The global non-woven bag market is experiencing robust growth, driven by increasing environmental regulations and a rising demand for sustainable packaging alternatives. According to Grand View Research, the global reusable shopping bag market size was valued at USD 14.2 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030, with non-woven polypropylene (NWPP) bags accounting for a significant share. This surge is fueled by government bans on single-use plastics across regions like Europe, North America, and parts of Asia-Pacific, as well as heightened consumer awareness toward eco-friendly products. As retailers and brands shift toward sustainable branding and packaging solutions, the demand for high-quality, customizable, and durable non-woven bags continues to climb. In this evolving landscape, a select group of manufacturers has emerged as industry leaders—scaling production, innovating materials, and meeting international quality standards. Based on market presence, export volume, production capacity, and sustainability practices, the following ten companies represent the top non-woven bag manufacturers shaping the future of eco-conscious packaging.

Top 10 Non Woven Bag Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

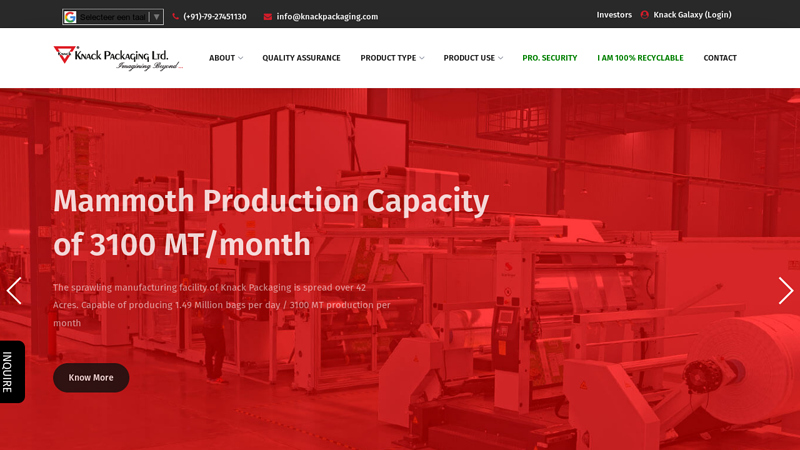

#1 Plastic Bags Manufacturers

Domain Est. 2006

Website: knackpackaging.com

Key Highlights: Knack Packaging is the largest manufacturer and exporter of PPE / PP Woven Fabrics & Bags / Printed and Laminated Woven PP Bags. (PLWPP)…

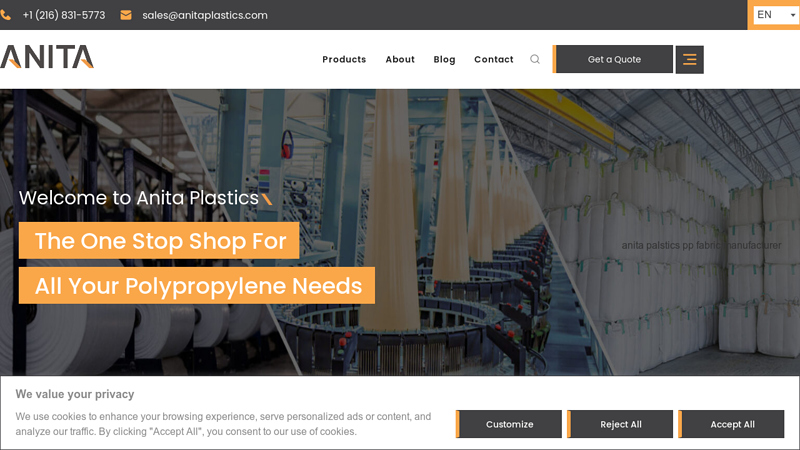

#2 PP/HDPE woven and non woven Fabric Manufacturer in the US

Domain Est. 2007

Website: anitaplastics.com

Key Highlights: Leading PP/HDPE woven and non-woven fabric manufacturer offering quality bags, geotextiles, and landscape fabrics for diverse industries….

#3 China Non woven Bags manufacturer

Domain Est. 2017

Website: sourcenonwoven.com

Key Highlights: Source Nonwoven is leading manufacturer and supplier of non woven bags with different non woven material, size and customerized logo….

#4 Non Woven Bags

Domain Est. 2022

Website: universal-bags.com

Key Highlights: Universal bags offer a wide range of non-woven bags at the best prices. Get reusable, eco-friendly & custom printed non-woven bags for shopping needs….

#5 Non-Woven Carry Bag Manufacturers

Domain Est. 2024

Website: fabricanonwoven.com

Key Highlights: Fabrica Non-Woven is a leading non-woven bag manufacturer and supplier, specializing in eco-friendly and custom bag solutions for various businesses….

