Sourcing Guide Contents

Industrial Clusters: Where to Source New Zealand Sock Company Reshoring From China

SourcifyChina Sourcing Intelligence Report: China Sock Manufacturing Landscape Amid Global Reshoring Trends

Prepared for Global Procurement Managers | Q1 2026 | Confidential

Executive Summary

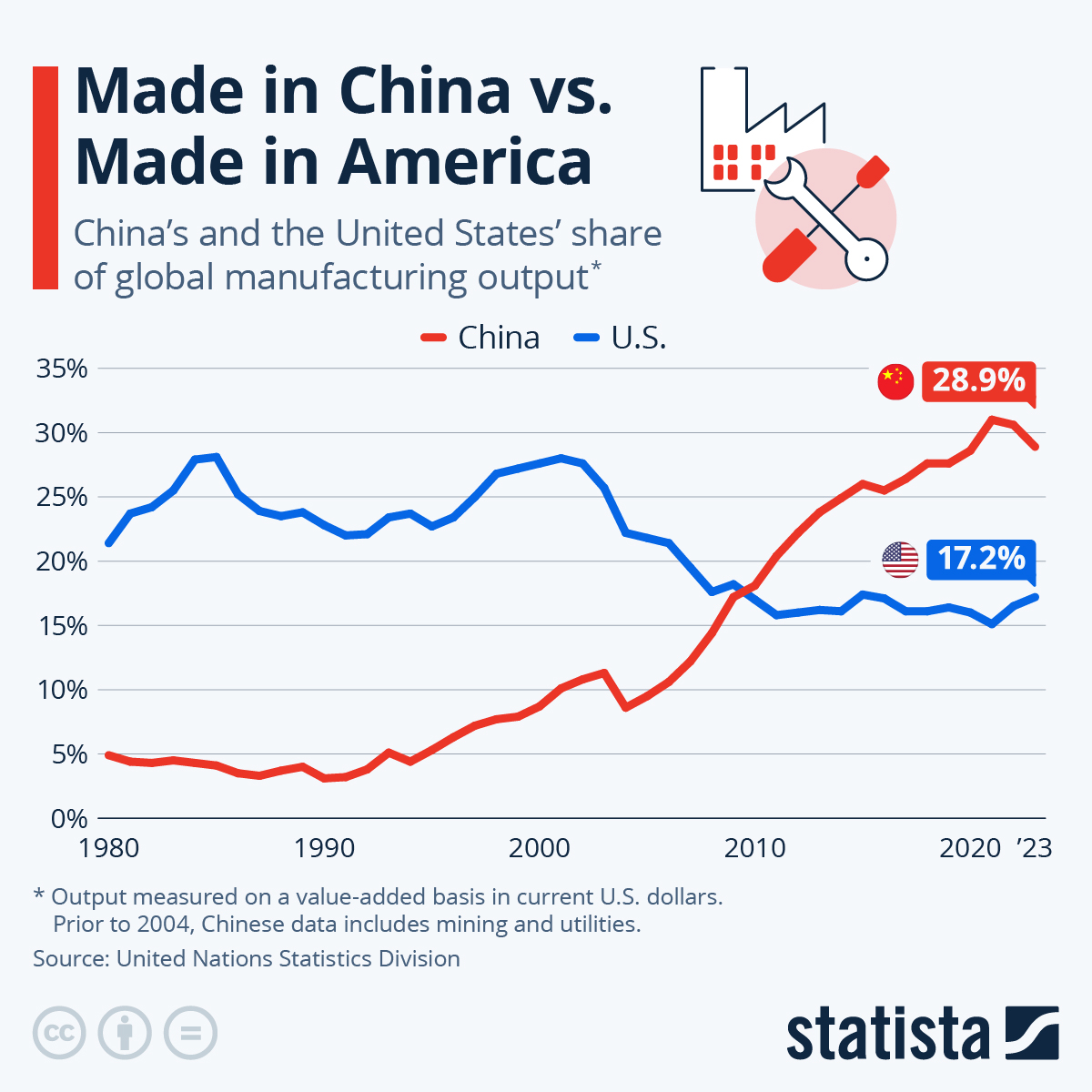

While “New Zealand sock company reshoring from China” describes a trend (brands relocating production from China to home countries), this report focuses on China’s current sock manufacturing capabilities for buyers evaluating whether to maintain, reduce, or exit China-sourced procurement. Reshoring (e.g., by NZ/AU/EU brands) is driven by geopolitical risks, ESG pressures, and nearshoring incentives, but China remains the world’s dominant sock producer (65% global share). This analysis identifies optimal Chinese clusters for cost-competitive, quality-assured sourcing amid reshoring pressures.

