The automotive paint market is experiencing robust growth, driven by rising vehicle production, increasing demand for aesthetic customization, and advancements in eco-friendly coating technologies. According to Grand View Research, the global automotive coatings market was valued at approximately $23.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This growth is further fueled by stringent environmental regulations promoting waterborne and high-solids coatings, as well as escalating consumer preference for premium finishes. Within this dynamic landscape, Nason—a trusted brand under Axalta Coating Systems—has emerged as a leading name in automotive refinishing solutions, offering high-performance paints trusted by professionals across body shops and custom fabrication centers. As demand for durable, color-accurate, and fast-curing automotive paints rises, several key manufacturers have distinguished themselves through innovation, scalability, and product reliability. Here’s a look at the top six Nason automotive paint manufacturers shaping the industry’s future.

Top 6 Nason Automotive Paint Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Automotive Color Supply

Domain Est. 2007

Website: automotivecolorsupply.com

Key Highlights: We carry a wide range of all of your favorite OEM-approved products! From Axalta to Nason and Ever Coat, we have everything you need from the world’s best ……

#2 Nason Finishes

Domain Est. 2010

Website: johnsonautobodysupply.com

Key Highlights: Johnson Supply Co and johnsonautobodysupply.com offer quality automotive and industrial products from Nason Finishes….

#3 Industrial Coatings Datasheets

Website: parkgroup.com.au

Key Highlights: Industrial Coatings Brands: Nason Industrial, Imron Fleet Line, Transocean, Rhino Floor Wagon Paints Datasheets, Aero Coatings Brands, Imron Aviation ……

#4 Nason Finishes

Domain Est. 2004

Website: axalta.com

Key Highlights: Formulated to be fast and easy to apply, Nason Finishes products are designed to work together as a system to provide an option when time and money are limited….

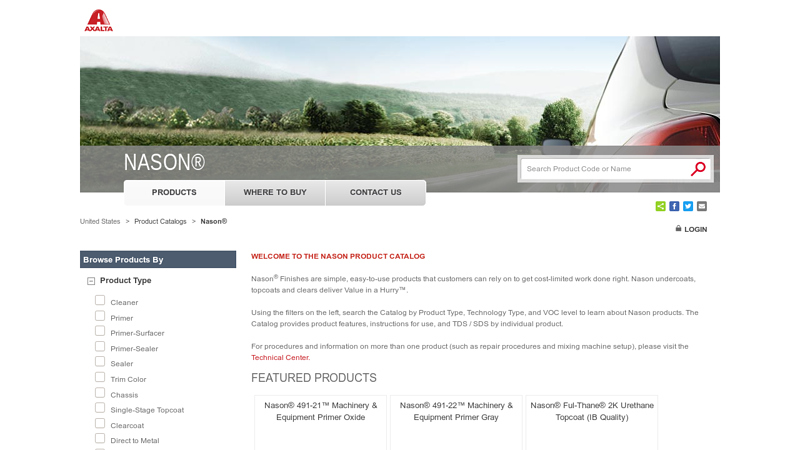

#5 Nason® Product Catalog

Domain Est. 2013

Website: products.axaltacs.com

Key Highlights: WELCOME TO THE NASON PRODUCT CATALOG Nason® Finishes are simple, easy-to-use products that customers can rely on to get cost-limited work done right….

#6 Nason

Website: sdstds.nsncolor.info

Key Highlights: The Axalta logo, Axalta™ , Axalta Coating Systems™ and all products denoted with ™ or ® are trademarks or registered trademarks of Axalta Coating Systems, LLC ……

Expert Sourcing Insights for Nason Automotive Paint

H2: Market Trends Shaping Nason Automotive Paint in 2026

As the automotive refinish and coatings industry evolves, Nason Automotive Paint—a leading brand under Axalta Coating Systems—is positioned to navigate key market trends in 2026. These trends are shaped by technological innovation, regulatory changes, consumer preferences, and sustainability demands. Below is a comprehensive analysis of the primary factors influencing Nason’s market trajectory in 2026.

