The global stepper motor market, driven by rising automation across industries such as robotics, healthcare, and consumer electronics, is poised for steady expansion. According to a 2023 report by Mordor Intelligence, the market was valued at USD 5.8 billion in 2022 and is projected to grow at a CAGR of 6.9% through 2028. A key segment within this space—NEMA size 17 stepper motors—has gained prominence due to its optimal balance of torque, size, and cost, making it a preferred choice for precision applications in 3D printing, CNC machinery, and automated manufacturing. As demand for compact, high-performance motion control solutions increases, manufacturers specializing in NEMA 17 motors are scaling production and innovation. Based on market presence, product quality, and technological advancements, the following seven companies have emerged as leading producers in the NEMA size 17 motor segment.

Top 7 Nema Size 17 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Nanotec

Domain Est. 1998

Website: nanotec.com

Key Highlights: Nanotec Electronic is a leading manufacturer and supplier of high-performance drive solutions for OEMs … NEMA 17 | 42 mm · NEMA 23 | 56 mm · Lead screws and ……

#2 [PDF] NEMA vs. IEC Motor Standards

Domain Est. 1994

Website: nema.org

Key Highlights: Page 25. Frame Size Designations. • NEMA MG 1 assigns a frame size based on enclosure, HP and rpm for 60 Hz operation. • IEC does not associate any specific ……

#3 Stepper Motors

Domain Est. 1996

Website: applied-motion.com

Key Highlights: 14-day returnsHT17-268D-WAA NEMA 17 High Torque Stepper Motor w/ WAA encoder. Price. $ 358.00. SKU. HT17-268D-WAA. Frame Size. NEMA 17. Motor Length. 1.86 ……

#4 Encoder Products Company

Domain Est. 1996

Website: encoder.com

Key Highlights: At Encoder Products Company (EPC), we take pride in designing, manufacturing, and assembling high-quality rotary encoders right here in Sagle, Idaho, USA….

#5 TorquePower™ Brand Stepper Motors

Domain Est. 2000

Website: electrocraft.com

Key Highlights: NEMA 17 1.8° Stepper Motor. Size: NEMA 17, 1.8° Holding Torque: up to 78 oz-in or 55 Ncm Speed: up to 80 RPS · TPE23. NEMA 23 1.8° Stepper Motor. Size: NEMA 23, ……

