The global market for electrical components used in home appliances, particularly ovens, has seen steady expansion driven by rising demand for energy-efficient and smart kitchen appliances. According to Grand View Research, the global home appliances market was valued at USD 238.0 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2023 to 2030. A critical yet often overlooked component in this ecosystem is oven electrical wiring, which must meet stringent safety, heat resistance, and durability standards. With increasing production of electric ovens across residential and commercial sectors, the demand for high-performance wiring solutions has surged. This growing need has positioned specialized manufacturers at the forefront of innovation and reliability. Based on industry benchmarks, certifications, and market presence, the following nine manufacturers have emerged as leaders in producing oven electrical wires, combining technical excellence with scalability to support the evolving appliance industry.

Top 9 Oven Electrical Wire Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Rea Magnet Wire Company Inc.

Domain Est. 1995

Website: reawire.com

Key Highlights: At Rea Magnet Wire, we deliver reliable magnet wire solutions that power your business, from industrial applications to consumer products….

#2 Hubbell Wiring Device

Domain Est. 1995

Website: hubbell.com

Key Highlights: Hubbell Wiring Device-Kellems is the leading manufacturer for all wiring devices and receptacles, Kellems cable grips, floor boxes, and more for all ……

#3 OMERIN French manufacturer of high temperature cables

Domain Est. 1997

Website: omerin.com

Key Highlights: Design and manufacture of specialised high temperature electrical wires, cables and braided sleevings for extreme operating conditions….

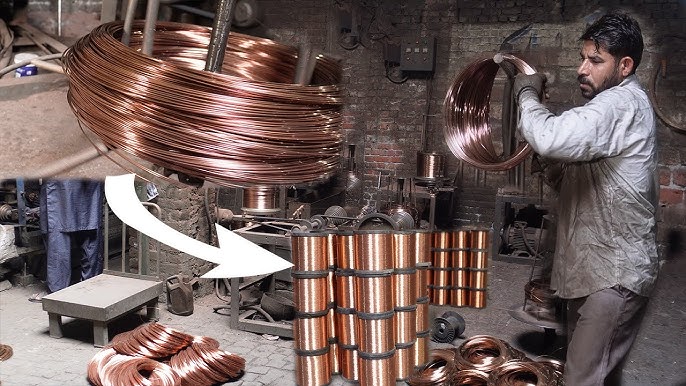

#4 U.S.-Based Copper Wire Manufacturer

Domain Est. 2000

Website: kristechwire.com

Key Highlights: When your project comes down to the wire, Kris-Tech is there with industry-best lead times and responses in less 30 minutes….

#5 Prysmian

Domain Est. 2005

Website: prysmian.com

Key Highlights: Welcome to Prysmian: the world leader in cable manufacturer, energy solutions, telecom cables and systems industry. Find out more!…

#6 Electronic Wire & Cable

Domain Est. 1997

Website: belden.com

Key Highlights: Belden cables are designed to provide reliable communication between corporate headquarters and the plant, management and staff, and everywhere in between….

#7 Elliott Electric Supply Company

Domain Est. 1997

Website: elliottelectric.com

Key Highlights: We specialize in custom cuts of building wire and electronic cable, like Romex, Seal-Tite, Flex, MC cabling and other electrical cords. Get great deals on power ……

#8 Remington Industries

Domain Est. 2000

Website: remingtonindustries.com

Key Highlights: Remington Industries is a trusted wire distributor. Trust us for electrical wire, raw metals, wire processing, coil winding, and 3D printing. Shop now….

#9 Bahra Electric

Domain Est. 2015

Website: bahra-electric.com

Key Highlights: Leading quality electrical equipment manufacturing in the Middle East and exporting our KSA brand globally for unparalleled recognition….

Expert Sourcing Insights for Oven Electrical Wire

H2: 2026 Market Trends for Oven Electrical Wire

The global market for oven electrical wire is poised for steady growth and transformation by 2026, driven by advancements in home appliance technology, increasing demand for energy-efficient and smart kitchen appliances, and evolving safety standards. This analysis explores key trends shaping the oven electrical wire sector in the coming years.

