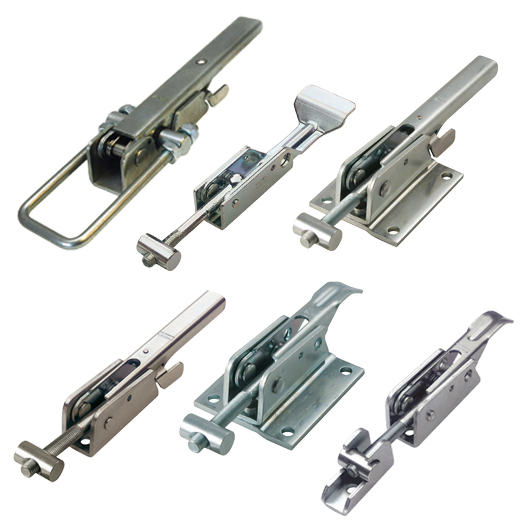

The global over center latches market is experiencing steady expansion, driven by increasing demand across automotive, industrial, and transportation sectors. According to a report by Mordor Intelligence, the global latches market is projected to grow at a CAGR of over 5.2% from 2023 to 2028, with over center latches representing a significant segment due to their reliability, compact design, and mechanical efficiency. Growth is further fueled by rising industrial automation, stringent safety standards, and the need for high-performance fastening solutions in commercial vehicles and heavy machinery. As demand escalates, innovation and manufacturing excellence have become critical differentiators. In this context, a select group of manufacturers has emerged as leaders, combining engineering precision, global supply capabilities, and a strong track record of quality. The following list highlights the top 7 over center latch manufacturers shaping the industry’s future through technology, scalability, and strategic market presence.

Top 7 Over Center Latches Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Latch Manufacturers

Domain Est. 2015

Website: latchmanufacturers.com

Key Highlights: We manufacture a large range of over centre fasteners often known as draw latches/toggle clamps/catches/over centre toggle fasteners. PROTEX $$$. Get Your ……

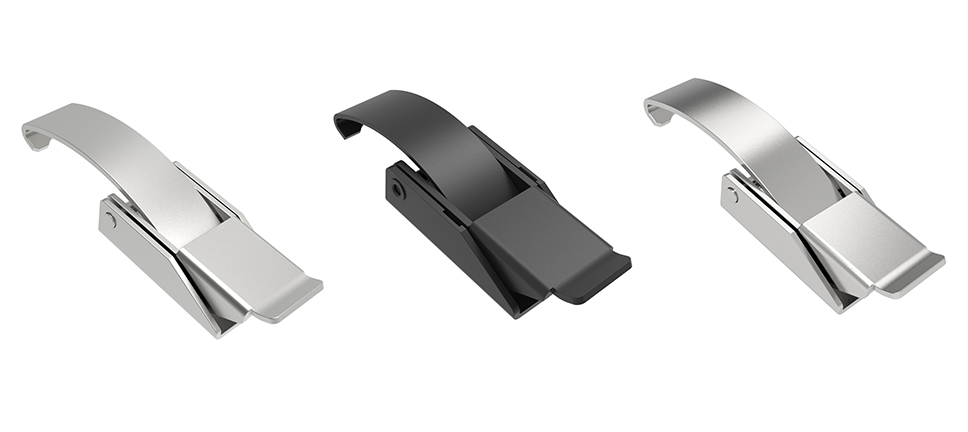

#2 97 – Over Center Series Latches

Domain Est. 1996

Website: southco.com

Key Highlights: 30-day returnsThe 97’s curved latching blade helps to absorb shock, vibration, or variations in mounting dimensions. Available in a range of sizes and materials….

