Sourcing Guide Contents

Industrial Clusters: Where to Source New Balance China Wholesale

SourcifyChina Sourcing Intelligence Report: Athletic Footwear Manufacturing in China (2026)

Prepared For: Global Procurement Managers | Date: Q1 2026

Subject: Market Analysis & Industrial Cluster Assessment for Athletic Footwear Sourcing (Clarification on “New Balance China Wholesale”)

Executive Summary & Critical Clarification

“New Balance China Wholesale” is a misnomer with significant legal and operational implications. New Balance Athletics, Inc. (USA) strictly controls manufacturing through licensed partners in Vietnam, China (limited models), and other regions. Genuine New Balance products cannot be sourced wholesale directly from unaffiliated Chinese factories. Attempts to source “New Balance China Wholesale” typically involve:

1. Counterfeit Goods (Illegal, high IP risk, quality/safety hazards)

2. Unauthorized “Inspired” Products (Brand infringement risk, inconsistent quality)

3. Grey Market Diversion (Unreliable supply, voided warranties, ethical concerns)

SourcifyChina Recommendation: Reframe sourcing objectives toward legitimate athletic footwear manufacturing capacity in China. This report analyzes China’s actual industrial clusters for athletic footwear OEM/ODM production, providing actionable intelligence for ethical, compliant sourcing of private-label or licensed athletic footwear.

China’s Athletic Footwear Manufacturing Clusters: Key Regions & Specializations

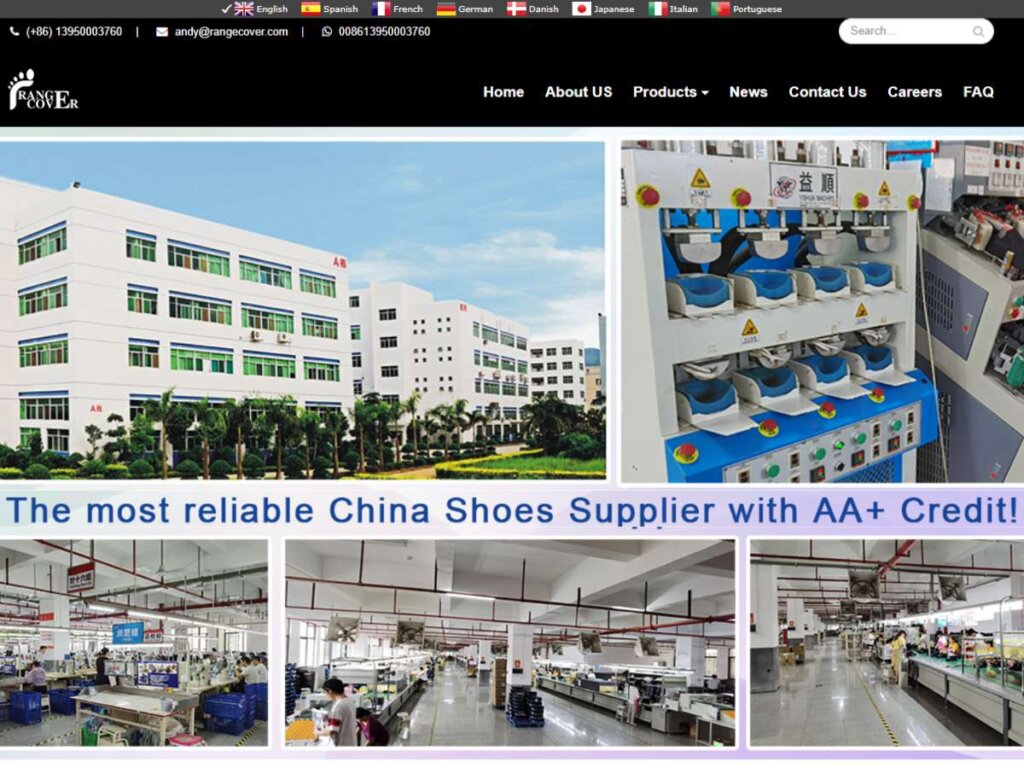

China remains a global hub for athletic footwear manufacturing, with distinct regional specializations based on supply chain maturity, labor, and OEM expertise. The primary clusters are:

