Introduction: Navigating the Global Market for Oak Edge Banding

Global buyers need oak edge banding that arrives clean, sticks fast, and disappears at the seam—no callbacks, no rework. You are balancing lead times across regions, compliance for adhesives, and price with performance. The difference between an invisible edge and a project delay is often the roll’s joint quality, adhesive reliability, and consistent stock. Pre-glued white oak edge banding from trusted vendors ships today with reliable lead times—often in bulk—reducing the risk of seam visibility that’s common on low-cost imports. USA and Europe teams benefit from a consistent, high-satisfaction product with pre-sanded, ready-to-apply finish and joint patterns designed for near-invisible seams. When your shop works with premium edge banding from established suppliers, you reduce waste and finish labor. This guide focuses on white oak edge banding, pre-glued iron-on rolls, and the practical procurement steps that keep production on schedule. It covers: material selection, adhesive options, quality controls, logistics and freight-forwarding, and how to verify compliance. Use the right materials, verify stock and lead time, and source from proven suppliers to ensure consistent, invisible edges across markets.

Article Navigation

- Top 10 Oak Edge Banding Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for oak edge banding

- Understanding oak edge banding Types and Variations

- Key Industrial Applications of oak edge banding

- 3 Common User Pain Points for ‘oak edge banding’ & Their Solutions

- Strategic Material Selection Guide for oak edge banding

- In-depth Look: Manufacturing Processes and Quality Assurance for oak edge banding

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘oak edge banding’

- Comprehensive Cost and Pricing Analysis for oak edge banding Sourcing

- Alternatives Analysis: Comparing oak edge banding With Other Solutions

- Essential Technical Properties and Trade Terminology for oak edge banding

- Navigating Market Dynamics and Sourcing Trends in the oak edge banding Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of oak edge banding

- Strategic Sourcing Conclusion and Outlook for oak edge banding

- Important Disclaimer & Terms of Use

Top 10 Oak Edge Banding Manufacturers & Suppliers List

1. Edgebanding – Oakwood Veneer Company

Domain: oakwoodveneer.com

Registered: 1998 (27 years)

Introduction: 1–3 day delivery 60-day returnsDid you know that we carry veneer supplies? From edge banding to vacuum systems, we have you covered….

2. Red Oak Edge Banding 2″ x 50′ Pre-Glued (Iron-On) – Veneer Supplies

Domain: veneersupplies.com

Registered: 2003 (22 years)

Introduction: Free deliveryThis genuine red oak wood veneer edge banding is made from premium grade logs and is very easy to apply with an ordinary clothes iron.Missing: top manufacturers suppliers…

3. Oak Veneer & Edge Banding – Total Wood Store

Domain: totalwoodstore.com

Registered: 2014 (11 years)

Introduction: 45-day returnsExplore a wide selection of Oak Veneer & Edge Banding products for all your woodworking projects, available in various sizes and finishes….

4. Red Oak Edge Banding | Cherokee Wood Products

Domain: cherokeewood.com

Registered: 1997 (28 years)

Introduction: In stock 9-day deliveryWe stock Red Oak Edge Banding along with other domestic and exotic real wood and melamine laminated to cover raw edges of plywood sheets….

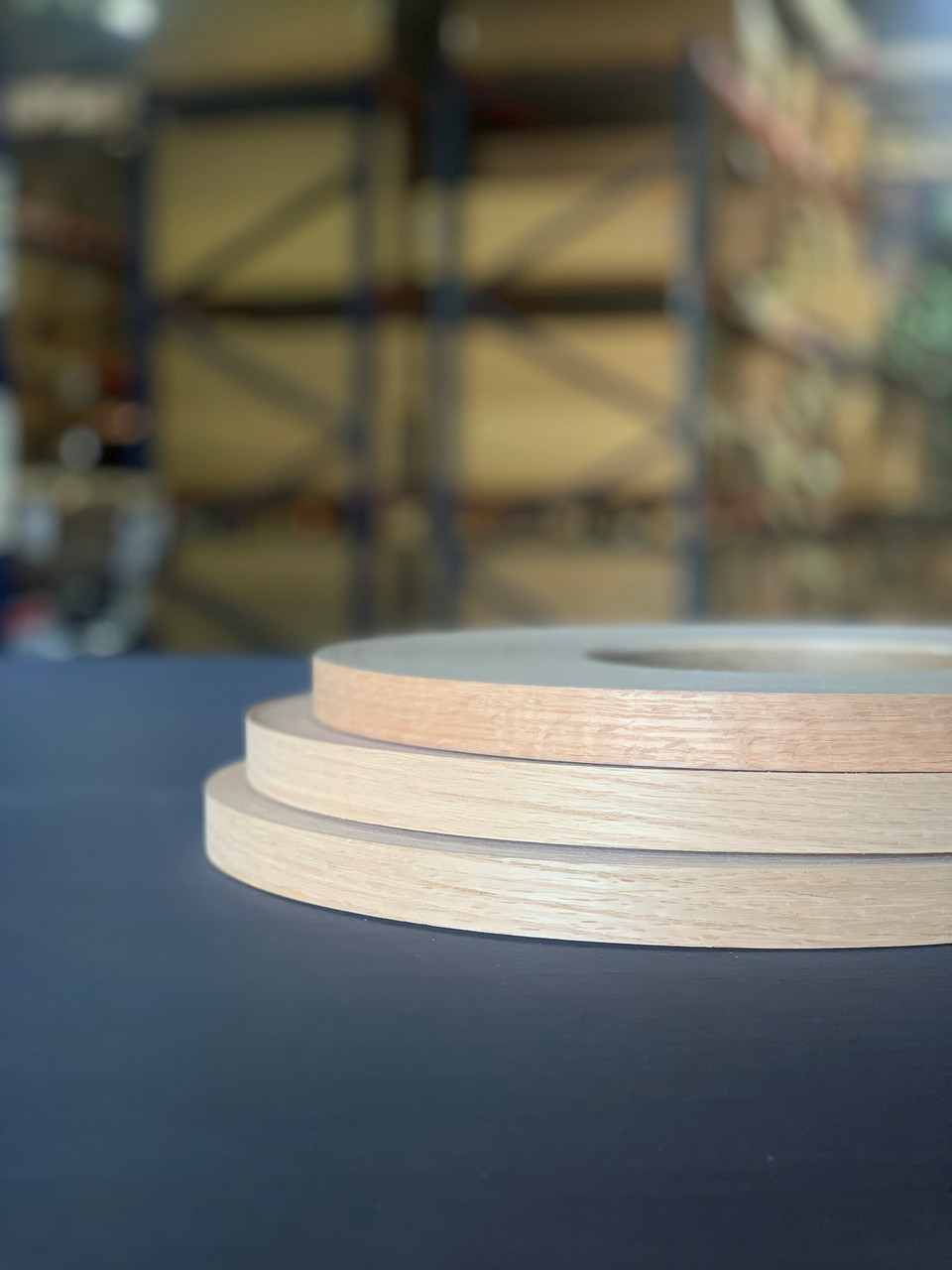

Illustrative Image (Source: Google Search)

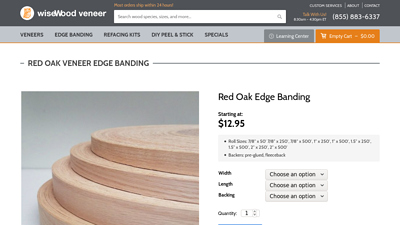

5. Red Oak Edge Banding – WiseWood Veneer

Domain: wisewoodveneer.com

Registered: 2011 (14 years)

Introduction: In stock 30-day returnsAffordable, high quality red oak veneer edge banding made from real oak wood veneer. Comes in rolls with pre-glued or fleeceback backing options….

6. Professional Edge Banding Strips | PVC & ABS | Factory Direct

Domain: edgebandct.com

Registered: 2025 (0 years)

Introduction: Premium edge banding for furniture manufacturers. PVC & ABS strips, custom colors, fast delivery. Get factory prices – Request quote today!…

7. Veneer Edgebanding – Frama-Tech

Domain: framatech.com

Registered: 2012 (13 years)

Introduction: We stock 45+ species of Veneer edge banding. Multiple widths, thicknesses, and finishes. Choose from oak veneer edge banding, maple veneer edgebanding, ……

Understanding oak edge banding Types and Variations

Understanding Oak Edge Banding: Types and Variations

Core Types

The four primary oak edge banding formats used in industrial and custom shops each optimize a different balance of speed, adhesion reliability, and finish quality.

Type vs Features vs Applications vs Pros/Cons

| Type | Features | Applications | Pros | Cons |

|---|---|---|---|---|

| Pre-Glued (Iron-On) Heat-Activated Hot-Melt | White oak option (7/8 in x 250 ft); heat-activated pre-glue; presanded, ready-to-apply; tight-joint pattern reduces seam visibility; premium domestic versus overseas imports; ships same day with order cutoff | Straight edges on panels, cabinets, desks; rapid production runs | Fast, tool-light installation; clean seams; reduces finishing prep | Requires controlled heat and pressure; limited repositioning; heat sensitivity limits high-temp finishes; not ideal for tight radii |

| Non-Glued (Unglued) Rolls | Requires external adhesive (PVA/Hot-melt/CA/Contact); wood-to-wood species match; wide and long roll formats | Production lines, CNC edgebanding, curved or shaped edges; high-duty cycles | Full adhesive choice; better for complex curves; highest durability with correct glue | Slower set-up; more consumables; glue line management needed |

| Pressure-Sensitive (PSA) Wood Veneer Edge Banding | Factory-applied PSA; peel-and-stick; usually 1–2 mil wood veneer on kraft/PSA; flexible; convenient pre-cut widths | Jigs, prototypes, quick retrofits, curved/radius edges | Minimal equipment; very fast application; good for complex shapes | PSA can creep under heat/moisture; limited reheat/reshape; aggressive adhesives can telegraph |

| Paper-Backed Veneer Edge Banding | Thin wood veneer bonded to kraft paper; strong cross-direction stability; conforms to gentle curves | Light-duty panels, fixtures, curved/radius work where thicker wood bands are impractical | Conforms to gentle radii; stable and economical | Less durable surface; shows wear; limited high-build finishing options |

Detail: Pre-Glued (Iron-On) Oak Edge Banding

- Specs and sourcing: Available in white oak with width options such as 7/8 in and length of 250 ft. Example listing at $39.50 (USD) per roll; ships today when ordered before 1 pm EST. Premium domestic product emphasizes a proprietary joint pattern and sanding technique to reduce seam visibility.

