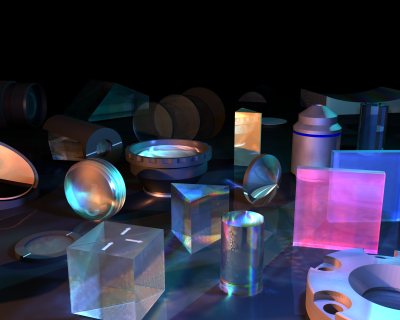

The global optical components market is experiencing robust growth, driven by escalating demand for high-speed data transmission, expanding fiber optic networks, and advancements in telecommunications, healthcare, and defense technologies. According to a report by Mordor Intelligence, the optical components market was valued at USD 43.5 billion in 2023 and is projected to reach USD 67.8 billion by 2029, growing at a CAGR of approximately 7.6% during the forecast period. This expansion is fueled by the proliferation of 5G infrastructure, cloud computing, and data center interconnects, all of which rely heavily on high-performance optical components. As innovation accelerates and global connectivity demands intensify, a select group of manufacturers are leading the charge in technological development, scalability, and market reach. Below are the top 10 optical components manufacturers shaping the future of photonic technologies.

Top 10 Optical Components Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Edmund Optics: Optics Manufacturer & Supplier

Domain Est. 1999

Website: edmundoptics.com

Key Highlights: Edmund Optics has been a leading producer of optics, imaging, and laser optics for 80 years. Discover the latest optical and imaging technology….

#2 Optical Components

Domain Est. 1994 | Founded: 1970

Website: zygo.com

Key Highlights: ZYGO Corporation was founded in 1970 by Paul Forman, Sol Laufer, and Carl Zanoni with the vision to become the premier manufacturer of plano optical components….

#3 Rochester Precision Optics

Domain Est. 2005

Website: rpoptics.com

Key Highlights: Rochester Precision Optics is globally-recognized as the premier manufacturer of precision optics for night vision applications….

#4 MEETOPTICS: Find & Compare Optics

Domain Est. 2018

Website: meetoptics.com

Key Highlights: Search for and compare optical components from manufacturers around the world, or for custom jobs we’ll match you with an industry expert service provider….

#5 OZ Optics Ltd.

Domain Est. 1995 | Founded: 1985

Website: ozoptics.com

Key Highlights: Located in Canada’s capital city of Ottawa and established in 1985, OZ Optics Limited is a leading worldwide supplier of fiber optic products for existing ……

#6 Laser Components

Domain Est. 1997

Website: lasercomponents.com

Key Highlights: We manufacture our components for the photonics industry at various locations in Germany, Canada, and the US. Laser optics; Pulsed laser diodes; Avalanche ……

#7 Optical Components

Domain Est. 2008

Website: eksmaoptics.com

Key Highlights: EKSMA Optics offers a wide range of optical components including mirrors, lenses, laser windows, optical filters, prisms, polarizing optics, UV & IR Optics….

#8 IDEX Optical Technologies

Domain Est. 2020

Website: idexot.com

Key Highlights: At CVI Laser Optics, we specialize in the design and manufacture of high performance optical components for use in lasers, laser beam conditioning, and ……

#9 TRIOPTICS

Domain Est. 2024

Website: trioptics.us

Key Highlights: We offer optical measurement and manufacturing systems for quality control and assembly of lenses, lens systems, camera modules….

#10 Optics supplier for optical components

Website: sinoptix.eu

Key Highlights: Sinoptix is a optical component supplier specialized in manufacturing optical lens, windows & glass. Discover our custom micro & precision optics solutions ……

Expert Sourcing Insights for Optical Components

H2: Optical Components Market Trends in 2026

By 2026, the optical components market is poised for significant transformation, driven by escalating data demands, technological innovation, and evolving infrastructure needs. Key trends shaping the industry include:

1. Explosive Growth in Coherent Optics Adoption

Coherent optical components will dominate long-haul, metro, and increasingly data center interconnect (DCI) applications. The shift toward 800G and emerging 1.6T coherent transceivers will be fueled by hyperscalers and telecom operators seeking higher bandwidth efficiency over existing fiber. Integrated coherent optics (ICO) and pluggable coherent modules (e.g., 400ZR, 800ZR) will reduce power consumption and space requirements, accelerating deployment.

2. Silicon Photonics (SiPh) Scaling and Mainstream Integration

Silicon photonics will move from niche to mainstream, particularly in data centers. By 2026, SiPh-based transceivers (especially for 800G and 1.6T) will achieve greater cost efficiency and scalability. Foundries will enhance manufacturing yields, enabling broader adoption. Integration with electronic ASICs via co-packaged optics (CPO) will gain traction, reducing latency and power in AI/ML clusters and high-performance computing (HPC) environments.