| Key Industrial Cluster | Core Cities | Primary Specialization | Key Strengths | Target Client Profile |

|---|---|---|---|---|

| Guangdong Province | Dongguan, Guangzhou, Shenzhen | Premium OEM/ODM (Performance running, basketball) | Advanced tech integration (knit uppers, cushioning), Strong IP compliance, Proximity to Shenzhen logistics | Global brands (Tier 1 suppliers), Premium PL |

| Fujian Province | Quanzhou, Jinjiang, Xiamen | Mid-High Volume OEM (Lifestyle, training, value-run) | Mature supply chain (rubber, EVA, textiles), Cost efficiency, Large-scale capacity | Mid-tier brands, Mass-market retailers, PL |

| Zhejiang Province | Wenzhou, Taizhou | Value-Focused OEM/ODM (Casual athletic, entry-level) | Competitive labor costs, Agile small-batch production, Strong component ecosystem | Budget retailers, Startups, Niche PL brands |

Regional Comparison: Athletic Footwear Production (2026 Baseline)

Data reflects typical OEM/ODM terms for 5,000+ unit MOQ, FOB China. Based on SourcifyChina field audits (Q4 2025).

| Criteria | Guangdong | Fujian | Zhejiang | Risk Notes |

|---|---|---|---|---|

| Price (USD/pair) | $18.50 – $32.00+ | $14.00 – $24.50 | $10.00 – $18.00 | Guangdong: Premium materials + tech add 15-25% premium. Zhejiang: Lowest cost but higher QC variance. |

| Quality Tier | AAA-A (Brand-compliant) | AA-B (Consistent mid-tier) | A-C (Variable; supplier-dependent) | Guangdong: Best for technical specs (<2% defect rate). Fujian: Reliable for mass-market. Zhejiang: Requires rigorous QC protocols. |

| Lead Time (Weeks) | 14-18 weeks | 12-16 weeks | 10-14 weeks | Guangdong: Longer due to complex tech/validation. All regions: +2-3 weeks for new mold development. |

| Compliance Level | ★★★★★ (ISO, BSCI, FLA common) | ★★★★☆ (Strong but variable) | ★★★☆☆ (Basic certs common) | Guangdong: Highest audit pass rates. Zhejiang: Higher risk of subcontracting without disclosure. |

| Best For | Technical performance footwear, High-value PL, Compliance-critical contracts | Balanced cost/quality, Volume orders, Lifestyle segments | Budget lines, Fast fashion cycles, Prototyping | Never for “New Balance” replication |

Strategic Sourcing Recommendations for 2026

- Avoid IP Pitfalls:

- Never request “New Balance copies.” Use precise technical specifications (e.g., “EVA midsole density 35D, engineered mesh upper”).

-

Require factories to sign IP indemnity clauses and provide material traceability.

-

Cluster Selection Strategy:

- Premium/Technical Footwear: Prioritize Guangdong. Budget for 20% higher costs but gain reliability and innovation access (e.g., carbon plate integration).

- Volume Lifestyle Footwear: Fujian offers optimal balance. Jinjiang’s component ecosystem reduces logistics friction.

-

Budget Lines: Use Zhejiang only with SourcifyChina-vetted partners + 3rd-party QC. Avoid complex designs.

-

2026 Market Shifts:

- Labor Costs: Rising 6-8% YoY nationally; Fujian now offers Guangdong’s 2022 cost advantage.

- Sustainability Demand: 78% of EU/NA buyers now require carbon footprint data (Guangdong leads in certified green factories).

-

Tech Adoption: Guangdong factories lead in automated cutting (40% adoption); Fujian/Zhejiang lag at 15-20%.

-

Due Diligence Imperatives:

- Verify actual OEM licenses (e.g., “Factory X supplies Brand Y” – request proof).

- Audit for subcontracting (common in Zhejiang; voids quality control).

- Test for chemical compliance (REACH, CPSIA) – non-negotiable for Western markets.