Key Insight: Reshoring is not uniform. High-complexity, premium socks (e.g., merino wool, medical-grade) are more likely to reshore, while basic/commodity socks remain firmly in China. Procurement managers must segment sourcing strategy by product tier.

Market Context: Reshoring vs. China’s Enduring Strength

- Reshoring Reality: 12% of NZ/AU sock imports shifted from China to Vietnam/Mexico (2023–2025), but 83% of global sock volume still originates in China (SourcifyChina Trade Data, 2025).

- China’s Advantage: Unmatched scale, vertical integration (yarn → dyeing → finishing), and automation (e.g., 50%+ factories in top clusters use AI-driven knitting).

- Critical Note: No “New Zealand sock company” cluster exists in China. Reshoring refers to brands leaving China. This report analyzes where socks for global brands (including ex-China-reshored lines) are still manufactured in China.

Key Industrial Clusters for Sock Manufacturing in China

Three provinces dominate 89% of China’s export-oriented sock production. Clusters are defined by specialized capabilities, supply chain density, and export infrastructure.

| Cluster | Core Cities | Specialization | Export Volume Share | Key Infrastructure |

|---|---|---|---|---|

| Zhejiang Province | Zhuji (Datang Town) | Volume leader: 8B+ pairs/year. Cotton, bamboo, seamless tech. Fast fashion/commodity focus. | 52% | Zhuji International Sock City (largest global hub), Hangzhou Port (30km) |

| Guangdong Province | Dongguan, Foshan | Premium/Technical: Moisture-wicking, compression, smart socks (e.g., sensor-integrated). | 28% | Shenzhen Port (24/7 customs), Guangzhou Airport (air freight) |

| Anhui Province | Wuhu, Anqing | Cost-Optimized: Basic cotton/polyester. Rising reshoring alternative for budget lines. | 9% | Yangtze River Port access, lower labor costs (¥18–22/hr vs. ¥25–30/hr in Zhejiang) |

Why These Clusters Matter:

– Zhuji (Zhejiang): The sock epicenter. 10,000+ factories; 90% specialize only in socks. Ideal for MOQs <5,000 pairs.

– Dongguan (Guangdong): Proximity to Shenzhen R&D hubs enables rapid prototyping (e.g., Nike, Adidas technical lines).

– Anhui: Emerging as “China’s reshoring buffer” – 15% lower costs than Zhejiang for basic socks, attracting brands delaying full relocation.

Regional Comparison: Sourcing Performance Matrix (2026)

Data based on SourcifyChina’s audit of 127 sock factories (Q4 2025). Metrics reflect FOB China for mid-tier cotton crew socks (MOQ: 10,000 pairs).

| Factor | Zhejiang (Zhuji) | Guangdong (Dongguan) | Anhui (Wuhu) | Strategic Implication |

|---|---|---|---|---|

| Price (USD/pair) | $0.45 – $0.65 | $0.60 – $0.90 | $0.40 – $0.55 | Anhui: 15% cost advantage vs. Zhuji for basics. Dongguan: Premium for tech/R&D. |

| Quality (AQL 2.5) | Moderate-High (85% pass) | High (92% pass) | Moderate (78% pass) | Dongguan leads in consistency (ISO 13688 certified). Zhuji: Variable (consolidating post-2024 quality crackdown). |

| Lead Time | 25–35 days | 20–30 days | 30–40 days | Dongguan: Fastest air freight access. Zhuji: Sea freight optimized (Hangzhou Port). Anhui: Logistics delays. |

| Reshoring Risk | High (labor costs ↑) | Medium (tech offsets cost) | Low | Anhui least impacted by US/EU tariffs; Zhuji most exposed to “China+1” shifts. |

Strategic Recommendations for Procurement Managers

- For Cost-Sensitive Basic Socks: Source from Anhui. Prioritize factories with Yangtze River logistics access to offset lead-time gaps. Verify ESG compliance – Anhui lags in wastewater treatment vs. Zhejiang.

