The global paint booth exhaust fans market is experiencing steady growth, driven by rising demand from automotive, aerospace, and industrial manufacturing sectors. According to Grand View Research, the global industrial ventilation equipment market—of which paint booth exhaust fans are a critical component—was valued at USD 52.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing regulatory emphasis on workplace safety, air quality standards, and the need for efficient volatile organic compound (VOC) removal in spray painting operations. With manufacturers increasingly investing in energy-efficient and high-performance ventilation systems, the competitive landscape has intensified. Based on performance metrics, market presence, innovation, and customer reviews, the following nine companies have emerged as leading manufacturers of paint booth exhaust fans, setting benchmarks in airflow efficiency, durability, and compliance with environmental regulations.

Top 9 Paint Booth Exhaust Fans Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Aerovent

Domain Est. 1996

Website: aerovent.com

Key Highlights: As a leading designer and manufacturer of high-quality industrial air moving equipment, Aerovent sets the industry standard….

#2 Paint Booth, Industrial Spray Booths Installation

Domain Est. 2000

Website: paintbooth.com

Key Highlights: High-quality paint booth for auto, booths for truck & industrial finishing or powder coating – System Design sales service & installation….

#3 Paint booth odor removal exhaust fans

Domain Est. 2012

Website: aeib.fr

Key Highlights: Take a look at our range of industrial fans that are specially adapted to provide ventilation in professional paint booths….

#4 Paint Booth Fans

Domain Est. 2016

Website: rttsolutions.com

Key Highlights: Featuring a continuous duty motor with an airtight seal, our tubeaxial fans ranging in size from 12 to 42”, will fit both industrial and commercial applications ……

#5 Oven Components and Industrial Curing Solutions

Domain Est. 2020

Website: infratechautomotive.com

Key Highlights: From the world’s largest furniture manufacturing lines to curing small paint jobs in large spray booths, Infratech can provide the services your facility ……

#6 Spray & Paint Booth Exhaust Fans

Domain Est. 1996

Website: nyb.com

Key Highlights: The New York Blower fans used for this application are designed and manufactured for removing paint fumes and paint over-spray. Request a quote or call us ……

#7 Spray Booth Exhaust

Domain Est. 1997

Website: tcf.com

Key Highlights: Twin City Fan offers an industry leading swingout design and axial fans are available in both clamshell and swingout construction for ease of cleaning….

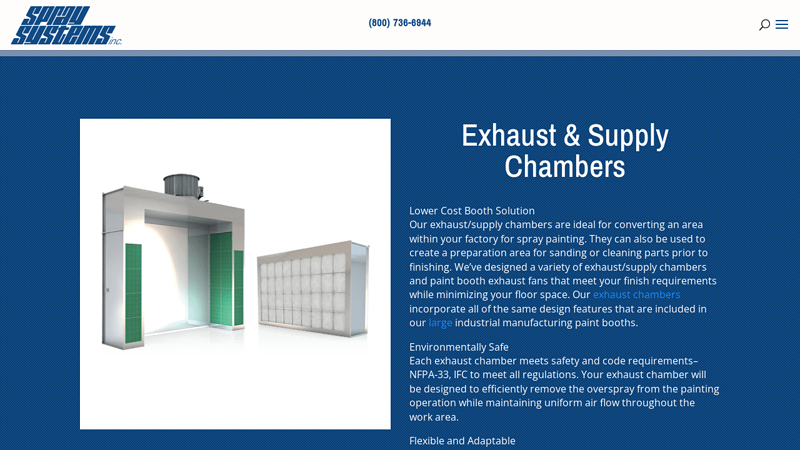

#8 Exhaust & Supply Chambers for Spray Booths

Domain Est. 1997

Website: spraysystems.com

Key Highlights: We’ve designed a variety of exhaust/supply chambers and paint booth exhaust fans that meet your finish requirements while minimizing your floor space. Our ……

#9 Paint Booth Exhaust Fans

Domain Est. 2002

Website: paint-booths.com

Key Highlights: 5.0 25 Standard Tools and Equipment offers a variety of paint booth exhaust fans for general ventilation. Our most popular fan configurations are available online….