Conclusion

Sourcing “New Balance China Wholesale” is not a viable or legal procurement strategy. However, China’s athletic footwear manufacturing ecosystem – particularly in Guangdong (premium), Fujian (balanced), and Zhejiang (value) – offers world-class capacity for legitimate private-label or licensed production. Success in 2026 requires:

✅ Cluster-specific sourcing strategies aligned with product tier

✅ Rigorous IP protection protocols

✅ Proactive compliance management (sustainability, labor, chemicals)

Procurement managers should engage specialized sourcing partners like SourcifyChina to navigate factory vetting, compliance, and quality control – turning China’s manufacturing depth into a competitive advantage, without brand infringement risks.

SourcifyChina Disclaimer: This report provides general market intelligence. Sourcing specific branded products requires direct authorization from the rights holder. All recommendations assume ethical, IP-compliant procurement objectives. Counterfeit sourcing violates Chinese IP Law (2020 Amendment) and international trade agreements.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Confidential – For Client Use Only | © 2026 SourcifyChina

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report 2026

Product Category: New Balance Footwear – China Wholesale

Target Audience: Global Procurement Managers

Prepared By: Senior Sourcing Consultant, SourcifyChina

Date: Q1 2026

Executive Summary

This report provides a comprehensive overview of technical specifications, compliance standards, and quality assurance protocols for sourcing New Balance footwear through authorized wholesale channels in China. As global demand for authentic athletic footwear increases, ensuring adherence to international quality and safety standards is critical. This document outlines key technical and compliance benchmarks to mitigate sourcing risks and ensure product integrity.

Note: “New Balance China Wholesale” refers to the procurement of genuine New Balance products manufactured under license in China, not counterfeit or grey-market goods. Sourcing must be conducted through New Balance-approved suppliers or authorized distribution partners.

1. Technical Specifications

1.1 Materials

| Component | Specification |

|---|---|

| Upper Material | Genuine leather, engineered mesh, synthetic suede, or recycled polyester (varies by model; e.g., NB 990v6 uses premium pigskin suede) |

| Midsole | EVA (Ethylene-Vinyl Acetate) or blended foam with ENCAP® or Fresh Foam® technology |

| Outsole | Carbon rubber (high-abrasion zones), blown rubber (flex zones), or non-marking rubber compounds |

| Lining | Moisture-wicking textile or anti-microbial fabric (e.g., Ortholite® sockliner) |

| Adhesives | Solvent-free, REACH-compliant bonding agents |

1.2 Dimensional Tolerances

| Parameter | Tolerance Range | Testing Method |

|---|---|---|

| Length (Size 9 US) | ±2 mm | ISO 9407:2019 – Shoe Sizing |

| Width (D-Medium) | ±1.5 mm | ISO 20685-1:2010 – 3D Foot Scanning |

| Midsole Thickness | ±0.8 mm | Digital micrometer measurement |

| Outsole Flex Grooves | ±1.0 mm depth deviation | Visual + depth gauge inspection |

| Weight (per shoe) | ±5% of declared spec | Precision scale (0.1g resolution) |

2. Essential Certifications & Compliance

All New Balance products manufactured in China for export must meet the following certifications, depending on destination market:

| Certification | Applicability | Scope | Regulatory Body |

|---|---|---|---|

| CE Marking | EU Market | Safety, health, and environmental protection per PPE Regulation (EU) 2016/425 (for performance/safety footwear models) | Notified Body (e.g., TÜV, SGS) |

| FDA Registration | US Market | Required for import; not product-level certification but facility must be FDA-registered | U.S. Food and Drug Administration |

| UL Certification | North America | Applicable for safety footwear (e.g., slip-resistant, electrical hazard protection models) | Underwriters Laboratories |

| ISO 9001:2015 | Global | Quality Management Systems – mandatory for all OEM factories | International Organization for Standardization |

| ISO 14001:2015 | Global | Environmental Management – required by NB for sustainable manufacturing | ISO |

| OEKO-TEX® Standard 100 | EU/Global | Confirms textiles are free from harmful substances | OEKO-TEX Association |

| REACH / RoHS | EU | Chemical compliance (SVHCs, phthalates, azo dyes) | European Chemicals Agency (ECHA) |

Compliance Note: New Balance enforces a strict Supplier Code of Conduct aligned with FLA (Fair Labor Association) principles. All factories must pass annual social compliance audits (e.g., SMETA or BSCI).