1. Growth in Electric Vehicle (EV) Refinishing Demand

The rapid adoption of electric vehicles (EVs) is reshaping the automotive repair landscape. In 2026, EVs are expected to make up over 20% of global vehicle sales, according to IEA projections. Nason is adapting its product portfolio to meet the unique refinish needs of EVs, which often feature advanced lightweight materials and conductive coatings. Demand for fast-cure, low-VOC (volatile organic compound) refinish solutions—such as Nason’s waterborne and high-solids systems—is rising among collision repair centers serving EV fleets.

2. Sustainability and Regulatory Compliance

Environmental regulations continue to tighten globally, particularly in regions like the European Union, California, and China. The push for lower emissions has accelerated the shift from solvent-based to waterborne coatings. By 2026, Nason’s waterborne product lines—such as the Envirobase® High Performance system—are projected to account for over 65% of its sales. Additionally, Nason is investing in bio-based resins and recyclable packaging to meet circular economy goals and align with ISO 14001 and REACH standards.

3. Digital Integration and Color-Matching Technology

Advancements in digital tools are transforming the paint-matching process. Nason is integrating AI-powered color-matching software and cloud-based tint libraries into its service platforms. In 2026, technicians increasingly rely on Nason’s digital tools—accessible via mobile apps and in-shop kiosks—to achieve precise color matches in less time. This enhances efficiency, reduces waste, and improves customer satisfaction in high-volume repair environments.

4. Expansion in Emerging Markets

Growth in automotive ownership across Asia-Pacific, Latin America, and Africa is driving demand for high-quality refinish solutions. Nason is expanding its distribution network and offering region-specific formulations that address local climate conditions and substrate types. Strategic partnerships with regional body shops and training centers are helping Nason strengthen brand presence in markets such as India, Brazil, and South Africa.

5. Labor Shortages and Training Initiatives

The skilled labor shortage in the collision repair industry remains a challenge in 2026. To address this, Nason continues to enhance its technical training programs through virtual reality (VR) simulations and e-learning platforms. Certified Nason training centers are reporting increased enrollment, helping shops adopt best practices and improve application consistency—key to maintaining brand reputation and warranty compliance.

6. Customization and Premium Finishes

Consumer demand for personalized vehicles is fueling interest in specialty finishes such as matte, metallic, and color-shifting effects. Nason’s premium product lines, including its Concept and Imron industrial-grade coatings adapted for automotive use, are gaining traction among custom shops and high-end repair centers. In 2026, Nason is expected to launch new effect pigments and easy-application systems to cater to this niche but growing segment.

Conclusion

By 2026, Nason Automotive Paint is poised to strengthen its leadership in the refinish market through innovation, sustainability, and digital transformation. The brand’s strategic alignment with EV trends, environmental regulations, and technician support systems positions it well to capture growth amid evolving industry dynamics. Continued investment in R&D and global outreach will be critical to maintaining competitive advantage in an increasingly complex and eco-conscious marketplace.

Common Pitfalls When Sourcing Nason Automotive Paint: Quality and Intellectual Property Concerns

Sourcing Nason automotive paint—known for high-performance finishes in collision repair and refinishing—can present significant challenges, especially regarding product authenticity, quality consistency, and intellectual property (IP) risks. Avoiding these pitfalls is crucial for maintaining shop reputation, ensuring compliance, and delivering reliable results.

Counterfeit or Non-Authentic Products

One of the most serious risks when sourcing Nason paint is encountering counterfeit or imitation products. These are often sold at lower prices through unauthorized distributors or online marketplaces. These fake products may bear the Nason name or logo but are not manufactured by Axalta, the legitimate owner of the Nason brand. Using such paint can lead to poor adhesion, inconsistent color matching, premature fading, and reduced durability, ultimately resulting in customer dissatisfaction and costly rework.

Unauthorized Distributors and Gray Market Goods

Purchasing from unauthorized resellers increases the risk of receiving gray market products—genuine Nason paint obtained through unofficial distribution channels. These paints may have been diverted from other regions, potentially violating regional distribution agreements. Gray market paint may not meet local regulatory standards (such as VOC content), may lack proper technical support, and could be stored or transported under suboptimal conditions, compromising quality and shelf life.

