The global non-reflective glass market is experiencing robust growth, driven by rising demand in high-tech industries such as electronics, solar energy, and architectural design. According to Mordor Intelligence, the anti-reflective glass market was valued at USD 5.8 billion in 2023 and is projected to grow at a CAGR of 6.7% from 2024 to 2029, reaching an estimated USD 8.6 billion by the end of the forecast period. This expansion is fueled by advancements in optical clarity requirements for displays, increased adoption in photovoltaic panels to enhance energy efficiency, and growing preference for aesthetically sleek building facades with minimal glare. As industries prioritize performance and visual quality, manufacturers specializing in non-reflective glass are positioned at the forefront of innovation. Below are the top 9 companies leading this space with advanced coating technologies, scalable production, and a strong global footprint.

Top 9 Non Reflective Glass Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Anti Glare Glass and Anti Reflective Glass Solutions

Domain Est. 1991

Website: corning.com

Key Highlights: Learn how miniscule structures constructed on the glass surface are a key factor in the advanced Anti-Reflective and Anti-Glare glass solutions….

#2 Anti

Domain Est. 1996

Website: mcgrory.com

Key Highlights: Luxar® anti-reflective glass offers no glare, no reflection, & no color shift. Ideal for facades, display cases, storefronts, museums, & more….

#3 Anti

Domain Est. 1996

Website: glastroesch.com

Key Highlights: Day and night, our specially coated anti-reflection glass ensures, in façades as well as indoors, particularly clear views both from inside and outside….

#4 Anti

Domain Est. 1997

Website: generalglass.com

Key Highlights: Anti-reflective laminated low iron glass has an optical coating on both surfaces of the glass eliminating over 98% of reflection for high quality viewing….

#5 Anti-reflective glass

Domain Est. 2001

Website: guardianglass.com

Key Highlights: Anti-reflective glass is an advanced coated glass with reflection control properties that reduce the reflection of light on the surface of the glass….

#6 Artglass by Groglass

Domain Est. 2006

Website: artglass.groglass.com

Key Highlights: Anti-reflective glass for picture framing, shadowboxes and museum showcases. UV-protective museum quality glazing for picture frames….

#7 Anti

Domain Est. 2007

Website: aiglass.com

Key Highlights: Available in 3/16”, 1/4″ and 1/2” thicknesses · Single-sided, double-sided · Eliminates reflections up to 99% · Higher visible light transmission than traditional ……

#8 Anti-Reflective Glass

Domain Est. 2023

Website: glass-manufacturer.com

Key Highlights: Anti-reflective glass, also known as AR glass, is an innovative type of glass with a thin layer of anti-reflective coating applied to its surface….

#9 Ultra-low Reflection Glass: Invisible Glass™

Website: neg.co.jp

Key Highlights: Glass with minimal reflection or glare. Anti-reflection (AR) coating minimizes light reflection, making the glass nearly invisible….

Expert Sourcing Insights for Non Reflective Glass

2026 Market Trends for Non-Reflective Glass

Rising Demand in Consumer Electronics and Displays

The non-reflective glass market is poised for significant growth by 2026, driven largely by increasing adoption in consumer electronics. As smartphones, tablets, laptops, and wearable devices continue to prioritize display clarity and user experience, manufacturers are integrating anti-reflective (AR) coated glass to reduce glare and improve visibility in bright environments. With the proliferation of outdoor usage and augmented reality (AR)/virtual reality (VR) applications, demand for high-performance non-reflective glass is accelerating. The push toward slimmer, bezel-less designs also favors AR glass, which enhances screen legibility without compromising aesthetics.

Expansion in Solar Energy Applications

Non-reflective glass is gaining traction in the solar photovoltaic (PV) sector, where maximizing light transmission is critical for energy efficiency. By 2026, advancements in AR-coated glass for solar panels are expected to boost energy output by up to 3–5%, making it a key enabler of cost-effective solar solutions. As global investments in renewable energy surge—especially in regions like Asia-Pacific, North America, and Europe—the demand for high-transmittance, durable solar cover glass will drive market expansion. Innovations such as multi-layer coatings and self-cleaning AR glass are further enhancing performance and reducing maintenance costs.

