The global personal protective equipment (PPE) market, driven by stringent workplace safety regulations and rising industrial automation, is projected to grow at a CAGR of 6.2% from 2023 to 2030, according to Grand View Research. Within this expanding sector, flame-resistant (FR) and high-durability workwear—particularly pants designed for welders—has gained significant traction due to the hazardous nature of welding operations and increased focus on occupational safety. The demand for specialized welding pants, engineered to resist sparks, molten metal, and abrasion, aligns with the broader industrial shift toward enhanced worker protection. As industries such as construction, manufacturing, and energy continue to prioritize safety compliance, the market for technical workwear is poised for sustained growth. In this context, several manufacturers have emerged as leaders, combining advanced fabric technologies with ergonomic design to meet rigorous performance standards. Based on performance metrics, material innovation, and market presence, here are the top 9 pants for welders manufacturers shaping the industry.

Top 9 Pants For Welders Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Welding & Industrial Clothing

Domain Est. 1995

#2 Kosto Aluskin Welding Women’s Pants

Domain Est. 1993

Website: spi.com

Key Highlights: 30-day returnsThe unique AluSkin fabric shields against metal splashes, flames, and intense heat, making it an ideal choice for foundry workers and welders. Additionally, ……

#3 Durable Welding Pants & Chaps for Safety and Comfort

Domain Est. 1995

Website: my.arbill.com

Key Highlights: 4-day deliveryShop Arbill for high-quality welding pants and chaps designed for durability, safety, and comfort on the job. Stay protected in every weld….

#4 Black welding trousers

Domain Est. 1996

Website: lincolnelectric.com

Key Highlights: Designed for practicality and comfort, these welding trousers are made from 305 g/m² flame-retardant cotton fabric in a striking black and red color ……

#5 Welding Gloves

Domain Est. 1998

Website: blackstallion.com

Key Highlights: With over 50 years of manufacturing experience, Black Stallion® leads the market in in high-quality, innovative gloves, FR garments and other PPE….

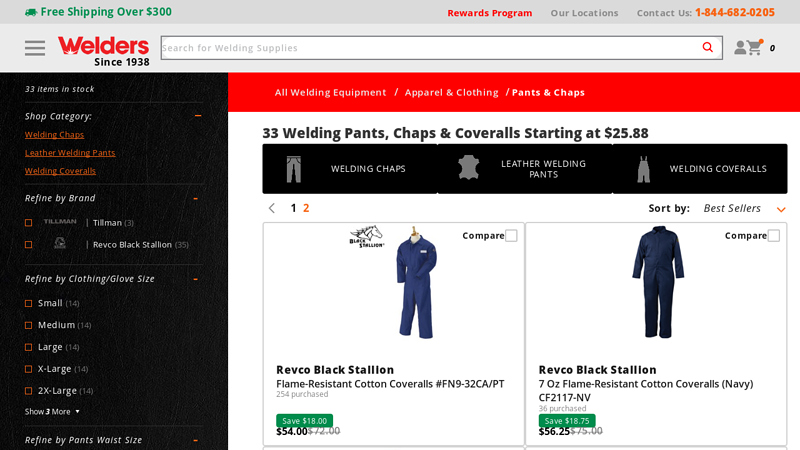

#6 33 Welding Pants, Chaps & Coveralls Starting at $25.88

Domain Est. 1998

Website: weldersupply.com

Key Highlights: Free delivery over $300Welding Pants and Chaps from Tillman, REVCO, Black Stallions provide great protection from welding sparks or accidents on your job site….

#7 Welding workwear: trousers, jackets, overalls & more

Domain Est. 1998

Website: kemppi.com

Key Highlights: Discover Kemppi’s certified flame-retardant welding workwear—durable trousers, jackets, overalls, and bib & braces—designed by welders, for welders….