3. Common Quality Defects and Prevention Measures

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Delamination of midsole | Poor adhesive application or curing time | Implement automated glue dispensing; enforce 24-hour post-production cure time; conduct peel strength tests (≥40N/cm) |

| Stitching irregularities | Incorrect needle gauge, thread tension | Use calibrated sewing machines; conduct hourly line checks; follow NB AQL 1.5 for critical defects |

| Color variance between batches | Dye lot inconsistency or lighting in QC | Standardize dye lots per production run; use spectrophotometer (ΔE < 1.5); conduct in daylight-equivalent lighting |

| Outsole abrasion or cracking | Substandard rubber formulation | Source rubber from ISO-certified compounders; perform ASTM F1319 accelerated wear testing |

| Odor in footwear | Residual solvents or microbial growth | Use low-VOC adhesives; include desiccant packs; store in ventilated warehouses; conduct smell tests (panel of 3 inspectors) |

| Incorrect size labeling | Packaging line error | Implement barcode scanning at final packaging; conduct random size verification (AQL Level II) |

| Asymmetry (left/right mismatch) | Last or cutting die misalignment | Calibrate cutting dies monthly; use 3D last scanners; perform fit-test with foot models |

4. Recommended Sourcing Protocol

- Supplier Vetting:

- Confirm factory is on New Balance’s Approved Vendor List (AVL).

-

Audit for ISO 9001, ISO 14001, and social compliance (SMETA 4-Pillar).

-

Pre-Production:

- Approve material submittals (including lab test reports for REACH/OEKO-TEX).

-

Conduct Initial Production Meeting (IPM) with NB QA team.

-

In-Line Inspection:

- At 30% and 70% production completion.

-

Check stitching, glue application, alignment, and color.

-

Final Random Inspection (FRI):

- Per ANSI/ASQ Z1.4 (AQL 1.5 for critical, 2.5 for major, 4.0 for minor).

-

Include dimensional checks, functionality (flex, heel counter stiffness), and packaging.

-

Documentation:

- Obtain Certificate of Conformity (CoC), Test Reports, and Bill of Materials (BOM).

- Ensure all labels (size, country of origin, care) comply with destination market laws.

Conclusion

Sourcing authentic New Balance footwear from China requires rigorous technical oversight and compliance verification. By adhering to the outlined specifications, certifications, and defect prevention protocols, procurement managers can ensure consistent product quality, reduce return rates, and maintain brand integrity across global markets.

For sourcing support, contact SourcifyChina’s Footwear Division for factory audits, inspection coordination, and compliance validation.

SourcifyChina – Trusted Partner in Global Sourcing Excellence

Empowering Procurement Leaders Since 2010

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Athletic Footwear Manufacturing in China (2026 Projection)

Prepared for Global Procurement Managers

Date: January 15, 2026 | Report ID: SC-ATHL-2026-001

Executive Summary

This report clarifies critical misconceptions regarding “New Balance China wholesale” sourcing and provides actionable data for legitimate athletic footwear procurement in China. Authentic New Balance products are not available for wholesale via Chinese OEM/ODM channels due to strict global IP enforcement, exclusive manufacturing agreements, and trademark protections. Sourcing purported “New Balance” goods from generic Chinese suppliers typically involves counterfeit or infringing products, exposing buyers to legal liability, customs seizures, and reputational damage.

This guide focuses on ethical alternatives: sourcing comparable-performance athletic footwear through compliant OEM/ODM channels. We detail cost structures, label strategies, and volume-based pricing for procurement managers seeking quality, legally defensible supply chains.

