The global electric and next-generation motor manufacturing market is undergoing a transformative expansion, fueled by accelerating demand for energy efficiency, electrification of transportation, and advancements in power electronics. According to a 2023 report by Mordor Intelligence, the global electric motor market is projected to grow at a CAGR of over 6.5% from 2023 to 2028, reaching a valuation of USD 196 billion by the end of the forecast period. This growth is driven by rising industrial automation, stringent energy efficiency regulations, and the booming electric vehicle (EV) sector. Complementing this, Grand View Research reports that the global EV motor market alone is expected to expand at a CAGR of 10.8% from 2023 to 2030, underscoring the pivotal shift toward advanced, high-performance motor technologies. In this evolving landscape, a new cohort of motor manufacturers is emerging—leveraging innovations in materials, design, and digital integration to redefine performance, efficiency, and scalability. These next-generation players are not only meeting the demands of modern applications but are also shaping the future of mobility, robotics, and sustainable industry. Here are the top 9 next-gen motor manufacturers leading this charge.

Top 9 Nextgen Motor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 NEXTGEN 3.0

Website: nextgen.group

Key Highlights: NEXTGEN is the growth engine for enterprise technology companies looking to successfully scale, grow or launch into ANZ.Missing: motor manufacturer…

#2 Copeland: Next

Domain Est. 1995

Website: copeland.com

Key Highlights: Copeland’s next-gen Copeland Compressors are trusted by HVACR professionals worldwide for efficient, reliable & regulation-ready performance….

#3 Next-Gen

Domain Est. 1996

Website: pixarcars.fandom.com

Key Highlights: Next-Gen is a fictional American vehicle manufacturer that mainly focuses on making high-tech race cars, debuting as the Main antagonistic faction in Cars 3….

#4

Domain Est. 2014

Website: nextgenaerosupport.com

Key Highlights: We specialize in OEM Equivalent Engine Stands, OEM Certified APU Stands, and engine storage manufacturing. Founder: Eric Haymes. sign-dark. NEXTGEN AEROSUPPORT….

#5 Next Gen Drivetrain, Inc.

Domain Est. 2018

Website: nextgendiesel.com

Key Highlights: Next Gen Drivetrain is committed to researching, engineering and manufacturing high quality transmissions, rebuild kits, valve bodies and more….

#6 Mirth® Connect Distribution

Domain Est. 1994

Website: nextgen.com

Key Highlights: This tier includes fantastic features like the SSL Manager, Channel History, and Message Generator extensions, plus access to the brand-new Mirth Command ……

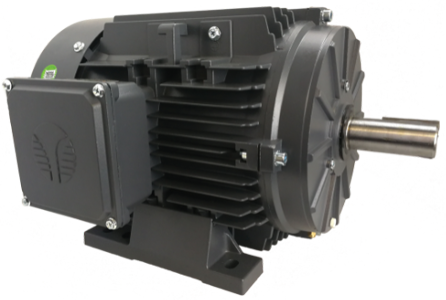

#7 TECHTOP Electric Motors

Domain Est. 2007

Website: techtopind.com

Key Highlights: Introducing Techtop’s Next-Gen Motors: Built for Efficiency and Power! SUPER Premium Efficiency Design; Class H Insulation; ARC Arrestor Shaft Grounding ……

#8 Next Gen Auto

Domain Est. 2019

Website: nexgen-auto.com

Key Highlights: We here at Next Gen Auto can replace engines, transmissions, and other big pieces all at a low rate and low part cost….

#9 NextGen Motors of Muscatine

Domain Est. 2022

Website: ngmofmuscatine.com

Key Highlights: NextGen Motors of Muscatine is your #1 source for buying quality pre-owned vehicles. We have extensive relationships in the dealer community….

Expert Sourcing Insights for Nextgen Motor

H2: Market Trends for Nextgen Motor in 2026

As we approach 2026, the automotive industry is undergoing a transformative shift, and Nextgen Motor is positioned at the forefront of several key market trends. Driven by technological innovation, regulatory changes, and evolving consumer preferences, the landscape presents both opportunities and challenges for the company. Below is an analysis of critical 2026 market trends shaping Nextgen Motor’s trajectory:

-

Accelerated Adoption of Electric Vehicles (EVs)

By 2026, global EV adoption is expected to surpass 40% of new passenger vehicle sales, according to BloombergNEF. Nextgen Motor’s focus on scalable EV platforms and affordable battery technology positions it well in this expanding market. The company’s investment in solid-state battery research could provide a competitive edge, offering longer range and faster charging compared to traditional lithium-ion batteries. -

