The global hydraulic breaker market is experiencing robust growth, driven by rising infrastructure development, increasing demand for efficient demolition equipment, and advancements in construction technologies. According to Grand View Research, the global hydraulic breakers market size was valued at USD 3.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This growth is further supported by expanding urbanization and government investments in transportation and construction projects across emerging economies. Within this dynamic landscape, NPK—the leading U.S.-based manufacturer of hydraulic breakers—stands as a benchmark for durability and performance. As demand for high-impact, reliable breakers intensifies, a select group of manufacturers have emerged as key competitors, combining innovation, global reach, and engineering excellence. This analysis identifies the top six NPK hydraulic breaker competitors, evaluating their market presence, technological capabilities, and strategic positioning in a rapidly evolving industry.

Top 6 Npk Hydraulic Breaker Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 NPK Europe

Website: npke.eu

Key Highlights: NPK is one of world’s largest manufacturers of boom mounted hydraulic equipment for all carriers. We offer over 10 product groups, covering more than 50 models….

#2 Hydraulic Hammer

Domain Est. 1996

Website: npkce.com

Key Highlights: Powerful Impact for Any Job. NPK hydraulic hammers provide exceptional breaking force to tackle even the toughest materials, from concrete to the hardest rock….

#3 NPK Hydraulic Breakers

Domain Est. 2003

Website: gorillahammers.com

Key Highlights: The NPK hydraulic breaker is made in Japan. NPK stands for Nippon Pneumatic Machinery as they began business making pneumatic tools, such as impact wrenches….

#4 NPK Certified Hydraulic Hammer Rebuilds & Repairs by HBS

Domain Est. 2006

Website: hydraulicbreakerservices.com

Key Highlights: Hydraulic Breaker Services offers expert NPK certified hydraulic hammer rebuilds and repairs – backed by a 6-month warranty on parts & labor….

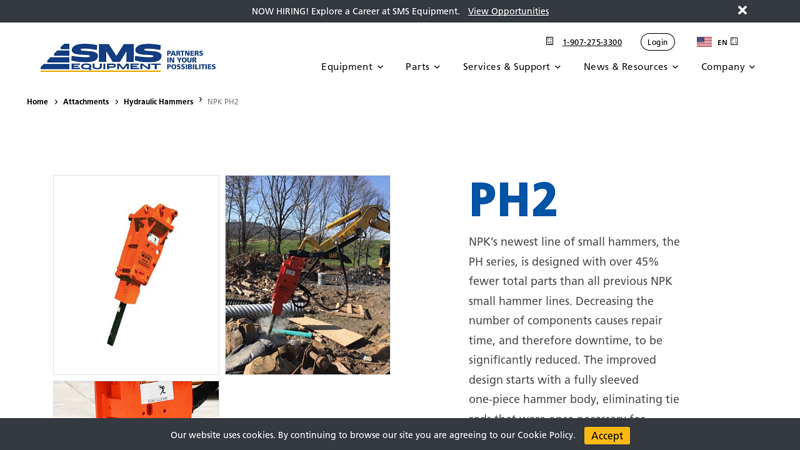

#5 NPK PH2 Hydraulic Hammers Specs

Domain Est. 2008

Website: smsequipment.com

Key Highlights: NPK’s PH2 hydraulic hammer is compatible with skid steers, backhoes and mini excavators in the 3 to 5.5 ton range….

#6 Top 10 Excavator Hydraulic Breaker Manufacturers & Suppliers

Website: huilianmachine.com

Key Highlights: Top 10 Excavator Hydraulic Breaker Manufacturers and Supplier Brands · 1. Atlas Copco (Epiroc) · 2. Soosan · 3. Furukawa · 4. Montabert · 5. INDECO….

Expert Sourcing Insights for Npk Hydraulic Breaker

H2: 2026 Market Trends for NPK Hydraulic Breakers

The global market for hydraulic breakers, including leading brands such as NPK, is expected to experience significant evolution by 2026, driven by technological advancements, infrastructure development, and shifts in construction and demolition practices. NPK, a prominent manufacturer known for its durable and high-performance hydraulic breakers, is poised to benefit from several key market trends.