-

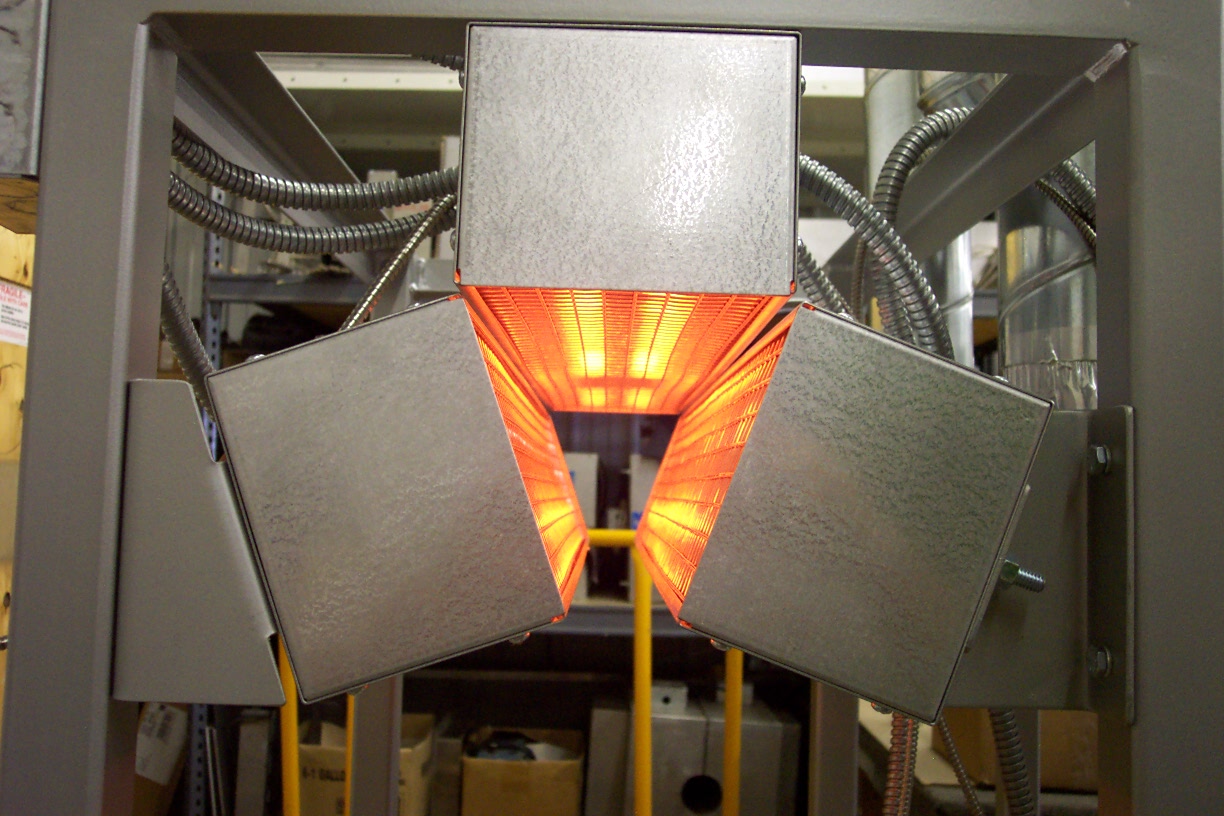

Rising Demand for High-Temperature Resistant Materials

As ovens—especially convection and induction models—operate at increasingly higher temperatures, there is a growing need for electrical wires capable of withstanding extreme heat. By 2026, manufacturers are expected to prioritize materials such as silicone rubber, fiberglass insulation, and PTFE (Teflon) coatings, which offer superior thermal resistance (up to 200°C or more). These materials enhance safety and longevity, aligning with consumer expectations for durable, low-maintenance appliances. -

Expansion of Smart Oven Adoption

The proliferation of smart ovens equipped with Wi-Fi connectivity, automated cooking programs, and remote control via mobile apps is driving demand for specialized electrical wiring that supports integrated circuitry and sensors. Oven electrical wires in 2026 will need to accommodate not only power transmission but also data signaling, requiring enhanced electromagnetic interference (EMI) shielding and miniaturization. This trend is particularly strong in North America and Western Europe, where smart home adoption rates are high. -

Stricter Global Safety and Regulatory Standards

Regulatory bodies such as UL (Underwriters Laboratories), IEC (International Electrotechnical Commission), and RoHS (Restriction of Hazardous Substances) continue to tighten safety and environmental standards. By 2026, oven electrical wires are expected to be predominantly halogen-free, flame-retardant, and low-smoke emitting to reduce fire hazards. Compliance with these standards will become a competitive necessity, especially in regulated markets like the EU and Japan. -