Lack of Technical Support and Color Matching Accuracy

Authentic Nason paint systems are supported by comprehensive technical data sheets, application guidelines, and digital color-matching technologies like Spies Hecker’s ColorNet or Axalta’s refinish systems. When sourcing from unofficial channels, access to these critical support tools may be limited or nonexistent. This increases the likelihood of improper mixing ratios, incorrect application techniques, and inaccurate color matches—leading to refinish failures and increased waste.

Intellectual Property Infringement Risks

Using or distributing counterfeit Nason products constitutes intellectual property infringement. Axalta actively protects its trademarks, formulations, and proprietary technologies. Shops found using counterfeit or unauthorized Nason-branded products may face legal action, fines, or damage to their professional credibility. Additionally, supporting counterfeit operations undermines innovation and fair competition in the automotive refinishing industry.

Inconsistent Quality Due to Improper Storage and Handling

Even genuine Nason paint can degrade if improperly stored. Unauthorized suppliers may lack the climate-controlled environments required to maintain paint integrity. Exposure to extreme temperatures, humidity, or prolonged storage can alter the chemical composition of the paint, resulting in application issues and finish defects. Authorized distributors adhere to strict handling protocols, ensuring product consistency and performance.

Absence of Warranty and Liability Protections

Purchases made through authorized Nason distributors typically come with manufacturer-backed warranties and technical liability support. If a paint failure occurs due to a product defect, Axalta may cover associated costs when the paint is sourced legitimately. This protection is generally voided when products are obtained from unauthorized sources, leaving the repair shop financially and legally exposed.

To avoid these pitfalls, always verify the distributor’s authorization status through Axalta’s official website, insist on documented proof of authenticity, and maintain proper procurement records. Investing in genuine Nason products through official channels ensures quality, compliance, and peace of mind.

Logistics & Compliance Guide for Nason Automotive Paint

Product Overview and Regulatory Classification

Nason automotive paint products, manufactured by Axalta Coating Systems, are high-performance coatings designed for professional automotive refinishing. These products typically contain solvents, resins, pigments, and additives, which may classify them as hazardous materials under various transportation and safety regulations. It is essential to identify the specific product line (e.g., solvent-based, water-based, basecoat, clearcoat) as classification and handling requirements may vary.

Hazardous Materials Classification

Nason paints, especially solvent-based formulations, are generally classified as hazardous for transport under international and national regulations, including:

- DOT (U.S. Department of Transportation): Classified as Class 3 Flammable Liquids (UN 1263, PAINT, or PAINT RELATED MATERIAL).

- IMDG Code (Maritime Transport): UN 1263, Class 3, PG II or III depending on flash point and formulation.

- IATA (Air Transport): UN 1263, Class 3, typically Packing Group II; subject to strict limitations on passenger and cargo aircraft.

- ADR (Road Transport in Europe): Class 3, Flammable Liquid, UN 1263.

Always refer to the Safety Data Sheet (SDS), Section 14, for the specific UN number, hazard class, packing group, and transport information.

Packaging and Labeling Requirements

Proper packaging and labeling are critical to ensure safe handling and regulatory compliance:

- Use UN-certified packaging with appropriate closures to prevent leakage.

- Pack in original containers unless repackaging into approved hazardous material containers.

- Affix correct hazard labels: Class 3 Flammable Liquid diamond labels, orientation arrows, and proper shipping name (e.g., “PAINT” or “FLAMMABLE LIQUID, N.O.S.”).

- Include shipper/consignee information and emergency contact details.

- For air transport, comply with IATA’s quantity limits per package and aircraft type.

Storage and Handling Procedures

Safe storage and handling minimize fire, health, and environmental risks:

- Store in a well-ventilated, temperature-controlled area away from direct sunlight and ignition sources.

- Maintain storage temperatures between 50°F and 80°F (10°C to 27°C).

- Keep containers tightly closed when not in use.