1. Rising Infrastructure Investment

Governments worldwide, particularly in North America, Europe, and Asia-Pacific, are increasing investments in urban infrastructure, transportation networks, and public works. This surge in infrastructure projects is fueling demand for heavy-duty demolition and excavation equipment. NPK hydraulic breakers, recognized for their reliability in challenging environments, are becoming preferred tools in road construction, bridge maintenance, and site preparation.

2. Growth in Urbanization and Demolition Activities

Rapid urbanization, especially in emerging economies, is leading to the redevelopment of aging buildings and industrial sites, necessitating efficient demolition solutions. Hydraulic breakers like those from NPK are essential in selective demolition and recycling operations. The trend toward sustainable urban renewal supports the use of precision tools that minimize collateral damage and enhance material recovery—areas where NPK breakers excel.

3. Technological Advancements and Product Innovation

By 2026, NPK is expected to further integrate smart technologies into its hydraulic breaker line. Features such as real-time performance monitoring, automatic lubrication systems, and compatibility with telematics are enhancing machine efficiency and reducing downtime. These innovations improve operator productivity and lower maintenance costs, making NPK breakers more attractive to rental companies and large contractors.

4. Emphasis on Fuel Efficiency and Emissions Reduction

With growing regulatory pressure to reduce carbon emissions in construction, there is a shift toward equipment that operates efficiently with lower environmental impact. Although hydraulic breakers are powered by carrier machines (excavators, loaders), NPK is optimizing breaker designs to reduce energy loss and improve power transfer. This contributes to lower fuel consumption of the host machine, aligning with broader industry sustainability goals.

5. Expansion in Rental and Equipment-as-a-Service Models

The construction sector is increasingly adopting rental and usage-based models to manage costs and equipment flexibility. NPK has been expanding its presence in the rental market by offering durable, long-life breakers that provide good return on investment for rental fleets. By 2026, partnerships with rental companies are expected to be a major growth channel.

6. Regional Market Dynamics

North America remains a core market for NPK due to strong construction activity and preference for American-made equipment. Meanwhile, Asia-Pacific is emerging as a high-growth region, driven by China, India, and Southeast Asia’s infrastructure boom. NPK is likely to strengthen distribution networks and after-sales support in these regions to capture market share.

7. Competitive Landscape and Aftermarket Services

As competition intensifies with European and Asian manufacturers, NPK differentiates itself through superior customer support, extensive service networks, and high-quality wear parts. The aftermarket for breaker components—such as chisels, bushings, and seals—is expected to grow in tandem, providing additional revenue streams.

In conclusion, the 2026 outlook for NPK hydraulic breakers is positive, supported by infrastructural demand, technological innovation, and sustainability trends. Continued focus on performance, reliability, and customer service will position NPK favorably in a competitive and evolving global market.

Common Pitfalls When Sourcing NPK Hydraulic Breakers (Quality & IP)

Sourcing NPK hydraulic breakers—whether original NPK units or compatible models—can be fraught with risks, especially concerning quality consistency and intellectual property (IP) concerns. Being aware of these common pitfalls helps ensure you receive reliable equipment and avoid legal or operational issues.