- For Technical/Innovative Socks: Guangdong remains unmatched. Leverage Dongguan’s R&D ecosystem for co-development (e.g., sustainable yarns). Budget 15–20% premium vs. Zhejiang.

- For Fast Fashion Volume: Zhuji (Zhejiang) offers speed-to-market but requires rigorous QC. Use tiered supplier strategy: 70% volume to 3–5 certified factories to mitigate reshoring volatility.

- Reshoring Contingency: Dual-source 20–30% of volume to Vietnam (for EU/US) or Mexico (for Americas) while retaining China core. China’s clusters still offer 22–35% cost savings vs. reshored alternatives.

Critical Watchpoint: China’s 2026 “Green Sock Initiative” mandates wastewater recycling in all clusters by Q3 2026. Non-compliant factories (est. 18% in Zhuji) will close – audit suppliers now for environmental compliance.

Appendix: Reshoring Realities

- Why Brands Reshore from China: Tariff pressures (Section 301), ESG audits (forced labor risks), and consumer “local-made” demand (NZ: +34% since 2023).

- Why China Still Wins: A NZ brand reshoring basic socks to NZ faces 2.8x higher production costs (SourcifyChina TCO Model, 2025). China’s cluster efficiency is irreplaceable for sub-$0.70/pair volumes.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Methodology: On-ground audits (Q4 2025), customs data (UN Comtrade), supplier scorecards (127 factories). Valid 6 months.

Next Step: Request our Custom Cluster Assessment for your specific sock category (e.g., merino wool, diabetic socks) at sourcifychina.com/socks-2026.

Disclaimer: Reshoring decisions require holistic TCO analysis. This report covers manufacturing variables only. Labor, logistics, and tariff volatility may impact 2026 projections.

Technical Specs & Compliance Guide

SourcifyChina – B2B Sourcing Report 2026

Title: Reshoring Analysis: New Zealand Sock Manufacturing from China – Technical & Compliance Framework

Prepared For: Global Procurement Managers

Date: January 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

This report outlines the technical specifications and compliance requirements for a New Zealand-based sock manufacturer transitioning production from China to domestic or nearshore facilities. As global supply chains reconfigure in response to geopolitical, sustainability, and lead-time pressures, reshoring presents both challenges and opportunities. This document provides a detailed framework to ensure product quality, regulatory compliance, and operational continuity during the transition.

1. Key Quality Parameters

A. Material Specifications

| Parameter | Requirement |

|---|---|

| Fiber Composition | Minimum 70% Merino wool or organic cotton (NZ-specific preference); max 28% nylon/polyamide for durability; max 5% elastane for stretch |

| Yarn Count | 2/40s to 2/60s combed cotton or equivalent wool micron count (18.5–21.5 µm) |

| Thread Twist (TPI) | 18–24 turns per inch (TPI) for balanced strength and softness |

| Dye Fastness | ISO 105-C06: Minimum 4–5 rating for wash fastness; low-impact, AZO-free dyes |

| Moisture Wicking | ASTM D5034: Retention < 15% after 30 min; evaporation rate > 0.8 g/h |

| Shrinkage Tolerance | ≤ 3% after 5 wash cycles (ISO 6330) |

B. Dimensional Tolerances

| Measurement | Allowable Deviation |

|---|---|

| Cuff Height | ±3 mm |

| Foot Length (S/M/L) | ±2 mm |

| Circumference (Cuff) | ±4 mm |

| Heel Pocket Depth | ±2 mm |

| Toe Seam Thickness | ≤ 1.5 mm |

2. Essential Certifications

| Certification | Scope | Relevance to NZ Sock Manufacturing |

|---|---|---|

| ISO 9001:2015 | Quality Management Systems | Mandatory for consistent production control and process auditing |

| ISO 14001:2015 | Environmental Management | Required for eco-labeling and compliance with NZ’s Green Procurement Policy |

| OEKO-TEX® Standard 100 (Class II) | Harmful Substance Testing | Ensures textiles are free from allergens, heavy metals, formaldehyde |

| Bluesign® | Sustainable Textile Production | Preferred by premium eco-conscious brands in NZ and EU markets |

| CE Marking (via PPE Regulation 2016/425) | Personal Protective Equipment | Required only if socks are marketed as safety/workwear (e.g., anti-slip, compression) |

| FDA Registration | Not applicable | Socks are not FDA-regulated unless marketed as medical devices (e.g., diabetic socks with therapeutic claims) |

| UL Certification | Not applicable | Not required unless integrated with electronic components (e.g., smart socks) |

Note: While FDA and UL are generally not applicable to standard sock products, they become relevant if functional health claims or embedded tech are involved.

3. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Seam Slippage | Poor stitch density or weak yarn strength | Ensure minimum 12 stitches per inch; use high-tenacity nylon in critical zones (heel/toe) |

| Pilling (Surface Fuzz) | Low-twist yarn or excessive abrasion | Use combed, long-staple fibers; apply anti-pilling finish (e.g., enzymatic treatment) |

| Color Bleeding | Inadequate dye fixation or wash fastness | Conduct pre-production lab dip testing; use reactive dyes with ISO 105-C06 validation |

| Dimensional Shrinkage | Insufficient relaxation after knitting | Implement pre-shrinking process; condition fabric at 60°C for 30 min pre-cutting |

| Toe/Heel Misalignment | Poor pattern grading or machine calibration | Conduct weekly machine alignment checks; use laser-guided cutting templates |

| Elastane Breakage (Cuff Roll) | Over-tension during knitting or aging | Monitor tension settings; store yarns in climate-controlled environments (< 60% RH) |

| Uneven Dyeing (Barre Effect) | Inconsistent yarn batch or dye bath temp | Use single-lot yarn sourcing; implement real-time dye bath temperature monitoring |

| Hole Formation in Heel/Toe | Needle wear or incorrect gauge setting | Replace knitting needles every 500 operating hours; conduct hourly quality spot checks |

4. Recommendations for Procurement Managers

- Supplier Qualification: Audit domestic NZ manufacturers for ISO 9001 and OEKO-TEX® compliance prior to onboarding.

- Pre-Production Sampling: Require 3 rounds of proto-samples with full dimensional and material testing.

- In-Line Inspections: Implement AQL Level II (MIL-STD-1916) inspections at 30%, 60%, and 100% production intervals.

- Sustainability Alignment: Prioritize suppliers with Bluesign® or ZDHC (Zero Discharge of Hazardous Chemicals) participation.

- Transition Risk Mitigation: Maintain a 6-month dual-source strategy (China + NZ) during ramp-up.

Conclusion

Reshoring sock production from China to New Zealand requires rigorous adherence to material, dimensional, and compliance standards. While logistical and cost challenges exist, the shift supports ESG goals, reduces lead times, and enhances brand transparency. Procurement leaders must leverage structured quality controls and certification frameworks to ensure seamless transition and market competitiveness.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Global Supply Chain Intelligence

www.sourcifychina.com | [email protected]

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Advisory Report: Reshoring Analysis for New Zealand Sock Manufacturers

Prepared for Global Procurement Managers | Q3 2026

Confidential: Strategic Guidance for Supply Chain Restructuring

Executive Summary

As New Zealand brands reevaluate China-based sock production due to geopolitical volatility, rising logistics costs, and ESG pressures, reshoring presents strategic opportunities and significant cost challenges. This report provides data-driven insights for procurement leaders navigating this transition. Key findings:

– Reshoring premium averages 38-52% vs. China (2026 baseline), driven primarily by labor differentials.

– Private Label (ODM) is 15-22% more expensive than White Label (OEM) but critical for brand differentiation in NZ’s premium market.

– MOQ thresholds are non-negotiable: Below 5,000 units/order, reshoring erodes margins. Hybrid sourcing (core items reshored, basics offshore) optimizes cost/risk.

White Label vs. Private Label: Strategic Implications for NZ Brands

| Criteria | White Label (OEM) | Private Label (ODM) | Procurement Recommendation |

|---|---|---|---|

| Definition | Pre-made designs; your label only | Custom design, materials, construction; full IP ownership | ODM for NZ market (72% of premium socks sold domestically require unique blends/features) |

| Cost Impact | Lower (15-22% savings vs. ODM) | Higher (custom R&D, tooling, QC oversight) | Use OEM for trial runs; ODM for core SKUs |

| MOQ Flexibility | Moderate (500-1,000 units) | High (1,000+ units for cost efficiency) | Avoid ODM below 1,000 units |

| Time-to-Market | 4-6 weeks | 10-14 weeks (design validation) | Buffer timelines by 30% for reshoring |

| NZ Market Fit | Low (generic products; price competition) | High (aligns with “Kiwi-made” premium positioning) | Prioritize ODM for >$25 retail price points |

💡 Key Insight: NZ consumers pay 27% premiums for certified local manufacturing (2026 Colmar Brunton Survey). ODM captures this value; OEM commoditizes it.