3. Demand Surge from AI and Hyperscale Data Centers

The proliferation of AI workloads will drive unprecedented demand for high-speed optical interconnects within and between data centers. Optical components enabling low-latency, high-bandwidth communication—such as active optical cables (AACs), optical engines, and advanced multiplexers—will see robust growth. AI clusters will increasingly rely on optics to support distributed training and inference across thousands of GPUs.

4. Expansion of 5G and Fiber-to-the-Home (FTTH) Infrastructure

Global rollout of 5G mid- and high-band networks will require dense fiber backhaul, boosting demand for passive optical components (e.g., splitters, WDM filters) and active elements (e.g., tunable lasers, photodetectors). Simultaneously, government broadband initiatives will accelerate FTTH deployments in emerging and developed markets, increasing volume for PON (Passive Optical Network) components.

5. Advancements in Photonic Integration and Heterogeneous Packaging

Multi-chip and heterogeneous integration techniques will enable more compact, power-efficient optical modules. Integration of III-V materials (e.g., InP) with silicon platforms will optimize laser and amplifier performance. This trend will support miniaturization and cost reduction, critical for consumer and edge applications.

6. Sustainability and Energy Efficiency as Key Drivers

As data traffic grows, energy consumption becomes a critical concern. Optical component manufacturers will prioritize low-power designs, aligning with ESG goals. Innovations in thermal management, modulation efficiency (e.g., PAM4, DMT), and component longevity will be essential selling points.

7. Supply Chain Resilience and Geopolitical Realignment

Ongoing supply chain diversification efforts will continue, with increased regional manufacturing (e.g., in India, Southeast Asia, and the Americas) to reduce dependency on single sources. Trade policies and national security concerns will influence procurement strategies, particularly in defense and critical infrastructure sectors.

In summary, the 2026 optical components market will be defined by high-speed innovation, integration, and scalability—catalyzed by AI, 5G, and global digitalization. Companies that invest in coherent technology, silicon photonics, and sustainable manufacturing will lead the next phase of optical connectivity.

Common Pitfalls Sourcing Optical Components (Quality, IP)

Sourcing optical components involves technical, quality, and legal complexities. Overlooking key aspects can lead to performance issues, project delays, and legal exposure. Below are common pitfalls related to quality and intellectual property (IP).

Inadequate Quality Control and Specifications

One of the most frequent issues is failing to define or verify component specifications rigorously. Optical components such as lenses, filters, mirrors, and lasers require tight tolerances in parameters like surface flatness, coating performance, transmission, wavefront distortion, and alignment.

Pitfall: Accepting vague or incomplete specifications from suppliers, or not verifying compliance through independent testing. Some suppliers, especially low-cost offshore vendors, may provide components that meet only nominal specs on paper but fail under real-world conditions.

Mitigation: Require detailed test reports (e.g., interferometry data, spectral transmission curves), conduct incoming inspections using metrology tools, and consider third-party validation for critical applications.

Lack of Traceability and Documentation

Optical systems used in defense, medical, or aerospace applications demand full traceability of materials, coatings, and manufacturing processes.

Pitfall: Procuring components without proper documentation (e.g., material certifications, coating deposition records, QA logs) can compromise regulatory compliance and make failure analysis difficult.

Mitigation: Enforce documentation requirements in procurement contracts and ensure suppliers adhere to industry standards (e.g., ISO 9001, AS9100).

Overlooking Intellectual Property Risks

Optical designs often incorporate proprietary technology, especially in areas like anti-reflective coatings, diffractive optics, or laser cavity designs.

Pitfall: Sourcing from vendors who may be using patented designs, trade secrets, or infringing on third-party IP—either knowingly or unknowingly. This exposes the buyer to legal liability even if they were unaware of the infringement.

Mitigation: Conduct IP due diligence on both the component and supplier. Include IP indemnification clauses in contracts and, when possible, work with trusted vendors who can certify freedom to operate.

Inconsistent or Unverified Coating Performance

Coatings (e.g., AR, HR, beam-splitter) are critical to optical performance and often a source of failure.

Pitfall: Assuming coating specs are consistent across batches without verification. Environmental durability (humidity, temperature cycling, abrasion) is often under-tested.

Mitigation: Require environmental stress testing reports and batch-specific spectral performance data. Perform sample testing under application-relevant conditions.

Supply Chain Transparency and Sub-Tier Sourcing

Many optical component suppliers outsource parts of the manufacturing process (e.g., polishing, coating) to sub-tier vendors.

Pitfall: Lack of visibility into sub-tier suppliers increases risk of quality inconsistencies and potential IP violations, especially if the final assembler does not control or audit these partners.

Mitigation: Require supply chain disclosure and audit rights, particularly for high-reliability applications.

Conclusion

To avoid these pitfalls, buyers should combine technical diligence with legal and supply chain scrutiny. Clear specifications, robust QA processes, thorough documentation, and proactive IP risk management are essential when sourcing optical components.