Expert Sourcing Insights for Paint Booth Exhaust Fans

2026 Market Trends for Paint Booth Exhaust Fans

As industries continue to prioritize environmental compliance, energy efficiency, and operational safety, the market for paint booth exhaust fans is undergoing significant transformation. By 2026, several key trends are expected to shape the demand, technology, and competitive landscape of this specialized ventilation sector.

Rising Demand from Automotive and Industrial Sectors

The automotive manufacturing and repair industries remain primary drivers of paint booth exhaust fan adoption. With the global push toward electric vehicles (EVs), new manufacturing facilities and upgraded paint shops are being built to accommodate advanced coating processes. These facilities require high-performance exhaust systems to maintain air quality and meet safety standards. Additionally, growth in aerospace, marine, and heavy equipment manufacturing is contributing to sustained demand for industrial-grade paint booth ventilation.

Stricter Environmental and Safety Regulations

Environmental protection agencies in North America, Europe, and parts of Asia are enforcing tighter air quality standards, particularly regarding volatile organic compound (VOC) emissions. By 2026, compliance with regulations such as the U.S. EPA’s National Emission Standards for Hazardous Air Pollutants (NESHAP) and EU Industrial Emissions Directive (IED) will necessitate more efficient exhaust systems. Paint booth exhaust fans will need to integrate with advanced filtration and abatement technologies, driving demand for smart, high-efficiency models capable of real-time monitoring and emission control.

Shift Toward Energy-Efficient and Smart Ventilation Systems

Energy consumption is a major operational cost in paint booths. As a result, manufacturers are increasingly adopting variable frequency drive (VFD) exhaust fans, which adjust airflow based on real-time conditions, reducing energy use by up to 40%. By 2026, the integration of IoT-enabled sensors and building management systems (BMS) will allow for predictive maintenance, remote monitoring, and optimized airflow control. These “smart” exhaust fans will become standard in modern paint booths, particularly in high-volume production environments.

Growth in Retrofit and Upgrade Projects

Many existing paint booths, especially in older collision repair shops and manufacturing plants, use outdated, inefficient exhaust systems. With rising energy costs and regulatory pressure, retrofitting these systems with modern, compliant exhaust fans will be a cost-effective solution. The retrofit market is expected to grow significantly by 2026, offering opportunities for manufacturers and service providers to offer modular, scalable fan solutions and turnkey upgrade packages.

Regional Market Dynamics

North America and Europe will continue to dominate the high-end segment due to strict regulatory frameworks and advanced manufacturing infrastructure. Meanwhile, the Asia-Pacific region—particularly China, India, and Southeast Asia—is expected to witness the fastest growth, fueled by expanding automotive production and urbanization. Local manufacturers in these regions are beginning to produce compliant systems, increasing competition and driving down prices while improving accessibility.

Innovation in Materials and Acoustic Performance

By 2026, demand for corrosion-resistant materials such as fiberglass-reinforced plastic (FRP) and stainless steel will rise, especially in high-humidity or chemical-heavy environments. Additionally, noise pollution regulations are prompting manufacturers to develop low-noise fan designs using advanced blade geometry and sound-dampening enclosures. These innovations will enhance workplace safety and comfort without compromising airflow performance.

Conclusion

The 2026 market for paint booth exhaust fans will be defined by regulatory compliance, energy efficiency, digital integration, and regional expansion. Companies that invest in smart, sustainable, and adaptable ventilation solutions will be best positioned to capture growth in both new installations and retrofit markets. As industries evolve, so too will the technologies that keep their paint operations safe, clean, and efficient.

Common Pitfalls When Sourcing Paint Booth Exhaust Fans (Quality, IP)

Sourcing paint booth exhaust fans requires careful attention to both quality and Ingress Protection (IP) ratings to ensure safety, efficiency, and compliance. Overlooking key factors can lead to costly failures, downtime, or hazardous conditions. Below are common pitfalls to avoid:

Underestimating the Importance of IP Rating

One of the most frequent mistakes is selecting a fan with an inadequate IP rating for the harsh environment of a paint booth. These areas are exposed to overspray, solvents, high humidity, and dust. Fans with low IP ratings (e.g., IP54 or lower) may allow particulate and moisture ingress, leading to motor failure, corrosion, and fire hazards. Always specify fans with a minimum IP55 rating, and consider IP65 or higher for wash-down areas or high-exposure zones to ensure complete protection against dust and water jets.