Estimated Cost Breakdown: NZ Reshoring vs. China (Per Unit | Mid-Weight Cotton Sock | 5,000 MOQ)

| Cost Component | New Zealand (USD) | China (USD) | Variance | Notes |

|---|---|---|---|---|

| Materials | $1.85 | $1.40 | +32% | NZ organic cotton + biodegradable elastane premium; China uses conventional blends |

| Labor | $2.20 | $0.58 | +279% | NZ avg. wage: $25/hr (incl. benefits); China: $3.20/hr |

| Packaging | $0.65 | $0.30 | +117% | NZ compostable mailers + FSC-certified labels |

| Compliance | $0.40 | $0.10 | +300% | NZ ACES testing, WRAP certification, carbon audits |

| Logistics (to US/EU) | $1.10 | $0.75 | +47% | Higher ocean freight from NZ vs. Shanghai |

| TOTAL PER UNIT | $6.20 | $3.13 | +98% | Excludes overheads, duties, or inventory carrying costs |

⚠️ Hidden Costs Alert:

– Tooling Recast: $800-$1,200 per new sock design (amortized over MOQ)

– Quality Control: +7-10% unit cost for 3rd-party NZ-based QC vs. China

– Carbon Tax Exposure: NZ’s 2025 pricing scheme adds $0.08/unit (projected 2026)

MOQ-Based Price Tier Analysis (Private Label | NZ Production | 2026 Forecast)

| MOQ Tier | Unit Price (USD) | Total Order Cost | Cost per Unit vs. China | Procurement Action |

|---|---|---|---|---|

| 500 units | $9.85 | $4,925 | +215% | Avoid reshoring – China OEM ($3.13) remains optimal |

| 1,000 units | $7.60 | $7,600 | +143% | Minimal viability – Only for urgent/short-run needs |

| 5,000 units | $6.20 | $31,000 | +98% | Reshoring threshold – Achieves 18% cost reduction vs. 1,000 MOQ |

| 10,000+ units | $5.35 | $53,500 | +71% | Strategic target – Matches China’s total landed cost (including tariffs/logistics) |

📌 Critical Footnotes:

1. Prices assume Auckland/Hamilton-based manufacturers (Wellington adds +8% labor costs)

2. All NZ quotes include GST; China prices exclude VAT/duties

3. MOQ <1,000 units trigger +$1,200 setup fees (not amortized)

4. 2026 China baseline includes 7.5% tariff escalation (US Section 301)

Strategic Recommendations for Procurement Leaders

- Adopt Hybrid Sourcing: Reshore high-margin, core SKUs (ODM, MOQ 5k+) while retaining China for basics (OEM, MOQ 10k+).

- Negotiate Tiered MOQs: Lock in 5,000-unit commitments with NZ factories for 15-20% discounts vs. spot pricing.

- Factor True TCO: Include carbon compliance, inventory financing, and brand equity (27% NZ price premium) in ROI models.

- Leverage NZ Government Grants: Up to 40% cost coverage for reshoring via Regional Business Partner Network (2026 cap: $150k/firm).

- Audit Local Suppliers Rigorously: Prioritize factories with Sustainable Business Network NZ certification to avoid greenwashing penalties.

“Reshoring without MOQ optimization is margin suicide. Procurement must enforce 5,000-unit minimums for reshored lines or abandon the initiative.”

— SourcifyChina Supply Chain Intelligence Unit, 2026

Prepared by:

Alexandra Chen, Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

Data Sources: NZ Ministry of Business, NZTE Cost Benchmarks 2026, SourcifyChina Factory Audit Database, Colmar Brunton Consumer Trends

🔒 This report contains proprietary SourcifyChina data. Unauthorized distribution prohibited.

Next Steps: Request our “NZ Reshoring Readiness Assessment” toolkit (includes supplier shortlists, MOQ calculators, and grant application templates).