Growth in Emerging Markets

Rising disposable incomes and urbanization in regions such as Southeast Asia, Latin America, and Africa are fueling demand for modern kitchen appliances, including electric ovens. As local appliance manufacturing expands in countries like India, Vietnam, and Mexico, the demand for cost-effective yet reliable oven electrical wire will grow. This presents opportunities for wire producers to scale production with region-specific solutions that balance performance and affordability. -

Sustainability and Circular Economy Initiatives

Environmental concerns are influencing material choices and manufacturing practices. By 2026, there will be increased emphasis on recyclable insulation materials and reduced use of PVC due to its environmental impact. Manufacturers are exploring bio-based polymers and recyclable copper alternatives to align with sustainability goals. OEMs may also demand traceability and greener supply chains, pushing wire suppliers toward eco-certifications and transparent sourcing. -

Supply Chain Resilience and Localization

Post-pandemic disruptions and geopolitical tensions have prompted appliance manufacturers to diversify and localize supply chains. By 2026, regional production of oven electrical wire is expected to increase, especially in North America and Europe, to reduce dependency on single-source suppliers. This shift will favor domestic wire manufacturers who can offer just-in-time delivery and customized solutions.

Conclusion

The oven electrical wire market in 2026 will be shaped by technological innovation, regulatory compliance, and sustainability imperatives. Key players must adapt by investing in R&D for high-performance materials, complying with global standards, and aligning with the growing smart and eco-conscious appliance markets. Companies that integrate agility, quality, and environmental responsibility into their operations are likely to lead the evolving landscape.

Common Pitfalls When Sourcing Oven Electrical Wire (Quality, IP)

Sourcing the right electrical wire for oven applications is critical for safety, performance, and compliance. Overlooking key factors—particularly quality and Ingress Protection (IP) ratings—can lead to serious risks. Below are common pitfalls to avoid:

Poor Quality Materials and Construction

Using substandard conductors, insulation, or jacketing materials can drastically reduce wire reliability in high-temperature environments. Low-quality oven wires may use impure copper or inadequate heat-resistant insulation (e.g., PVC instead of silicone or fiberglass), leading to premature degradation, short circuits, or fire hazards. Always verify compliance with relevant standards (e.g., UL, IEC, or EN) and insist on certified materials rated for continuous oven temperatures (often 150°C to 200°C+).

Incorrect or Missing IP Rating for the Environment

The Ingress Protection (IP) rating must match the oven’s operating environment. A common mistake is selecting wire without adequate dust or moisture resistance (e.g., using IP20-rated wire in a high-humidity or washdown area). For commercial or industrial ovens, wires may need at least IP65 or higher to prevent contamination and electrical faults. Ignoring IP requirements increases the risk of corrosion, insulation failure, and safety incidents.

Misunderstanding Temperature Ratings

Many sourced wires claim high temperature tolerance but fail under sustained oven conditions. Ensure the wire’s temperature rating exceeds the oven’s maximum operating temperature, including hotspots near heating elements. Confusing short-term peak ratings with continuous-use ratings is a frequent error that compromises long-term safety.

Lack of Flame Retardancy and Safety Certifications

Oven environments demand flame-retardant and low-smoke materials. Sourcing wires without proper certifications (e.g., UL 1063, UL 1426, or IEC 60754) can violate safety codes and insurance requirements. Always request test reports and verify third-party certifications to confirm fire resistance and toxic emission levels.

Inadequate Mechanical Durability

Oven wires are subject to vibration, flexing, and abrasion during installation and use. Thin or non-reinforced jackets may crack or wear prematurely. Avoid wires lacking mechanical robustness—opt for braided or armored variants where needed, especially in industrial settings with moving parts or frequent maintenance.

Cost-Driven Compromises

Prioritizing low cost over performance often leads to sourcing inferior wire that fails early or creates hazards. While budget is important, cutting corners on such a critical component risks equipment damage, downtime, and liability. Invest in high-quality, purpose-built oven wire to ensure longevity and compliance.

Logistics & Compliance Guide for Oven Electrical Wire

This guide outlines key considerations for the safe and compliant transportation, storage, handling, and regulatory adherence of electrical wiring components used in ovens. Proper logistics and compliance are essential to ensure product integrity, worker safety, and regulatory approval.