Prioritizing Cost Over Build Quality

Choosing the lowest-cost option often results in poor long-term performance. Low-quality fans may use thin-gauge steel, inferior motors, or substandard bearings that degrade quickly under continuous operation and chemical exposure. This leads to frequent maintenance, energy inefficiency, and potential downtime. Invest in fans constructed from heavy-duty, corrosion-resistant materials such as galvanized steel or stainless steel, and ensure motors are thermally protected and designed for 24/7 operation.

Ignoring Spark-Resistant Construction Requirements

Paint booths handle flammable vapors, making spark-resistant design critical. Standard fans can generate sparks through metal impeller contact or static buildup, posing explosion risks. A common pitfall is sourcing non-compliant fans that lack Class I, Division 1 or 2 certifications or fail to meet NFPA 33 standards. Always select fans with non-sparking components (e.g., aluminum or bronze impellers), grounded housings, and anti-static features to mitigate ignition risks.

Overlooking Proper Airflow and Static Pressure Specifications

Fans undersized for the booth’s airflow (CFM) or static pressure requirements will fail to remove contaminants effectively, leading to poor finish quality and health hazards. Conversely, oversized fans waste energy and increase noise. Avoid generic assumptions—perform accurate calculations based on booth size, filter resistance, duct length, and regulatory requirements (e.g., OSHA or local codes). Partner with suppliers who provide performance-certified fans with detailed airflow curves.

Failing to Verify Compliance with Industry Standards

Not all fans marketed for paint booths meet required safety and performance standards. Some suppliers may misrepresent certifications. Always confirm that the fan complies with NFPA 33, UL 705, ATEX (if applicable), and AMCA 210 for airflow testing. Request documentation and ensure third-party testing has been conducted.

Neglecting Maintenance Accessibility and Service Support

Poorly designed fans can be difficult to access for cleaning or repair, increasing downtime and labor costs. Avoid fans with inaccessible motors or complex disassembly requirements. Choose models designed for easy maintenance, with removable access panels and serviceable components. Additionally, verify that the supplier offers local technical support and spare parts availability to minimize operational disruptions.

By addressing these common pitfalls—particularly around IP rating accuracy and build quality—buyers can ensure reliable, safe, and compliant ventilation for their paint booth operations.

Logistics & Compliance Guide for Paint Booth Exhaust Fans

Overview and Purpose

This guide outlines key logistics considerations and compliance requirements for the procurement, transportation, installation, and operation of paint booth exhaust fans. These systems are critical for maintaining air quality, worker safety, and regulatory compliance in industrial and automotive painting environments. Adhering to proper logistics and compliance protocols ensures operational efficiency, safety, and legal adherence.

Regulatory Compliance

Paint booth exhaust fans must meet several federal, state, and local regulations to ensure safe and legal operation. Key compliance standards include:

- OSHA (Occupational Safety and Health Administration)

- 29 CFR 1910.94 – Ventilation standards for health protection in spray finishing operations.

-

Requires adequate exhaust airflow to control flammable vapors and airborne contaminants.

-

NFPA (National Fire Protection Association)

- NFPA 33 – Standard for Spray Application Using Flammable and Combustible Materials.

-

Mandates explosion-proof motors, spark-resistant construction, and proper ducting to prevent fire hazards.

-

EPA (Environmental Protection Agency)

- National Emission Standards for Hazardous Air Pollutants (NESHAP), particularly 40 CFR Part 63, Subpart HHHHHH.

- Regulates VOC (Volatile Organic Compound) emissions from paint operations.

-

May require filtration (e.g., carbon adsorption or oxidizers) in conjunction with exhaust systems.