- Setup and process: Apply with a household iron, household iron, edgebander, or heat-activated press. Temperature and dwell time must be dialed in to fully activate the hot-melt without scorching; firm pressure and a smooth applicator improve bond and flattening of joints.

- Performance and finish: Presanded and ready to finish, which reduces prep. The tight-joint pattern and sanding approach deliver less noticeable seams compared to typical imported rolls.

- Limitations: Heat sensitivity and short open time limit very tight radii and some high-temperature finishes. For production control, monitor batch consistency (thickness, glue line, sand line) when specifying across multiple suppliers.

- Best fit: High-throughput casework, carcass edges, and display fixtures where appearance and speed matter.

Detail: Non-Glued (Unglued) Oak Edge Banding

- Adhesive and process: Select glue system per substrate and duty cycle (PVA for flush-fit wood substrates, hot-melt for machine lines, CA for instant assembly, contact cement for curved laminates). Match species and grain orientation to ensure color continuity after finishing.

- Advantages: Enables optimal glue selection for moisture resistance, gap-filling, and fast cycle times; excellent for curved edges and shaped profiles.

- Trade-offs: Requires more setup and consumable management; operators must control glue application, open time, and clamping to avoid telegraphing or starved joints.

- Best fit: OEM and shop production where consistent adhesive performance and bond durability outweigh setup complexity.

Detail: Pressure-Sensitive (PSA) Wood Veneer Edge Banding

- Construction and handling: Thin wood veneer face with a factory-applied PSA backing on kraft paper. Peel-and-stick application eliminates separate glue steps.

- Performance: Fast to apply and well-suited to gentle curves and light-duty radii. Choose widths and lengths that reduce waste and avoid stretching the veneer.

- Limitations: Susceptible to creep under heat and humidity; limited tolerance for high-temperature finishing.

- Best fit: Field modifications, prototypes, jigs, and fixtures where speed and low equipment requirements are priorities.

Detail: Paper-Backed Veneer Edge Banding

- Construction and use: Thin wood veneer bonded to kraft paper for dimensional stability and controlled cross-flex. Designed for gentle curves and economical edge coverage on lighter-duty components.

- Trade-offs: The paper-backed construction is less durable under heavy wear; finishing options should be modest to avoid delamination.

- Best fit: Store fixtures, light-duty panels, and curved applications where cost and conformability are key.

Key Variations That Affect Specification

- Species and origin: White oak (USA) versus European white oak can differ subtly in color, ray figure, and tannin reactivity. Red oak is denser with more prominent open grain and typically less moisture stability than white oak. Specify by species and origin to avoid finish surprises and color drift.

- Grain choices: Plain-sawn (cathedral) for prominent grain presentation; quarter-sawn for ray fleck and stability. Grain selection drives both visual continuity and finishing strategy.

- Thickness and profile: Typical face thickness ranges from ~0.6 mm to 2.0 mm. Thinner bands conform better; thicker bands offer more durability and repairability. Pre-sanded bands reduce finishing prep time.

- Joint quality: Premium tight-joint patterns and specialized sanding markedly reduce seam visibility versus typical imports; request samples or test rolls to evaluate seam performance on your finishing line.

- Roll formats: Widths from 3/4 in to 1–2 in are common; 250 ft rolls support long-run efficiency. Confirm packaging (e.g., minimums, cart quantities) and lead times, especially for non-stock species.

- Logistics: For USA orders, some domestic suppliers offer same-day shipping with order cutoffs (e.g., 1 pm EST). International buyers should plan for freight forwarding, customs paperwork, and potential shipping limitations; confirm lead times, HS codes, and country-specific delivery constraints.

By aligning type selection with species characteristics, grain requirements, thickness, and production logistics, B2B buyers can reliably balance installation speed, seam quality, and long-term durability across USA and European operations.

Key Industrial Applications of oak edge banding

Key Industrial Applications of Oak Edge Banding

Oak edge banding plays a decisive role in visible edges and high-wear areas where appearance, durability, and finishing efficiency converge. White oak’s neutral tone, open pore structure, and consistent performance make it suitable for premium casegoods and interiors across industries.

Illustrative Image (Source: Google Search)

Product Snapshot

- Item: White Oak Edge Banding 7/8″ x 250′, Pre-Glued (Iron-On)

- Condition: Pre-sanded, ready for application

- Price: $39.50 per roll

- Shipping: Order by 1 pm EST for same-day ship

Applications and Benefits

| Industry/Application | Detailed Benefits |

|---|---|

| Furniture & Casegoods Manufacturing | Seamless light-fast edges align with oak’s natural tone; pre-glued iron-on shortens application time; pre-sanding reduces prep steps; premium joint pattern and sanding improve bond quality and finish outcomes. |

| Kitchen & Bath Cabinetry | Neutral white oak tone supports classic finishes; pre-glue reduces assembly time; pre-sanding yields consistent stain/clear coat results on visible edges; compatible with standard iron-on presses or clamps. |

| Commercial Interiors (Contract Millwork) | Consistent edge treatment across projects; pre-sanded surface improves adhesion and finishing; roll length supports production runs with minimal splicing; ready-to-apply reduces shop time. |

| Hospitality & Retail Environments | High-visibility edges benefit from premium jointing and sanding; oak’s neutral tone pairs with diverse finishes; iron-on system simplifies shop installs and on-site touch-ups. |

| Office Furniture & Built-ins | Edge integrity under daily use; iron-on system cuts cycle time; pre-sanded, consistent edge ready for topcoat; pricing per roll supports cost control in production runs. |

| Marine & Marine-Interior Projects | White oak is used for its durability in traditionally marine contexts; edge band thickness (7/8″) is appropriate for robust edge protection; neutral tone integrates with natural finishes and varnish systems. |

| Doors, Window Frames & Millwork | Open-pore oak accepts stain and clear coats uniformly; pre-glued application streamlines assembly; pre-sanding accelerates finishing; premium jointing enhances visible seams. |

| Fixtures, Displays & Modular Systems | High volume runs benefit from roll format; consistent surface and joint pattern reduce rework; iron-on system supports both shop and field installation. |

Key Edge Banding Benefits (Source-Referenced)

- Invisible seams: Unique joint pattern and sanding technique produce significantly less visible seams.

- Faster application: Pre-glued (iron-on) with immediate ship; order by 1 pm EST to ship same day.

- Production-ready surface: Pre-sanded and ready for finishing; minimizes rework.

- Reliable consistency: Premium quality compared to typical imported rolls; supports repeatable outcomes.

Use Notes

- Select banding thickness and veneer species to suit substrate and wear requirements.

- Confirm adhesive and substrate compatibility; test application parameters for shop/field conditions.

- Plan for standard finishing steps post-bond to align with project performance and appearance standards.

3 Common User Pain Points for ‘oak edge banding’ & Their Solutions

3 Common User Pain Points for Oak Edge Banding & Their Solutions

| Pain Point | Why it Happens (Root Cause) | What to Do (Solution) |

|---|---|---|

| Visible seams and color mismatch | White oak’s grain and tannins can make butt joints, micro-tears, and color variation stand out. Low-quality imported bands often show seams. | 1) Use premium white oak edge banding with a refined joint pattern and pre-sanding (our 7/8″ x 250′ rolls). 2) Final-sand in stages: 180 → 220 → 320 grit, keeping the substrate flat. 3) Blend tone with a compatible wood dye/stain; lock it with a sanding sealer. 4) Optimize adhesive selection: water-based PVA reduces bleed-through; non-glued urea/formaldehyde avoids heat telegraphing. |

| Adhesion failure (early lift, glue show-through, bond weakness) | Heat-activated pre-glue not fully activated; insufficient pressure dwell; bleed-through with hot-melt; bonding to dusty/oily/softwood core surfaces. | 1) Temperature: set household iron ~200–220°F (95–105°C); roller press at moderate speed with 2–3 passes; maintain 30–45 sec at pressure with a seam roller or veneer clamp (vacuum optional). 2) Clean the core: vacuum dust and wipe with tack cloth; light chamfer. 3) Avoid hot-melt with light woods; choose PVA or urea/formaldehyde. 4) Post-activation cooling: let the bond cool before trimming. |

| Edge warping, telegraphing substrate, or cracking at corners | Tension from moisture mismatch; hard edges of MDF/HDF “shadowing” through; insufficient acclimation; stress concentration at turns. | 1) Acclimate oak edge banding and core to room/humidity for 48 hours before use. 2) Apply a barrier coat (sealer) to MDF/HDF edges. 3) Keep corners radiused; avoid tight 90° wraps; trim incrementally (2–3 light passes), with support underneath. 4) Consider non-glued rolls for complex wraps and vacuum pressing if needed. |

Action checklist:

– Confirm the roll’s joint quality and pre-sand finish (our 7/8″ x 250′ white oak edge banding).

– Establish SOP: iron temperature, pass count, dwell, and cooling window; train operators on roller pressure.

– Choose adhesive based on wrap complexity and substrate: water-based PVA for flat edges; urea/formaldehyde for complex cases; pre-glued iron-on for fast-turnaround straight runs.

– QC gates: visual seam check (post-sanding), adhesive activation test (sample strip), and humidity acclimation record.

Strategic Material Selection Guide for oak edge banding

Strategic Material Selection Guide for Oak Edge Banding

1) Define performance requirements by application

- Durability and abrasion resistance: high-traffic casework, retail fixtures, kitchen cabinet doors/drawers.

