The global pallet wrapper market is experiencing robust growth, driven by rising demand for automated packaging solutions across logistics, warehousing, and manufacturing sectors. According to Grand View Research, the global stretch wrapper market size was valued at USD 3.1 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. This growth is fueled by increasing e-commerce activity, the need for load stability during transportation, and a growing emphasis on operational efficiency and product protection. Additionally, advancements in semi-automatic and fully automatic wrapping technologies are enabling higher throughput and reduced film consumption, making pallet wrapping an essential component of modern supply chains. As industries prioritize automation and sustainability, leading manufacturers are innovating to deliver energy-efficient, smart, and customizable wrapping solutions. Against this backdrop, we examine the top 10 pallet wrapper manufacturers shaping the industry through technological leadership, global reach, and strong R&D investments.

Top 10 Pallet Wrappers Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wulftec International Inc.

Domain Est. 1996

Website: wulftec.com

Key Highlights: We are the leader in the industry when it comes to Stretch Wrapping, Strapping Systems and Pallet Handling Solutions. We fear no packaging challenge!…

#2 Stretch Wrappers & Pallet Wrapping Equipment

Domain Est. 1996

Website: orionpackaging.com

Key Highlights: Orion is an industry leading Stretch Wrapping & Pallet Unitizing Machinery manufacturer of automatic and semi-automatic stretch wrapping equipment….

#3 Phoenix Wrappers Pallet Stretch Wrap

Domain Est. 2006

Website: phoenixwrappers.com

Key Highlights: Phoenix Wrappers is a leading manufacturer of stretch wrappers and stretch wrapping equipment with a full line of semi-automatic stretch wrap machines and high ……

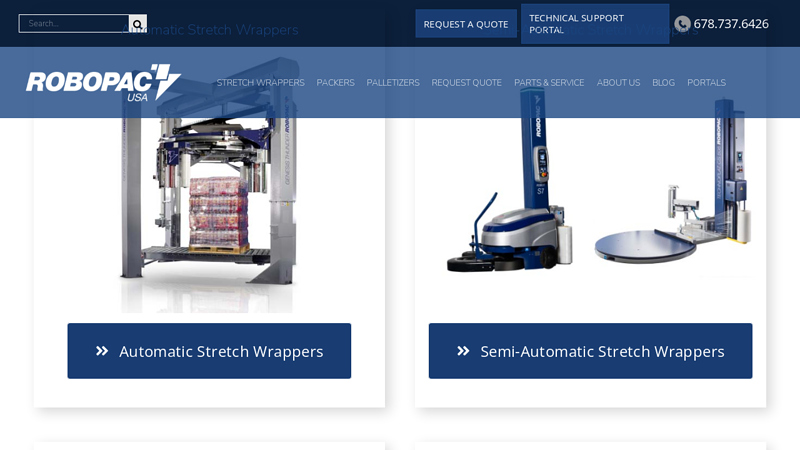

#4 Robopac USA

Domain Est. 2017

Website: robopacusa.com

Key Highlights: We offer the largest line of configurable machinery that are designed perfectly to stretch wrap, pack, palletize, erect, and seal any product….

#5 Innovative Packaging Solutions from Lantech

Domain Est. 1995

Website: lantech.com

Key Highlights: Lantech Automatic Stretch Wrappers run 24/7 in real world environments and are backed by our superior global after market support. They deliver more uptime and ……

#6 Efficient Stretch and Pallet Wrapping Solutions

Domain Est. 1996

Website: signode.com

Key Highlights: Stretch & Pallet Wrapping. Signode offers a complete line of equipment from stretch wrapping machines, pallet wrappers, stretch film, and stretch hood machines….

#7 Cousins Packaging

Domain Est. 1999

Website: cousinspackaging.com

Key Highlights: Cousins Packaging designs and manufactures a full range of stretch wrap machines, including semi-automatic, fully automatic, and custom pallet wrappers. Built ……

#8 Handle-It

Domain Est. 2000

Website: handleitinc.com

Key Highlights: We offer a wide variety of stretch wrappers – also known as pallet wrappers – to help you improve your current packaging process….