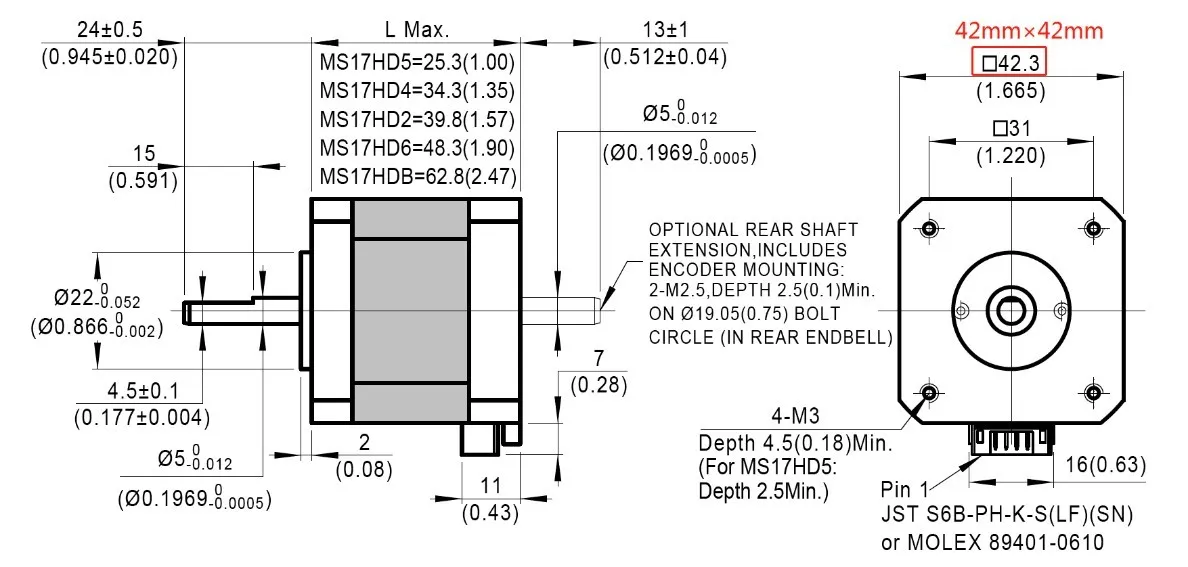

#6 NEMA 17 Brushless DC motor

Domain Est. 2013

Website: hemotors.com

Key Highlights: NEMA 17 Brushless DC motor characteristic parameters ; length(mm), 45 ; pole pair. 4 ; rated torque(Nm). 0.1 ; rated current(A). 1.7 ; rated speed(RPM). 3000….

#7 NEMA 17

Domain Est. 2020

Website: botland.store

Key Highlights: It has slots and holes that allow the device to be mounted to virtually any structure. The metal thickness is 3 mm. The kit includes screws and nuts. Mounting ……

Expert Sourcing Insights for Nema Size 17

2026 Market Trends for NEMA Size 17 Stepper Motors

The NEMA 17 stepper motor, a staple in precision motion control due to its optimal balance of size, torque, and cost, is poised for continued evolution and growth into 2026. Driven by advancements in automation, robotics, and industrial digitization, several key trends are expected to shape its market landscape:

1. Surge in Demand from Automation and Robotics: The proliferation of collaborative robots (cobots), automated guided vehicles (AGVs), and small-scale industrial automation systems will be a primary growth driver. NEMA 17 motors are ideal for the joint actuation, linear motion, and precision positioning required in these applications, especially in compact designs. The push for factory automation and smart manufacturing (Industry 4.0) will further amplify demand.

2. Integration of Smart and Connected Features: The trend towards IoT-enabled devices will push NEMA 17 motors beyond simple open-loop control. Expect increased integration of encoders for closed-loop operation (improving accuracy and preventing stalling), built-in drivers, and communication interfaces (like CANopen or Ethernet-based protocols). This enables real-time monitoring, predictive maintenance, and seamless integration into larger control systems.

3. Focus on Miniaturization and High Efficiency: While the NEMA 17 frame size remains standard, there will be a strong push for motors delivering higher torque density (more torque in the same footprint) and improved energy efficiency. This is crucial for battery-powered devices (drones, portable equipment) and applications where heat dissipation and power consumption are critical. Advances in magnet materials (e.g., stronger neodymium variants) and optimized electromagnetic design will fuel this trend.

4. Growth in Consumer and Prosumer Applications: Beyond industrial uses, NEMA 17 motors will see sustained demand in high-end consumer and prosumer markets. This includes advanced 3D printers (faster, more precise), CNC routers, automated photography equipment, and sophisticated hobbyist robotics. The accessibility of these motors and controllers (like Trinamic drivers) will continue to empower innovation in this space.

5. Supply Chain Resilience and Regionalization: Lessons learned from recent global disruptions will lead manufacturers to diversify supply chains and potentially increase regional production (near-shoring or friend-shoring). This could impact pricing and availability but aims to improve reliability for end customers. Sustainability considerations may also influence material sourcing and manufacturing processes.

6. Competitive Pressure and Value Engineering: The market will remain competitive, with both established industrial players and agile Chinese manufacturers vying for share. This will drive continuous value engineering – offering better performance, features, or reliability at similar or lower price points. Customization for specific OEM applications will also be a key differentiator.

In conclusion, the NEMA 17 stepper motor market in 2026 will be characterized by increasing demand driven by automation, a shift towards smarter and more efficient designs, expansion into diverse applications, and intensified competition focused on innovation and supply chain stability. While the core form factor remains relevant, the motors themselves will become more intelligent, powerful, and integrated, solidifying their role as a fundamental building block in modern motion control.