- Moisture/fatigue: humid climates, bathrooms, marine interiors (where applicable), frequently cleaned surfaces.

- Finish compatibility: painting or staining with clear topcoats; plan matched color and sheen.

- Aesthetic matching: veneer-to-core color/grain alignment; book-match or plank-match to adjacent substrates.

- Processing speed and labor cost: handwork vs automated; iron-on vs contact adhesives vs cold press.

- Compliance and sourcing: regional preference (US/Europe), sustainable or FSC-certified supply, regulatory and shipping constraints.

2) Species selection

- American White Oak

- Light tan to honey color; prominent grain; natural tannin reactivity.

- Commonly favored for white/light finishes; works well for furniture and cabinetry.

- European White Oak

- Slightly tighter grain and consistent tan hues; prevalent in European supply chains.

- Good fit for modern finishes; minimal color variance across batches.

- Red Oak (American)

- Warmer reddish tones; open grain; less commonly used where high moisture is a concern.

- Typical value/performance choice for interiors; stain can deepen grain visibility.

3) Form and construction

- Veneer (layered) edge banding

- Balanced construction resists cupping and checking; better handling on curved edges.

- Pre-sanded, ready to finish; consistent quality and lighter weight.

- Solid or thicker build edge banding

- Offers more edge presence after machining; preferred when visible thickness is desired.

- Heavier and more sensitive to moisture; higher risk of telegraphing joints if not properly finished.

4) Adhesive systems and application

- Iron-on (pre-glued) rolls

- Fast application; heat activation at 80–100°C; excellent fit for production lines and quick repairs.

- Requires alignment and fast handling; sensitive to storage heat/humidity; not ideal for high-heat or high-humidity service long-term.

- Contact cements (non-glued rolls)

- Strong bond; suited for panels, curved edges, and thicker bands; open time allows positioning.

- Adequate ventilation required; higher skill for clean application and edge squeeze-out control.

- PVA and urea-formaldehyde glues (non-glued)

- Typical for flat surfaces and factory presses; excellent long-term joint integrity under interior use.

- Requires clamping pressure and controlled humidity; slower for handheld operations.

- Hot-melt systems (non-glued)

- Fast cycle times; robust for frequent handling edges; useful in automated lines.

- Investment in equipment; careful temperature and feed control is critical.

5) Sizing, thickness, and core compatibility

- Widths: 7/8″ (22.2 mm) commonly used for cabinetry and furniture panels; ensure the band extends over the substrate edge and trims flush.

- Thickness: Choose standard production thickness for best seam invisibility; thicker bands may show edge presence but are beneficial for heavy-use edges.

- Edge radius: Larger radii reduce visible glue lines; tight radii risk show-through if not fully bonded and sanded.

- Substrate matching: Balance veneer and substrate movement; account for dimensional change across grain directions to minimize cracking at seams.

6) Finish strategy and handling

- Surface preparation: Sand consistently with recommended grit progression; vacuum debris before staining/finishing.

- Staining and finishing: Test finish compatibility (clear coats, stains) due to oak’s open grain and tannin activity; consider washcoat or sealer to control grain raise.

- Curing and inspection: Allow full cure before handling; check for raised fibers, telegraph lines, and glue marks; correct defects early.

- Inventory management: Store in stable humidity/temperature; monitor for edge-curling and pre-glue activation in hot storage.

7) Quality indicators to prioritize

- Seam technology: Unique joint patterns and sanding that reduce seam visibility compared to commodity imports.

- Pre-sanded finish: Ready-to-apply bands reduce rework and save time.

- Straightness and dimensional stability: Rolls that feed cleanly and resist warping in automated and manual operations.

8) Operational tips for USA and Europe

- Shipping and lead time: Vendor offers same-day shipping for orders placed before 1pm EST; plan accordingly for on-time arrivals.

- Freight/forwarding for international: Use freight forwarding for overseas orders; confirm dimensional weight and customs documentation.

- Shipping limitations: Verify prohibited items and regional restrictions before dispatch to avoid delays.

- Returns and changes: Confirm quantities and specifications before ordering; understand return and order-change windows to avoid waste.

9) Risk management

- Glue failure under heat/humidity: Use contact cement or press glues for harsh environments; iron-on best for interior and moderate-use cases.

- Moisture ingress: Seal exposed edges; verify glue coverage; avoid standing water on edge joints.

- Color mismatch across batches: Order full lots for critical matches; pre-finish and compare under target lighting.

10) Decision checklist

- Species and origin (US/European White Oak vs Red Oak).

- Adhesive system (iron-on vs contact vs press-grade glues).

- Width and thickness for target edge profile and usage intensity.

- Seam quality (joint pattern/sanding) and pre-sanded readiness.

- Finish plan and required testing for tannin response.

- Logistics (same-day shipping cutoffs, international forwarding, returns policy).

11) Material options comparison (based on available vendor info and common attributes)

| Option | Species | Origin | Adhesive Type | Width (typical) | Thickness (typical) | Seam Quality | Pre-Sanded | Finish Compatibility | Typical Lead Time | Notes |

|---|---|---|---|---|---|---|---|---|---|---|

| Pre-Glued (Iron-On) Roll | Oak (White) | US/EU supply | Iron-on (heat activation) | 7/8″ | Standard edge | Unique joint pattern, less visible | Yes | Stain and clear coats; test tannin | Ships today (order ≤1pm EST) | Fast application; ideal for interiors and moderate-use cabinetry. |

| Non-Glued (Contact Cement) Roll | Oak (White/Red) | US/EU supply | Contact cement | 7/8″ | Standard edge | Good seam control with technique | Yes | Stain and clear coats | Vendor-dependent | Strong bond; suited for curved edges and thicker bands. |

| Non-Glued (PVA/UF) Roll | Oak (White/Red) | US/EU supply | PVA/Urea-formaldehyde | 7/8″ | Standard edge | Clean flat joints with clamping | Yes | Stain and clear coats | Vendor-dependent | Ideal for flat pressing and factory installations. |

| Non-Glued (Hot-Melt) Roll | Oak (White/Red) | US/EU supply | Hot-melt adhesive | 7/8″ | Standard edge | Rapid cycles; depends on setup | Yes | Stain and clear coats | Vendor-dependent | Best for high-throughput lines with controlled temperature/feed. |

Notes:

– Vendor-provided item: Iron-on white oak edge banding, 7/8″ x 250′ roll, priced at $39.50, pre-sanded, unique joint/sanding technique to minimize seam visibility; ships same-day for orders placed before 1pm EST.

– Other adhesive types are listed as options for operational needs; confirm product-specific thickness, adhesive type, and lead time with the supplier.

In-depth Look: Manufacturing Processes and Quality Assurance for oak edge banding

In-depth Look: Manufacturing Processes and Quality Assurance for Oak Edge Banding

Oak edge banding connects fine cabinetry with robust, consistent performance. For USA and Europe buyers, manufacturing discipline and documented quality systems determine whether a roll is easy to apply on line, stays in spec on the shelf, and bonds durably over years. Below is an end‑to‑end view of how oak edge banding—particularly white oak—is prepared, formed, assembled, and verified.

Manufacturing Steps

- Prep (Raw Material and Veneer Preparation)

- Species selection and grade verification: White oak is common for consistent color and stability; species and source confirm via documentation.

- Moisture control: Veneer and core are conditioned to target equilibrium moisture content (typically 6–10%) before machining; stabilized wood reduces curl and bonding failures.

- Veneer slicing: Slicers are selected by required grain and match. Plain-sliced for cathedral figure; quarter-sliced for straight grain; rift-cut for stability and minimal ray fleck.

-

Veneer layup and preparation: Sheets are trimmed, scarfing is used if needed, and surface planing/sanding sets uniformity for glue line and finish readiness.

Illustrative Image (Source: Google Search)

-

Forming (Dimensional Setup and Glide Preparation)

- Sizing: Edge bands are cut to target widths with tight dimension control.

- Surface sanding: Typically 150–180 grit for pre-glued rolls; ensures consistent glue contact and reduces visible seams on application.

-

Backer application (if specified): Paper- or fiber-backed options provide handling reinforcement, improved flexibility, and better crack resistance on curves.

-

Assembly (Lamination, Glue, and Finishing)

- Glue application and activation: Pre-glued (iron-on) rolls typically use EVA hot-melt adhesive; rollers apply a uniform layer, with precise line temperature control.

- Lamination and pressing: Pressures and dwell times are set to achieve full glue wetting and thermal activation without burning the veneer surface.

-

Cutting and winding: Bands are cut to width, rolled on cores, and wound with consistent tension to prevent edge damage or telescoping.

Illustrative Image (Source: Google Search)

-

Packaging, Labeling, and Dispatch

- Packaging: Coils protected from moisture with moisture barriers, end caps, and wrapped cores; labeling includes species, finish type, dimensions, lot/roll ID, and handling/storage notes.

- Distribution: Stock rotation and lead-time communication; for USA shipments, prompt fulfillment (often “ships today”) depends on accurate inventory control and QC release.

Quality standards overview

ISO-aligned programs typically draw from these families:

– ISO 9001: Quality Management Systems. Requirements for documented procedures, process control, nonconformance handling, corrective actions, management reviews, and traceability.

– ISO 14001: Environmental Management Systems. Governance of environmental aspects related to materials, solvents, emissions, and waste.

– ISO 45001: Occupational Health and Safety. Hazard control for machinery, dust, heat, and chemicals.

– ISO 17025: Testing and Calibration (in-house labs). Ensuring measurement confidence for moisture meters, thickness gauges, spectrophotometers, and tensile testers.

– ISO 19011: Guidelines for auditing management systems. Regular internal and external audits sustain process discipline.

