The global sewing machine market continues to demonstrate steady growth, driven by rising demand in both consumer and industrial segments. According to a report by Mordor Intelligence, the global sewing machine market was valued at USD 3.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of over 5.2% from 2023 to 2028. A key contributor to this growth is the sustained popularity of non-electric sewing machines, particularly in developing regions where manual models offer affordable, durable, and energy-independent alternatives. These machines remain essential in artisanal crafts, small-scale tailoring, and educational settings where simplicity and reliability are prioritized. As automation advances, the enduring demand for mechanical, foot-powered, and hand-cranked sewing machines highlights a resilient niche market. In this landscape, several manufacturers have stood out for their craftsmanship, innovation, and long-standing heritage. Below is a list of the top 9 non-electric sewing machine manufacturers shaping this segment with legacy, precision, and global reach.

Top 9 Non Electric Sewing Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Merrow® Sewing Machine Co. Manufacturer of Industrial Sergers …

Domain Est. 1996

Website: merrow.com

Key Highlights: The Merrow Sewing Machine Company makes over 360 models of production grade sewing machines, each one hand built to the highest quality and precision tolerances ……

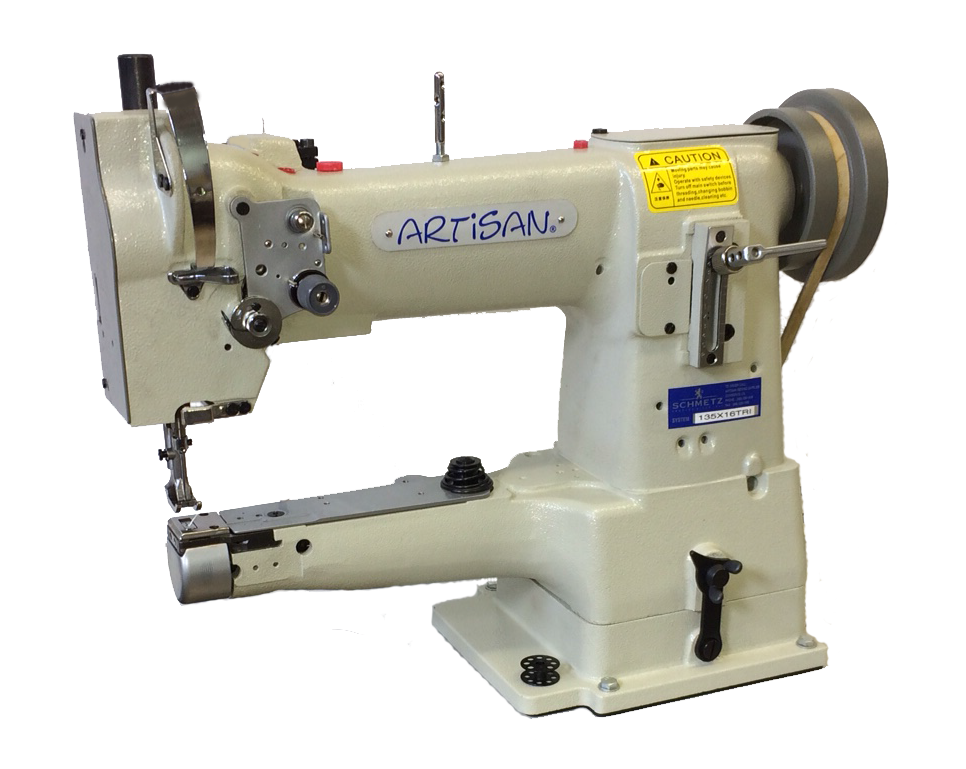

#2 Artisan Sewing Supplies

Domain Est. 1999

Website: artisansew.com

Key Highlights: Artisan Sewing Machines – a quality manufacturer of industrial sewing machines, Leather Sewing Machine, Heavy Duty Sewing Machine, and cutters….

#3 About us – SiRUBA Sewing Machine

Domain Est. 1997

Website: siruba.com

Key Highlights: We are committed to the R&D of industrial sewing machines, including overlock, interlock, lockstitch, chainstitch, multi-needle sewing machines….

#4 Sewing machines — English

Domain Est. 2000

Website: pfaff-industrial.com

Key Highlights: PFAFF 487. Special high-speed sewing machine with drop feed and variable top feed. Typical field of application: Sewing of fullness and/or sewing without ply ……

#5 Driving Innovations, stitch by stitch.