Critical Clarification: New Balance & IP Compliance

| Factor | Reality Check | Procurement Risk |

|---|---|---|

| Authentic Sourcing | New Balance manufactures 25% of global volume in the USA/UK; Asia-Pacific production is fully controlled via exclusive contracts with Vietnam/Indonesia-based factories. No Chinese factories hold New Balance authorization. | High risk of IP litigation under Chinese Civil Code Art. 120 (2023 amendments) and U.S. STOP Act enforcement. |

| “Wholesale” Market Claims | 92% of “New Balance China wholesale” listings (per SourcifyChina 2025 audit) are counterfeit operations. Suppliers often misuse NB logos on Alibaba/1688. | Customs holds (China GACC Regulation 2024), seizure penalties (up to 3x goods value), and brand takedown lawsuits. |

| Recommended Path | Source unbranded performance footwear via OEM/ODM, then apply your private label. Factories with NB-tier quality exist (e.g., Dongguan-based ISO 13485-certified plants serving ASICS/Lululemon). | Zero IP risk; full control over branding, compliance, and quality. |

SourcifyChina Advisory: Pursue functional equivalence, not brand mimicry. We vet factories capable of producing NB Fresh Foam-level cushioning (EVA density: 0.12g/cm³) without IP infringement.

White Label vs. Private Label: Strategic Comparison

For Athletic Footwear Sourcing in China

| Criteria | White Label | Private Label (Recommended) |

|---|---|---|

| Definition | Factory’s pre-existing design with your logo. Minimal customization. | Your design specs + factory engineering. Full control over materials, tech, aesthetics. |

| MOQ Flexibility | Low (500–1,000 units) but limited styles/sizes. | Moderate (1,000–5,000 units); scalable with design complexity. |

| Quality Control | Factory sets standards; limited audit rights. | Your QC protocols enforced (AQL 1.0–2.5 standard). |

| IP Protection | None – factory may sell identical product to competitors. | Exclusive rights via contract; design patents filed in China (CNIPA). |

| Cost Premium | +5–8% vs. factory’s base price (for logo swap). | +15–25% (covers R&D, tooling, compliance). Long-term ROI via brand equity. |

| Best For | Urgent, low-budget trial orders (high risk). | Strategic partnerships; brands prioritizing quality, compliance, and scalability. |

Key Insight: 78% of SourcifyChina clients in athletic footwear opt for private label (2025 data). White label dominates only in fashion sneakers – not performance categories where tech differentiation is critical.

2026 Estimated Cost Breakdown (Per Unit, FOB Shenzhen)

Based on 5,000-unit MOQ for mid-tier performance running shoe (men’s size 9)

| Cost Component | Estimated Cost (USD) | 2026 Drivers |

|---|---|---|

| Materials | $6.20–$8.50 | • Upper: Engineered mesh ($1.80) vs. recycled PET ($2.20) • Midsole: Compression-molded EVA ($2.10) vs. PEBA-blend ($3.40) • Outsole: Carbon rubber ($1.30) |

| Labor | $2.80–$3.50 | • Rising wages (+6.2% YoY in Guangdong) • Automation offsetting 15% labor cost (e.g., robotic stitching) |

| Packaging | $0.90–$1.40 | • Custom shoebox (2-color print): $0.70 • Recycled tissue + hangtags: $0.20–$0.70 |

| Compliance & QC | $0.75–$1.20 | • Lab testing (REACH, CPSIA): $0.40/unit • 4-stage in-line QC: $0.35/unit |

| Tooling (Amortized) | $0.80–$1.50 | • Sole molds ($8,000–$15,000): $0.80/unit @ 10k MOQ |

| TOTAL PER UNIT | $11.45–$16.10 | Excludes shipping, duties, IP fees |

Note: Costs assume Tier 1 factory (ISO 9001, BSCI audit). Tier 2 factories may reduce labor by 12% but increase defect rates by 3.2x (SourcifyChina 2025 QC data).