#6 Custom Non Woven Bags & Totes

Domain Est. 2007

Website: reusethisbag.com

Key Highlights: At ReuseThisBag.com, we offer a variety of bulk wholesale non woven bags to suit a wide range of business promotional needs….

#7 Green Sustainable & Eco-friendly Packaging Supplier

Domain Est. 2009

Website: bk-bags.com

Key Highlights: PP (polypropylene) non-woven bags are excellent solution for reusable shopping bags in competitive cost. Our PP woven bags customized to any shape and size….

#8 Category

Domain Est. 2013

Website: non-woven.com

Key Highlights: Category: Non Woven Bags, EcoBag · Nonwoven Fabric (160) · Medical Non-woven Fabric (7) · Flower&Gift Wrapping (92) · Table Cloth (26) · Non Woven Bags, EcoBag (128) ……

#9 Eco Friendly Non-Woven Bags

Domain Est. 2019

Website: bagsguru.in

Key Highlights: We offer a wide range of non-woven bags like 3 side seal bag, non-woven box bag, BOPP laminated nonwoven bag, screen printed non-woven bag, D cut bag, loop ……

#10 Buy Non Woven Bags

Domain Est. 2020

Website: patekpackaging.com

Key Highlights: Free deliveryPatek Packaging’s non woven bags are made from eco-friendly, recycled fibres bonded through advanced heat, mechanical, or chemical processes. This creates ……

Expert Sourcing Insights for Non Woven Bag

2026 Market Trends for Non-Woven Bags: A Strategic Outlook

The non-woven bag market is poised for significant evolution by 2026, driven by escalating environmental concerns, regulatory shifts, technological advancements, and changing consumer preferences. As a sustainable alternative to traditional plastic, non-woven polypropylene (NWPP) bags are transitioning from a simple utility item to a strategic tool for branding and environmental responsibility. Here are the key trends shaping the market landscape in 2026:

Rising Regulatory Pressure and Plastic Bans

By 2026, an increasing number of countries and municipalities will have implemented or expanded bans and levies on single-use plastic bags. These regulations are a primary driver for the adoption of reusable alternatives like non-woven bags. Governments worldwide are recognizing the long-term environmental benefits of promoting reusable options, creating a favorable policy environment. This regulatory tailwind will continue to push retailers, supermarkets, and e-commerce platforms toward non-woven solutions to remain compliant and avoid penalties.

Growing Consumer Demand for Sustainability

Eco-conscious consumers are a powerful force behind the growth of the non-woven bag market. By 2026, sustainability will be a core purchasing criterion for a majority of shoppers, particularly among Millennials and Gen Z. Non-woven bags, marketed as reusable and recyclable, align with this demand. Brands leveraging non-woven bags as part of their sustainability messaging will gain competitive advantage, with consumers favoring companies that visibly reduce plastic waste.

Innovation in Materials and Design

To meet evolving expectations, manufacturers will focus on enhancing non-woven bags with improved durability, recyclability, and aesthetic appeal. Innovations will include:

– Biodegradable and Compostable Blends: Development of non-woven fabrics incorporating bio-based polypropylene or polylactic acid (PLA) to address end-of-life concerns.

– Enhanced Durability: Stronger stitching, reinforced handles, and thicker fabrics to increase reusability and perceived value.

– Design Customization: Advanced digital printing allows for vibrant, detailed branding, turning bags into walking advertisements and gift-worthy items.

Expansion in E-Commerce and Retail Packaging

The booming e-commerce sector will increasingly adopt non-woven bags as sustainable packaging solutions. By 2026, many online retailers will replace plastic mailers with reusable non-woven pouches or bags, promoting a circular economy. Additionally, premium retail and luxury brands will use high-quality non-woven bags to elevate unboxing experiences while maintaining environmental commitments.

Cost Optimization and Production Efficiency

As demand grows, manufacturers will invest in automated production lines and process improvements to reduce costs and maintain margins. Economies of scale, especially in regions like Asia-Pacific, will support competitive pricing. However, fluctuating raw material prices (e.g., polypropylene) will remain a challenge, pushing innovation toward recycled content and supply chain resilience.

Regional Market Dynamics

Asia-Pacific will remain the largest market due to population density, rapid urbanization, and growing environmental awareness in countries like India and China. North America and Europe will see steady growth driven by strict regulations and high consumer environmental engagement. Emerging markets in Latin America and Africa will begin adopting non-woven bags as part of broader sustainability initiatives.

