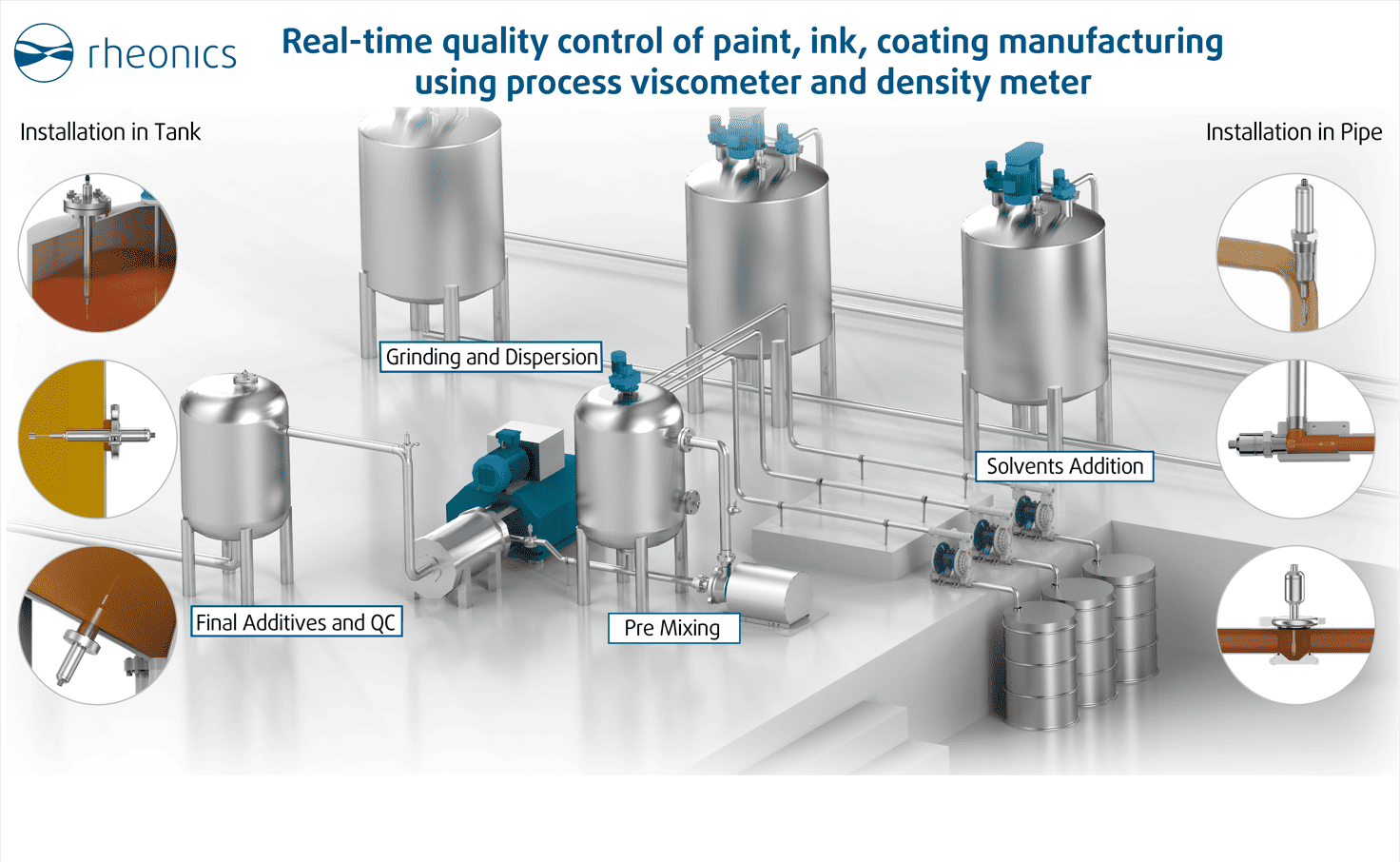

The global paint and coatings market is undergoing significant expansion, driven by rising demand across construction, automotive, and industrial sectors. According to Mordor Intelligence, the market is projected to grow at a CAGR of approximately 5.8% from 2023 to 2028, underpinned by increasing urbanization and infrastructure development worldwide. With quality control becoming ever more critical in coating applications, precision tools such as viscosity cups play an essential role in ensuring consistent product performance. Among these, paint viscosity cups are widely used for their simplicity, reliability, and cost-effectiveness in measuring the flow characteristics of liquids. As formulation standards tighten and regulatory compliance becomes more stringent, manufacturers of viscosity measurement equipment are seeing growing demand. This surge has fostered innovation and competition among leading suppliers, establishing a core group of eight manufacturers that dominate in accuracy, durability, and global reach. These companies are not only advancing product design but are also aligning with industry standards such as ASTM and ISO to meet evolving customer needs.

Top 8 Paint Viscosity Cup Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Viscosity Cup

Domain Est. 1997

Website: globalindustrial.com

Key Highlights: In stock Rating 4.5 12 The Ford #4 viscosity cup is used for measuring the viscosity of paints and finishes to ensure a flawless finish….

#2 IWATA Viscosity Cup

Domain Est. 2003

Website: gppt.com.tw

Key Highlights: Guan Piin specializes in providing various IWATA Viscosity Cup, spray paint machines, spray guns, filters, pressure regulators and spray control accessories ……

#3 AMETEK Brookfield

Domain Est. 1996

Website: brookfieldengineering.com

Key Highlights: Go beyond viscosity with AMETEK Brookfield! Brookfield has been considered the world standard in viscosity measurement and control for more than 85 years….