#9 Atlanta Stretch: Automatic and Semi

Domain Est. 2005

Website: atlantastretch.com

Key Highlights: Atlanta Stretch are specialists in the design, construction and manufacturing of stretch wrappers and other solutions for the end of line….

#10 Pallet wrappers

Domain Est. 2023

Website: ihress.com

Key Highlights: Range of automatic and semi-automatic pallet stretch wrappers. Ideal option to improve end-of-line efficiency. Ask us for more information….

Expert Sourcing Insights for Pallet Wrappers

H2: Market Trends for Pallet Wrappers in 2026

As the global logistics, warehousing, and manufacturing sectors continue to evolve, the pallet wrapper market is poised for significant transformation by 2026. Driven by automation, sustainability demands, and supply chain resilience, several key trends are expected to shape the industry in the coming years.

1. Accelerated Adoption of Automation and Smart Technology

By 2026, semi-automated and fully automated pallet wrappers will dominate new installations, particularly in high-volume distribution centers and e-commerce fulfillment hubs. Integration with Warehouse Management Systems (WMS) and IoT-enabled sensors will allow for real-time monitoring of wrapping cycles, film usage, and machine performance. Predictive maintenance and remote diagnostics will reduce downtime, while AI-driven optimization will improve load stability and film efficiency.

2. Growth in Robotics and Collaborative Solutions

Robotic pallet wrapping systems, including robotic arms and autonomous mobile robots (AMRs) with integrated wrapping capabilities, will gain traction. These systems offer flexibility in dynamic warehouse environments and reduce reliance on manual labor. Collaborative wrappers designed to work safely alongside human operators will be increasingly adopted in mid-sized facilities seeking efficiency without full automation.

3. Sustainability as a Key Driver

Environmental regulations and corporate ESG goals will push demand for sustainable wrapping solutions. This includes the use of recyclable and biodegradable stretch films, as well as high-performance pre-stretched films that reduce plastic consumption by up to 30%. Equipment manufacturers will emphasize energy-efficient motors and designs that minimize film waste. Refurbished and remanufactured wrappers will also see growing demand as part of circular economy initiatives.

4. Customization and Scalability

One-size-fits-all solutions will give way to modular and customizable wrapping systems. Businesses will seek scalable equipment that can adapt to varying load sizes, weights, and production speeds. Quick-change components and user-friendly interfaces will allow for faster setup and reduced changeover times, supporting just-in-time manufacturing and omnichannel logistics.

5. Regional Market Diversification

While North America and Europe remain strong markets due to advanced automation and strict safety standards, Asia-Pacific—especially China, India, and Southeast Asia—will experience the fastest growth. This is fueled by expanding manufacturing sectors, rising e-commerce, and modernization of supply chain infrastructure. Localized manufacturing and service networks will become critical for global suppliers.

6. Focus on Total Cost of Ownership (TCO)

Buyers will increasingly evaluate pallet wrappers based on long-term TCO rather than upfront cost. Factors such as film savings, energy efficiency, maintenance requirements, and durability will influence purchasing decisions. Vendors offering service contracts, film supply partnerships, and performance guarantees will gain competitive advantage.

Conclusion

By 2026, the pallet wrapper market will be defined by intelligent, sustainable, and flexible solutions that align with the broader trends in Industry 4.0 and green logistics. Companies that innovate in automation, eco-friendly materials, and data-driven performance will lead the market, while traditional manual and basic semi-automatic models will gradually decline in favor of smarter, more efficient alternatives.