Common Pitfalls When Sourcing NEMA Size 17 Stepper Motors (Quality & IP Considerations)

Sourcing NEMA 17 stepper motors is common in motion control applications, but overlooking quality and ingress protection (IP) ratings can lead to performance issues, premature failure, and system downtime. Here are key pitfalls to avoid:

Choosing Based Solely on Price

Opting for the cheapest available NEMA 17 motors often results in subpar components—such as weaker magnets, lower-grade bearings, and inconsistent tolerances. These compromises lead to reduced torque accuracy, shorter lifespan, and higher failure rates under load. Investing in reputable brands ensures consistent performance and long-term reliability.

Ignoring Ingress Protection (IP) Ratings

Many standard NEMA 17 motors lack defined IP ratings and are not sealed against dust or moisture. Using them in environments with humidity, dust, or splashing liquids without proper protection can cause internal corrosion, winding damage, and motor failure. Always verify the required IP rating (e.g., IP54 or IP65) for your operating environment and select appropriately sealed motors.

Assuming All Motors Meet Specified Torque and Electrical Ratings

Low-cost or counterfeit motors often overstate torque, inductance, or resistance values. This leads to mismatched driver performance, unexpected stalling, or overheating. Always request test reports or sample testing to validate manufacturer specifications, especially for critical applications.

Overlooking Shaft and Bearing Quality

Poor-quality motors may use soft shafts prone to bending or low-grade bearings that wear quickly, especially under radial or axial loads. This results in noise, vibration, and reduced accuracy. Check for hardened shafts and industrial-grade bearings if your application involves mechanical stress or high precision.

Neglecting Thermal Performance and Insulation Class

Motors operating in enclosed or high-temperature environments require proper thermal management. Inadequate insulation (e.g., Class A instead of Class B or F) can lead to winding insulation breakdown and failure. Confirm the motor’s temperature rating and ensure it matches your thermal operating conditions.

Missing Compliance and Certification Requirements

For industrial or medical applications, motors may need certifications such as RoHS, REACH, or UL. Sourcing non-compliant motors can delay product approvals or lead to regulatory issues. Always verify that the motor meets necessary regional and industry standards.

By addressing these pitfalls during the sourcing process, you ensure reliable integration, improved system longevity, and reduced maintenance costs in your NEMA 17 stepper motor applications.

Logistics & Compliance Guide for NEMA Size 17 Stepper Motors

NEMA 17 stepper motors are widely used in automation, 3D printing, CNC machines, and robotics due to their compact size and reliable performance. Ensuring smooth logistics and compliance across supply chains requires attention to packaging, shipping, regulatory standards, and documentation. Below is a comprehensive guide to help manufacturers, distributors, and integrators manage the logistics and compliance aspects of NEMA 17 motors.

Packaging Requirements

Proper packaging is essential to prevent physical damage during transit and ensure product integrity.

- Anti-static Packaging: Use anti-static bags or containers to protect motors from electrostatic discharge (ESD), especially if the motor includes sensitive electronics or integrated drivers.

- Cushioning: Include foam inserts, bubble wrap, or molded pulp to minimize vibration and shock during handling and transport.

- Secure Boxing: Place motors in rigid corrugated cardboard boxes with sufficient internal bracing to prevent movement.

- Labeling: Clearly label packages with handling instructions (e.g., “Fragile,” “Do Not Stack,” “This Side Up”) and include product identifiers (model number, batch/lot number).

Shipping & Transportation

Choose appropriate shipping methods based on volume, destination, and delivery timelines.

- Domestic vs. International: For international shipments, ensure compliance with customs regulations and provide accurate commercial invoices, packing lists, and certificates of origin.

- Hazard Classification: NEMA 17 motors are typically not classified as hazardous goods, but verify with current IATA/IMDG regulations if motors contain magnets or batteries.

- Temperature & Humidity: Avoid extreme environmental conditions during transit; store and ship in temperature-controlled environments when possible.

- Tracking & Insurance: Use tracked shipping services and consider insurance for high-value shipments.