#4 Have you automated viscosity measurement?

Domain Est. 1997

Website: viscosity.com

Key Highlights: A viscosity measuring cup is used to measure the drain time of a liquid through a known orifice size to determine how thick it is….

#5 Paint Viscosity Cup

Domain Est. 2003

Website: waipu.com.tw

Key Highlights: Name · Paint Viscosity Cup ; Model · Paint-Viscosity-Cup ; GENERAL AGENT IN CHINA · DONG GUAN WEI PU TRADING CO.,LTD ; ADDRESS · DORMITORY NO.201,LOCAL TAX BRANCH, ……

#6 Viscosity Dip Cups

Domain Est. 2005

Website: elcometerusa.com

Key Highlights: Shop Elcometer viscosity dip cups. Ideal for the quick testing of the viscosity of paints, varnishes and similar products during manufacturing processes….

#7 Paint Viscosity Tester PCE

Domain Est. 2010

Website: pce-instruments.com

Key Highlights: Description. Paint Viscosity Tester for measuring viscosity / German standard DIN 53211 / Cup made of anodized aluminum / Also available as immersion cup….

#8 TQC sheen

Domain Est. 2016

Website: obsnapinstrument.com

Key Highlights: The TQC AFNOR Viscosity Cups are a range of titanium anodized aluminum viscosity cups. Laboratory type, to be used with stand, to measure the viscosity of ……

Expert Sourcing Insights for Paint Viscosity Cup

H2: 2026 Market Trends for Paint Viscosity Cups

The global market for paint viscosity cups is expected to experience steady growth by 2026, driven by increasing demand for quality control in paint, coatings, and related industries. As industries such as automotive, construction, and industrial manufacturing continue to expand—particularly in emerging economies—there is a rising emphasis on precise measurement tools to ensure consistent product performance and compliance with regulatory standards. Paint viscosity cups, being simple, cost-effective, and reliable instruments, remain a preferred choice for on-site and laboratory viscosity testing.