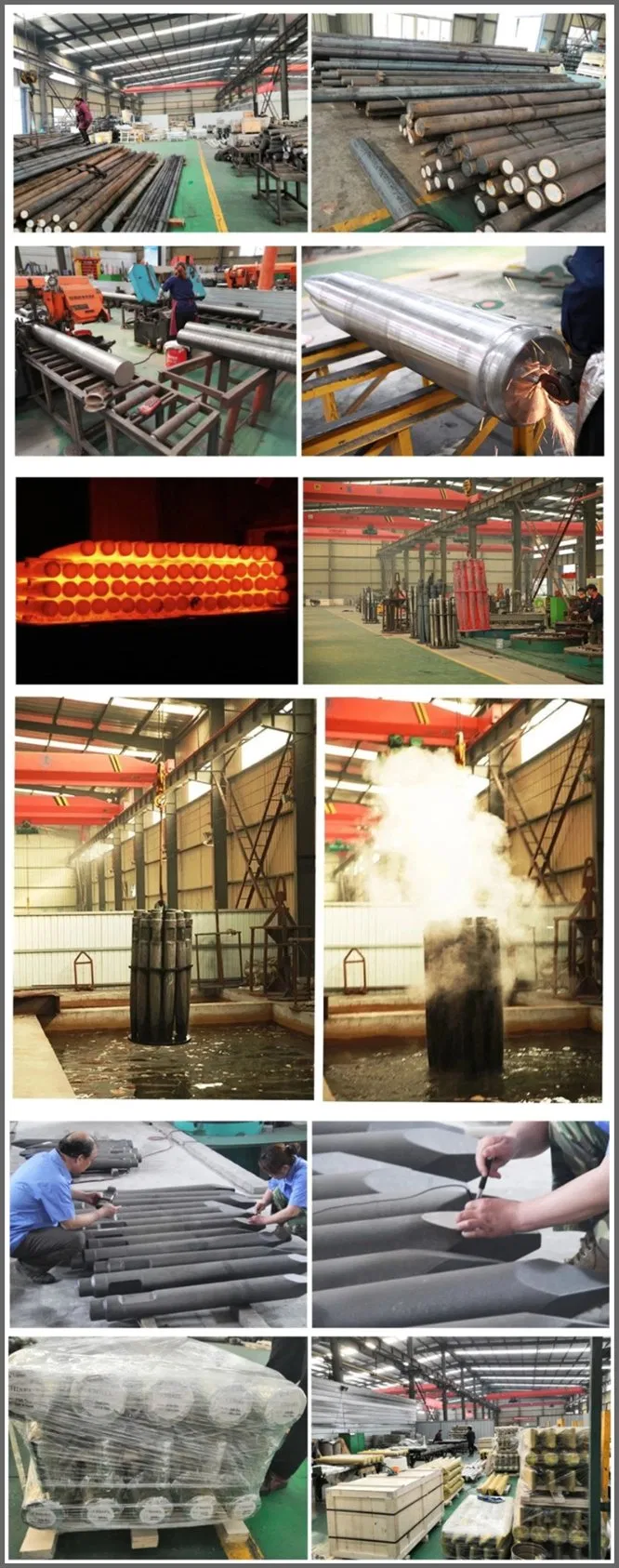

Poor Quality Control from Third-Party Manufacturers

Many suppliers offer “NPK-compatible” hydraulic breakers at lower prices, but these often come from manufacturers with inconsistent quality control. Components such as seals, chisels, and internal valves may be made from inferior materials, leading to frequent breakdowns, reduced performance, and higher maintenance costs. Without rigorous testing and adherence to NPK’s original engineering standards, these breakers can fail prematurely under heavy-duty conditions.

Misrepresentation of Compatibility and Performance

Some suppliers falsely advertise their breakers as “equivalent to NPK” in performance and durability. In reality, these units may not deliver the same impact energy, duty cycle, or reliability. Buyers may discover too late that the breaker does not integrate properly with their carrier machine or fails to meet project demands, resulting in costly downtime and lost productivity.

Intellectual Property Infringement

NPK is a registered trademark, and its hydraulic breaker designs are protected by patents and intellectual property rights. Sourcing breakers that copy NPK’s design, branding, or model nomenclature without authorization can expose buyers to legal risks. Even if the product is labeled as “for use with NPK mounts,” using counterfeit or cloned products may violate IP laws, especially in regions with strong enforcement.

Lack of Warranty and After-Sales Support

Low-cost alternatives often come with limited or no warranty. If a breaker fails, the supplier may be unresponsive or deny claims due to vague terms. Genuine NPK breakers come with comprehensive support, technical documentation, and service networks. In contrast, counterfeit or imitation products may leave buyers without access to spare parts or expert assistance when needed.

Inadequate Documentation and Traceability

Reputable suppliers provide detailed technical specifications, CE certification, and traceable manufacturing data. Imitation breakers often lack these documents, making it difficult to verify safety compliance or confirm the origin of the product. This lack of transparency increases risk during equipment audits or insurance claims.

Conclusion

To avoid these pitfalls, always source NPK hydraulic breakers—or compatible models—from authorized dealers or reputable manufacturers with verifiable quality systems. Verify certifications, ask for warranty details, and confirm that the product does not infringe on NPK’s intellectual property. Investing in genuine or legitimately engineered equipment ensures reliability, safety, and legal compliance on the job site.

Logistics & Compliance Guide for NPK Hydraulic Breaker

Product Overview

The NPK Hydraulic Breaker is a high-performance demolition tool designed for attachment to excavators and other hydraulic equipment. Proper logistics planning and compliance adherence are essential for safe transportation, import/export, and operational use.