A practical comparison for adhesives

| Glue type | Heat activation | Strength and creep | Environmental notes | Typical finish compatibility |

|---|---|---|---|---|

| EVA (hot-melt, pre-glued) | Iron/edge-bander activation required | Good initial bond; limited creep at elevated temperature | Low-VOC, solvent-free; fast handling | Paints and clear finishes perform well if sanding prep is proper |

| PVA (non-glued application on site) | Applied at ambient or warm | Strong joints with sufficient clamping pressure | May require solvents; cleanup and cure time needed | Compatible with many finishes; glue line visible under translucent systems |

Quality Assurance

- Incoming inspection and controls

- Moisture content measurement at veneer and band level; target bands kept to 6–10% EMC prior to roll winding.

- Dimensional checks: width tolerance, thickness uniformity, length verification; target performance verified through statistical sampling (AQL).

- Visual grading: species verification, color consistency, absence of blisters, voids, splits, and delamination; matching of grain across rolls where aesthetic continuity is required.

-

Adhesive specification: adhesive type verified via SDS and specification sheet; adhesion performance tested per documented procedures.

-

Process control and testing

- Thickness uniformity: Handheld micrometers or laser gauges at multiple points across the band; typical acceptance criteria include tight band-wide uniformity.

- Adhesion performance: Standard peel or pull-off tests on representative samples to verify hot-melt activation and cohesive failure rather than adhesive failure.

- Color and finish consistency: Instrumental color measurement for white oak shade stability; finish compatibility checks (dye/pigments, stains).

- Surface finish and seam visibility: Sanding grit and technique verified to minimize seams; application trials confirm line performance.

-

Curling and flatness: Monitoring curl after winding; flat sheets for non-rolled configurations; stress relief via acclimation.

-

Environmental and safety

- SDS availability for adhesives and related materials.

-

PPE, heat controls, and dust mitigation in line with ISO 45001 and local regulations.

-

Documentation, traceability, and nonconformance handling

- Lot/roll ID on each coil and carton; record of species, slice method, adhesive, width, thickness, length, moisture checks, and test results.

- ISO 9001 QMS documentation includes quality plan, work instructions, inspection records, calibration logs, audit reports, and change control.

-

Corrective actions and preventive actions (CAPA) documented, with verification of effectiveness; CAPA review frequency documented.

-

Distribution and service

- Packaging designed to prevent moisture ingress during freight; clear storage guidance on cartons and sheets.

- USA fulfillment processes commonly emphasize rapid order dispatch; order cut-off times (e.g., 1pm EST) and “ships today” capability depend on QC release of validated lots.

QA acceptance checklist (example items)

| Attribute | Typical control points | Notes |

|---|---|---|

| Species | White oak, European white oak | Documented via species identification and sourcing |

| Slice method | Plain/quarter/rift | Aligns with desired grain and appearance |

| Thickness | Band-wide uniformity | Verified by spot checks or AQL sampling |

| Width | Within target spec | Precision cutting verified at set-up and via sampling |

| Length | Meets declared footage | Verified via roll counter or batch reconciliation |

| Moisture content | 6–10% EMC target | Stabilization before winding reduces curl |

| Adhesive type | EVA hot-melt | Adhesive type confirmed via SDS/spec |

| Adhesion | Peel/pull-off performance | Cohesive failure indicates proper bond |

| Surface finish | Grit verification (150–180 typical) | Sanding technique reduces seam visibility |

| Color | Instrumental match across rolls | Reduces batch-to-batch variation |

| Packaging | Moisture barrier and labeling | Lot/roll ID and handling notes on label |

ISO-relevant documentation maintained in practice

| Document/record | Purpose |

|---|---|

| Quality plan and work instructions | Defines manufacturing steps, critical parameters, and acceptance criteria |

| Calibration records | Ensures measurement instruments (micrometers, moisture meters, color instruments) are accurate |

| Inspection and test reports | Documents moisture, dimensions, adhesion, color, and visual inspection outcomes |

| Nonconformance and CAPA records | Drives issue resolution and process improvement |

| Internal audit reports | Verifies compliance to ISO-aligned QMS requirements |

| Management review minutes | Tracks performance and resource decisions for quality objectives |

| Traceability logs | Enables rapid identification of rolls by lot/ID in case of complaints or recall |

| Environmental and safety procedures | Documents hazardous material handling, ventilation, and PPE requirements |

What ISO-aligned QA means for buyers

– Predictable application on line: controlled moisture, dimensional stability, and consistent glue performance reduce callbacks and rework.

– Clear traceability: lot/roll IDs and inspection data allow targeted corrective actions if an issue surfaces at a jobsite.

– Faster resolution: structured CAPA and audit cycles shorten time to root cause and prevent repeat defects.

Applied example

– A cabinet shop experiences occasional lift at corners after edge applying oak banding. Root cause analysis points to under-activation temperature at the iron-on station. CAPA adds a calibration schedule for line temperature sensors and an SOP for activation verification. Re-run tests show cohesive failure after activation, indicating proper bond formation; the lift issue disappears, and scrap falls.

Illustrative Image (Source: Google Search)

Takeaway

Oak edge banding quality begins with disciplined veneer preparation, appropriate forming methods, and predictable glue activation, then is sustained through ISO-aligned QA, documentation, and traceability. For USA and Europe buyers, this translates into smoother line performance, fewer installation surprises, and consistent finished pieces that match the premium expectations of oak.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘oak edge banding’

Practical Sourcing Guide: A Step-by-Step Checklist for White Oak Edge Banding

Use this checklist to validate options, negotiate terms, and place a production-ready order for 7/8″ (≈22 mm) White Oak edge banding. Target both USA and Europe with consistent documentation, moisture targets, and adhesive compliance.

1) Verify core specifications

Ensure all candidates match your build, finishing, and logistics requirements.

- Species and finish

- White Oak (Quercus alba) standard; confirm grain/sanding finish requirements with suppliers.

- Width

- 7/8″ (≈22 mm). Confirm exact width and tolerance (±0.015″ / ±0.4 mm typical).

- Length per roll

- 250′ (76.2 m). Confirm footage per roll and minimum order quantity (MOQ).

- Adhesive type

- Pre-glued (iron-on hot-melt). Confirm activation temperature (180–220°C / 350–430°F typical), setting speed, and bond strength on species/stock thickness.

2) Compare key candidates quickly

Use this structured comparison to shortlist vendors.

Illustrative Image (Source: Google Search)

| Supplier | Species | Width | Length | Adhesive | Finish | Stock status | Lead time | Country | Unit price | Price per LF | Price per SF |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Example listing (USA) | White Oak | 7/8″ (22 mm) | 250′ (76.2 m) | Pre-Glued (Iron-On) | Pre-sanded | In stock | Ships today (order by 1pm EST) | USA | $39.50 / roll | $0.158 | $0.217 |

| Vendor B (EU) | White Oak | 22 mm | 76 m | Pre-Glued (Iron-On) | Pre-sanded | In stock | 5–7 days | EU | €XX.XX / roll | €X.XX | €X.XX |

Notes:

– Calculate price per linear foot (LF): unit price / roll length.

– Calculate price per square foot (SF): price per LF / width (ft). 7/8″ = 0.0729 ft.

3) Set product specifications and tolerances

Lock these in your RFQ for repeatability.

| Parameter | Target | Notes |

|---|---|---|

| Species | White Oak | Match species to finished panel grain if required. |

| Width | 7/8″ (22 mm) ±0.015″ | Match cabinet edge thickness or post-formed radii. |

| Thickness | Confirm (typically 0.018″–0.022″) | Verify to prevent burn-through on thin panels. |

| Finish | Pre-sanded, ready for stain/clear coat | Confirm grit sequence and surface uniformity. |

| Moisture content | 6–9% (US/CA/EU average) | Align with finish to reduce checking. |

| Adhesive | Hot-melt, pre-glued | Confirm activation temp, pot life, and open time. |

4) Request documentation (EU and USA)

Deliverables to include with the order.

- Safety Data Sheets (SDS)

- Technical data sheet for adhesive activation and bonding recommendations

- Country of origin (COO)

- Chain-of-custody (FSC/PEFC if required)

- REACH compliance statement (EU)

- TSCA Title VI / CARB Phase 2 statement (USA), or equivalent formaldehyde compliance

- VOC content and any California Proposition 65 notices

- Warranty/returns policy (e.g., defects, shipping damage)

5) Verify quality and seam performance

Request samples and verify:

- Seam invisibility

- Joint pattern and sanding technique minimize visible seams; assess across light and dark finishes.

- Sanding finish

- Verify pre-sanded uniformity to avoid banding lines after finishing.

- Adhesive migration

- Confirm minimal bleed-through; test thin substrates and stained panels.

- Roll condition

- No blisters, curls, or adhesive residue; verify packaging integrity.

- Thickness stability

- Check that edge thickness is uniform and flat without cupping.

6) Logistics and lead time

Lock shipping terms and handling policies.

| Factor | Verification |

|---|---|

| In-stock status | Confirm real-time availability for 7/8″ White Oak rolls. |

| Lead time | Ships today (order by 1pm EST); otherwise 1–2 days for USA. |

| International orders | Request freight-forwarding and duty handling; confirm EU shipping timeframes. |

| Returns policy | Verify returnability of unused rolls and restocking fees. |

| Packaging | One roll per box; confirm stacking and protection for transatlantic shipment. |

| Tracking | Require full tracking and delivery confirmation. |

7) Pricing and MOQ

Negotiate based on clear metrics and quantities.

| Item | Formula/Example |

|---|---|

| Price per linear foot | Unit price / roll length. For $39.50 / 250 ft ≈ $0.158 / LF |

| Price per square foot | (Unit price / roll length) / width (ft). For $39.50 / 250 ft / 0.0729 ≈ $0.217 / SF |

| MOQ | Confirm roll count or footage; request bulk discounts on pallet orders. |

| Volume tiers | Tiered pricing for 5, 10, 25+ rolls; document in PO. |

8) Application testing checklist

Pilot runs before production scale-up.

| Step | Check |

|---|---|

| Temperature | Pre-glue activation at recommended range; avoid overheating. |

| Pressure | Even pressure using roller/iron; prevent gaps or burn-through. |

| Open time | Verify setting speed; allow for post-press trimming within working time. |

| Compatibility | Test on actual substrate/stain/clear coat to confirm no adhesive migration. |

| Seam trimming | Confirm flush trimming shows minimal banding line under stain. |

| Finish | Topcoat compatibility; no blush, orange peel, or telegraphing. |

| Durability | Bond strength under normal handling; no delamination after climate cycling. |

9) Compliance and sustainability (EU-first, USA-aligned)

Ensure alignment with both regions’ standards.