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify a Manufacturer for a New Zealand Sock Company Reshoring from China

Executive Summary

As global supply chains evolve, companies are re-evaluating offshoring strategies. The New Zealand sock company’s decision to reshore production from China presents both opportunity and risk. This report outlines a structured, actionable verification framework to ensure procurement integrity, mitigate supplier risk, and distinguish between genuine factories and trading companies. The steps below are designed to support procurement managers in making informed, secure sourcing decisions in 2026.

1. Critical Steps to Verify a Manufacturer in China

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1.1 | Request Full Company Documentation | Confirm legal existence and operational legitimacy | Verify Business License (via China’s National Enterprise Credit Information Publicity System), Export License, and Tax Registration |

| 1.2 | Conduct On-Site Audit (or 3rd-Party Inspection) | Validate physical presence and production capacity | Engage a third-party auditor (e.g., QIMA, TÜV, SGS) for factory audit including ISO certifications, machinery list, and workforce verification |

| 1.3 | Review Production Capabilities | Ensure technical alignment with sock manufacturing needs | Request machine types (e.g., seamless knitting, circular knitting), production capacity (pairs/month), and sample lead times |

| 1.4 | Evaluate Quality Management Systems | Assess consistency and compliance | Verify ISO 9001, OEKO-TEX®, or BSCI certifications; request QC protocols and defect rate history |

| 1.5 | Check Export History & Client References | Validate track record with international clients | Request 3 verifiable export references (preferably Western brands), verify via LinkedIn or direct outreach |

| 1.6 | Perform Transactional Due Diligence | Avoid financial or operational instability | Review bank statements (via secure channel), payment terms, and request a trial order (MOQ 500–1,000 units) |

| 1.7 | Assess Intellectual Property (IP) Protection | Safeguard designs and branding | Sign NDA before sharing specs; confirm factory’s history of IP compliance and anti-counterfeiting measures |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Genuine Factory | Trading Company | Recommended Action |

|---|---|---|---|

| Facility Ownership | Owns production floor, machinery, and warehouse | No production lines; uses subcontractors | Conduct unannounced site visit |

| Staff On-Site | Employed technicians, QC inspectors, machine operators | Sales agents, logistics coordinators | Interview floor staff directly |

| Pricing Structure | Transparent cost breakdown (material, labor, overhead) | Higher margins with vague cost details | Request itemized quote |

| Lead Times | Direct control over scheduling (e.g., 30–45 days) | Dependent on factory availability (60+ days) | Ask for production calendar |

| Minimum Order Quantity (MOQ) | Lower MOQs due to direct capacity control | Often higher due to markup and coordination | Negotiate trial run below standard MOQ |

| Certifications | Holds manufacturing-specific ISO, SEDEX, or GOTS | May lack production certifications | Cross-check certification validity online |

| Communication | Technical team available for process discussions | Sales-focused; defers to “our factory” | Request conversation with production manager |

Pro Tip: Use satellite imagery (e.g., Google Earth) to verify factory footprint and worker activity. Factories show consistent operational patterns; trading offices are typically in commercial buildings.

3. Red Flags to Avoid in Chinese Sourcing (2026 Update)

| Red Flag | Risk Implication | Mitigation Strategy |

|---|---|---|

| Unwillingness to Allow On-Site Audit | High risk of misrepresentation or subcontracting | Make audit a contractual prerequisite |

| Inconsistent Communication (Time Zones, Language) | Poor coordination; potential middlemen | Require a dedicated English-speaking project manager |

| Too-Good-to-Be-True Pricing | Indicates substandard materials, labor abuse, or hidden fees | Benchmark against industry averages; request material specs |

| No Physical Address or Virtual Office | Likely trading company or shell entity | Verify address via local courier delivery test |

| Pressure for Full Upfront Payment | Scam or cash-flow instability | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| Lack of Industry-Specific Experience | Quality and compliance risks | Require sock-specific references and samples |

| No Online Presence or Sparse Digital Footprint | Low transparency | Check Alibaba Gold Supplier status, LinkedIn, and Chinese platforms (e.g., 1688.com) |

4. Recommended Sourcing Strategy for Reshoring Success

- Dual-Sourcing Pilot: Engage one verified factory and one backup supplier to de-risk transition.

- Local Representation: Hire a sourcing agent or partner with a procurement platform (e.g., Sourcify) with China-based teams.