#3 Over Center & Draw Latches

Domain Est. 1996

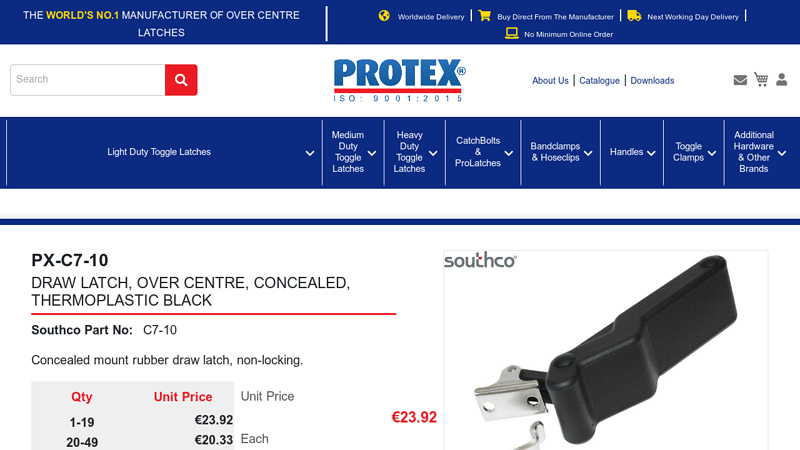

#4 Southco Draw Latch Over Centre Concealed Thermoplastic Black

Domain Est. 1996

#5 Over

Domain Est. 1997

Website: spep.com

Key Highlights: We make over center latches in stainless steel, die cast zinc and steel, with a range of finishes to coordinate with your product’s design, including ……

#6 Over center draw latches

Domain Est. 1998

Website: motioncontrol.metrol.com

Key Highlights: 14-day returnsAt Metrol Motion Control, we provide the highest-quality over-centre draw latches from the most durable materials and aesthetically pleasing finishes….

#7 Over Center Latches

Domain Est. 2003

Website: nielsenhardware.com

Key Highlights: Over Center Latches · Quick View. 12472-00. $41.26 Add to cart · Quick View. 13027-00. $119.14 Add to cart · Quick View. 13000-50 · Quick View. 13000-00 · Quick View ……

Expert Sourcing Insights for Over Center Latches

2026 Market Trends for Over Center Latches

The global market for over center latches is poised for notable evolution by 2026, driven by advancements in industrial design, growing demand across key end-use sectors, and an increasing focus on safety and ergonomics. As a critical component in closures for enclosures, doors, and panels, over center latches—known for their robust locking mechanism and reliability—are witnessing shifts in demand patterns, material innovation, and regional market dynamics.

Rising Demand in Transportation and Industrial Equipment

One of the most significant drivers shaping the 2026 outlook is the sustained growth in the transportation sector, including commercial vehicles, rail, and off-highway machinery. Over center latches are widely used in truck compartments, bus doors, and railcar access panels due to their ability to maintain a secure seal under vibration and dynamic stress. As global infrastructure investment increases—especially in emerging economies—the demand for durable latching solutions is expected to rise. Additionally, the trend toward electrification in vehicles is prompting redesigns of enclosures for battery packs and control units, creating new opportunities for specialized over center latches with enhanced environmental sealing and corrosion resistance.

Expansion in Renewable Energy and Utility Applications

The renewable energy sector, particularly in solar and wind power installations, is emerging as a high-growth application area. Over center latches are increasingly specified for access hatches, control cabinets, and switchgear enclosures in outdoor and harsh environments. By 2026, rising investments in smart grids and distributed energy systems are expected to boost demand for latches that offer quick access, tamper resistance, and long service life with minimal maintenance. This trend is further amplified by global push for energy resilience, prompting utility companies to upgrade aging infrastructure with modern, secure enclosures.

Material and Design Innovation

Material innovation is a key trend influencing product development. Manufacturers are increasingly adopting lightweight yet durable materials such as glass-filled nylon, marine-grade stainless steel, and corrosion-resistant aluminum alloys. These materials enhance performance in extreme temperatures and corrosive environments—critical for applications in marine, oil & gas, and outdoor telecom. Additionally, ergonomic design improvements, such as lever handles with reduced actuation force and visual or tactile feedback mechanisms, are becoming standard, improving user experience and safety compliance.

Regional Market Dynamics

Regionally, Asia-Pacific is anticipated to lead market growth by 2026, fueled by industrialization in India, Southeast Asia, and China. Local manufacturing expansion, coupled with government initiatives promoting domestic production of industrial and transportation equipment, is increasing the adoption of high-performance latching systems. North America and Europe will maintain steady growth, driven by stringent safety regulations, retrofitting of industrial facilities, and demand for high-reliability components in defense and aerospace applications.