Common Pitfalls When Sourcing Pallet Wrappers: Quality and Intellectual Property Issues

Poor Build Quality and Material Standards

One of the most frequent pitfalls when sourcing pallet wrappers—especially from low-cost manufacturers—is substandard build quality. Many budget suppliers use inferior steel, weak motors, or low-grade components to cut costs, leading to frequent mechanical failures, reduced lifespan, and higher maintenance expenses. Buyers may receive machines that fail under regular operational loads or require constant repairs, ultimately increasing total cost of ownership.

Inconsistent Performance and Reliability

Pallet wrappers sourced without proper vetting may suffer from inconsistent wrapping tension, misalignment, or uneven film application. These performance issues compromise load stability during transit, increasing the risk of product damage and safety hazards. Without third-party testing or certifications, it can be difficult to verify the machine’s reliability before deployment.

Lack of Compliance with Safety and Industry Standards

Some imported pallet wrappers do not meet essential safety regulations such as CE, UL, or OSHA standards. Non-compliant machines may lack emergency stop functions, proper guarding, or electrical safety features, posing serious risks to operators. Using non-compliant equipment can also lead to legal liability, insurance complications, or workplace inspection failures.

Intellectual Property Infringement Risks

Sourcing from certain regions may expose buyers to intellectual property (IP) concerns. Some manufacturers produce “clone” or reverse-engineered versions of well-known pallet wrapper models, infringing on patents, designs, or trademarks. Purchasing such equipment—even unknowingly—can result in legal exposure, shipment seizures, or reputational damage, especially in regulated industries.

Limited or No After-Sales Support and Spare Parts

Low-cost suppliers often lack robust after-sales infrastructure. This means limited technical support, delayed spare parts delivery, or no local service network, leading to extended downtime. Without access to genuine replacement parts, maintenance becomes challenging and may require costly modifications.

Misrepresentation of Technical Specifications

Some suppliers exaggerate key performance metrics such as wrapping speed, load capacity, or film pre-stretch ratios. This misrepresentation can result in selecting a machine unsuitable for the intended application, leading to operational inefficiencies or the need for costly replacements.

Hidden Costs from Poor Integration and Installation

Pallet wrappers that are not designed to current industrial standards may require custom modifications to integrate with existing conveyor systems, control software, or facility layouts. These hidden engineering costs can quickly erode the initial savings gained from choosing a low-priced supplier.

Conclusion

To avoid these pitfalls, buyers should conduct thorough due diligence—requesting product certifications, inspecting manufacturing facilities, verifying IP compliance, and securing service agreements. Partnering with reputable suppliers who offer warranties, technical documentation, and support is crucial for ensuring long-term reliability and legal safety.

Logistics & Compliance Guide for Pallet Wrappers

Pallet wrappers are essential equipment in material handling and logistics, used to secure loads on pallets for transport and storage. Ensuring proper logistics and compliance when procuring, operating, and maintaining pallet wrappers is critical for safety, efficiency, and adherence to regulatory standards. This guide outlines key considerations across transportation, installation, operation, and regulatory compliance.

Equipment Transportation and Handling

Transporting pallet wrappers—especially stretch wrap machines, turntable systems, or rotary arm models—requires careful logistics planning due to their size, weight, and sensitivity.

- Secure Packaging: Ensure the machine is packed in a wooden crate or protective casing to prevent damage during transit.

- Forklift Accessibility: Confirm that the equipment has forklift entry points or skids for safe unloading.

- Weight and Dimensions: Verify that transport vehicles and loading docks can accommodate the machine’s dimensions and weight (typically 300–1,500 lbs depending on model).

- Site Preparation: Ensure the receiving site has clear access routes, floor load capacity, and adequate space for setup.

Installation and Site Requirements

Proper installation ensures safe and efficient operation while minimizing downtime.

- Flooring: Install on a level, hard, non-slip surface. Uneven floors can cause instability and wrapping inconsistencies.

- Power Supply: Confirm electrical requirements (voltage, phase, amperage) match local standards (e.g., 110V/220V, single or three-phase).

- Clearance: Allow at least 2–3 feet of clearance around the machine for maintenance, load placement, and operator access.