Domain Est. 2017

Website: industrialsewingmachine.global.brother

Key Highlights: Brother industrial sewing machine, official website. Stitch machine lineup, Manual, Catalog, Parts-book, Video, Maintenance info, Repair, ……

#6 BERNINA Sewing Machines

Domain Est. 1994

Website: bernina.com

Key Highlights: Discover BERNINA sewing machine models for novices or professionals. Precise stitches and long-lasting quality for over 125 years of tradition and ……

#7 The Free Sewing Machine Company Collection

Domain Est. 1996

Website: ismacs.net

Key Highlights: A visual collection showcasing the diverse range of Free-Westinghouse sewing machines, celebrated as “America’s Finest” and featuring both treadle and electric ……

#8 JACK World NO.1

Domain Est. 1999

Website: chinajack.com

Key Highlights: JACK 14 Years World NO.1 Who Provides a Great Number of High-Quality Precision Sewing Machines at Affordable Prices. Browse Our Vast Selection and Enjoy ……

#9 What is a Household Sewing Machine?|Products & Solutions

Website: juki.co.jp

Key Highlights: This page introduces JUKI’s household sewing machines, professional sewing machines, and compact overlock sewing machines….

Expert Sourcing Insights for Non Electric Sewing Machine

H2: Projected 2026 Market Trends for Non-Electric Sewing Machines

As the global textile and DIY crafting markets evolve, non-electric sewing machines are expected to maintain a niche yet resilient presence in 2026. Despite the dominance of computerized and electric models, several key trends are shaping the demand and application of manual, non-electric sewing machines.

1. Growing Interest in Sustainable and Off-Grid Living

A significant driver for the non-electric sewing machine market in 2026 is the rising global emphasis on sustainability and energy conservation. With increasing awareness of environmental issues, consumers are turning to low-energy, mechanical alternatives. Non-electric machines, which require no power and have minimal environmental impact during production and usage, are gaining favor among eco-conscious users, homesteaders, and off-grid communities.

2. Expansion in Developing Markets

In regions with unreliable electricity infrastructure—such as parts of Sub-Saharan Africa, South Asia, and rural Latin America—non-electric sewing machines remain practical and essential tools. As micro-enterprises and cottage industries grow, these durable, low-maintenance machines support local garment production and income generation. By 2026, emerging markets are expected to contribute significantly to overall demand, especially with support from NGO-led vocational training programs.

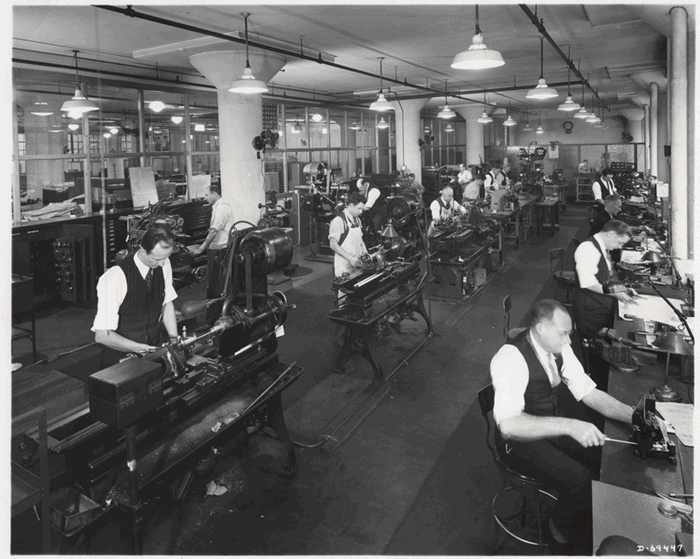

3. Resurgence in DIY and Craft Communities

The handmade and slow fashion movements continue to gain momentum, appealing to hobbyists and artisans who value craftsmanship over speed. Non-electric sewing machines, often associated with vintage models like the Singer Treadle or modern hand-crank versions, are becoming popular among crafters seeking a tactile, meditative sewing experience. Online platforms and social media are amplifying this trend, with tutorials and restoration projects boosting visibility and demand.

4. Educational and Skill-Building Applications

Non-electric machines are increasingly being adopted in educational settings, especially in developing regions and vocational schools. Their simplicity makes them ideal for teaching basic sewing techniques without the complexity of electronic components. By 2026, partnerships between governments, NGOs, and manufacturers may expand distribution for skill development and women’s empowerment initiatives.

5. Product Innovation and Niche Manufacturing

While the market is not dominated by high-tech innovation, some manufacturers are introducing improved ergonomic designs, lightweight portability, and compatibility with modern fabrics. Startups and boutique brands are responding to demand for stylish, functional hand-operated machines, blending retro aesthetics with updated mechanics.

6. Market Challenges

Despite these positive trends, the non-electric sewing machine market faces constraints. Limited functionality for heavy-duty or high-speed tasks restricts use in commercial settings. Additionally, younger generations may perceive these machines as outdated, posing adoption challenges without targeted marketing and education.

Conclusion

In 2026, the non-electric sewing machine market is anticipated to remain modest in size but stable in demand, driven by sustainability trends, off-grid lifestyles, and grassroots economic development. While not a mainstream choice in industrialized nations, its role in education, craftsmanship, and underserved markets ensures continued relevance in a rapidly digitizing world.

