The global garden hose market, a subset of the broader fluid conveyance systems industry, has demonstrated steady growth, projected to expand at a CAGR of approximately 5.3% from 2023 to 2030, according to Grand View Research. Increasing urbanization, rising emphasis on landscaping, and growing residential and commercial green spaces are key drivers fueling demand. With irrigation needs in agriculture, gardening, and industrial applications becoming more sophisticated, consumers are prioritizing durability, flexibility, and reliability—especially in non-kink hose pipes. These hoses, engineered with reinforced layers and advanced polymers, resist tangling and maintain consistent water flow, making them a preferred choice across end users. As competition intensifies, several manufacturers have emerged as leaders in innovation, quality, and market reach. Based on production capacity, distribution networks, material technology, and customer reviews, the following eight companies represent the top non-kink hose pipe manufacturers shaping the industry today.

Top 8 Non Kink Hose Pipe Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Hoses

Domain Est. 1996

Website: trelleborg.com

Key Highlights: Improve efficiency with our kink-resistant hoses and hose assemblies for high pressure street cleaning, floor cleaning and sewer jetting in municipal ……

#2 Neverkink Garden Hose

Domain Est. 1997

Website: apexhose.com

Key Highlights: Apex Neverkink Garden Hoses contain patented NTS Reflex Mesh® technology so the hose automatically self-straightens preventing kinks, twists & tangles….

#3 Expandable Garden Hose

Domain Est. 2018

Website: aquahung.com

Key Highlights: Expandable Garden Hose. Hung Ta, a leading hosepipe manufacturer in Taiwan, has been at the forefront of developing innovative gardening solutions for years….

#4 Neverkink

Domain Est. 2024

Website: theneverkink.com

Key Highlights: Neverkink hoses deliver smooth, hassle-free watering every time. Built for durability and designed with innovative kink-resistant technology….

#5 Contact Us

Domain Est. 1997

Website: teknorapex.com

Key Highlights: If you would prefer to speak with a representative directly, please dial Toll Free 800-556-3864 or 401-725-8000….

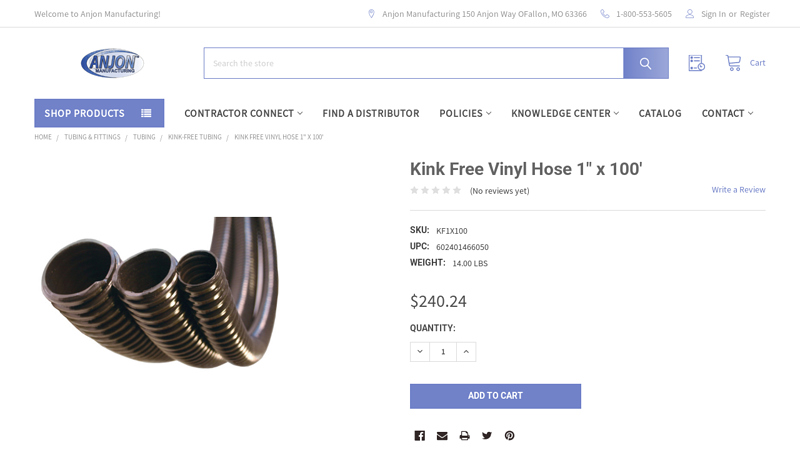

#6 Kink Free Vinyl Hose 1″ x 100′

Domain Est. 2008

Website: anjonmfg.com

Key Highlights: Extremely flexible; will not kink or collapse even around tight turns, bends or curves … Kink Free Vinyl Hose 1.5″ x 25′ 1. $74.36. Kink Free Hose Pipes. KF1….

#7 Garden Hoses

Domain Est. 2012

#8 HydroTech

Domain Est. 2020

Website: hydrotechproducts.com

Key Highlights: HydroTech Hose | · Best Seller. Standard Expandable. Lightweight, kink-free, and durable. · Pro Series Expandable. Designed for 2x the water flow. · FLATJACKET….

Expert Sourcing Insights for Non Kink Hose Pipe

H2: 2026 Market Trends for Non-Kink Hose Pipes

The global market for non-kink hose pipes is poised for significant transformation by 2026, driven by advancements in material science, rising demand from residential and agricultural sectors, and growing consumer emphasis on durability and convenience. As sustainability and efficiency become central themes across industries, non-kink hose pipes—engineered to resist tangling and collapse during use—are gaining traction due to their functional advantages over traditional hoses.