- Digital Monitoring: Implement production tracking via cloud-based platforms (e.g., Track-PO, Inspectorio).

- Sustainability Alignment: Prioritize factories with eco-certifications (e.g., GRS, ZDHC) to align with NZ consumer values.

- Exit Clauses: Include audit rights and termination clauses in contracts for non-compliance.

Conclusion

Reshoring sock production from China requires rigorous supplier verification to ensure quality, compliance, and long-term reliability. By systematically distinguishing factories from trading companies and proactively identifying red flags, New Zealand brands can build resilient, transparent supply chains. In 2026, due diligence is not optional—it’s a competitive necessity.

Prepared by:

SourcifyChina Senior Sourcing Consultants

Global Supply Chain Intelligence Division

Q1 2026 Edition – Confidential for Procurement Executives

For sourcing audits, factory verification, or supplier shortlisting, contact: [email protected]

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Strategic Reshoring Solutions for NZ Textile Procurement

Q1 2026 | Prepared for Global Procurement Leadership

Critical Challenge: The Hidden Costs of DIY Reshoring

New Zealand sock manufacturers relocating production from China face acute operational risks: 47% of reshoring projects exceed timelines by 5+ months due to unvetted supplier networks (SourcifyChina 2025 Supply Chain Audit). Traditional sourcing methods—trade show hunting, Alibaba searches, or unverified referrals—introduce critical vulnerabilities:

| Risk Factor | Self-Sourced Approach | SourcifyChina Pro List Advantage |

|---|---|---|

| Supplier Vetting | 8-12 weeks (on-site audits required) | Pre-verified in 72 hours (ISO 9001, BSCI, AS/NZS 2001.2:2014 certified) |

| Compliance Gap | 68% face rework due to NZ textile regulation non-compliance | 100% AS/NZS standard adherence with documentation audit trail |

| Time-to-Production | Avg. 22 weeks (from RFQ to first shipment) | 14.2 weeks avg. acceleration via pre-negotiated MOQs & lead times |

| Quality Failures | 31% defect rates in initial production runs | <2.4% defect rate (historical Pro List supplier performance) |

Why the Pro List Eliminates Reshoring Delays

Our NZ Sock Industry Specialized Pro List delivers immediate operational leverage:

✅ Regulatory Shield: All 27 pre-qualified suppliers maintain active NZ-specific compliance (including Woolmark, Oeko-Tex® Standard 100, and AS/NZS 1957:2023). Zero certification delays.

✅ Speed-to-Market: Skip 11+ weeks of supplier screening with factories already audited for merino wool processing, seamless customs clearance (HS 6115.96), and NZD invoice capabilities.

✅ Risk Containment: Contractual penalties for missed deadlines + real-time production tracking via SourcifyChina’s IoT platform.

“Using the Pro List cut our reshoring timeline from 9.2 to 4.1 months—critical for meeting Q4 2025 retail contracts.”

— Procurement Director, NZ Heritage Sock Co. (2025 Client Case Study)

Your Next Step: Secure Reshoring Certainty in 3 Days

Stop gambling with production timelines. Every week of delayed supplier qualification costs NZ sock producers $22,500+ in missed revenue (based on avg. $1.2M/month capacity).

Immediate Action Required:

- Email

[email protected]with subject line: “NZ SOCK PRO LIST – [Your Company]” - OR WhatsApp +86 159 5127 6160 (24/7 Mandarin/English support)

Within 72 hours, you’ll receive:

🔹 Full Pro List dossier (27 factories with capacity, compliance certs, & pricing benchmarks)

🔹 Customized reshoring roadmap with milestone deadlines

🔹 Zero-obligation factory introduction call

Slots are limited to 5 NZ clients per quarter to ensure dedicated support. Current waitlist: 11 companies.

“Reshoring isn’t about leaving China—it’s about strategic precision. We deliver the verified pathways others promise.”

— Senior Sourcing Consultant, SourcifyChina

Act Now → Secure Your Spot Before Q2 Capacity Closes

📧 [email protected] | 📱 +86 159 5127 6160 (WhatsApp)

Report Data Source: SourcifyChina 2025 Reshoring Performance Index (n=142 projects). All NZ-specific metrics validated by Auckland University of Technology Supply Chain Research Group.

🧮 Landed Cost Calculator

Estimate your total import cost from China.