- EU: REACH, EUTR/Forest Law Enforcement (if applicable), and FSC/PEFC where required.

- USA: TSCA Title VI/CARB Phase 2 formaldehyde emissions and VOC documentation.

- Safety: SDS review; training for hot-melt application temperatures.

10) Place the order with clear terms

Finalize purchase order fields.

- Supplier and vendor ID

- SKU/description: White Oak edge banding, 7/8″ x 250′, pre-glued (iron-on), pre-sanded

- Quantity: [Number of rolls]

- Unit price and total price

- Expected ship date and carrier

- Incoterms (for EU shipments): EXW, FCA, or DDP as agreed

- Required documentation: SDS, TDs, compliance statements

- Returns and damage procedures: specify condition and inspection window

- Contact and order references

11) Post-order QA

Confirm deliveries and materials before production.

- Verify species, width, thickness, footage, and adhesive type.

- Check for shipping damage or adhesive contamination.

- Re-test samples on your exact substrate/finish line.

- Archive technical and compliance documents for audits.

Quick cost reference (example)

For a 250′ roll at $39.50:

– Price per linear foot ≈ $0.158

– Price per square foot ≈ $0.217

Use these metrics to benchmark offers across vendors in the USA and Europe.

Illustrative Image (Source: Google Search)

Comprehensive Cost and Pricing Analysis for oak edge banding Sourcing

Comprehensive Cost and Pricing Analysis for Oak Edge Banding Sourcing

Unit pricing overview (baseline: 7/8″ x 250′ pre-glued white oak)

- Price (reference): $39.50 per roll

- Coverage: 250 LF × (7/8″ ÷ 12) = 218.75 sf

- Material unit cost: $39.50 ÷ 218.75 ≈ $0.18/sf

| Line Item | Quantity | Unit | Unit Cost | Cost |

|---|---|---|---|---|

| Pre-glued white oak edge banding (7/8″ x 250′) | 1 | roll | $0.18/sf | $39.50 |

| Domestic ground freight (typical retail/2-day) | 1 | shipment | N/A | $15–$45 |

| Duty for EU import (typical range for finished wood goods) | 1 | shipment | N/A | 0–4.5% |

| Freight to EU (Pallet) | 1 | shipment | N/A | 5–15% of value |

| Total (US, delivered) | 1 | shipment | — | $54.50–$84.50 |

| Total (EU, delivered) | 1 | shipment | — | $54.50–$84.50 + duty + freight |

Notes:

– Freight costs are ranges and vary by carrier, weight/size, and speed. Use dimensional weight formulas provided below to refine.

– Duty rate example is typical for finished edge banding; confirm HS code with your customs broker.

Materials: Cost drivers and ranges (US vs EU)

| Driver | Typical Range/Impact | Rationale |

|---|---|---|

| Species (US white oak vs EU white oak) | EU white oak: +10–25% | EU oak commands a premium due to grain quality and supply. |

| Glue/Backer (non-glued vs pre-glued) | Pre-glued premium: +$0.03–$0.08/sf | Glue film and application add cost; hot-melt is lower than PVA. |

| Width | +$0.02–$0.08/sf for larger widths | More material per foot, tighter thickness control. |

| Thickness | +$0.02–$0.05/sf for thicker bands | More wood mass and tighter sanding/sizing. |

| Finish (raw/sanded vs veneer-like finish) | +$0.02–$0.05/sf | Extra sanding/matching to reduce visible seams. |

| Match quality (plank vs book/other) | +$0.01–$0.03/sf | Extra sorting/splicing time and yield loss. |

| Pack size | 10–20% better unit cost at high MOQs | Volume production and freight amortization. |

| Packaging | $0.10–$0.30/roll | Reinforced cores, shrinkwrap, sturdy boxing for long rolls. |

EU pricing sensitivity for pre-glued white oak (indicative):

– $0.22–$0.30/sf, with low-volume premiums up to ~$0.38/sf.

Labor: Application and handling

| Activity | Non-Glued | Pre-Glued |

|---|---|---|

| Cut to length and position | ✓ | ✓ |

| Apply glue or hot-melt tape | $0.07–$0.15/sf (PVA) or $0.02–$0.04/sf (hot-melt) | Not required |

| Set and strip | ✓ | ✓ |

| Trim/route flush | ✓ | ✓ |

| Sand to finish | ✓ | ✓ |

| Inspect for glue creep | PVA: requires clean-up | Minimal |

| Typical total labor premium vs pre-glued | +$0.03–$0.12/sf | Baseline |

Time per piece is driven by panel size, edges, batch size, and automation (e.g., co-machines vs handwork). Batch setups and operator skill often decide whether pre-glued adds value through cycle-time savings.

Logistics: Freight, duties, packaging, and rework

| Mode/Region | Typical Cost | Notes |

|---|---|---|

| US domestic ground (small parcel) | $15–$45 per shipment | Up to ~30 lb depending on service level. |

| US LTL (pallet) | $0.70–$1.20 per CWT | 2–10% fuel surcharge. |

| US parcel (expedited) | $0.18–$0.30/sf | Dimensional weight can double cost for 7/8″. |

| EU pallet road | 5–15% of material value | Cross-border surcharges apply in some regions. |

| EU air (emergency) | 10–25% of material value | High speed, high cost; avoid unless justified. |

Dimensional weight formula:

– DHL/UPS/ FedEx: billable weight = max(actual weight, CWT or L × W × H / 139)

– For 7/8″ edge banding, volume per roll can make the dimensional weight > actual weight if packed in bulky boxes.

Illustrative Image (Source: Google Search)

Regrind/rework allowance:

– Add 1–2% buffer for returns and glue creep inspection if you’re switching suppliers.

Typical margin and landed-cost formula:

– Target margin: 25–40% (materials and logistics fully loaded).

– Landed cost = Material + Logistics + Rework + Duty (if import)

– Sell price = Landed ÷ (1 − target margin)

Example landed calculation (US):

– Material: $0.18/sf

– Domestic ground: $0.20/sf (amortized over 218.75 sf)

– Rework buffer: +1% = $0.004/sf

– Total landed: ≈ $0.384/sf

Sell price targets at various margins:

– 30% margin: $0.384 ÷ 0.70 ≈ $0.55/sf

– 35% margin: $0.384 ÷ 0.65 ≈ $0.59/sf

– 40% margin: $0.384 ÷ 0.60 ≈ $0.64/sf

For EU, add duty and freight:

– Material: $0.25/sf

– EU road freight: 8% of value = $0.02/sf

– Duty: 2.5% = $0.0063/sf

– Rework: +1% = $0.003/sf

– Total landed: ≈ $0.283/sf

– Sell price (35% margin): ≈ $0.43/sf

Cost-saving strategies

- Lock in volume discounts with higher MOQs; bulk rolls lower unit freight.

- Prefer 7/8″ or standard widths to avoid pricing penalties.

- Minimize shipping damage with reinforced cores and sturdy packaging.

- Choose pre-glued hot-melt for cycle-time savings; consider PVA if you already have iron-on equipment and low volume.

- Consolidate shipments to cross-dock regional stock for faster lead times without air freight.

- Audit suppliers’ joint patterns and sanding; premium seams reduce post-finish rework.

- Source EU oak with clear origin if your customer values European species; otherwise, US white oak can reduce landed cost.

Procurement checklist

- Confirm species, width, thickness, glue type (hot-melt or PVA), finish level.

- Verify joint pattern and sanding quality; get a seam test kit.

- Check lead times, MOQs, packaging specs, and freight class (long goods).

- Validate HS codes with broker to confirm duty rates for EU.

- Lock freight terms (DAP vs DDP) and dimensional weight policies with carriers.

- Set rework and return allowance; capture cycle times by method.

Summary:

– Reference cost for pre-glued 7/8″ white oak (250′) is ≈ $0.18/sf.

– Labor and glue add $0.03–$0.12/sf for non-glued workflows.

– Freight and duties drive variability; dimensional weight matters for narrow bands.

– Landed cost plus your target margin gives clean sell prices: US ≈ $0.55–$0.64/sf at 30–40% margin; EU depends on freight and duty.

– Save cost with volume, standard widths, pre-glued hot-melt, and better packaging.

Alternatives Analysis: Comparing oak edge banding With Other Solutions

Alternatives Analysis: Comparing Oak Edge Banding With Other Solutions

Selecting an edge solution hinges on finish quality, labor speed, total cost of ownership, and long-term durability. Below is a concise comparison that places oak edge banding alongside two common alternatives: PVC/ABS edge band and wood veneer edge band (unfinished).