- Use grounding and bonding procedures during transfer to prevent static discharge.

- Segregate from oxidizers and incompatible materials.

- Comply with OSHA 29 CFR 1910.106 for flammable and combustible liquids storage.

Safety Data Sheet (SDS) Compliance

The SDS is a critical compliance document. Ensure the following:

- Maintain up-to-date SDS for every Nason product used or shipped.

- SDS must be accessible to employees and emergency responders.

- Verify that SDS Section 14 includes accurate transport classification and regulatory information.

- Review SDS revisions regularly for changes in formulation or regulatory status.

Transportation and Carrier Requirements

When shipping Nason paints:

- Use carriers authorized to transport hazardous materials (HazMat-certified).

- Provide carriers with a completed Shipper’s Declaration for Dangerous Goods (for air and sea) when required.

- Ensure drivers have appropriate training (e.g., DOT HazMat training, valid certifications).

- Domestic ground shipments in the U.S. require proper placarding if bulk quantities exceed thresholds.

Environmental and Disposal Compliance

Nason paints and their containers are subject to environmental regulations:

- Empty containers may still contain residual hazardous material and must be managed as hazardous waste under RCRA (U.S. EPA) unless properly cleaned.

- Dispose of waste paint, thinner, and contaminated materials through licensed hazardous waste disposal facilities.

- Comply with local, state, and federal regulations for waste handling and reporting.

- Prevent spills through secondary containment and spill kits in storage and handling areas.

Worker Safety and Training

Personnel handling Nason paints must be trained in:

- Hazard Communication (HazCom) Standard (29 CFR 1910.1200).

- Proper use of PPE (gloves, respirators, eye protection, flame-resistant clothing).

- Emergency procedures (spill response, fire, exposure).

- DOT HazMat employee training if involved in shipping.

- Regular refresher training required annually or when processes change.

Emergency Response and Spill Management

Prepare for incidents with:

- Spill kits containing absorbents suitable for flammable liquids.

- Fire extinguishers rated for Class B fires (flammable liquids) onsite.

- Emergency procedures outlined in facility spill response plans.

- Immediate reporting of large spills to local authorities and environmental agencies as required.

- Contact information for Axalta Technical Support and emergency response services (e.g., CHEMTREC: 1-800-424-9300).

International Shipping Considerations

For cross-border shipments:

- Verify import regulations in the destination country (e.g., REACH in EU, TDG in Canada).

- Some countries restrict or ban certain solvents or VOC content; check product compliance.

- Provide bilingual labeling and documentation if required.

- Use customs brokers experienced in hazardous goods to ensure smooth clearance.

Recordkeeping and Documentation

Maintain accurate records for compliance audits:

- Shipping manifests with proper hazardous material declarations.

- Training records for HazMat employees (retained for 3 years under DOT).

- SDS files, updated and organized by product.

- Waste disposal manifests and certificates of destruction.

- Incident reports and spill logs.

Adherence to this guide ensures safe, legal, and efficient logistics for Nason automotive paint products. Always consult the latest SDS, regulatory texts, and Axalta’s technical resources for product-specific guidance.

Conclusion for Sourcing Nason Automotive Paint

Sourcing Nason automotive paint presents a reliable and high-performance solution for both professional auto body shops and detailers. As a reputable brand under PPG Industries, Nason offers a comprehensive range of primers, basecoats, clearcoats, and reducers known for their durability, color consistency, and ease of application. When sourcing Nason products, it is essential to purchase from authorized distributors or suppliers to ensure authenticity, quality, and access to technical support and warranties.

Key considerations when sourcing include verifying product compatibility with existing systems, evaluating volume needs for cost efficiency, and ensuring compliance with local environmental regulations (such as VOC requirements). Additionally, training and certification in Nason’s application techniques can maximize performance and minimize waste, ultimately improving return on investment.

In conclusion, sourcing Nason automotive paint from trusted channels ensures consistent quality, superior finishes, and long-term customer satisfaction—making it a strategic choice for achieving professional-grade results in the automotive refinishing industry.