Growth in Architectural and Building Integration

Architectural applications are another major growth vector. Urban developments and smart buildings increasingly incorporate large glass facades, skylights, and glass railings, where non-reflective properties reduce light pollution, improve occupant comfort, and support energy efficiency. Regulatory pushes for sustainable building standards (e.g., LEED, BREEAM) are encouraging the use of advanced glazing technologies. By 2026, the integration of AR glass in commercial and high-end residential projects is expected to rise, particularly in megacities with high solar exposure.

Technological Advancements and Coating Innovations

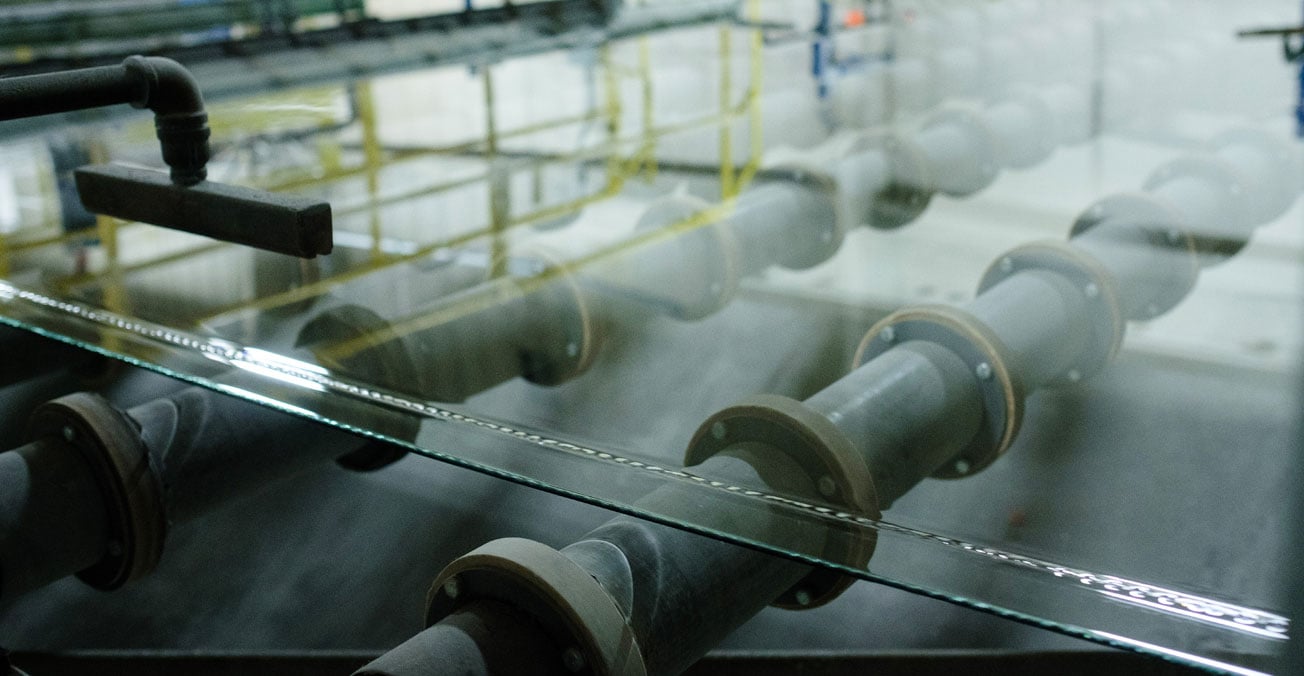

The evolution of coating technologies—such as sol-gel processes, magnetron sputtering, and nanostructured surfaces—is enabling more durable, scratch-resistant, and environmentally stable non-reflective glass. Emerging hybrid coatings that combine anti-reflective, anti-fog, and hydrophobic properties are opening new applications in automotive, medical devices, and optical instruments. These innovations are expected to lower production costs over time, making AR glass more accessible across mid-tier markets.