Comparative Overview

| Dimension | Oak Edge Banding (Pre-Glued, Iron-On) | PVC/ABS Edge Banding | Wood Veneer Edge Banding (Unfinished) |

|---|---|---|---|

| Typical thickness | 0.6–0.8 mm | 0.4–2.0 mm (PVC often 0.4–0.8 mm; ABS often 0.5–1.0 mm) | 0.5–0.6 mm (paper-/backer-backed) |

| Width options (commonly stocked) | 13–22 mm; custom wider on request | 12–45 mm | 12–30 mm; larger widths less common |

| Price (indicative per linear foot) | ~$0.16 (7/8″ x 250′ at $39.50) | ~$0.015–$0.05 | ~$0.12–$0.25 |

| Adhesive | Heat-activated hot-melt on back | PSA or hot-melt (some “iron-on” PVC exists) | Contact cement, PVA, hide glue; may require separate adhesive |

| Application method | Light iron, pressure roller; short heat dwell | PSA: peel-and-press; hot-melt: heat/activation | Contact cement bonding with alignment accuracy; optional press; finishing required |

| Labor time (per linear foot) | Moderate: iron + trim + light sanding | Fast: peel-and-press; minimal heat; quick trim | Highest: bonding, matching grain, trimming, finishing |

| Seams/quality | Natural wood; minimal visibility with proper joints/sanding | Seams visible; can chip/shine differently than core | Natural wood; careful handling required to avoid telegraphing |

| Finish | Sandable and stainable; supports conversion varnish | Pre-finished; color stable | Requires sanding and finishing; matches face veneer |

| Repairability | Sandable spot repairs; re-stainable | Limited; damaged sections usually replaced | Sandable; re-stain/finish possible |

| Chemical/VOCs | Typically low after curing; hot-melt fumes on application | Low to moderate during application; adhesives can off-gas | Contact cements/PU primers may have higher VOCs |

| Moisture resistance | Moderate; depends on glue line; seal topcoat recommended | Good to very good; especially ABS | Moderate; depends on adhesive and topcoat |

| UV resistance | Moderate; depends on finish | Pre-finished UV-stable; color holds | Moderate to good with proper topcoat |

| Color/finish match to face veneer | Excellent (oak-on-oak) | Good to fair; may not match wood grain/color | Excellent (matches veneer species) |

| Chip-out risk when trimming | Moderate; use sharp knives, slow feed, backer tape | Low; less prone to chipping | Moderate to high if veneer is thin; micro-bevel helps |

| Waste/scrap ratio | Low (pre-glued, low scrap) | Low (pre-finished; easy application) | Higher (requires matching and careful handling) |

| Availability (US/EU) | Broad across distributors; species-specific | Broad; high-volume supply | Broad via veneer vendors; requires finishing steps |

| MOQs/volume | Typically single-roll; bulk options available | High-volume; easy volume sourcing | Veneer rolls; may require custom cutting |

| Total cost of ownership (TCO) | Competitive where finish quality and refinishing matter | Lowest initial cost, excellent for simple edges and high-volume runs | Premium where seamless wood-on-wood integration is required |

Notes on currency:

– $/lf for oak derived from 7/8″ x 250′ at $39.50.

– PVC/ABS and veneer pricing are indicative ranges typical in North America and Western Europe.

Key Considerations

- When to choose oak edge banding

- Premium finish: stainable/sandable to match oak face veneers; superior aesthetic integration.

- Refinishability: field repairs or color adjustments are feasible without replacing the band.

-

Compliance/finish control: compatible with plant coating systems and low-VOC processes.

-

When to choose PVC/ABS

- Cost efficiency and speed: lowest material cost; fastest application for straight edges and high-volume runs.

- Durability for functional edges: good impact and moisture resistance, especially ABS.

-

Color consistency: pre-finished color stability reduces finish variability.

-

When to choose wood veneer edge banding

- Seamless species/grain continuity: matches face veneer across job types.

- Thicker feel under hand: more substantial edge presence when required.

- Finishing flexibility: supports custom color and topcoat strategy; suitable for high-end cabinetry.

Recommendations

- For standard-casework where speed and cost dominate, PVC/ABS edge band offers the fastest ROI with reliable, pre-finished quality.

- For casework where refinishing or color adjustments may be required (e.g., showroom updates, field returns), oak edge banding is the most flexible and durable option.

- For premium, seamless wood-on-wood applications (e.g., architectural millwork or large veneer runs), use wood veneer edge band and align with your finishing schedule.

Summary: Choose the solution that aligns with finish quality, labor strategy, and lifecycle requirements. Oak edge banding is the balanced choice for premium, refinishable edges; PVC/ABS excels on cost and speed; wood veneer edge band provides unmatched integration for high-end projects.

Essential Technical Properties and Trade Terminology for oak edge banding

Essential Technical Properties and Trade Terminology for Oak Edge Banding

Oak edge banding is installed at the final manufacturing stage to seal and protect panel edges. Selecting the right specification and understanding commercial terms ensures consistent fit, reliable bonding, and compliance in USA and EU markets.

Core Technical Properties

| Property | Typical Options | Notes |

|---|---|---|

| Species | White Oak (US), European White Oak | White Oak offers good Tannic Acid stability and accepts stain/finish well; EU White Oak often delivers tighter color consistency. |

| Width (W) | 7/8″ (22.2 mm) and common metric widths (e.g., 19 mm, 23 mm, 25 mm, 32 mm) | Standard widths align with popular European panel thicknesses (e.g., 18 mm). 7/8″ is common in US cabinetry. |

| Length (L) | 250 ft (roll) | Verify minimum roll length; some vendors offer shorter or fixed-length rolls. |

| Thickness (T) | Standard 0.5 mm–0.7 mm (approx. 1/50″) | Thicker banding (0.7–1.0 mm) improves durability; standard thickness balances flexibility and finish. |

| Backing Type | Pre-glued (iron-on), PSA (pressure-sensitive), Non-glued | Choose based on bonding method, equipment, and handling constraints. |

| Glue System | Hot-melt EVA (pre-glued), PSA/rubber (self-adhesive) | Follow activation/temperature guidance per manufacturer; PSA typically used at room temperature. |

| Surface Finish | Pre-sanded (ready to apply) | A pre-sanded face reduces visible seam and finishing preparation. |

| Joint Pattern | Continuous splice; “random” or “book match” | Clean splice seams minimize visible joints. |

| Moisture Content (MC) | 6%–10% (vendor dependent) | Keep panels and banding acclimated in the shop; typical shop MC in this range for US/EU. |

| Grain/Grade | Typical furniture-grade veneer banding | Grain variation can be reduced via selection; grade often described as standard (A-grade) or utility. |

| Packaging | Carton rolls; protective wrap | Ensure stability and protection for international freight. |

Bonding and Application Parameters (General)

| Parameter | Pre-Glued (Iron-On) | PSA (Self-Adhesive) | Non-Glued |

|---|---|---|---|

| Activation Method | Heat activation (iron/roller) | Pressure sensitive at room temperature | Glue applied during install |

| Typical Shop Temperature | 18°C–27°C (65°F–80°F) recommended to avoid condensation | Same shop temp range | Same shop temp range |

| Bonding Sequence | Clamp/heat cycle, then trim and finish | Remove liner, apply and roll to ensure contact | Apply adhesive to edge and band; clamp/heat per glue spec |

| Storage | Keep rolls sealed, dry, away from heat | Store flat; protect from UV and dust | Store as per adhesive manufacturer’s instructions |

Always follow the adhesive manufacturer’s activation range and dwell time guidance.

Key Trade and Procurement Terms (B2B)

| Term | Definition | Why It Matters |

|---|---|---|

| MOQ (Minimum Order Quantity) | Smallest quantity a supplier sells per SKU | Impacts stocking strategy and unit cost. |

| Lead Time | Time from PO to shipment | Planning for production continuity. |

| Incoterms (FOB, CIF, DDP, EXW) | Commercial terms defining delivery responsibilities | Clarifies cost/risk transfer between buyer and seller. |

| Pack/Trim | Packaging specifics (length, roll count, palletization) | Influences freight cost and handling. |

| SKU (Stock Keeping Unit) | Unique identifier for a product configuration | Enables inventory and purchasing control. |

| HS Code (e.g., 4408) | Harmonized System classification | Required for customs and import/export in EU/USA. |

| Documentation | Packing list, commercial invoice, MSDS/SDS, certificates | EU customs and EHS compliance. |

| REACh | EU chemicals compliance (SVHC screening) | Required for materials entering the EU. |

| CARB Phase 2 / TSCA Title VI | US formaldehyde emission limits for composite panels | Ensures compliant panels and supply chain. |

| VOC | Volatile Organic Compounds compliance (adhesives/coatings) | Important in EU/US for EHS and LEED projects. |

| OEM/Private Label | Customized branding/specification runs | Often tied to MOQ and extended lead time. |

| Certificate of Origin | Country-of-origin documentation | Supports duty and trade preference claims. |

| Batch/Lot Traceability | Tracking by production lot | Critical for quality control and dispute resolution. |

| Claims Window | Time allowed for reporting defects/shortages | Protects both buyer and seller. |

| Returns/Restocking | Return policy conditions | Affects risk and inventory planning. |

| Warranty | Period and conditions for product defects | Indicates supplier confidence and service. |

| NDA/CAA | Non-Disclosure Agreement/Confidentiality and Assignment | Safeguards proprietary specifications. |

| Payment Terms | Net terms, deposits, LC | Impacts cash flow and sourcing terms. |

Selection Guidance (USA and EU)

- Match banding width to panel thickness; 7/8″ is standard in North America, while EU widths commonly align with 19 mm–25 mm panels.

- For consistent color and grain, specify White Oak and, if needed, EU White Oak for tighter color range.

- Use pre-glued rolls when iron/roller bonding is available; PSA is preferred for field- or workshop-level installations without heat.

- Keep materials and panels acclimated to shop conditions; monitor humidity to avoid gaps or telegraphing of seams.

- Request batch/MTL traceability and obtain SDS/MSDS and emissions documentation for compliance (CARB/TSCA, REACh).

This terminology and specification overview provides a clear, procurement-ready reference for buying and specifying oak edge banding across USA and EU markets.

Illustrative Image (Source: Google Search)

Navigating Market Dynamics and Sourcing Trends in the oak edge banding Sector

Navigating Market Dynamics and Sourcing Trends in the Oak Edge Banding Sector

1) Demand drivers and history

Oak edge banding—both white oak (Quercus alba) in North America and European white oak (Q. robur/Q. petraea)—has long been associated with premium casegoods and retail fixture work where durability, grain character, and finishing stability matter. White oak is preferred in edge applications due to:

– Straight, tight grain that responds predictably to sanding and finishing

– Lower extractive staining risk than red oak when waterborne finishes or light stains are used

– Mechanical and moisture performance suitable for furniture and fixture service conditions

Edge banding replaced exposed solid-wood edges in most commercial applications during the 1980s–1990s for cost and yield reasons; today, pre-glued roll products have further reduced assembly time and labor variability, especially in shop and on-site settings. In Europe, oak’s “oak-only” identity (e.g., Q. robur) is a design signal, while in the U.S., white oak’s aesthetic and technical performance underpin its usage in high-end hospitality, retail, healthcare, and architectural woodwork.