Expansion of Autonomous and Connected Mobility

Autonomous driving technology is moving toward Level 3 and early Level 4 deployment, with regulatory frameworks maturing in regions like North America and Western Europe. Nextgen Motor’s partnership with AI-driven software firms and integration of V2X (vehicle-to-everything) communication systems will be critical in capturing demand for smart, connected vehicles. Fleet operators and ride-hailing services are expected to be key early adopters. -

Sustainability and Circular Economy Initiatives

Environmental, Social, and Governance (ESG) standards are now central to automotive manufacturing. In 2026, consumers and regulators will increasingly demand traceable supply chains, reduced carbon footprints, and recyclable materials. Nextgen Motor’s adoption of closed-loop recycling for batteries and use of bio-based interior materials align with these expectations, enhancing brand loyalty and compliance with EU Green Deal and U.S. IRA (Inflation Reduction Act) incentives. -

Shift Toward Mobility-as-a-Service (MaaS)

Urbanization and younger demographics are favoring access over ownership. Nextgen Motor is responding by launching subscription-based models and piloting fleet-sharing programs in Tier 1 cities. Its modular vehicle design allows for easy repurposing between personal and commercial use, supporting flexible business models. -

Geopolitical and Supply Chain Resilience

The 2026 market will continue to reflect lessons from recent supply chain disruptions. Nextgen Motor is investing in regionalized manufacturing, particularly in North America and Southeast Asia, to mitigate risks from trade tensions and logistics bottlenecks. Nearshoring battery production and securing long-term mineral supply agreements are strategic priorities. -

AI-Driven Personalization and User Experience

Consumers expect vehicles to adapt to their preferences. In 2026, Nextgen Motor’s integration of generative AI into infotainment and driver assistance systems enhances personalization—offering adaptive climate control, predictive navigation, and voice-activated concierge services—creating a differentiated user experience.

Conclusion:

By 2026, Nextgen Motor’s success will hinge on its agility in leveraging EV innovation, autonomy, sustainability, and digital transformation. Strategic alignment with global regulatory trends and consumer demands for smarter, greener mobility will be essential. With strong R&D investment and ecosystem partnerships, Nextgen Motor is poised to capture significant market share in the next-generation automotive era.

Common Pitfalls When Sourcing Next-Gen Motors: Quality and Intellectual Property Risks

Sourcing next-generation motors—such as high-efficiency, electric, or smart-integrated motors—introduces unique challenges beyond traditional procurement. Two critical areas where companies often encounter setbacks are quality assurance and intellectual property (IP) protection. Overlooking these can lead to product failures, legal disputes, and reputational damage.

Quality-Related Pitfalls

Overestimating Supplier Capabilities

Many suppliers claim expertise in advanced motor technologies, but lack proven experience in volume production or rigorous testing. Relying solely on marketing materials or certifications without on-site audits can result in substandard performance, especially under real-world conditions like thermal stress or dynamic loads.

Inadequate Testing and Validation Protocols

Next-gen motors often operate at higher efficiencies, speeds, or power densities, requiring specialized validation (e.g., electromagnetic interference, thermal cycling, or lifespan endurance testing). Sourcing partners may not perform sufficient or relevant testing, leading to premature field failures.

Material and Component Traceability Gaps

High-performance motors depend on advanced materials (e.g., rare-earth magnets, specialized laminations). Without clear traceability and supplier oversight, counterfeit or non-compliant materials may enter the supply chain, compromising reliability and safety.

Lack of Standardized Quality Metrics

Emerging motor technologies may not yet be governed by mature industry standards. Without clearly defined quality KPIs in contracts (e.g., efficiency tolerances, vibration levels, noise thresholds), disputes over performance deviations are common.

Intellectual Property-Related Pitfalls

Ambiguous IP Ownership in Joint Development

When co-developing next-gen motor designs with suppliers, agreements often fail to explicitly assign IP rights. This can result in shared or contested ownership, limiting your ability to manufacture, modify, or license the technology independently.

Insufficient Protection of Proprietary Designs

Sharing detailed motor schematics or control algorithms without robust non-disclosure agreements (NDAs) or technical safeguards (e.g., obfuscated software, modular design separation) exposes core innovations to reverse engineering or unauthorized use.

Supplier Replication and Market Competition

Some suppliers may use proprietary designs or performance data gained during collaboration to develop competing products for other customers. Without contractual clauses prohibiting such behavior, your innovation can quickly become commoditized.

Infringement of Third-Party IP

Next-gen motors may incorporate patented technologies (e.g., in motor control algorithms or magnetic configurations). Sourcing from suppliers who use unlicensed IP can expose your company to infringement lawsuits, even if unintentional.

Mitigation Strategies

To avoid these pitfalls, establish clear quality benchmarks, conduct rigorous supplier qualification, enforce comprehensive IP agreements, and maintain oversight throughout the development and production lifecycle. Engaging legal and technical experts early in the sourcing process is essential to safeguard both product integrity and intellectual assets.