One of the key drivers shaping the 2026 market landscape is innovation in materials. Manufacturers are increasingly adopting high-performance polymers such as thermoplastic elastomers (TPE), reinforced polyurethane, and hybrid rubber compounds. These materials enhance flexibility, UV resistance, and pressure tolerance, reducing the likelihood of kinking while improving lifespan. By 2026, hoses made with eco-friendly, recyclable materials are expected to capture a larger market share, aligning with global sustainability goals.

The residential gardening and landscaping sector remains a dominant end-user, with urban homeowners seeking reliable, low-maintenance watering solutions. The trend toward smart homes has also influenced hose design, with integration potential for automated irrigation systems and water-saving technologies. By 2026, smart non-kink hoses featuring flow control, pressure sensors, and compatibility with mobile apps are expected to enter mainstream markets, particularly in North America and Western Europe.

In agriculture, especially in emerging economies, the shift toward precision irrigation is boosting demand for durable, kink-resistant hoses. Governments and agribusinesses are investing in efficient water delivery systems to combat water scarcity, further accelerating adoption. Lightweight, portable non-kink hoses are becoming essential for small-scale and drip irrigation applications.

Additionally, e-commerce growth is reshaping distribution channels. Online platforms offer detailed product comparisons, customer reviews, and subscription models for replacement hoses, enhancing consumer access and brand loyalty. By 2026, direct-to-consumer sales are projected to account for over 40% of non-kink hose transactions in developed markets.

In summary, the 2026 non-kink hose pipe market will be defined by material innovation, smart functionality, sustainability, and digital retail expansion. As competition intensifies, brands that prioritize performance, environmental responsibility, and user-centric design will lead the market.

Common Pitfalls When Sourcing Non-Kink Hose Pipes (Quality & Intellectual Property)

Sourcing non-kink hose pipes may seem straightforward, but overlooking key quality and intellectual property (IP) aspects can lead to poor performance, customer dissatisfaction, and legal risks. Here are the most common pitfalls to avoid:

1. Prioritizing Low Cost Over Material Quality

A major mistake is selecting hoses based solely on price. Low-cost hoses often use inferior materials like recycled or low-grade PVC or rubber, which degrade quickly under UV exposure, extreme temperatures, or water pressure. This leads to premature cracking, leaking, or bursting—defeating the purpose of a “non-kink” hose. Always verify material specifications and request durability test reports.

2. Misunderstanding True “Non-Kink” Performance

Not all hoses marketed as “non-kink” deliver equal performance. Some rely on reinforced mesh layers that only resist kinking temporarily or under ideal conditions. Poor braid density, weak inner liners, or inadequate wall thickness compromise kink resistance. Request real-world performance data or samples to test flexibility and recovery under stress.

3. Ignoring Pressure and Flow Rate Specifications

Suppliers may advertise high-pressure ratings without clarifying burst pressure vs. working pressure. Using a hose beyond its working limit risks failure. Also, overly thick reinforcement can restrict water flow, reducing efficiency. Ensure specs match your application’s pressure and flow needs—don’t assume all non-kink hoses perform similarly.

4. Overlooking UV and Weather Resistance

Many non-kink hoses degrade when exposed to sunlight, leading to brittleness and surface cracking. Sourcing hoses without UV stabilizers or weather-resistant additives results in short lifespans, especially in outdoor applications. Confirm whether the product includes UV protection and verify with accelerated aging test results.

5. Failing to Verify Certifications and Compliance

Reputable hoses meet safety and environmental standards such as FDA (for potable water), NSF, RoHS, or REACH. Sourcing from suppliers who can’t provide valid certifications risks regulatory non-compliance and health hazards—particularly for hoses used in gardens or drinking water systems.

6. Neglecting Intellectual Property (IP) Risks

Using or sourcing hose designs, logos, or patented technologies without authorization exposes your business to IP infringement claims. Some suppliers replicate branded hose patterns or patented connector systems. Always vet suppliers for original designs or proper licensing, and avoid “knock-off” products that mimic well-known brands.

7. Inadequate Testing and Sample Validation

Relying solely on supplier claims without testing samples leads to quality surprises. Conduct your own kink resistance, pressure, and durability tests before bulk ordering. Poor batch consistency is common—ensure your supplier maintains quality control across production runs.

8. Poor Packaging and Logistics Planning

Even high-quality hoses can be damaged during shipping if improperly coiled or packed. Lightweight packaging may lead to tangling or deformation. Confirm packaging standards with the supplier and inspect incoming goods for transit damage that could affect performance.

By addressing these pitfalls proactively, you can source reliable, high-performing non-kink hose pipes while safeguarding your brand and minimizing legal and operational risks.