Circular Economy and End-of-Life Management

By 2026, stakeholders will place greater emphasis on the full lifecycle of non-woven bags. Initiatives promoting take-back programs, recycling infrastructure, and consumer education on proper disposal will gain traction. Brands will increasingly report on the environmental footprint of their bags, including carbon emissions and recyclability rates.

Conclusion

The 2026 non-woven bag market will be defined by sustainability leadership, innovation, and regulatory support. As companies align with environmental goals and consumers demand responsible products, non-woven bags will solidify their role as a key component of the global shift toward reusable packaging. Success will belong to those who combine eco-design, brand value, and circular economy principles in their offerings.

Common Pitfalls When Sourcing Non-Woven Bags (Quality and Intellectual Property)

Sourcing non-woven bags can be cost-effective and sustainable, but overlooking key quality and intellectual property (IP) aspects can lead to significant problems. Here are common pitfalls to avoid:

Poor Material Quality and Inconsistent Weight

One of the most frequent issues is receiving non-woven bags made from substandard polypropylene (PP) fabric. Suppliers may use recycled or low-grade materials, or fabric with a lower GSM (grams per square meter) than specified. This results in thin, weak bags that tear easily, compromising durability and brand image. Inconsistent GSM across production batches can also lead to unpredictable performance and customer dissatisfaction.

Inaccurate or Misleading Specifications

Suppliers may advertise certain specifications (e.g., 80 GSM, 100% virgin PP) that don’t match the delivered product. Without third-party verification or clear quality control protocols, buyers risk receiving inferior goods. Misrepresentation can extend to bag dimensions, handle strength, and printing capabilities, leading to functional and aesthetic flaws.

Lack of Durability Testing

Many suppliers fail to conduct or provide documentation for essential durability tests such as tensile strength, seam strength, and drop testing. Without these, there’s no assurance the bags can withstand typical use, especially when carrying heavy or sharp items. Bags that fail under load reflect poorly on the sourcing company and can result in returns or complaints.

Substandard Printing and Design Execution

Poor print quality—such as misalignment, fading, color variation, or ink bleeding—is common when working with inexperienced or low-cost manufacturers. Additionally, using low-resolution artwork or incorrect color models (e.g., RGB instead of CMYK) can lead to disappointing results. This degrades brand presentation and reduces the perceived value of the product.

Intellectual Property Infringement Risks

Using copyrighted logos, brand names, or patented designs without proper authorization exposes buyers to legal liability. Some suppliers may offer to replicate popular branded bags, which can lead to trademark or design patent violations. Always ensure you have the rights to use any artwork or design elements and verify that the supplier isn’t infringing on third-party IP.

Unauthorized Use of Your Designs

When sharing your own custom designs with suppliers, there’s a risk they may reproduce and sell them to competitors without permission. This is especially prevalent in regions with weak IP enforcement. Without a clear Non-Disclosure Agreement (NDA) or IP ownership clause in the contract, your creative work may not be protected.

No Compliance with Environmental or Safety Standards

Non-woven bags are often marketed as eco-friendly, but some contain harmful chemicals (e.g., heavy metals, phthalates) or aren’t recyclable as claimed. Suppliers may lack certifications like REACH, RoHS, or ASTM D6400, leading to compliance issues in regulated markets. Misleading environmental claims can also result in greenwashing accusations.

Inadequate Quality Control and Inspection Processes

Relying solely on supplier assurances without independent pre-shipment inspections can result in large volumes of defective products. Common defects include stitching errors, incorrect dimensions, or inconsistent lamination. Implementing a third-party QC audit helps catch issues before shipment.

Hidden Costs from Rework and Rejection

Poor initial quality often leads to rejected shipments, delays, and the need for costly reorders. These hidden expenses can negate any upfront savings from choosing a low-cost supplier. Always factor in potential risks and have contingency plans.

Failure to Verify Supplier Credentials

Working with unverified manufacturers increases the risk of fraud, inconsistent quality, and IP theft. Always perform due diligence: check certifications, request references, conduct factory audits, and start with small trial orders before scaling up.

Avoiding these pitfalls requires clear specifications, strong contracts, IP protection measures, and proactive quality management throughout the sourcing process.

Logistics & Compliance Guide for Non-Woven Bags

Overview

Non-woven bags, typically made from polypropylene (PP) or similar synthetic fibers, are widely used as eco-friendly alternatives to plastic bags. Efficient logistics and strict compliance with international and local regulations are essential for their import, export, and distribution. This guide outlines key considerations for businesses involved in the supply chain of non-woven bags.

Material & Product Classification

Non-woven bags are generally classified under the following HS (Harmonized System) codes:

– HS 4202.92: Travel, sports, and similar bags with an outer surface of plastics or textiles.

– HS 6307.90: Other made-up articles, including reusable shopping bags.