Growth in Smart and Integrated Latching Solutions

A transformative trend on the horizon is the integration of smart technologies into mechanical latches. By 2026, the market is expected to see increased adoption of over center latches with embedded sensors for position monitoring, access control, and predictive maintenance. These “smart latches” can interface with IoT platforms, enabling remote monitoring of enclosure integrity—a valuable feature for data centers, telecom shelters, and critical infrastructure. While still a niche segment, the convergence of mechanical reliability with digital connectivity is set to redefine product offerings.

Conclusion

The 2026 market for over center latches reflects a convergence of traditional mechanical reliability and modern technological demands. Growth will be sustained by expanding applications in transportation, renewable energy, and industrial automation, while innovation in materials and smart functionality will differentiate leading suppliers. As industries prioritize safety, efficiency, and digital integration, over center latches will remain a vital component—evolving to meet the performance expectations of a connected and resilient global infrastructure.

Common Pitfalls Sourcing Over Center Latches (Quality, IP)

When sourcing over center latches—mechanical fasteners widely used in enclosures, doors, and panels—buyers often encounter challenges related to quality inconsistencies and intellectual property (IP) risks. Being aware of these pitfalls can help ensure reliable performance and legal compliance.

Poor Material and Build Quality

One of the most frequent issues is receiving latches made from substandard materials. Low-cost suppliers may use inferior-grade zinc alloys, weak springs, or thin plating, leading to premature wear, corrosion, or failure under load. This compromises the latch’s over center mechanism, which relies on precise tolerances and durable components to maintain secure locking.

Inconsistent Performance and Tolerance Drift

Over center latches depend on exact engineering tolerances to function correctly—engaging smoothly and holding securely. Poorly manufactured units often suffer from inconsistent spring tension, misaligned cams, or variable handle resistance. These inconsistencies can lead to unreliable closure, user frustration, or safety hazards in critical applications.

Misrepresentation of Ingress Protection (IP) Ratings

Many over center latches are marketed with specific IP ratings (e.g., IP65, IP67) indicating dust and water resistance. However, it’s common for suppliers—especially generic or third-party manufacturers—to falsely claim compliance without proper testing or certification. The actual sealing performance may fall short due to poor gasket materials, inadequate housing design, or lack of proper ingress testing.

Lack of Traceable Certifications

Reputable applications (e.g., in marine, military, or outdoor electronics) require latches with verifiable certifications. Sourcing from suppliers who cannot provide test reports, material certifications (e.g., RoHS, REACH), or IP validation increases the risk of non-compliance and field failures.

Intellectual Property (IP) Infringement

Many well-known over center latch designs (e.g., Southco, Camloc, Bulldog) are protected by patents, trademarks, or design rights. Sourcing “compatible” or “generic” versions from unauthorized manufacturers can lead to legal exposure. Even if a latch appears functionally similar, it may infringe on protected mechanisms or aesthetic designs, resulting in shipment seizures, fines, or litigation.

Inadequate Documentation and Support

Low-cost suppliers often lack detailed technical documentation, installation guidelines, or performance data. This makes integration into end products more difficult and increases engineering risk. Additionally, poor after-sales support limits the ability to troubleshoot issues or obtain replacements consistently.

Supply Chain and Long-Term Availability Risks

Generic or copycat latches may be discontinued without notice, leading to supply chain disruptions. Unlike OEM manufacturers who offer long-term product availability and lifecycle management, counterfeit or unbranded suppliers rarely provide such stability.

By addressing these quality and IP concerns proactively—through supplier vetting, sample testing, and legal due diligence—businesses can mitigate risks and ensure the reliability and compliance of over center latches in their applications.

Logistics & Compliance Guide for Over Center Latches

Over center latches are essential mechanical fasteners widely used in industrial, transportation, and equipment applications. Ensuring proper logistics handling and compliance with applicable standards is critical for safety, performance, and regulatory adherence. This guide outlines key considerations for shipping, storage, documentation, and regulatory requirements related to over center latches.

Packaging and Shipping Requirements

Proper packaging ensures that over center latches arrive at their destination in optimal condition. Follow these guidelines:

- Protective Packaging: Use moisture-resistant and shock-absorbent materials (e.g., bubble wrap, foam inserts, or corrugated dividers) to prevent surface damage or deformation during transit.