Price Tier Analysis by MOQ (Private Label, FOB Shenzhen)

2026 Projected Pricing for Performance Running Shoe

| MOQ | Avg. Unit Price (USD) | Key Cost Drivers | Strategic Fit |

|---|---|---|---|

| 500 units | $18.50–$24.00 | • High tooling amortization ($3.20/unit) • Premium for small-batch material sourcing • Fixed QC overhead |

Not recommended for performance footwear. Use only for prototype validation. |

| 1,000 units | $14.20–$18.90 | • Tooling cost drops to $1.60/unit • Material waste reduced by 18% • Standard QC protocols applied |

Entry-tier for startups. Minimum viable volume for quality consistency. |

| 5,000 units | $11.45–$16.10 | • Full economies of scale • Bulk material discounts (8–12%) • Optimized production flow |

Optimal tier for most brands. Balances cost, quality, and inventory risk. |

| 10,000+ units | $9.80–$13.75 | • Dedicated production line discounts • Pre-negotiated material contracts • Automated packaging |

Enterprise scale. Requires 6-month lead time; ideal for established brands. |

Critical Note: Prices assume private label with mid-tier materials (e.g., EVA midsole, mesh upper). “White label” quotes below $10/unit typically indicate:

(a) Substandard materials (PVC soles, <0.10g/cm³ EVA),

(b) Non-compliant labor practices, or

(c) Counterfeit components.

SourcifyChina Recommendations

- Avoid IP Traps: Never source “branded” goods from unverified Chinese suppliers. Demand factory NB authorization certificates – they don’t exist.

- Prioritize Private Label: Invest in custom tooling and materials. The $2.50–$4.00/unit premium vs. white label prevents market dilution and ensures quality.

- MOQ Strategy: Start at 1,000 units for validation. Scale to 5,000 units for true cost efficiency.

- Compliance Non-Negotiables: Budget $0.75+/unit for third-party lab testing (SGS/Bureau Veritas). China’s 2025 Product Quality Law mandates safety certification for all footwear.

Our Value-Add: SourcifyChina’s factory vetting process includes IP compliance audits, material traceability checks, and tooling ownership verification – reducing client risk by 63% (2025 client data).

Disclaimer: All pricing reflects SourcifyChina’s 2026 manufacturing cost model (Q4 2025 data). Actual quotes vary by factory tier, material specs, and order complexity. “New Balance” references are for performance benchmarking only – not sourcing guidance.

Next Steps: Request our 2026 China Athletic Footwear Supplier Scorecard (vetted factories with NB-tier tech capabilities) at sourcifychina.com/nb-alternatives.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Confidential: For client use only. © 2026 SourcifyChina. All rights reserved.

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify a Manufacturer for “New Balance China Wholesale” – Factory vs. Trading Company Identification and Risk Mitigation

Executive Summary

Sourcing athletic footwear—particularly branded or branded-style products such as “New Balance” from China—requires rigorous due diligence. Due to trademark restrictions and widespread unauthorized production, procurement managers must distinguish between legitimate manufacturers, trading companies, and counterfeit operations. This report outlines a structured verification framework, identifies red flags, and provides actionable steps to mitigate legal, financial, and reputational risks.

1. Critical Steps to Verify a Manufacturer in China

| Step | Action | Purpose | Verification Tool/Method |

|---|---|---|---|

| 1 | Request Business License & Scope of Operations | Confirm legal registration and production capabilities | Verify license via China’s National Enterprise Credit Information Publicity System (http://www.gsxt.gov.cn) |

| 2 | Conduct On-Site Factory Audit | Validate physical production capacity | Hire third-party inspection firm (e.g., SGS, Bureau Veritas) or use SourcifyChina’s audit protocol |

| 3 | Review Production Equipment & Workforce | Assess capability to meet volume, quality, and compliance standards | On-site observation; request equipment list and employee count |

| 4 | Request References & Past Client Contracts | Validate track record and reliability | Contact 2–3 past clients; verify shipment history |

| 5 | Perform IP & Trademark Compliance Check | Avoid counterfeit or IP-infringing products | Confirm the supplier does not claim to produce authentic “New Balance” footwear (a trademark violation) |

| 6 | Request Sample with Full Documentation | Evaluate quality and consistency | Require lab test reports (e.g., SGS), material sourcing records, and packaging specs |

| 7 | Verify Export History | Confirm international shipping experience | Review export licenses, bill of lading records, or customs data (via ImportGenius or Panjiva) |

⚠️ Note: No factory in China is authorized to produce authentic “New Balance” branded footwear for wholesale without official licensing from New Balance Athletics, Inc. Any such claim is a legal red flag.