Regional Market Dynamics

Asia-Pacific will remain the dominant market by 2026, led by China, Japan, and South Korea’s strong manufacturing bases in electronics and solar panels. North America and Europe will follow, driven by green building initiatives and advanced automotive displays. Meanwhile, emerging economies in Latin America and the Middle East are beginning to adopt AR glass in infrastructure and solar projects, presenting long-term growth opportunities.

Sustainability and Circular Economy Considerations

Environmental regulations are influencing material choices across industries. By 2026, manufacturers of non-reflective glass are expected to focus on eco-friendly coating processes and recyclable substrates. Life-cycle assessments and carbon footprint transparency will become competitive differentiators, aligning with corporate ESG goals and regulatory requirements.

In summary, the 2026 market for non-reflective glass will be shaped by technological innovation, sustainability demands, and expanding applications across electronics, energy, and construction sectors—positioning it as a critical material in the next generation of high-performance surfaces.

Common Pitfalls When Sourcing Non-Reflective Glass (Quality and Intellectual Property)

Sourcing non-reflective (also known as anti-reflective or AR) glass requires careful attention to both product quality and intellectual property (IP) considerations. Overlooking these aspects can lead to performance issues, legal risks, and increased costs. Below are key pitfalls to avoid:

Inadequate Optical Performance Verification

Many suppliers claim their glass is “non-reflective,” but actual performance can vary significantly. Buyers may receive glass with insufficient reflectivity reduction (e.g., >2% average reflectance instead of the <0.5% expected from high-end AR coatings). Always request spectral reflectance data across visible wavelengths (400–700 nm) and verify performance under real-world lighting conditions.

Poor Coating Durability and Environmental Resistance

Low-quality AR coatings may degrade quickly when exposed to humidity, abrasion, or cleaning agents. Pitfalls include delamination, scratching, or hazing over time—especially in outdoor or high-use environments. Ensure the coating meets industry standards such as ASTM D3359 (adhesion), MIL-C-48497 (durability), or ISO 9211 (environmental resistance).

Inconsistent Manufacturing Quality

Batch-to-batch variations in coating thickness or substrate flatness can result in inconsistent optical performance or visual defects. This is common with less-reputable manufacturers who lack tight process controls. Require certificates of conformance and conduct incoming inspections to verify dimensional tolerances and coating uniformity.

Unverified Intellectual Property (IP) Rights

AR glass technology often involves patented coating processes (e.g., multi-layer thin-film designs, sol-gel methods). Sourcing from suppliers who use counterfeit or unlicensed technologies can expose buyers to IP infringement claims, especially in regulated markets like medical devices or consumer electronics. Always ask for proof of IP ownership or licensing agreements.

Hidden Costs from Customization and Minimum Order Quantities

Custom AR glass (specific sizes, shapes, or coating formulations) may come with high NRE (non-recurring engineering) fees or mandatory minimum order quantities. Buyers may be locked into long-term contracts or face supply chain inflexibility. Clarify pricing terms, tooling costs, and scalability options before committing.

Lack of Technical Support and Documentation

Some suppliers provide inadequate technical data sheets (TDS), installation guidelines, or compatibility information. This can lead to improper handling, reduced performance, or warranty voids. Ensure the supplier offers comprehensive documentation and access to technical experts for integration support.

Supply Chain and Lead Time Risks

AR glass production may depend on specialized equipment or rare materials, leading to extended lead times or supply disruptions. Relying on single-source suppliers without contingency plans increases risk. Evaluate supplier reliability, geographic location, and alternative sourcing options.

By proactively addressing these pitfalls—through rigorous supplier vetting, performance testing, and IP due diligence—buyers can secure high-quality, legally compliant non-reflective glass that meets technical and commercial requirements.

Logistics & Compliance Guide for Non-Reflective Glass

Overview

Non-reflective glass, often treated with anti-reflective (AR) coatings, is widely used in applications such as display cases, picture framing, optical instruments, and architectural glazing where glare reduction is essential. Due to its specialized surface treatment and fragility, handling, transportation, and regulatory compliance require specific attention. This guide outlines key logistics and compliance considerations for the safe and compliant movement of non-reflective glass.