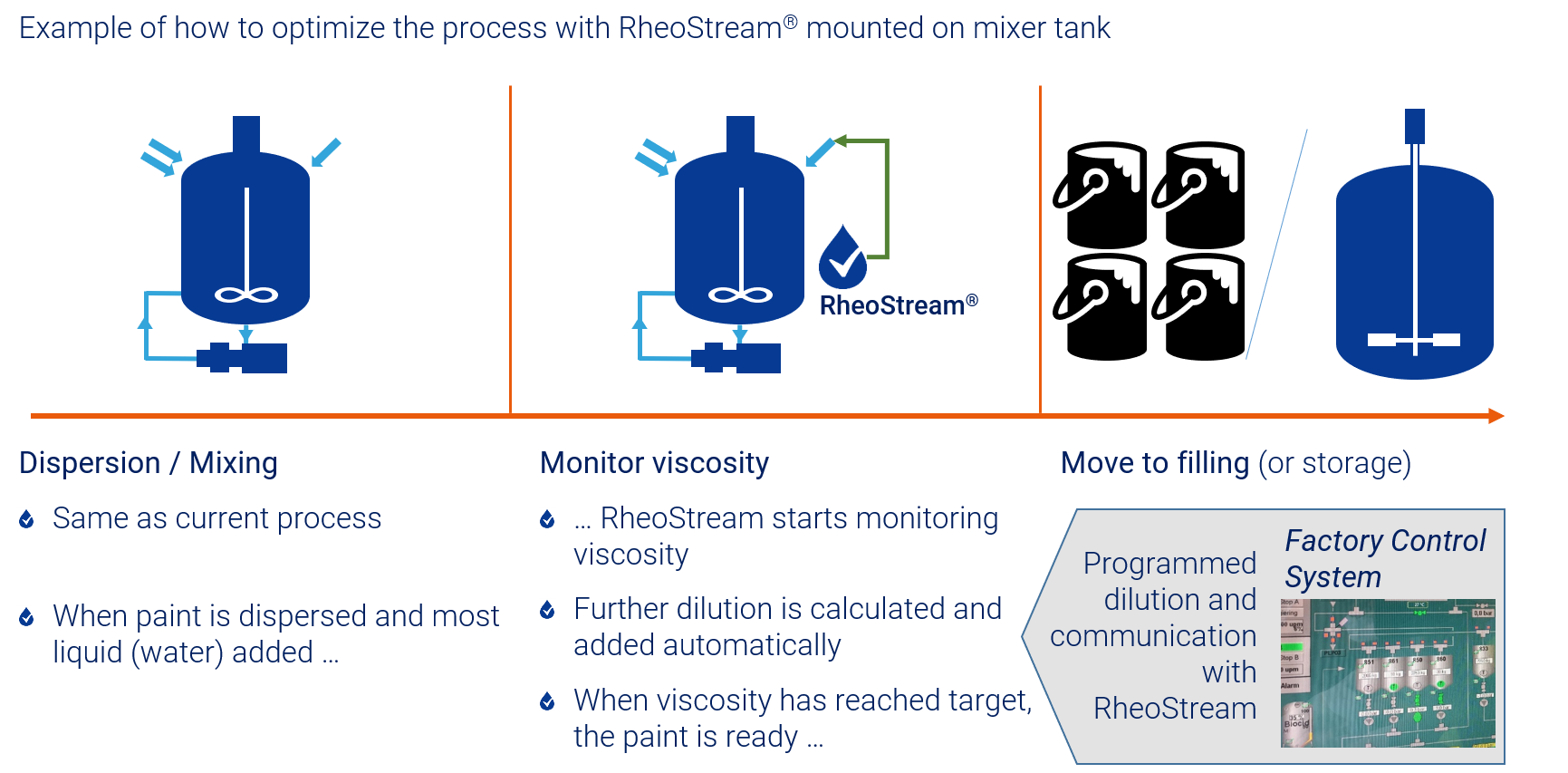

One major trend shaping the 2026 landscape is the integration of digitalization and smart technology. While traditional manual viscosity cups (such as Ford, Zahn, and ISO cups) continue to dominate, manufacturers are beginning to offer digital variants or companion apps that assist in data logging, temperature correction, and automatic viscosity calculation. This hybrid approach enhances accuracy and traceability, appealing to industries adopting Industry 4.0 practices.

Additionally, sustainability initiatives are influencing material choices and manufacturing processes. Leading suppliers are shifting toward producing viscosity cups from recyclable or corrosion-resistant materials like anodized aluminum and high-grade stainless steel, extending product lifespan and reducing environmental impact. There is also growing demand for cups that support eco-friendly water-based and low-VOC (volatile organic compound) coatings, which have different viscosity profiles compared to solvent-based formulations.