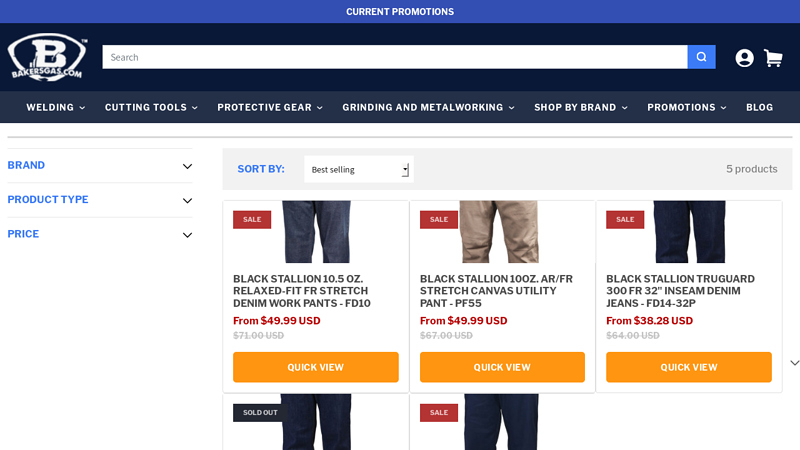

#8 FR Work Pants

Domain Est. 1999

Website: bakersgas.com

Key Highlights: Free delivery over $150 · 14-day returnsMade from durable flame-resistant materials, these pants shield you from heat, sparks, and potential fire hazards while providing all-day c…

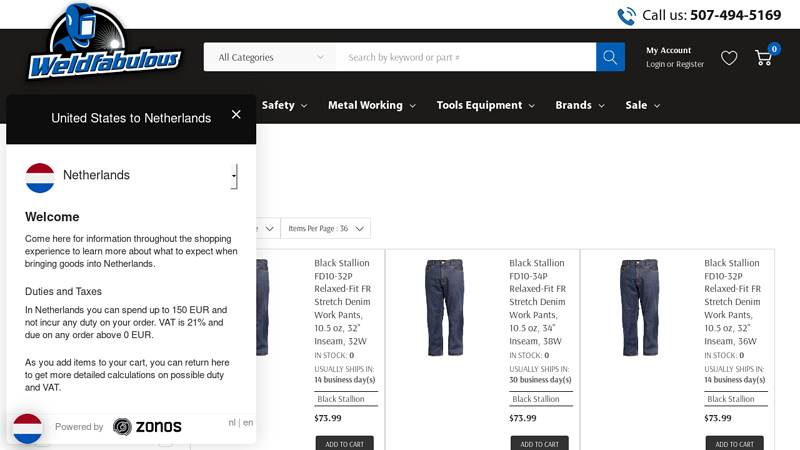

#9 Fire Resistant Pants for Welding at Weldfabulous.com

Domain Est. 2003

Website: weldfabulous.com

Key Highlights: Free deliveryWho else wants a great deal on name brand fire resistant pants? Weldfabulous carries heavy duty fire resistant pants for welding at low prices!…

Expert Sourcing Insights for Pants For Welders

H2: 2026 Market Trends for Pants for Welders

The market for pants specifically designed for welders is poised for significant evolution by 2026, driven by advancements in materials, increasing focus on occupational safety, and shifting workforce expectations. As demand for personal protective equipment (PPE) continues to rise in industrial and construction sectors, specialized welding pants are becoming a critical component of comprehensive safety gear. The following trends are expected to define the 2026 landscape for welders’ pants:

1. Adoption of Advanced Flame-Resistant (FR) Materials

By 2026, manufacturers are anticipated to widely adopt next-generation flame-resistant fabrics such as modacrylic, aramid blends (e.g., Nomex® and Kevlar®), and inherently FR-treated cotton. These materials offer superior protection against sparks, molten metal, and UV radiation while improving breathability and comfort. Innovations in nanotechnology may also lead to lighter, more durable textiles that maintain integrity under repeated exposure to high heat.

2. Integration of Smart Features and Wearable Technology

The rise of smart PPE is expected to influence the design of welding pants. By 2026, leading brands may incorporate embedded sensors to monitor heat exposure, posture, or movement fatigue. Some models could include RFID tags for inventory tracking or connectivity with safety management systems, enhancing workplace compliance and worker accountability.

3. Focus on Ergonomics and Mobility

As younger, more mobile workforces enter the trade, demand for ergonomic designs will grow. Welding pants in 2026 are likely to feature gusseted crotches, articulated knees, and stretch panels made from flexible FR-elastane blends. These designs support dynamic movement during overhead or confined-space welding, reducing strain and increasing productivity.

4. Sustainability and Eco-Friendly Manufacturing

Environmental concerns are shaping procurement decisions across industries. By 2026, brands producing welder pants are expected to prioritize sustainable sourcing, waterless dyeing processes, and recyclable materials. Certifications such as OEKO-TEX® or bluesign® may become standard, appealing to environmentally conscious contractors and industrial clients.

5. Customization and Sizing Inclusivity

The market will increasingly cater to diverse body types and regional preferences. Online configurators and made-to-order options may allow welders to customize fit, pocket placement, and FR protection levels. Inclusivity in sizing—especially for women in welding trades—will expand product lines beyond traditional unisex cuts.