Logistics & Compliance Guide for Optical Components

Overview

Optical components—including lenses, mirrors, filters, prisms, and fiber optics—are critical in industries such as telecommunications, medical devices, defense, and aerospace. Due to their precision, sensitivity, and potential dual-use applications, shipping and handling these components require strict adherence to logistics best practices and international compliance regulations.

Packaging and Handling

- Protective Packaging: Use anti-static, shock-absorbent materials (e.g., foam inserts, padded enclosures) to prevent scratches, contamination, and mechanical damage.

- Cleanroom Packaging: For high-precision optics, package in cleanroom environments using lint-free materials to avoid particulate contamination.

- Labeling: Clearly label packages with “Fragile,” “This Side Up,” and “Protect from Moisture” indicators. Include handling instructions if components are temperature- or humidity-sensitive.

- Environmental Controls: Maintain stable temperature and humidity during storage and transit. Use climate-controlled containers when necessary.

Transportation Requirements

- Mode of Transport: Choose air freight for time-sensitive or high-value shipments; sea freight for bulk, non-urgent deliveries. Ground transport is suitable for domestic or regional deliveries.

- Tracking and Visibility: Use real-time GPS and RFID tracking to monitor shipment location and environmental conditions.

- Insurance: Ensure adequate insurance coverage for loss, damage, or delay, especially for high-value or custom-made components.

Export Controls and Compliance

- Dual-Use Regulations: Many optical components may be classified as “dual-use” under international frameworks such as the Wassenaar Arrangement. Verify whether your product falls under export control lists (e.g., ECCN in the U.S. Commerce Control List).

- Export Licenses: Obtain necessary export licenses or authorizations when shipping to restricted countries or for sensitive end-uses (e.g., military, surveillance).

- End-User Verification: Conduct due diligence on end-users and obtain End-User Statements (EUCs) when required by regulatory authorities.

Customs Documentation

- Commercial Invoice: Include detailed product descriptions, HS codes, value, quantity, and country of origin.

- Packing List: Provide a comprehensive list of contents, weights, and dimensions.

- Certificate of Origin: Required by some countries for tariff determination and trade agreement eligibility.

- Harmonized System (HS) Codes: Accurately classify optical components using appropriate HS codes (e.g., 9001 for optical fibers, 9004 for corrective lenses).

Regulatory Compliance

- ITAR/EAR (U.S.): Determine if components are subject to the International Traffic in Arms Regulations (ITAR) or Export Administration Regulations (EAR). ITAR applies to defense-related optics; EAR covers commercial and dual-use items.

- REACH & RoHS (EU): Ensure components comply with EU regulations on restricted hazardous substances (RoHS) and chemical safety (REACH).

- CE Marking: Required for optical products sold in the European Economic Area, indicating conformity with health, safety, and environmental standards.

Import Regulations

- Duties and Tariffs: Research applicable tariffs based on destination country and product classification.

- Import Licenses: Some countries require import permits for high-tech or sensitive optical equipment.

- Local Standards: Verify compliance with local technical standards and certification requirements (e.g., CCC in China, PSE in Japan).

Recordkeeping and Audits

- Documentation Retention: Maintain export records for a minimum of 5 years (or as required by jurisdiction) including licenses, invoices, and correspondence.

- Internal Audits: Conduct regular compliance audits to ensure adherence to export control policies and logistics protocols.

Risk Mitigation

- Supply Chain Security: Work with trusted logistics partners and monitor for counterfeit components.

- Incident Response Plan: Establish procedures for handling customs delays, damaged shipments, or compliance violations.

Conclusion

Effective logistics and compliance management for optical components require attention to detail, regulatory awareness, and collaboration across supply chain partners. By following this guide, organizations can ensure safe, timely delivery while maintaining compliance with global trade laws.

Conclusion for Sourcing Optical Components

Sourcing optical components requires a strategic approach that balances performance specifications, cost, quality, and supply chain reliability. As optical systems become increasingly integral to industries such as telecommunications, medical devices, defense, and advanced manufacturing, selecting the right suppliers is critical to ensuring product success and long-term viability.

Key considerations in the sourcing process include technical expertise, manufacturing capabilities, adherence to quality standards (such as ISO certifications), and the ability to support custom or volume requirements. Additionally, geographic location, lead times, and intellectual property protection play significant roles—especially in global supply chains vulnerable to disruptions.

Establishing strong partnerships with reputable suppliers, conducting thorough due diligence, and maintaining flexibility in the supply chain can mitigate risks and support innovation. Furthermore, leveraging vertical integration or dual sourcing strategies may enhance resilience and reduce dependency on single vendors.

In conclusion, successful sourcing of optical components hinges on a comprehensive evaluation of technical, operational, and strategic factors. By prioritizing quality, reliability, and collaboration, organizations can secure high-performance components that meet demanding application requirements while supporting scalability and competitive advantage.