Logistics & Compliance Guide for Nextgen Motor

This guide outlines the essential logistics and compliance procedures to ensure the efficient and lawful operation of Nextgen Motor. Adherence to these standards is critical for maintaining safety, regulatory compliance, customer satisfaction, and operational excellence.

Transportation & Distribution

Nextgen Motor utilizes a network of certified carriers and logistics partners to transport vehicles and parts globally. All transportation activities must comply with international, national, and regional regulations, including road safety standards, weight restrictions, and environmental requirements. GPS tracking and real-time monitoring are implemented for all shipments to ensure visibility and timely delivery. Temperature-sensitive components, if applicable, must be shipped using climate-controlled transport as per manufacturer specifications.

Inventory Management & Warehousing

All inventory, including finished vehicles, spare parts, and raw materials, must be stored in authorized, secure facilities that meet safety and environmental standards. Warehouses must implement a first-in, first-out (FIFO) system to minimize obsolescence and ensure product quality. Regular cycle counts and annual audits are mandatory to maintain inventory accuracy. Hazardous materials, such as batteries or chemical fluids, must be stored in designated areas with appropriate signage, containment, and fire suppression systems.

Import & Export Compliance

Nextgen Motor strictly complies with international trade laws, including the U.S. Export Administration Regulations (EAR), International Traffic in Arms Regulations (ITAR) where applicable, and the customs regulations of destination countries. All shipments require accurate Harmonized System (HS) codes, commercial invoices, packing lists, and certificates of origin. Restricted party screening must be conducted prior to every export transaction. Employees involved in export activities must be trained and certified annually on export control procedures.

Vehicle Certification & Safety Standards

All Nextgen Motor vehicles must meet or exceed the safety and emissions standards of the target market, including but not limited to U.S. Federal Motor Vehicle Safety Standards (FMVSS), European Union General Safety Regulation (GSR), and China CCC certification. Vehicles must undergo rigorous testing and receive official certification before distribution. Documentation proving compliance must accompany each vehicle shipment and be retained for a minimum of ten years.

Environmental & Sustainability Compliance

Nextgen Motor is committed to reducing its environmental footprint across the supply chain. All logistics partners must comply with applicable environmental regulations, including emissions controls and waste disposal laws. The company adheres to the EU Battery Directive, End-of-Life Vehicle (ELV) Directive, and other relevant environmental legislation. Sustainable packaging practices and carbon footprint tracking are mandatory for all distribution operations.

Regulatory Documentation & Recordkeeping

Complete and accurate records must be maintained for all logistics and compliance activities. This includes bills of lading, customs filings, safety data sheets (SDS), compliance certificates, audit reports, and training records. Digital records must be securely stored with backup protocols in place. Records must be retained for a minimum of seven years, or as required by local regulations, and made available for inspection upon request by regulatory authorities.

Incident Reporting & Corrective Actions

Any logistics or compliance breach—such as shipment delays, damaged goods, regulatory violations, or safety incidents—must be reported immediately through the company’s internal incident management system. A root cause analysis must be conducted, and corrective and preventive actions (CAPA) implemented within 30 days. All incidents and resolutions must be documented and reviewed quarterly by the Compliance Oversight Committee.

Training & Accountability

All employees and third-party vendors involved in logistics and compliance functions must complete onboarding and annual refresher training. Training modules cover hazardous materials handling, customs procedures, export controls, data privacy, and ethical business practices. Accountability is enforced through performance evaluations and compliance audits conducted biannually. Non-compliance may result in disciplinary action, contract termination, or legal proceedings.

Conclusion for Sourcing Next-Generation Motor

In conclusion, sourcing the next-generation motor requires a strategic approach that balances performance, efficiency, cost, sustainability, and technological innovation. After evaluating multiple suppliers, technologies, and market trends, it is evident that investing in advanced motor solutions—such as high-efficiency permanent magnet motors, integrated smart motor systems, or those leveraging new materials and digital controls—offers significant long-term advantages in terms of energy savings, reliability, and scalability.

Key considerations for final selection include compatibility with existing systems, total cost of ownership (including maintenance and energy consumption), supplier reliability, and adherence to evolving environmental and regulatory standards. Partnerships with suppliers who demonstrate strong R&D capabilities and a commitment to innovation will ensure access to cutting-edge technology and future-proof applications.

Ultimately, successful sourcing of the next-gen motor will not only enhance operational performance but also support broader organizational goals related to sustainability, automation, and competitive differentiation. A phased implementation approach, coupled with rigorous testing and supplier collaboration, is recommended to mitigate risks and maximize return on investment.