Packaging Requirements

Proper packaging is critical to prevent scratches, coating damage, and breakage during transit.

– Use edge protectors and corner guards made of non-abrasive materials (e.g., foam or rubber).

– Separate individual panes with interleaving paper or low-adhesion film to prevent coating contact.

– Encase glass in rigid, double-walled cardboard or wooden crates with internal cushioning (e.g., foam inserts).

– Clearly label packages with “Fragile,” “This Side Up,” and “Protect from Moisture” indicators.

– Avoid plastic wraps that may trap moisture and degrade AR coatings.

Handling & Storage Guidelines

- Always handle with clean gloves to prevent oil or residue transfer to the glass surface.

- Store vertically in a dry, temperature-controlled environment (15–25°C, 40–60% RH).

- Keep away from direct sunlight and high humidity to prevent delamination of anti-reflective coatings.

- Ensure storage racks are padded and prevent contact between glass panes.

- Limit stacking height to avoid pressure damage.

Transportation Considerations

- Secure loads to prevent shifting; use straps or anti-slip mats in trucks or containers.

- Minimize vibration and shock by using suspension-equipped vehicles or cushioned transport beds.

- Avoid extreme temperature fluctuations; do not leave glass in vehicles exposed to direct sun or freezing conditions.

- For international shipments, comply with international packaging standards such as ISTA 3A or ISO 11985.

- Consider climate-controlled transport if moving through extreme environments.

Regulatory Compliance

Non-reflective glass may be subject to regional and international regulations depending on composition and destination.

– REACH (EU): Ensure coating materials do not contain restricted substances (e.g., certain heavy metals or phthalates).

– RoHS (EU/UK): Verify compliance if glass is used in electronic displays or devices.

– TSCA (USA): Confirm that chemical components in AR coatings are listed and compliant.

– Customs & Tariff Codes: Classify under correct HS code (typically 7007 or 7008 for coated glass); provide accurate product descriptions.

– Safety Data Sheets (SDS): Provide SDS for coated glass if required by jurisdiction or carrier policy.

Quality Assurance & Documentation

- Conduct pre-shipment inspections to verify coating integrity and absence of defects.

- Maintain batch traceability (including coating type, manufacturer, and production date).

- Include Certificates of Conformance (CoC) and test reports (e.g., transmittance, scratch resistance) with shipments when required.

- Document handling procedures and training for logistics personnel.

Emergency & Damage Response

- In case of breakage, follow local hazardous material protocols if coating contains regulated substances.

- Train staff on proper cleanup procedures using protective equipment (gloves, eye protection).

- Report damages immediately to insurers and logistics providers; retain packaging for inspection.

- Implement a returns or replacement process for damaged non-reflective glass.

Conclusion

Effective logistics and compliance for non-reflective glass require attention to its sensitive surface treatment, fragility, and potential chemical regulations. Adhering to proper packaging, handling, transport, and documentation standards ensures product integrity and regulatory alignment across supply chains. Regular training and audits further enhance compliance and reduce risk.

Conclusion: Sourcing Non-Reflective Glass

Sourcing non-reflective glass requires a strategic approach that balances optical performance, durability, cost, and supplier reliability. Non-reflective (or anti-reflective) glass is essential in applications demanding high clarity and minimal glare, such as display cases, picture framing, optical instruments, and digital screens. When procuring this specialized glass, it is critical to evaluate key factors including the quality of the anti-reflective coating, light transmittance levels, scratch resistance, and compliance with industry standards.

Working with reputable suppliers who offer consistent manufacturing processes and quality control ensures reliable product performance. Additionally, considering customization options, lead times, and total cost of ownership—rather than just upfront price—can lead to better long-term outcomes. As technology advances, newer coating technologies such as nano-structured or multi-layer AR coatings provide improved performance, making it worthwhile to stay informed on innovations.

In conclusion, successful sourcing of non-reflective glass hinges on thorough supplier vetting, clear specification of technical requirements, and a focus on application-specific performance. By prioritizing these elements, organizations can secure high-quality, durable, and effective non-reflective glass solutions that enhance the functionality and user experience of their end products.