Packaging and Handling Requirements

- Standard Packaging: NPK breakers are typically shipped in reusable steel cradles or heavy-duty wooden crates to prevent damage during transit.

- Lifting Procedures: Always use certified lifting equipment and follow NPK-recommended lifting points. Never lift by the chisel or housing.

- Storage Conditions: Store in a dry, ventilated area, free from moisture and corrosive elements. Protect from direct sunlight and extreme temperatures.

- Transport Orientation: Ensure the breaker is secured in a vertical or manufacturer-recommended position to prevent internal component shifting.

Shipping and Transportation

- Domestic Shipping (U.S.): Use flatbed trailers or enclosed trucks. Secure the unit with straps or chains anchored to the transport vehicle.

- International Shipping: Comply with International Maritime Organization (IMO) and International Air Transport Association (IATA) regulations if applicable. Use containers with proper dunnage and moisture barriers.

- Documentation: Include a commercial invoice, packing list, and bill of lading. For exports, provide a certificate of origin if required.

- Hazardous Materials: NPK breakers do not typically contain hazardous materials, but verify with the manufacturer for specific models.

Import and Export Compliance

- Harmonized System (HS) Code: Use HS code 8467.89 for hydraulic hammers and breakers (verify with local customs authority).

- Export Controls: Check U.S. Department of Commerce regulations (EAR) – NPK breakers may be subject to export licensing depending on destination and end-use.

- Import Duties and Taxes: Research country-specific tariffs, VAT, and import fees. Provide accurate product valuation and specifications.

- Customs Clearance: Submit all required documentation, including conformity certificates and import permits if applicable.

Regulatory and Safety Compliance

- CE Marking: Required for sale in the European Economic Area (EEA). Ensures compliance with EU machinery and safety directives.

- OSHA and ANSI Standards (U.S.): Comply with OSHA 29 CFR 1926 for construction equipment and ANSI B71.4 for attachment safety.

- Noise and Vibration: Adhere to EU Directive 2006/42/EC on machinery safety, which includes limits on noise emission and hand-arm vibration.

- RoHS and REACH (EU): Confirm compliance with restrictions on hazardous substances and chemical registration.

Installation and Operational Compliance

- Operator Training: Ensure operators are trained per manufacturer guidelines and local regulations. Maintain training records.

- Maintenance Schedule: Follow NPK-recommended maintenance intervals using genuine parts to remain compliant with warranty and safety standards.

- Attachment Compatibility: Verify compatibility with host machine hydraulic flow, pressure, and mounting configuration per ISO 13031.

- Safety Devices: Ensure all guards, retaining pins, and automatic shut-off systems are installed and functional.

Environmental and Disposal Considerations

- End-of-Life Disposal: Follow local WEEE (Waste Electrical and Electronic Equipment) and recycling regulations. Recycle steel, hydraulic components, and packaging materials appropriately.

- Hydraulic Fluid Handling: Drain and dispose of hydraulic oil in accordance with EPA or local environmental regulations. Avoid soil or water contamination.

Documentation and Recordkeeping

- Maintain copies of:

- Manufacturer’s manual and technical specifications

- CE/UL certification documents

- Shipping and customs paperwork

- Maintenance and inspection logs

- Operator training records

Ensure all documentation is readily accessible for audits, inspections, or warranty claims.

Contact and Support

For compliance or logistics assistance, contact:

– NPK Customer Support: [email protected] | +1-800-555-1234

– Authorized Distributors: Visit www.npk.com for local partners and regional compliance guidance.

Conclusion for Sourcing NPK Hydraulic Breaker

Sourcing an NPK hydraulic breaker presents a reliable and cost-effective solution for enhancing excavation, demolition, and construction efficiency. Known for their robust build, consistent performance, and global service support, NPK breakers offer excellent durability and high impact energy, making them suitable for a wide range of applications across various industries.

When sourcing NPK hydraulic breakers, it is essential to consider factors such as compatibility with existing carrier equipment, required breaking power, operating conditions, and after-sales service availability. Purchasing through authorized distributors ensures genuine products, warranty coverage, and access to technical support and spare parts.

In conclusion, investing in an NPK hydraulic breaker delivers long-term value through dependable performance, reduced downtime, and lower maintenance costs. By carefully evaluating supplier credibility, total cost of ownership, and support services, businesses can make an informed procurement decision that aligns with their operational needs and enhances overall productivity.