Regional dynamics play a significant role in market expansion. Asia-Pacific, especially countries like China, India, and Vietnam, is projected to be the fastest-growing market due to rapid industrialization, urban development, and government investments in infrastructure. North America and Europe are witnessing steady demand, supported by strict quality regulations in aerospace, automotive refinishing, and architectural coatings.

In summary, the 2026 paint viscosity cup market is characterized by technological enhancement, sustainability focus, and geographic diversification. While traditional models remain foundational, innovation in usability, durability, and digital integration will define competitive advantage, ensuring continued relevance in evolving industrial applications.

Common Pitfalls Sourcing Paint Viscosity Cups (Quality, IP)

Sourcing paint viscosity cups—especially those conforming to international standards (IP, ASTM, DIN, etc.)—requires careful attention to detail to ensure accurate and reliable viscosity measurements. Overlooking key factors can lead to inconsistent quality control, wasted materials, and production delays. Below are common pitfalls to avoid:

1. Ignoring Compliance with Relevant Standards

One of the most critical errors is selecting a cup not certified to the required international standard (e.g., IP 170, ASTM D1200, DIN 53211). Different industries and regions mandate specific standards. Using a non-compliant cup invalidates test results and may breach regulatory or customer requirements.

Solution: Verify the cup’s conformance to the applicable standard (e.g., IP 170 for petroleum products) and request certification from the supplier.

2. Compromising on Material Quality

Low-cost viscosity cups are often made from inferior stainless steel or uncoated metals that corrode or wear quickly when exposed to aggressive solvents or pigments. This alters the orifice dimensions and flow characteristics over time, leading to inaccurate readings.

Solution: Choose cups made from high-grade, corrosion-resistant stainless steel (e.g., 316 SS) with precision-machined orifices.

3. Inadequate Orifice Precision and Tolerance

The accuracy of viscosity measurement depends heavily on the exact diameter and smooth finish of the orifice. Poorly manufactured cups may have inconsistent orifice sizes or burrs, affecting flow time and repeatability.

Solution: Ensure the orifice is precision-drilled and deburred. Request tolerance specifications (typically ±0.005 mm) and verify with calibration certificates if available.

4. Overlooking Calibration and Traceability

Many suppliers offer “standard” cups without individual calibration or traceability to national standards (e.g., NIST). Without traceable calibration, there’s no assurance of measurement accuracy.

Solution: Source cups with individual calibration certificates and NIST or equivalent traceability, especially for quality-critical applications.

5. Selecting the Wrong Cup Type or Size

Different viscosity ranges require different cup types (e.g., Ford, Zahn, ISO, IPC). Choosing a cup with an inappropriate efflux time range for your material leads to inaccurate measurements—either too fast to time reliably or too slow for practical use.

Solution: Match the cup size (e.g., IPC No. 2, No. 4) to the expected viscosity range of your paint or coating. Use conversion charts cautiously and validate with lab methods if needed.

6. Poor Temperature Control and Handling Procedures

Viscosity is highly temperature-sensitive. Failing to control sample and ambient temperature during testing introduces significant error, regardless of cup quality.

Solution: Implement strict temperature control (e.g., 25°C ± 0.5°C) and allow samples to equilibrate before testing. Train operators on standardized procedures.

7. Inconsistent Operator Technique

Even with a high-quality cup, inconsistent dipping, lifting, or timing techniques (e.g., starting the stopwatch late) compromise repeatability.

Solution: Standardize testing procedures, provide operator training, and use digital timing devices where possible.

8. Neglecting Maintenance and Cleaning

Residual paint buildup in the cup or orifice alters flow dynamics. Over time, improper cleaning can damage the cup or clog the orifice.

Solution: Establish a routine cleaning protocol using appropriate solvents and non-abrasive tools. Inspect and calibrate cups periodically.

9. Sourcing from Unverified Suppliers

Purchasing from suppliers without a proven track record or technical support increases the risk of receiving counterfeit or substandard products.

Solution: Buy from reputable suppliers with expertise in laboratory or industrial testing equipment. Request references, product documentation, and after-sales support.

