Material)

- While PBV itself is not solid wood, wooden pallets or crates used in shipping must comply with ISPM 15.

- Ensure all wood packaging is heat-treated (HT) or die-pressed (DB) and marked with the official IPPC stamp.

CITES (Convention on International Trade in Endangered Species)

- If the veneer species is listed under CITES (e.g., certain tropical hardwoods like Rosewood or Mahogany), an export permit and import authorization are required.

- Verify species classification and maintain documentation throughout the supply chain.

Lacey Act (USA)

- The Lacey Act prohibits trade in illegally sourced wood products. Importers must submit a Plant and Plant Product Import Declaration (PPQ Form 505) for shipments arriving in the United States.

- Include details such as scientific name of the wood, country of harvest, and quantity.

EU Timber Regulation (EUTR)

- Companies placing PBV on the EU market must exercise due diligence to minimize the risk of illegal wood.

- Maintain a risk assessment and mitigation system, including supplier verification and traceability documentation.

Documentation Requirements

Ensure all shipments are accompanied by:

– Commercial invoice (with HS code)

– Packing list

– Bill of lading or air waybill

– Phytosanitary certificate (if required by destination)

– CITES permit (if applicable)

– Lacey Act declaration (for U.S. imports)

– Proof of ISPM 15 compliance for wood packaging

HS Code Classification

The Harmonized System (HS) code for paper backed veneer typically falls under:

– 4408.39 – Veneered sheets, wood, whether or not put up in packets, other than of coniferous wood (specific sub-codes may vary by country and wood species).

Confirm the correct code with local customs authorities to ensure accurate duty assessment.

Environmental & Sustainability Considerations

- Source PBV from suppliers with FSC® (Forest Stewardship Council) or PEFC™ (Programme for the Endorsement of Forest Certification) certification to support responsible forestry practices.

- Maintain chain-of-custody documentation if marketing products as sustainably sourced.

Conclusion

Successful logistics and compliance for paper backed veneer require attention to packaging, climate control, international regulations, and accurate documentation. Proactive compliance reduces delays at customs, avoids penalties, and supports sustainable supply chain practices. Always verify country-specific requirements before shipping.

Conclusion for Sourcing Paper-Backed Veneer

In conclusion, sourcing paper-backed veneer requires a strategic approach that balances quality, cost, sustainability, and supplier reliability. Paper-backed veneer offers distinct advantages such as improved stability, reduced risk of splitting, and easier handling during application, making it a preferred choice for both industrial and custom woodworking projects. However, successful sourcing hinges on selecting reputable suppliers who adhere to consistent manufacturing standards and provide transparent information about veneer origin, adhesive types, and environmental certifications.

Key considerations include evaluating the intended application—whether for high-end furniture, architectural panels, or cabinetry—to ensure the veneer meets performance and aesthetic requirements. Additionally, factoring in lead times, minimum order quantities, and logistical costs is essential for maintaining project timelines and budgets.

Emphasizing sustainable and ethically sourced materials not only supports environmental stewardship but also meets growing market demand for responsible manufacturing practices. Ultimately, building strong relationships with trusted vendors, staying informed about market trends, and conducting regular quality assessments will ensure a reliable supply of high-performing paper-backed veneer that enhances the final product’s value and durability.