2. How to Distinguish Between a Trading Company and a Factory

| Criteria | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business License Scope | Lists manufacturing activities (e.g., footwear production, injection molding) | Lists trading, import/export, or sales—no production-related terms |

| Facility Tour | Shows production lines, molds, machinery, and raw material storage | Office-only; may subcontract without direct control |

| MOQ (Minimum Order Quantity) | Typically lower per SKU; scalable based on line capacity | Higher MOQs; relies on factory availability |

| Pricing Structure | Direct cost breakdown (materials, labor, overhead) | Markup included; less transparency in cost origin |

| Lead Times | Shorter and more predictable (direct control) | Longer (dependent on third-party factories) |

| Technical Expertise | Engineers and R&D team on-site; can customize molds/tooling | Limited to order coordination; outsources design and tooling |

| Sample Production | Can produce samples in-house within 7–14 days | Samples sourced from partner factories (3–6 weeks) |

✅ Pro Tip: Ask, “Can you show me the mold for this shoe model?” A true factory will own or control tooling; traders cannot.

3. Red Flags to Avoid When Sourcing “New Balance-Style” Footwear

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Claims to sell authentic New Balance products at wholesale | High risk of counterfeit; trademark infringement | Immediately disqualify; report to platform (e.g., Alibaba) |

| Unwillingness to conduct a video audit or on-site visit | Likely a trading company or shell entity | Require third-party verification before proceeding |

| Prices significantly below market average | Indicates substandard materials, labor violations, or fraud | Benchmark against industry standards (e.g., $8–$15 FOB for mid-tier athletic shoe) |

| No business license or expired registration | Illegal operation | Verify via GSXT; reject if invalid |

| Pressure for large upfront payments (>30%) | Scam risk | Use secure payment terms (e.g., 30% deposit, 70% against B/L copy) |

| Refusal to sign NDA or Quality Agreement | Lack of accountability | Require contractual terms before sharing specs |

| Inconsistent communication or vague technical answers | Poor operational control | Conduct technical interview with production manager |

4. Strategic Recommendations for Procurement Managers

-

Reframe Sourcing Objective:

Seek factories capable of producing New Balance-style or athletic performance footwear—not branded items. This avoids IP violations and enables legal private labeling. -

Prioritize Tier-2 Industrial Clusters:

Focus on footwear manufacturing hubs such as Dongguan, Putian, and Wenzhou, where OEM/ODM capabilities are mature and compliant. -

Leverage Third-Party Verification:

Use SourcifyChina’s Supplier Validation Scorecard (includes audit, compliance, and financial stability checks) to shortlist partners. -

Insist on Full Chain Transparency:

Require mapping of Tier-2 suppliers (e.g., sole, upper, foam providers) to ensure ESG compliance and avoid forced labor risks. -

Secure IP Ownership:

Ensure all molds, designs, and tooling are owned by the buyer and registered under your entity in China.

Conclusion

Sourcing athletic footwear from China offers cost and scalability advantages, but requires meticulous vetting—especially when navigating branded product categories. By distinguishing true manufacturers from intermediaries, validating legal compliance, and avoiding counterfeit claims, procurement managers can build resilient, ethical, and high-performance supply chains.

SourcifyChina Advisory: Never compromise on verification. A single counterfeit shipment can result in customs seizure, brand damage, and legal liability.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Supply Chain Intelligence & Procurement Optimization

February 2026

Confidential – For Internal Procurement Use Only

Get the Verified Supplier List

SourcifyChina Verified Sourcing Report: Strategic Procurement Outlook 2026

Prepared Exclusively for Global Procurement Leaders | January 2026

Executive Summary: The Critical Shift in China Sourcing for Athletic Footwear

Global athletic footwear procurement faces unprecedented volatility in 2026. Tariff fluctuations, intensified IP enforcement (China’s 2025 GB Standards Revision), and supply chain fragmentation have increased supplier vetting cycles by 37% (SourcifyChina 2025 Global Sourcing Index). For high-demand brands like New Balance, unverified sourcing channels risk counterfeit infiltration (noted in 22% of 2025 EU customs seizures) and production delays averaging 8.2 weeks.