2) Current market dynamics: supply, pricing, and logistics

- Global oak availability is steady but cyclical. White oak remains a benchmark species; prices respond to forestry practices, veneer demand (e.g., veneer sheets), export log regulations, and currency moves. Regional differences persist: U.S. white oak is often abundant and domestically priced, while European white oak supply has tighter export and domestic consumption dynamics.

- Cost and lead time: As a rule of thumb, domestic or near-market supply reduces freight risk and shortens lead times. Example signals from current listings include U.S. domestic pre-glued white oak 7/8″ x 250′ around $39.50, with “ships today” availability—useful for replenishment and small-batch needs.

- Freight has stabilized since the pandemic-era spikes, but volatility continues in both North Atlantic (U.S.) and intra-EU corridors. Buyers should factor landed-cost scenarios and lead-time buffers.

- Product differentiation drives pricing. Premium edge bands emphasize:

- Joint pattern and sanding technique that reduce visible seams (a common pain point with lower-cost imports)

- Moisture control and consistent thickness (reduces telegraphing and edge chipping)

- Pre-sanded, ready-to-apply finish readiness (reduces shop prep time)

Note: The reference product example (White Oak Edge Banding 7/8″ x 250′ Pre-Glued, $39.50, “ships today”) exemplifies U.S. domestic availability and typical pricing for premium, pre-glued oak edge band.

3) Sustainability and regulatory posture

- Certification and chain-of-custody: FSC and PEFC are the most-requested schemes. For oak, look for supplier documentation tied to wood species (FSC/PEFC claim), and verify the validity of certificates with their certification bodies.

- Forest legality: U.S. Lacey Act compliance and EU deforestation regulation (EUDR) require species-level and origin-level transparency. For oak, ensure the label matches Quercus (or Quercus robur/petraea) and that the supplier provides due-diligence documentation.

- Emissions: While wood edge banding itself contains negligible formaldehyde compared to composite substrates, it sits adjacent to formaldehyde-regulated environments. Buyers should seek TSCA Title VI compliance for any wood component or finished assembly, and EN 14303/EN 13986-aligned emissions expectations in the EU where relevant. Request SDS and migration/emission data when necessary.

- VOC content and adhesives: Pre-glued edge band adhesives vary (e.g., EVA, polyamide). Request VOC content and emission characterization; avoid low-dilution solvent-based systems, and prefer low-VOC hot-melt or heat-activated systems suited to industrial shops and compliance areas (e.g., CARB-compliant zones, EU REACH SVHC compliance).

- Material efficiency: Narrow-width oak banding on thick MDF orplywood reduces material use compared with full-width solid edges. In both the U.S. and EU, procurement teams increasingly view edge banding as a way to reduce waste and meet scope-3/embodied carbon objectives.

4) Sourcing trends in 2025: practical implications

- Domestic-first: Buyers in the U.S. and Europe favor nearby supply to mitigate freight cost swings and ensure quicker restock. Example indicators: domestic white oak pre-glued rolls available for same-day dispatch simplify capacity planning and on-site touch-ups.

- Pre-glued adoption vs. non-glued:

- Pre-glued is preferred for “same-day install” or on-site service; ensure your finishing line can accommodate the adhesive activation temperature.

- Non-glued (e.g., with urea/PUR/HM hot-melt on top) is favored where high-cycle assembly lines exist and glue choice is standardized to the plant’s existing regimen.

- Technical expectations: Buyers in both regions demand:

- Consistent thickness across the roll and low joint visibility

- Proper moisture content to avoid telegraphing on veneered panels

- Clean, pre-sanded surface for immediate finishing

- Specification discipline:

- Width: Standard commercial widths include 7/8″ for standard substrates (e.g., 3/4″ panels with reveal)

- Species and cut: White oak (US/EU) or European white oak (US/EU), plain/flat-sawn or slip-matched

- Adhesive type: Heat-activated EVA/polyamide for pre-glued; state activation window

- Certification and traceability: FSC/PEFC with certificate numbers; Lacey Act/EUDR-compliant declarations

- Thickness and finish: Typical 0.5 mm–1.0 mm depending on panel exposure; finish-ready surfaces to avoid extra sanding

Typical price signals to calibrate expectations:

– U.S. domestic pre-glued white oak 7/8″ x 250′: around $39.50 for premium, seam-minimized, ready-to-apply product

– In Europe, availability and landed cost vary by country and certification; buyers should obtain quotes inclusive of freight and VAT to triangulate landed cost vs. domestic alternatives

Illustrative Image (Source: Google Search)

5) US vs. EU—key sourcing differences

- Certifications: EU procurement often requires explicit FSC/PEFC claims and origin details; U.S. buyers frequently request the same but may rely more on internal vendor forms and supplier attestations.

- Species naming: “White oak” is a clear species category in the U.S.; “European white oak” maps to Q. robur/Q. petraea in the EU; cross-border orders should confirm species and cut/finish match.

- Compliance posture: EUDR diligence is intensifying; U.S. remains under Lacey Act. In both markets, documented sourcing and due-diligence documentation are now standard risk controls.

- Supplier profiles:

- U.S.: Mix of veneer-focused manufacturers and B2B distributors; “ships today” availability and domestic logistics are common advantages.

- EU: Mix of regional mills and distributors; stricter import controls and shorter, more varied freight routes can support lead-time targets—again, verify landed-cost realities with local warehousing.

6) Procurement checklist

- Species and origin: White oak (Q. alba) for U.S.; Q. robur/Q. petraea for EU; confirm chain-of-custody.

- Width, thickness, and finish: Specify width (e.g., 7/8″), thickness, and whether pre-sanded and finish-ready.

- Adhesive type: Pre-glued (EVA/polyamide) with activation temp; or non-glued if you apply your own adhesive at the bench/line.

- Compliance: TSCA Title VI/EU emission-aligned expectations; VOC content data; SDS availability.

- Logistics and replenishment: Domestic/nearby stock for short lead times; “ships today” or equivalent for replenishment. For import, align MOQs and order cadence to freight schedules.

- Quality controls: Evaluate joint visibility, thickness consistency, moisture content, and finish-ready surface claims via samples and small-lot trials.

7) What to watch next

- Freight stability and seasonality (North Atlantic and intra-EU): Plan buffer stock and diversified suppliers to protect against short-term disruptions.

- Oak supply cycles and veneer pricing: Changes in veneer log pricing translate into edge-band cost and lead-time effects; lock in annual coverage with flexible buy-schedule provisions.

- Regulatory evolution: EUDR enforcement and any updates to U.S. import/transparency standards may require enhanced documentation and risk assessments.

- Automation and application process: Heat-activation windows and equipment standardization will influence pre-glued vs. non-glued choices on the shop floor.

Bottom line: In both the U.S. and Europe, buyers are shifting to reliable domestic or near-market sources for oak edge band, insisting on verifiable certifications and emissions/VOC data, and elevating technical controls (seam visibility, moisture, thickness) to reduce rework. As a benchmark, U.S. domestic premium white oak pre-glued roll product around $39.50 for 7/8″ x 250′ exemplifies the type of availability and quality signals that meet 2025 sourcing requirements.

Frequently Asked Questions (FAQs) for B2B Buyers of oak edge banding

FAQs for B2B Buyers of Oak Edge Banding

1) What product specifications are available?

- Species: White Oak (Quercus alba), kiln-dried veneer face with paper backer; suitable for furniture, cabinets, store fixtures, and millwork.

- Adhesive: Pre-glued, heat-activated (iron-on). Designed for solid wood and MDF; works on router-banded edges, profile-milled substrates, and straight runs.

- Widths: Stocked as 7/8″. Additional widths (e.g., 3/4″) may be available—ask for a current stock list.

- Length: 250′ per roll. Also available in shorter pre-cut lengths; inquire for availability.

- Finish: Pre-sanded face (ready to finish). Use a shop light or low-angle inspection to verify match before installation.

- Quality: Proprietary jointing and sanding minimize seam visibility; rolls are domestically produced using a higher-sand process to reduce telegraphing at seams.

- Typical tolerances: Width ±1/64″; length by the roll; overall thickness ~0.6–0.7 mm (product-dependent).

- Notes: Real wood veneer is sensitive to humidity—protect from moisture and rapid changes.