Accurate classification is critical for determining applicable tariffs, import duties, and regulatory requirements in target markets.

Regulatory Compliance

International Standards

- REACH (EU): Ensure that chemical substances used in the production (e.g., dyes, coatings) comply with REACH regulations. Registration, Evaluation, Authorization, and Restriction of Chemicals must be observed.

- RoHS (EU): Although primarily for electronics, certain additives in non-woven materials may fall under restricted substances.

- Proposition 65 (California, USA): Bags sold in California must not contain chemicals known to cause cancer or reproductive harm without proper warning labels.

- FDA Compliance (USA): If bags are intended for food contact (e.g., grocery use), they must meet FDA standards for food-safe materials.

Labeling & Packaging Requirements

- Country of Origin Labeling: Bags must clearly display the country of manufacture (e.g., “Made in China”).

- Care & Usage Instructions: Include washing instructions if applicable.

- Recycling & Material Labels: Indicate recyclability (e.g., “Recyclable PP”) and include appropriate recycling symbols.

- Branding and Trademarks: Ensure logos and brand names do not infringe on intellectual property rights in the destination country.

Packaging & Shipping

Packaging

- Use moisture-resistant and durable packaging (e.g., poly-woven sacks or cardboard cartons) to prevent damage during transit.

- Stack bags uniformly and secure with straps to avoid shifting in containers.

- Include desiccants in humid climates to prevent mold.

Shipping & Logistics

- Container Load Optimization: Maximize space utilization in 20’ or 40’ containers. Estimate approximately 5,000–10,000 bags per pallet depending on size and thickness.

- Freight Options:

- Sea Freight: Most cost-effective for large volumes; lead time 2–6 weeks.

- Air Freight: Faster (3–7 days) but significantly more expensive; suitable for urgent or small shipments.

- Incoterms: Clearly define responsibilities using standard Incoterms (e.g., FOB, CIF, DDP) to manage risks and costs.

Customs Clearance

- Prepare complete documentation:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin (may be required for tariff preferences)

- Test Reports (e.g., for REACH or food safety)

- Be prepared for customs inspections, especially for shipments entering the EU, USA, or Canada.

Environmental & Sustainability Compliance

- Single-Use Plastic Bans: Many countries regulate or ban single-use plastic bags. Non-woven bags are often exempt if they meet durability and reusability criteria (e.g., minimum thickness of 60–100 microns).

- Extended Producer Responsibility (EPR): In some EU countries, importers must register and report on packaging waste and contribute to recycling schemes.

- Carbon Footprint & Declarations: Consider providing environmental product declarations (EPD) or carbon footprint data for sustainability-focused markets.

Quality Control & Inspection

- Conduct pre-shipment inspections to verify:

- Fabric weight (gsm)

- Stitching strength and seam durability

- Print quality and color accuracy

- Dimensions and handle strength

- Third-party inspection services (e.g., SGS, Bureau Veritas) can provide certification and reduce risk of rejection.

Risk Management

- Supplier Verification: Audit manufacturers for compliance with labor, environmental, and safety standards (e.g., BSCI, ISO 9001).

- Insurance: Secure cargo insurance covering loss, damage, or delay.

- Documentation Accuracy: Errors in HS codes or invoices can lead to fines or shipment delays.

Conclusion

Successfully managing the logistics and compliance of non-woven bags requires attention to detail across material sourcing, regulatory adherence, shipping efficiency, and sustainability standards. Proactive planning and documentation ensure smooth customs clearance and market access while minimizing risks and costs.

Conclusion for Sourcing Non-Woven Bags

Sourcing non-woven bags presents a sustainable, cost-effective, and customizable packaging solution for businesses aiming to promote environmental responsibility while maintaining brand visibility. With their durability, reusability, and lower environmental impact compared to single-use plastics, non-woven bags align well with global trends toward eco-conscious consumerism.

When sourcing, it is essential to evaluate suppliers based on material quality, production standards, ethical practices, and compliance with environmental regulations. Conducting due diligence—such as requesting samples, verifying certifications (e.g., REACH, RoHS), and assessing lead times and MOQs—ensures that the final product meets both functional and sustainability goals.

Additionally, bulk sourcing from reputable manufacturers, particularly in regions with established textile industries, can significantly reduce costs without compromising quality. Customization options such as logo printing, varied sizes, and color choices further enhance their appeal for promotional and retail use.

In conclusion, sourcing non-woven bags is a strategic move that supports brand image, meets customer expectations for sustainability, and contributes to reducing plastic waste. With careful supplier selection and quality control, non-woven bags offer a practical, eco-friendly alternative that benefits both businesses and the environment.