Regulatory Compliance

Ensure motors meet applicable international and regional standards.

- RoHS Compliance (EU): Confirm that motors comply with the Restriction of Hazardous Substances Directive (RoHS 2, 2011/65/EU), restricting lead, mercury, cadmium, and other hazardous materials.

- REACH (EU): Comply with Registration, Evaluation, Authorization, and Restriction of Chemicals regulations, particularly regarding SVHCs (Substances of Very High Concern).

- CE Marking: Required for sale in the European Economic Area (EEA), indicating conformity with health, safety, and environmental protection standards.

- FCC Compliance (USA): If the motor includes electronic components or drivers, ensure electromagnetic compatibility (EMC) per FCC Part 15 regulations.

- UL/CSA Recognition: Optional but recommended for North American markets; motors with integrated drivers may require certification for safety.

- IP Rating: If applicable, provide ingress protection ratings (e.g., IP54) for motors used in dusty or damp environments.

Documentation & Traceability

Maintain accurate records for compliance audits and customer support.

- Bill of Materials (BOM): Retain a full BOM showing all components and sub-assemblies, including country of origin.

- Compliance Certificates: Provide RoHS, REACH, and CE declarations upon request.

- Test Reports: Keep electrical, mechanical, and environmental test data (e.g., torque, current, temperature range).

- Serial/Batch Tracking: Implement batch or serial number traceability to support recalls or warranty claims.

Import/Export Considerations

Understand trade regulations for cross-border shipments.

- HS Code Classification: Use the appropriate Harmonized System (HS) code (e.g., 8501.31 or 8501.32 for electric motors) for customs declarations.

- Export Controls: Verify if motors fall under export control regulations (e.g., EAR in the U.S.)—typically not controlled unless used in military or aerospace applications.

- Duty & Tariff Rates: Research applicable tariffs based on destination country and free trade agreements.

Environmental & Sustainability Practices

Adopt eco-friendly logistics and disposal practices.

- Recyclable Packaging: Use recyclable or biodegradable materials for packaging.

- WEEE Compliance (EU): Adhere to Waste Electrical and Electronic Equipment directives; provide take-back or recycling options if required.

- Carbon Footprint: Optimize shipping routes and consolidate shipments to reduce environmental impact.

By following this guide, stakeholders can ensure efficient, compliant, and sustainable handling of NEMA 17 stepper motors throughout the supply chain.

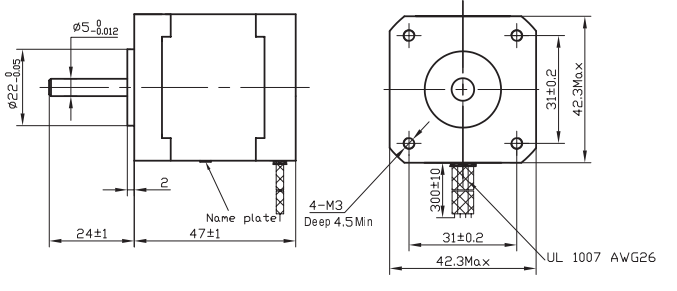

In conclusion, sourcing NEMA 17 stepper motors requires careful consideration of several key factors to ensure optimal performance and compatibility with your application. These include torque requirements, step angle, voltage and current ratings, shaft configuration, holding torque, and physical dimensions. Additionally, evaluating the supplier’s reliability, product certifications, availability, and pricing is essential for long-term project success. Whether sourcing from established electronics distributors like Digi-Key, Mouser, or RS Components, or directly from manufacturers such as Adafruit, SparkFun, or OEMs in Asia, it’s important to balance cost with quality and technical support. By thoroughly assessing both technical specifications and supply chain factors, you can effectively source NEMA 17 motors that meet your project’s needs while ensuring reliability, consistency, and scalability.

![[PDF] NEMA vs. IEC Motor Standards](https://www.fobsourcify.com/wp-content/uploads/2026/01/pdf-nema-vs-iec-motor-standards-539.jpg)