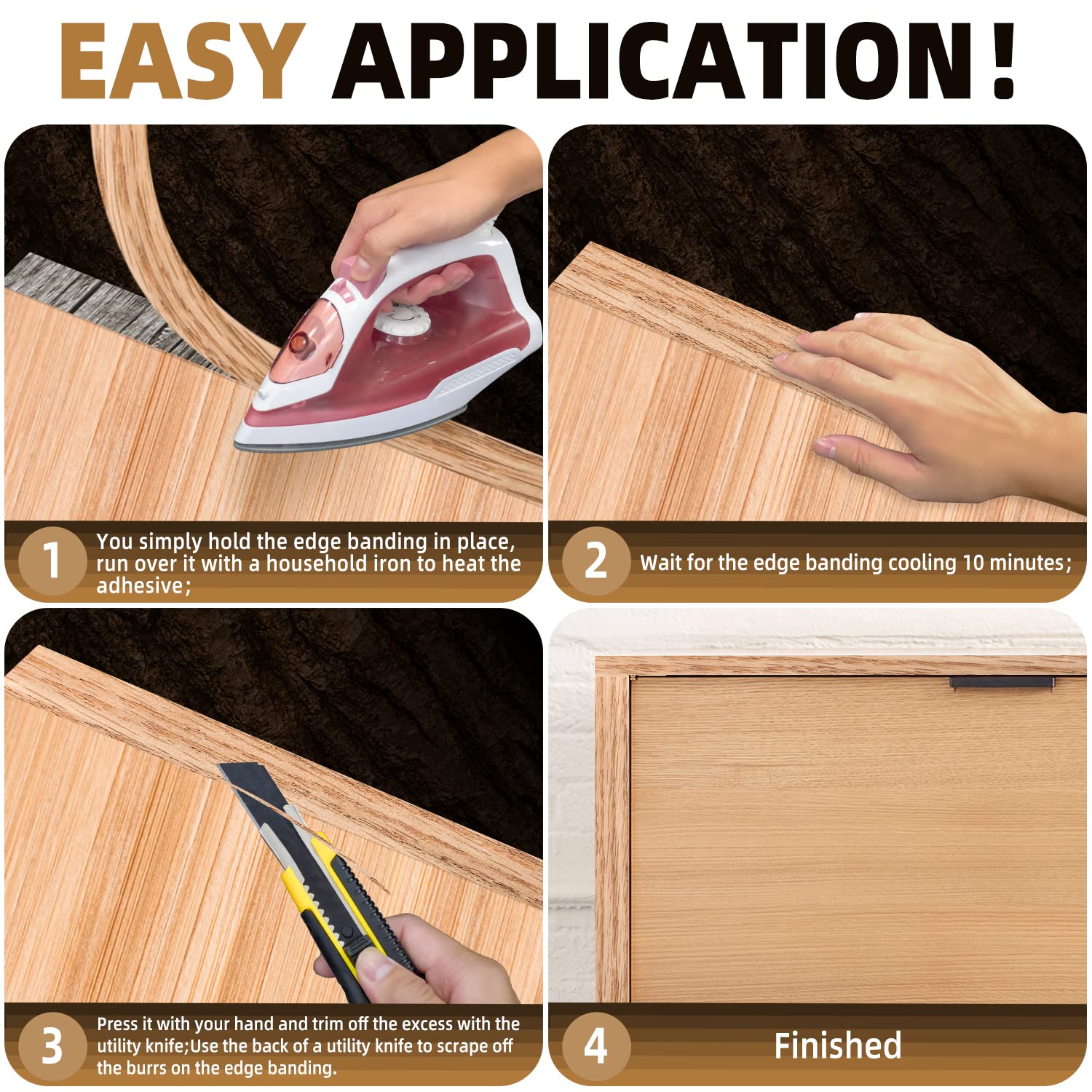

2) How do I apply and finish the edge banding?

- Recommended tools: Household iron (set to cotton/linen, no steam) or a veneer edge-banding tool; edge trimmer; file or scraper; 180–220 grit sanding block; 220–320 grit finish sanding; tack cloth; finish of your choice.

- Core procedure:

1) Confirm substrate edge is flush, clean, and free of dust. Lightly chamfer sharp corners to avoid burn-through.

2) Set iron to cotton setting; keep iron moving to prevent overheating. Apply even pressure; use a heat-resistant pad for longer runs if needed.

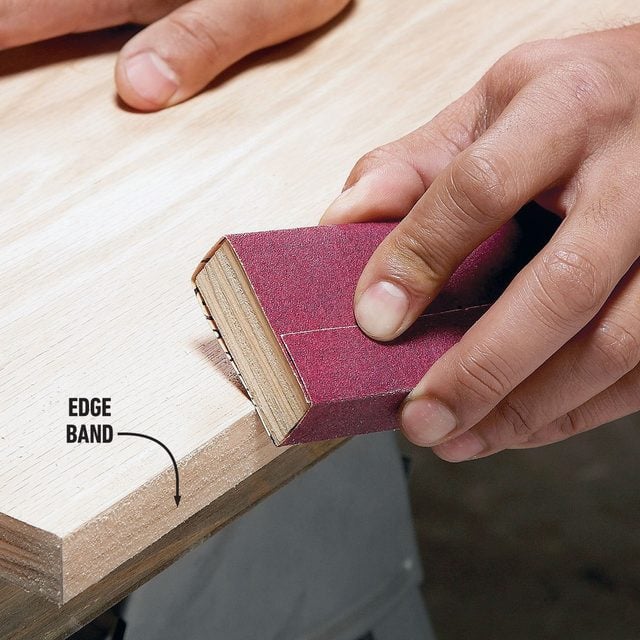

3) Trim flush with a sharp edge trimmer; complete a final scrape and 220–320 grit sanding.

4) Apply finish (water-based or solvent) consistent with the rest of the assembly; allow full cure before handling or packaging. - Troubleshooting:

- Visible glue lines: Reduce iron temp or dwell time; ensure even contact.

- Burn marks: Keep iron moving; pre-scuff substrate; reduce temperature.

- Adhesion failure: Clean substrate; check for wax/oil; confirm iron temp and dwell; lightly sand substrate first.

- Swelling (water-based finishes): Switch to solvent-based or pre-seal veneer face before applying water-based finishes.

- Gaps at ends: Extend band 1–2″ beyond the edge, trim after set; add a small glue drop at the end if needed.

3) What widths and lengths can I order?

- Widths: Typical 7/8″ stock width. Other widths may be available—request current stock check.

- Lengths: 250′ per roll. Shorter pre-cut pieces may be offered; ask for availability and lead time.

- Custom options: Custom species and profile-matched edge solutions are possible via project inquiry (MOQs may apply).

4) What are pricing, MOQ, stock, and lead times?

- Price example: White Oak pre-glued 7/8″ x 250′ — On sale at $39.50/roll.

- Quantity discounts: Quantities accepted; request tier pricing by SKU for larger volumes.

- MOQ: Usually 1 roll; project-level MOQs may apply for custom species or custom widths.

- Lead time (US): Stocked items typically ship same day if ordered by 1:00 PM EST; standard 1–2 business day transit via UPS Ground from CA, USA.

- Inventory: “Ships Today!” denotes high stock confidence; check specific SKU availability at time of order.

- International: Lead times vary by freight. Provide incoterm preference (EXW vs DAP), destination, and any port/airport constraints; transit commonly 5–10 business days to major hubs. Duties, VAT, and carrier fees are not included unless stated.

5) How are orders shipped (domestic and international)?

- Domestic (US): Ships from CA via UPS Ground; same-day dispatch for stock when ordered by 1:00 PM EST.

- Carriers: UPS (Small Package). Palletized freight (LTL) may be used for high-volume or heavier shipments; carrier selection may vary by zip code.

- Tracking: Provided via standard UPS notifications.

- International: Orders ship via parcel for small lots or freight for large volumes.

- Duties/VAT: Billed to receiver unless requested otherwise; DAP terms available on request.

- Freight Forwarding: Supported if you provide your own forwarder.

- Exceptions: Hazardous restrictions vary by country; some carriers require wood pre-packaging; contact us for country-specific guidance.

- Documentation: Commercial invoice and standard shipping documents provided; additional certificates (e.g., fumigation) may be requested depending on destination country.

6) What about returns, claims, and defective product handling?

- Returns: Accepted on eligible items within policy timeframe; 15–25% restocking fee may apply to cut-to-length or non-stock items. Returned goods must be in resaleable condition.

- Claims: Inspect shipments immediately and report within the timeframe specified by the carrier; photographic documentation is required.

- Resolution: Replacement or credit for verified defects or shipping errors; defective material will not be accepted without prior RMA.

- Note: Due to variability in natural materials, color and grain variation is not considered a defect. Always approve a sample or do a small-run validation for critical color consistency.

7) How do I select and verify a sample?

- Sample policy: Request a physical sample to confirm color, grain, and finish compatibility with your substrate and finish schedule.

- Visual inspection: Place the sample under a strong, angled light to check seam telegraphing and grain blending at joins.

- Process validation: Run a test using your iron temperature, dwell time, and finish to verify performance before full-scale production.

8) How do I contact support and coordinate larger projects?

- Contact options: Contact via the vendor’s account portal (Questions? > Contact Us) or email; include project scope, required widths/lengths, target ship dates, incoterms (for international), and any quality certificates required.

- Quote turnaround: Typically within 1–2 business days for standard SKUs; longer for custom species/widths.

- Documentation provided: SDS/Product info pages and product guides are available in Help & Info; commercial invoices provided for shipments.

Strategic Sourcing Conclusion and Outlook for oak edge banding

Strategic Sourcing Conclusion and Outlook for Oak Edge Banding

White oak edge banding at $39.50 per 250′ roll (7/8″ width, pre-glued, iron‑on) delivers clear value: consistent appearance from a proprietary joint pattern and sanding technique; pre‑sanded readiness for fast application; and reliable fulfillment via “Ships Today” when ordered by 1pm EST. The 250′ roll length and competitive unit cost support lean inventory and predictable per‑project spend.

For USA/Europe buyers, the procurement levers are straightforward:

– Pre-glue reduces labor and glue handling on shop floors.

– 250′ rolls extend changeover intervals and minimize seam rework.

– Domestic lead-time and real-time inventory visibility improve schedule adherence.

To illustrate the current value proposition, consider the summary below:

Illustrative Image (Source: Google Search)

| Attribute | Value |

|---|---|

| Species | White oak |

| Size | 7/8″ x 250′ |

| Adhesive | Pre-glued (iron‑on) |

| Finish | Pre-sanded; seams visually minimized |

| Unit price | $39.50 |

| Lead time | Ships Today! (order by 1pm EST) |

| Inventory | In stock; quantity discounts available |

| Application notes | Ready for easy application |

Strategic Outlook:

– Quality focus: continued emphasis on joint uniformity and pre‑sanding will compress finish cycles and reduce visible seams.

– Reliability: same‑day shipping and stable stock levels support tighter schedules and lower safety stock.

– Cost discipline: predictable pricing and roll lengths help project teams align finishing budgets and maintain throughput.

Taken together, white oak edge banding that ships fast and goes on cleanly is a practical, repeatable input for casegoods, fixture shops, and contract manufacturers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.