Common Pitfalls When Sourcing Non-Electric Sewing Machines (Quality and Intellectual Property)

Logistics & Compliance Guide for Non-Electric Sewing Machines

Product Classification & HS Code

Non-electric sewing machines are typically classified under the Harmonized System (HS) code 8452.21.00 – “Household sewing machines, non-electric.” Accurate classification is essential for correct duty assessment, import regulations, and customs clearance across countries. Confirm the applicable HS code with local customs authorities, as minor variations may exist by jurisdiction.

Import Regulations & Documentation

Importers must prepare and submit standard international trade documents, including:

– Commercial Invoice

– Packing List

– Bill of Lading (B/L) or Air Waybill (AWB)

– Certificate of Origin (may be required for preferential tariff treatment)

– Import License (if required by destination country)

Ensure the commercial invoice clearly describes the product as “Non-Electric Household Sewing Machine” and includes the correct HS code, value, and country of manufacture.

Safety & Technical Standards

While non-electric sewing machines do not require electrical safety certifications (e.g., CE, UL, RoHS), they may still be subject to general consumer product safety regulations. Key considerations include:

– Mechanical Safety: Sharp parts, pinch points, and moving components must be designed to minimize injury risk.

– Child Safety: If marketed to children, compliance with toy safety standards (e.g., ASTM F963 in the U.S., EN 71 in the EU) may apply.

– Labeling Requirements: Product labels should include manufacturer details, model number, country of origin, and basic safety warnings in the local language.

Packaging & Labeling Compliance

Packaging must meet international shipping standards and destination country requirements:

– Use durable, moisture-resistant materials suitable for sea or air freight.

– Include barcodes, handling symbols (e.g., “Fragile,” “This Side Up”), and proper stacking information.

– Labels must display:

– Product name and model

– Manufacturer/importer contact information

– Country of origin

– Safety warnings (e.g., “Keep fingers away from moving parts”)

Environmental & Chemical Compliance

Non-electric sewing machines may contain metals, plastics, and lubricants subject to environmental regulations:

– REACH (EU): Ensure restricted substances (e.g., phthalates, heavy metals) in components are within permissible limits.

– Proposition 65 (California, USA): Provide warnings if the product contains chemicals known to cause cancer or reproductive harm.

– WEEE & Battery Directives: Not applicable, as these machines are non-electric and typically contain no batteries.

Transportation & Freight Considerations

- Mode of Transport: Suitable for sea, air, or land freight. Sea freight is most cost-effective for bulk shipments.

- Weight & Dimensions: Standard non-electric sewing machines are compact and lightweight; optimize container or pallet loading accordingly.

- Insurance: Recommend full cargo insurance to cover potential damage or loss during transit.

- Incoterms: Clearly define responsibilities using standard Incoterms (e.g., FOB, CIF, DDP) in sales contracts.

Customs Clearance & Duties

- Pre-verify tariff rates and import duties based on the destination country’s tariff schedule.

- Some countries may impose anti-dumping duties on sewing machines from certain manufacturing regions—verify applicability.

- Use a licensed customs broker to facilitate smooth clearance and avoid delays.

Post-Import Requirements

- Maintain records of all import documentation for a minimum of 5–7 years, as required by most customs authorities.

- Monitor for product recalls or regulatory updates related to mechanical consumer goods.

- Provide user manuals in the local language, including assembly instructions and safety guidelines.

Conclusion

Successfully shipping and selling non-electric sewing machines globally requires attention to proper classification, safety standards, labeling, and customs procedures. While exempt from electrical compliance, these products must still meet mechanical safety and consumer protection regulations. Partnering with experienced logistics providers and legal advisors ensures compliance and smooth market entry.

Conclusion for Sourcing a Non-Electric Sewing Machine

Sourcing a non-electric sewing machine offers a sustainable, reliable, and cost-effective solution for individuals and communities with limited access to electricity, unstable power supplies, or a desire for environmentally friendly alternatives. These durable, manually operated machines are ideal for off-grid living, emergency preparedness, and traditional craftsmanship, providing consistent performance without dependency on external energy sources.

From this sourcing effort, it is evident that non-electric sewing machines maintain high value in educational programs, rural development projects, and artisanal industries due to their low maintenance, ease of use, and resilience. Although modern electric and computerized machines dominate the market, the demand for hand-crank or treadle-powered models persists among environmentally conscious users, hobbyists, and underserved populations.

Successfully sourcing these machines requires identifying reputable manufacturers or refurbished suppliers, ensuring quality craftsmanship, and considering long-term usability. While challenges such as limited availability and slower stitching speed exist, the benefits—energy independence, quiet operation, and mechanical simplicity—outweigh the drawbacks in appropriate contexts.

In conclusion, investing in non-electric sewing machines supports sustainability, self-reliance, and inclusive access to essential tools. As global interest in low-impact living grows, these time-tested machines remain a relevant and valuable asset, bridging the past and future of textile work.