6. Growth in E-Commerce and Direct-to-Consumer Sales

Digital platforms will play a larger role in distribution by 2026. Brands are likely to invest in immersive online experiences, including AR-enabled fit previews and detailed safety specification guides, to support informed purchasing decisions. Subscription models for PPE replacement may also emerge.

7. Regulatory and Safety Standard Harmonization

With global safety standards like EN ISO 11612 and NFPA 2112 becoming more uniformly enforced, manufacturers will align production to meet stringent international requirements. This will drive innovation and raise the baseline quality of welding pants across price segments.

In conclusion, the 2026 market for welders’ pants will be defined by a convergence of safety, comfort, and technology. As the welding industry modernizes, pants will transition from basic protective garments to intelligent, high-performance wearables that support worker well-being and operational efficiency.

Common Pitfalls When Sourcing Pants for Welders: Quality and Protection Issues

Logistics & Compliance Guide for Pants for Welders

Product Classification & HS Code

Welder-specific pants typically fall under textile apparel, specifically protective workwear. The Harmonized System (HS) code for these garments is generally 6211.43 (Other garments, of man-made fibers, men’s or boys’, of flame-resistant fabric). Confirm with your customs broker, as classification may vary by region and fabric composition (e.g., cotton vs. FR-treated synthetics).

Import/Export Regulations

Ensure compliance with destination country regulations for personal protective equipment (PPE). In the European Union, pants must meet EN ISO 11612 (protective clothing against heat and flame). In the U.S., refer to OSHA 29 CFR 1910.252 and NFPA 2112 standards for flame resistance. Documentation such as conformity certificates, test reports, and technical files may be required.

Packaging & Labeling Requirements

Use durable packaging suitable for bulk shipping—corrugated cartons with moisture barrier liners are recommended. Each garment must have a permanent label indicating:

– Fiber content

– Care instructions

– Manufacturer or distributor information

– Compliance with relevant safety standards (e.g., “Complies with NFPA 2112”)

– Size and model number

Include safety warnings (e.g., “Not flameproof—may burn if exposed to ignition source”).

Shipping & Transportation

Ship via freight (LTL or FTL) for bulk orders. Ensure warehouse storage is dry and away from direct sunlight to preserve fabric integrity. For international transport, provide a commercial invoice, packing list, and bill of lading/air waybill. Declare goods accurately to avoid customs delays.

Duty & Tariff Considerations

Tariff rates vary by country. For example:

– U.S. imports: Duty rates for HS 6211.43 average 16–20%, depending on trade agreements.

– EU imports: Often subject to 12% import duty.

Explore duty savings under trade preference programs (e.g., USMCA, GSP) if applicable.

Environmental & Safety Compliance

Ensure dyes and fabric treatments comply with REACH (EU) and Proposition 65 (California) regulations regarding restricted substances. Maintain records of chemical usage and environmental certifications (e.g., OEKO-TEX® Standard 100).

Recordkeeping & Audits

Retain product test reports, supplier compliance documents, and shipping records for a minimum of five years. Conduct annual compliance audits to verify adherence to safety, labeling, and customs requirements across all markets served.

Returns & Reverse Logistics

Establish a clear return policy for defective or non-compliant items. Use return authorization numbers (RMA) and inspect returned pants for safety violations before restocking. Dispose of damaged PPE according to local environmental regulations.

In conclusion, sourcing pants for welders requires a careful balance between safety, durability, comfort, and compliance with industry standards. Flame-resistant (FR) materials such as cotton blends treated with fire-retardant chemicals or inherently FR fabrics like Nomex or Modacrylic are essential to protect against sparks, open flames, and heat exposure. Reinforced stitching, double-knee construction, and thoughtful design features—like gusseted crotches and tool pockets—enhance longevity and functionality in demanding environments.

It is crucial to ensure that the selected pants meet recognized safety standards such as NFPA 70E or CSA Z462, especially when working with high-voltage equipment or in hazardous conditions. Additionally, considering the specific needs of the welding tasks—such as frequent kneeling, overhead work, or exposure to molten slag—can guide the selection of the most appropriate style and cut.

Sourcing from reputable suppliers with proven track records in protective workwear, and ideally those offering customization or bulk-order options, can ensure consistent quality and value. Ultimately, investing in high-quality welding pants not only protects workers from injury but also boosts productivity and morale by providing comfort and confidence on the job. Prioritizing safety and performance in the procurement process leads to long-term benefits for both employees and employers.