-

UL/CSA Certification

- Fans must carry UL 705 (Air-Cooling and Air-Cleaning Equipment) or CSA C22.2 No. 113 certification for safety and performance.

-

Explosion-proof (Class I, Division 1 or 2) ratings may be required depending on booth classification.

-

Local Building and Fire Codes

- Compliance with municipal fire department regulations and permitting requirements for exhaust discharge location and duct routing.

Transportation and Logistics

Efficient and safe handling of paint booth exhaust fans during shipping and delivery is essential due to their size, weight, and sensitivity.

- Packaging and Handling

- Units must be securely crated with protective padding to prevent damage to motors, blades, and housings.

-

Forklift or crane points should be clearly marked; use appropriate lifting equipment during unloading.

-

Shipping Requirements

- Confirm dimensional and weight specifications with freight carriers; oversized shipments may require special permits.

- Use freight carriers experienced in industrial equipment transport.

-

Insure high-value or custom units during transit.

-

Storage Prior to Installation

- Store in a dry, indoor environment to prevent corrosion, especially for galvanized or aluminum components.

- Keep motors covered and protected from moisture and debris.

- Avoid stacking or placing heavy objects on fan crates.

Installation and Site Preparation

Proper installation ensures optimal performance and compliance with safety standards.

- Site Assessment

- Verify structural support capacity for rooftop or wall-mounted units.

-

Confirm electrical supply meets voltage, phase, and amperage requirements (typically 208–480V, 3-phase).

-

Ductwork and Discharge

- Ducts must be constructed from non-combustible materials (e.g., galvanized steel).

- Discharge point must be located away from air intakes, windows, and pedestrian areas per local codes.

-

Include spark arrestors and fire dampers as required by NFPA 33.

-

Electrical and Control Integration

- Wiring must comply with NEC (National Electrical Code), Article 511 – Spray Booths.

- Integrate fan controls with booth lighting and safety interlocks to prevent operation without ventilation.

Commissioning and Documentation

Before operational use, complete commissioning and maintain records for compliance audits.

- Performance Testing

- Conduct airflow tests (CFM) to ensure system meets design specifications.

-

Verify static pressure and fan speed alignment with manufacturer data.

-

Compliance Documentation

- Retain product certification labels (UL, CSA, NFPA compliance).

- Keep records of installation, testing, and maintenance.

- Submit required reports to environmental agencies if VOC control systems are in use.

Maintenance and Ongoing Compliance

Regular maintenance ensures long-term compliance and operational safety.

- Scheduled Inspections

- Monthly visual inspections for debris, corrosion, or belt wear.

-

Annual professional inspection and cleaning of fan blades, motors, and ducts.

-

Filter and Safety System Checks

- Replace or service filters (if applicable) per manufacturer guidelines.

-

Test explosion-proof features and emergency shutdown systems regularly.

-

Recordkeeping

- Log all maintenance, repairs, and performance tests.

- Update compliance documentation for facility audits or regulatory reviews.

Conclusion

Proper logistics and compliance management for paint booth exhaust fans are vital for safety, environmental responsibility, and legal operation. By adhering to OSHA, NFPA, EPA, and electrical standards, and following best practices in shipping, installation, and maintenance, facilities can ensure reliable ventilation performance and avoid regulatory penalties.

In conclusion, sourcing paint booth exhaust fans requires a careful evaluation of several key factors, including airflow capacity (CFM), static pressure performance, compliance with safety standards (such as UL, ATEX, or NFPA for explosion-resistant models), energy efficiency, durability, and ease of maintenance. It is essential to match the fan specifications to the specific requirements of the paint booth, including size, usage frequency, and the types of coatings being applied, to ensure optimal ventilation, operator safety, and regulatory compliance.

Sourcing from reputable suppliers with experience in industrial ventilation and paint booth systems can help ensure reliability and long-term performance. Additionally, considering total cost of ownership—factoring in energy consumption, maintenance needs, and warranty support—can lead to more cost-effective and sustainable decisions.

Ultimately, investing in a high-quality, properly sized exhaust fan system not only enhances air quality and worker safety but also contributes to superior finish quality and regulatory adherence, making it a critical component in any professional painting operation.