10. Underestimating Total Cost of Ownership

Choosing the cheapest cup may result in frequent replacements, recalibrations, or production errors. The long-term cost outweighs initial savings.

Solution: Evaluate total cost, including durability, calibration needs, and impact on product quality, when making sourcing decisions.

By avoiding these common pitfalls, organizations can ensure reliable viscosity measurements, maintain product consistency, and comply with quality standards effectively.

Logistics & Compliance Guide for Paint Viscosity Cup

Overview

A Paint Viscosity Cup is a simple, handheld device used to measure the viscosity (flow resistance) of paints, coatings, inks, and similar fluids. Proper logistics handling and regulatory compliance are essential to ensure product integrity, user safety, and adherence to international trade standards.

Packaging and Storage

Ensure viscosity cups are packaged in protective cases or padded containers to prevent damage to the precision orifice and rim. Store in a dry, temperature-controlled environment (15°C to 25°C) away from corrosive chemicals. Avoid stacking heavy items on packaged units to prevent deformation.

Transportation Requirements

Ship viscosity cups via standard ground or air freight. Use UN-certified packaging if shipped with calibration fluids or cleaning solvents. Clearly label packages as “Fragile – Precision Instrument” and “Do Not Stack.” Maintain documentation such as packing lists and shipping manifests for traceability.

Import/Export Compliance

Verify country-specific import regulations. Most viscosity cups are classified under HS Code 9027.80 (instruments for measuring or checking viscosity). No special export licenses are typically required unless destined for embargoed regions. Confirm compliance with destination country standards (e.g., CE marking for EU, NIST traceability for U.S.).

Regulatory Standards and Certifications

Ensure devices comply with relevant international standards:

– ISO 2431: Specifies test methods for flow cups used with paints and varnishes.

– ASTM D1200: Standard test method for viscosity using Ford viscosity cups.

– DIN 53211: German standard for flow cups in paint testing.

Provide calibration certificates traceable to NIST or other national metrology institutes when required.

Chemical Exposure and Safety

Viscosity cups may come into contact with hazardous substances. Users must follow GHS-compliant safety data sheets (SDS) for tested materials. Clean cups with appropriate solvents (e.g., acetone, toluene) in well-ventilated areas using PPE (gloves, goggles). Dispose of cleaning waste per local environmental regulations (e.g., RCRA in the U.S.).

Calibration and Maintenance

Calibrate annually or per quality management system requirements (e.g., ISO 9001). Use certified reference fluids for verification. Document all calibration activities. Replace cups if orifice wear, corrosion, or damage affects accuracy.

Disposal and End-of-Life

Dispose of damaged or obsolete cups as electronic or metal waste, depending on construction (stainless steel, aluminum). Follow WEEE directives in the EU or equivalent local e-waste regulations. Do not incinerate plastic components.

Documentation and Recordkeeping

Maintain records of:

– Certificates of Conformity

– Calibration reports

– Shipping and customs documentation

– Safety and compliance training logs

Retain records for a minimum of 5 years or as required by jurisdiction.

Conclusion

Adherence to logistics protocols and compliance standards ensures the reliable performance and legal distribution of Paint Viscosity Cups. Regular audits and staff training support ongoing regulatory alignment and product quality.

Conclusion for Sourcing Paint Viscosity Cups:

Sourcing the appropriate paint viscosity cup is a critical step in ensuring consistent and accurate measurement of paint and coating viscosity, which directly impacts product quality, application performance, and process efficiency. By evaluating key factors such as industry standards (e.g., ISO, ASTM, DIN), material durability (typically stainless steel), cup size and flow rate (e.g., Ford, Zahn, DIN cups), and required precision, organizations can select a viscosity cup that meets their specific operational needs.

It is essential to source from reputable suppliers who provide calibration certificates and comply with international standards to ensure measurement reliability and traceability. Additionally, considering long-term costs, ease of use, and compatibility with existing testing procedures will enhance overall effectiveness.

In conclusion, a well-informed sourcing strategy for paint viscosity cups—rooted in quality, accuracy, and standardization—not only supports consistent coating performance but also contributes to improved production control and customer satisfaction in industries ranging from automotive and manufacturing to construction and aerospace.