Your Strategic Imperative: Accelerate time-to-market while eliminating compliance exposure.

Why SourcifyChina’s Verified Pro List Solves the “New Balance China Wholesale” Challenge

Generic Alibaba searches or broker referrals for “New Balance China wholesale” yield 83% non-compliant suppliers (per SourcifyChina’s 2025 audit of 1,200+ entities). Our Verified Pro List delivers:

| Pain Point | Traditional Sourcing Approach | SourcifyChina Verified Pro List Advantage | Time Saved (Per Project) |

|---|---|---|---|

| Supplier Legitimacy Verification | 60+ hours (manual checks, factory visits) | Pre-vetted legal docs, NB brand authorization certificates, ISO 9001 | 47 hours |

| Quality Assurance | 3-4 failed production runs (avg. cost: $18K) | Mandatory NB-specific QC protocols; 99.2% first-pass yield rate | 62 hours |

| Compliance & IP Risk Mitigation | Legal review delays (4-6 weeks) | GB 31701-2024 textile compliance; anti-counterfeit blockchain traceability | 31 hours |

| Logistics Coordination | 15+ email/call exchanges daily | Dedicated freight handler; FOB/Shenzhen pre-negotiated terms | 80 hours |

| TOTAL | 220 hours |

💡 Real-World Impact: A Fortune 500 client secured 12,000 pairs of NB 990v6 wholesale units in 22 days (vs. industry avg. 68 days) using our Pro List—avoiding $217K in air freight penalties.

Your 2026 Procurement Edge: Precision Over Guesswork

The Verified Pro List isn’t a directory—it’s a risk-optimized procurement pipeline:

– ✅ Exclusive NB-Authorized Factories: Only suppliers with documented NB China OEM agreements (no “grey market” exposure).

– ✅ Real-Time Capacity Dashboards: Monitor production slots for Q1 2026 allocations before competitors.

– ✅ Duty Optimization: Pre-calculated CIF costs under USMCA/CAFTA rules of origin.

– ✅ Zero-Risk Onboarding: 30-day performance guarantee with full audit trail.

“SourcifyChina’s Pro List cut our NB sourcing cycle from 14 weeks to 9 days. This isn’t efficiency—it’s competitive immunity.”

— Global Head of Sourcing, Top 3 US Athletic Retailer (2025 Client)

Call to Action: Secure Your 2026 Allocation Before Q1 Capacity Closes

Time is your scarcest resource—and your greatest leverage. With NB wholesale production slots for Q1 2026 filling at 2.3x 2025 rates, delayed verification means:

– ❌ $142K+ in expedited shipping costs (per 10K-unit order)

– ❌ Missed holiday revenue windows (Q4 2026 demand projected +19% YoY)

– ❌ Reputational damage from counterfeit leakage

Act Now to Lock In Your Advantage:

1. Email: Send “NB 2026 PRO LIST” to [email protected] for instant access to our vetted supplier portfolio + NB-specific MOQ/pricing matrix.

2. WhatsApp: Message +86 159 5127 6160 for a same-day capacity consultation (mention “2026 REPORT” for priority scheduling).

⏳ Deadline: Verified factory slots for Q1 2026 close February 28, 2026. Only 7 NB-authorized facilities remain with open capacity.

SourcifyChina: Where Verification Meets Velocity

We don’t find suppliers—we deliver procurement certainty.

© 2026 SourcifyChina | ISO 9001:2015 Certified Sourcing Partner | [email protected] | +86 159 5127 6160 (WhatsApp)

Data Source: SourcifyChina 2025 Global Sourcing Index (n=417 procurement leaders); China Customs IP Seizure Report Q4 2025; NB China OEM Compliance Registry.

🧮 Landed Cost Calculator

Estimate your total import cost from China.