Logistics & Compliance Guide for Non-Kink Hose Pipe

Product Overview

Non-kink hose pipes are flexible, durable hoses designed to resist collapsing or twisting during use, ensuring consistent water flow. Commonly used in gardening, agriculture, industrial cleaning, and construction, these hoses are typically made from reinforced PVC, rubber, or hybrid materials. Key features include crush resistance, UV protection, and flexibility across varying temperatures.

Packaging & Labeling Requirements

- Packaging: Coiled and secured with non-abrasive ties; packed in polyethylene bags or cardboard boxes to prevent kinking and surface damage during transit. Bulk shipments should use palletized stacking with edge protectors.

- Labeling: Each unit must display product specifications (length, diameter, working pressure), material composition, manufacturer details, batch number, and compliance marks (e.g., CE, WRAS, NSF, or EPA where applicable). Include handling icons (e.g., “Do Not Crush,” “Keep Dry”) on outer packaging.

Transportation & Handling

- Mode of Transport: Suitable for road, sea, and air freight. Avoid prolonged exposure to direct sunlight or extreme temperatures (below -5°C or above 60°C) during transit.

- Handling Instructions: Use mechanical aids (forklifts, pallet jacks) for heavy loads. Do not drag or drop packages. Maintain upright orientation to prevent coil deformation.

- Storage: Store in a cool, dry, well-ventilated area away from oils, solvents, and ozone sources (e.g., electric motors). Stack no more than 2 meters high to prevent compression damage.

Regulatory Compliance

- International Standards:

- CE Marking (EU): Comply with EU Regulation (EU) 2016/425 (PPE) if used in industrial safety applications; otherwise, follow REACH and RoHS for chemical safety.

- WRAS Approval (UK): Required if used with potable water; ensures material safety and non-contamination.

- NSF/ANSI 61 (USA/Canada): Mandatory for hoses in contact with drinking water.

- AS/NZS 2003 (Australia/NZ): Applies to hoses used in irrigation and plumbing.

- Environmental Regulations: Adhere to local waste disposal laws. Non-kink hoses containing phthalates or heavy metals may be restricted under REACH or Prop 65 (California).

Customs & Documentation

- HS Code: Typically 3917.31 (Plastic tubing) or 4008.21 (Rubber hoses), depending on material. Confirm locally.

- Required Documents: Commercial invoice, packing list, bill of lading/air waybill, certificate of origin, and compliance certificates (e.g., NSF, WRAS).

- Import Restrictions: Some countries restrict PVC content or require brominated flame retardant (BFR) disclosures. Verify destination-specific rules (e.g., China’s CCC, India’s BIS).

Quality Control & Traceability

- Implement batch tracking using QR codes or barcodes for end-to-end traceability.

- Conduct periodic pressure testing, flexibility checks, and UV resistance validation. Maintain records for minimum 5 years.

- Audit suppliers for ISO 9001 and ISO 14001 compliance to ensure consistent quality and environmental standards.

Sustainability & End-of-Life

- Recyclability: PVC and rubber hoses may be recyclable through specialized facilities; label with resin codes (e.g., PVC #3).

- Disposal: Follow WEEE or local hazardous waste protocols if containing regulated substances. Encourage take-back programs for end-user recycling.

- Eco-Design: Prioritize phthalate-free, recyclable materials and minimal packaging to meet evolving green regulations.

Emergency & Risk Management

- Spill/Leak Response: If damaged in transit, isolate and inspect for chemical leaching (especially with reinforced chemical hoses). Follow SDS guidelines.

- Recall Procedure: Establish a rapid recall protocol in case of non-compliance or safety issues. Notify authorities and customers within 24 hours of identified risk.

- Insurance: Ensure cargo coverage includes damage from kinking, UV degradation, or compliance-related claims.

Conclusion

Effective logistics and compliance management for non-kink hose pipes require strict adherence to packaging, regulatory, and transportation standards. Proactive documentation, quality assurance, and environmental responsibility ensure market access and customer safety across global supply chains.

In conclusion, sourcing a non-kink hose pipe is a practical and efficient solution for ensuring consistent water flow and long-term durability in both domestic and industrial applications. By selecting hoses made from high-quality, flexible materials such as reinforced rubber, polyurethane, or specially engineered PVC, users can significantly reduce the risk of kinking, twisting, and blockages. Key considerations when sourcing include burst pressure ratings, length, diameter, UV and weather resistance, and compatibility with specific water pressure systems. Additionally, opting for hoses with features like spiral wire reinforcement or layered construction further enhances kink resistance. Investing in a reliable non-kink hose not only improves operational efficiency but also reduces maintenance costs and downtime. Ultimately, choosing the right non-kink hose pipe from reputable suppliers ensures dependable performance, longevity, and user satisfaction.