- Labeling: Clearly label packages with product identifiers, quantities, part numbers, and handling instructions (e.g., “Fragile,” “Do Not Stack”).

- Unit Load Stability: Securely palletize bulk shipments. Use stretch wrap or strapping to prevent shifting during transport.

- Hazardous Materials (if applicable): Most over center latches are non-hazardous, but if coated with certain chemical treatments (e.g., specific anti-corrosion coatings), verify compliance with IATA, IMDG, or DOT regulations.

Storage Conditions

To maintain product integrity, store over center latches under controlled conditions:

- Environment: Store indoors in a dry, temperature-controlled environment. Avoid exposure to humidity, direct sunlight, and corrosive atmospheres.

- Shelving: Use non-reactive shelving (e.g., powder-coated metal or plastic) to prevent galvanic corrosion.

- Inventory Rotation: Implement a first-in, first-out (FIFO) system to reduce the risk of material degradation over time.

Regulatory and Compliance Standards

Over center latches must comply with relevant industry and regional regulations depending on application and destination:

- Material Compliance:

- RoHS (EU): Ensure latches do not contain restricted substances (e.g., lead, cadmium, mercury) above allowable limits.

- REACH (EU): Confirm registration and communication of Substances of Very High Concern (SVHC).

-

Proposition 65 (California, USA): Provide warnings if components contain listed carcinogens or reproductive toxicants.

-

Safety and Performance Standards:

- ISO 9001: Adhere to quality management systems for manufacturing consistency.

- ANSI/ASME Standards: Comply with dimensional and performance standards where applicable.

-

ATEX (EU): If used in explosive atmospheres, ensure compliance with ATEX directives for mechanical equipment.

-

Export Controls:

- Verify if latches contain materials or technologies subject to export restrictions (e.g., ITAR, EAR). Most standard latches are EAR99, but confirm based on composition and end-use.

Documentation and Traceability

Maintain thorough documentation to support compliance and traceability:

- Certificate of Conformance (CoC): Provide with each shipment, verifying compliance with specifications and standards.

- Material Test Reports (MTRs): Include when required, especially for latches used in safety-critical applications.

- Bill of Materials (BOM): Maintain internal records detailing raw materials and coatings for regulatory audits.

- Customs Documentation: Accurately classify products using HS codes (e.g., 8302.41 or 8302.49 for iron/steel latches) and provide commercial invoices, packing lists, and origin declarations.

Industry-Specific Considerations

- Transportation (Truck, Rail, Marine): Ensure latches meet vibration and load retention standards (e.g., FMVSS, AAR, or DNV-GL for maritime applications).

- Defense and Aerospace: May require DFARS compliance, specialty certifications (e.g., NASM), and traceable lot control.

- Medical and Food Equipment: Use stainless steel or non-toxic coated latches compliant with FDA or NSF standards.

Conclusion

Effective logistics and compliance management for over center latches ensures product reliability and legal adherence across global supply chains. By following proper packaging, storage, documentation, and regulatory practices, manufacturers and distributors can minimize risk and enhance customer confidence. Always consult the end-use application and regional regulations to determine specific compliance obligations.

Conclusion on Sourcing Over-Center Latches

Sourcing over-center latches requires a strategic approach that balances quality, cost, durability, and application-specific requirements. These latches are essential in numerous industries—including automotive, marine, industrial enclosures, and transportation—due to their positive locking mechanism, ease of use, and reliability under vibration and dynamic loads.

When sourcing over-center latches, it is crucial to evaluate material composition (such as stainless steel, aluminum, or engineered polymers), corrosion resistance, load capacity, environmental suitability, and compliance with relevant industry standards. Suppliers should be assessed not only on price but also on consistency, lead times, technical support, and customization capabilities.

Global sourcing offers competitive pricing and a wide range of options, especially from manufacturers in Asia and Europe; however, it may introduce challenges related to logistics, communication, and quality control. Partnering with reputable suppliers, conducting sample testing, and implementing a robust quality assurance process can mitigate these risks.

In conclusion, successful sourcing of over-center latches involves a thorough understanding of technical specifications, a clear assessment of supplier reliability, and a focus on long-term performance and total cost of ownership. By prioritizing these factors, organizations can ensure reliable, efficient, and cost-effective procurement of over-center latches that meet both operational and safety requirements.