- Ventilation: For motorized or automated models, ensure adequate airflow to prevent overheating.

Operational Safety and Best Practices

Adhering to safety protocols protects operators and maintains equipment integrity.

- Operator Training: Train personnel on startup, shutdown, emergency stop usage, and load handling procedures.

- Personal Protective Equipment (PPE): Require gloves and safety footwear; eye protection is recommended when handling film rolls.

- Machine Guards: Ensure all moving parts (turntable, film carriage) are properly guarded per OSHA or local standards.

- Load Stability: Verify that loads are evenly stacked and within the machine’s weight and height limits to prevent tipping.

Regulatory and Compliance Standards

Pallet wrappers must comply with regional and international safety and environmental regulations.

- Electrical Safety: Comply with IEC 60204-1 (safety of machinery – electrical equipment) or local equivalents such as NEC (US) or CE (EU).

- Machine Guarding: Follow OSHA 29 CFR 1910.212 (US) or PUWER regulations (UK) for guarding moving parts.

- CE Marking (Europe): Required for all machinery placed on the EU market. Includes compliance with Machinery Directive 2006/42/EC.

- RoHS and REACH Compliance: Ensure materials used in construction meet restrictions on hazardous substances (EU).

- Lockout/Tagout (LOTO): Implement procedures per OSHA 29 CFR 1910.147 for maintenance and servicing.

Maintenance and Recordkeeping

Regular maintenance extends equipment life and ensures consistent performance.

- Scheduled Inspections: Conduct weekly checks of belts, bearings, film carriage, and emergency stops.

- Lubrication and Cleaning: Follow manufacturer guidelines for lubricating moving parts and cleaning debris.

- Record Logs: Maintain logs of maintenance, repairs, and safety inspections for compliance audits.

- Spare Parts: Keep critical spare parts (e.g., turntable bearings, film pre-stretch rollers) on hand to minimize downtime.

Environmental and Sustainability Considerations

Modern logistics increasingly prioritize eco-friendly practices.

- Film Efficiency: Use pre-stretch film technology to reduce plastic usage by up to 50%.

- Recyclable Components: Choose models with recyclable metal frames and minimal packaging.

- Energy Efficiency: Opt for variable frequency drives (VFDs) to reduce power consumption during operation.

Import/Export Considerations

For international logistics, ensure compliance with customs and trade regulations.

- HS Code Classification: Pallet wrappers typically fall under HS Code 8422.40 (other packaging machinery).

- Documentation: Prepare commercial invoices, packing lists, and certificates of origin.

- Voltage Compatibility: Verify that electrical specifications match destination country standards; use transformers if necessary.

- Certification Requirements: Provide CE, UL, or CSA certification documentation as required by the importing country.

Adhering to this logistics and compliance guide ensures safe, efficient, and legally compliant use of pallet wrappers across global supply chains. Always consult the manufacturer’s manual and local regulatory bodies for model-specific and region-specific requirements.

Conclusion for Sourcing Pallet Wrappers

Sourcing the right pallet wrapper is a critical decision that directly impacts operational efficiency, product safety, load stability, and overall packaging costs. After evaluating various options—including manual, semi-automatic, and fully automatic stretch wrapping systems—it is evident that the optimal choice depends on factors such as production volume, load consistency, available space, labor costs, and long-term scalability.

Investing in the appropriate pallet wrapping solution not only ensures secure and reliable load containment but also enhances workplace safety and reduces film waste through optimized stretch capabilities. Additionally, energy-efficient and eco-friendly models contribute to sustainability goals, while automated systems offer significant ROI for high-throughput operations by minimizing downtime and labor dependency.

Ultimately, a thorough assessment of current and future packaging needs, combined with supplier reliability, after-sales support, and total cost of ownership, will guide the successful sourcing of pallet wrappers. By aligning the equipment with operational demands, businesses can achieve improved packaging performance, reduce damage in transit, and support streamlined logistics processes.