Regulatory Compliance

Ensure all oven electrical wire products meet the following standards and regulations:

- Electrical Safety Standards: Confirm compliance with IEC 60227 (PVC-insulated cables) and IEC 60245 (rubber-insulated cables), or regional equivalents such as UL 62 (USA) and CSA C22.2 No. 49 (Canada).

- Temperature Resistance: Verify wire is rated for high-temperature environments (typically ≥90°C, often up to 105°C or higher) as required for oven applications.

- Flame Retardancy and Smoke Emission: Comply with flame resistance standards such as IEC 60332-1 and low smoke zero halogen (LSZH) requirements where applicable.

- RoHS and REACH Compliance: Ensure materials are free from restricted substances (e.g., lead, cadmium, phthalates) per EU directives.

- Country-Specific Approvals: Obtain certifications such as UL, CSA, CE, or UKCA as required by the destination market.

Packaging Requirements

Proper packaging safeguards wire integrity during transit and storage:

- Use moisture-resistant, sealed packaging (e.g., polyethylene wraps or vacuum sealing) to prevent insulation degradation.

- Spool or coil wires securely to prevent kinking, tangling, or abrasion.

- Label packaging clearly with product specifications, voltage rating, temperature class, compliance marks, and handling instructions (e.g., “Keep Dry,” “Do Not Crush”).

- Include lot numbers and traceability information for quality control and recalls.

Storage Conditions

Store oven electrical wire under controlled conditions to maintain performance:

- Temperature: Store between 5°C and 35°C; avoid exposure to extreme heat or freezing temperatures.

- Humidity: Maintain relative humidity below 70% to prevent moisture absorption in insulation.

- Light Exposure: Protect from direct sunlight and UV radiation, which can degrade insulation materials.

- Ventilation: Ensure adequate airflow to prevent condensation and chemical buildup.

- Shelving: Store on elevated pallets or racks; avoid direct contact with concrete floors.

Transportation Guidelines

Follow best practices during shipping to prevent damage:

- Protect spools from mechanical stress, impact, and compression during loading and transit.

- Use weatherproof containers or covered vehicles for shipments exposed to outdoor conditions.

- Avoid sharp bends or twisting of wire during handling; use appropriate lifting equipment for large reels.

- Segregate from hazardous materials (e.g., chemicals, oils) that could compromise insulation.

Handling Procedures

Train personnel on safe handling techniques:

- Use proper PPE (gloves, safety glasses) when unloading or installing wire.

- Avoid dragging or dropping reels, which may deform wire or damage insulation.

- Use cable dispensers or payout stands to unwind wire smoothly and prevent kinks.

- Inspect wire for cuts, abrasions, or deformities before use.

Documentation & Traceability

Maintain comprehensive records for compliance and quality assurance:

- Keep certificates of conformity, test reports, and material declarations on file.

- Track batch/lot numbers throughout the supply chain for traceability.

- Provide safety data sheets (SDS) for insulation and jacketing materials upon request.

Disposal & Environmental Responsibility

Dispose of defective or unused wire in accordance with local environmental regulations:

- Recycle copper conductors and compatible insulation materials where facilities exist.

- Follow hazardous waste protocols if wire contains restricted substances.

- Partner with certified e-waste recyclers to ensure responsible end-of-life management.

Adhering to this guide ensures that oven electrical wire is handled safely and meets all technical and regulatory requirements from manufacturer to end-user.

In conclusion, sourcing the appropriate electrical wire for an oven requires careful consideration of several key factors, including temperature rating, insulation type, gauge (wire size), compliance with local electrical codes (such as NEC in the U.S.), and the specific requirements of the oven manufacturer. High-temperature wires such as NM-B, THHN/THWN, or specialized appliance wires like FT1 or H05VV-F are commonly used, depending on the installation environment and regional standards.

It is essential to ensure that the selected wire can safely handle the oven’s voltage and current load to prevent overheating, fire hazards, or equipment damage. Consulting a qualified electrician and adhering to national and local electrical codes not only ensures safety but also guarantees compliance for inspection and insurance purposes.

Ultimately, sourcing the correct oven electrical wire involves balancing safety, performance, and regulatory requirements to ensure a reliable and long-lasting electrical connection.