The global nail polish packaging market is experiencing robust growth, driven by rising consumer demand for premium beauty products and sustainable packaging solutions. According to Grand View Research, the global nail cosmetics market size was valued at USD 11.1 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. This surge in demand directly impacts the need for high-quality, visually appealing, and functional nail polish boxes, positioning packaging as a critical component of brand differentiation. With e-commerce and private label brands further accelerating market expansion, manufacturers specializing in nail polish boxes are increasingly adopting eco-friendly materials, custom designs, and innovative structural solutions to meet evolving industry standards. As the market grows, identifying reliable and scalable packaging partners becomes essential for beauty brands aiming to capture consumer attention in a competitive landscape. The following list highlights the top 10 nail polish box manufacturers that combine craftsmanship, sustainability, and production efficiency to meet current and future market demands.

Top 10 Nail Polish Boxes Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 CNC International

Website: cncinternational.eu

Key Highlights: CNC is the leading private label manufacturer of HEMA & TPO free UV nail gels. Our professional nail products have the best quality….

#2 Arka: Design Eco

Domain Est. 1995

Website: arka.com

Key Highlights: Design custom boxes for Ecommerce with Arka! Use our integrations with Shopify, BigCommerce, Square & more! Order your sustainable custom boxes today….

#3 Blank Beauty

Domain Est. 2013

Website: blankbeauty.com

Key Highlights: Create your own nail polish color or choose from our range of high gloss, 13-free and incredibly long-lasting shades. Our nail colors are made in the USA….

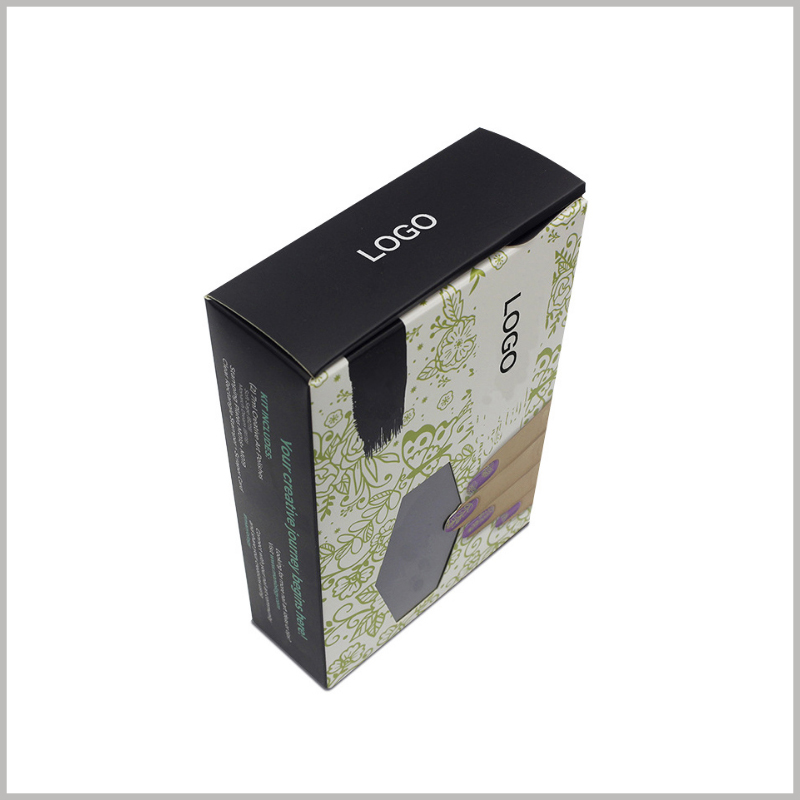

#4 Custom Nail Polish Packaging

Domain Est. 2014

Website: packagingblue.com

Key Highlights: In stock Rating 5.0 (63) Custom designed & printed nail polish packaging can help your products attract new customers. Get free design help & shipping for custom nail polish ……

#5 Custom Nail Polish Boxes Wholesale

Domain Est. 2017

Website: oxopackaging.com

Key Highlights: OXO Packaging is amazingly expert at manufacturing, designing, printing, and customizing your Nail Polish Boxes in any shape and design you require to market ……

#6 custom

Domain Est. 2017

Website: wecustomboxes.com

Key Highlights: In stock Rating 5.0 (458) WeCustomBoxes is a company that offers smart and instant packing solutions like nail polish boxes and others, full of novelty….

#7 Nail Polish Boxes – Custom Nail Polish Packaging

Domain Est. 2018

#8 Custom Nail Polish Boxes

Domain Est. 2019

Website: gatorpackaging.com

Key Highlights: Rating 4.9 (18) · Free deliveryGrow your nail polish sales by packing them into eye-catching and alluring Custom Nail Polish Boxes. Get perfect Packaging for your nail polish b…

#9 Custom Nail Polish Boxes

Domain Est. 2021

#10 Custom Boxes with Logo

Domain Est. 2024

Website: boxitpackages.com

Key Highlights: Create dream custom printed boxes for your products! Explore personalized designs to choose that suit your industry or products….

Expert Sourcing Insights for Nail Polish Boxes

H2: 2026 Market Trends for Nail Polish Boxes

The global nail polish boxes market is poised for significant transformation by 2026, driven by evolving consumer preferences, sustainability demands, technological advancements, and shifting retail dynamics. Below are the key market trends expected to shape the nail polish packaging industry in 2026:

-

Dominance of Sustainable and Eco-Friendly Packaging

By 2026, sustainability will be a central focus in the nail polish boxes market. Consumers, particularly millennials and Gen Z, are increasingly demanding environmentally responsible packaging. Brands are expected to adopt biodegradable, recyclable, and compostable materials such as recycled paperboard, bamboo, and plant-based plastics. Water-based inks and minimalistic designs that reduce material usage will also gain traction, aligning with global ESG (Environmental, Social, and Governance) goals. -

Rise of Customization and Personalization

Custom nail polish boxes will become a key differentiator in a competitive beauty market. In 2026, brands will leverage digital printing technologies to offer personalized packaging featuring names, custom colors, or limited-edition designs. This trend not only enhances customer engagement but also supports direct-to-consumer (DTC) and subscription-based business models that are growing in popularity. -

Emphasis on Premium and Luxury Packaging

As the global nail care market expands, especially in emerging economies, there will be a surge in demand for high-end nail polish products. Consequently, luxury nail polish boxes made from textured finishes, soft-touch laminates, embossing, foil stamping, and magnetic closures will gain favor. These premium boxes enhance perceived product value and support brand positioning in the upscale beauty segment. -

Integration of Smart Packaging Features

By 2026, smart packaging technologies such as QR codes, NFC (Near Field Communication), and AR (Augmented Reality) will become more prevalent. Nail polish boxes equipped with these features will allow consumers to access product information, tutorials, authenticity verification, and exclusive content via smartphones. This digital integration boosts brand interaction and improves customer experience, especially in e-commerce environments. -

Growth of E-Commerce Optimized Packaging

With the continued rise of online beauty retail, nail polish boxes will be designed specifically for e-commerce durability and unboxing appeal. Sturdy, compact, and tamper-evident boxes that protect products during shipping while offering an Instagram-worthy unboxing experience will dominate. Lightweight designs will also help reduce shipping costs and carbon footprint. -

Minimalist and Clean Design Aesthetics

Clean, minimalist packaging with transparent windows, neutral color palettes, and clear labeling will appeal to consumers seeking authenticity and transparency. This trend reflects broader consumer shifts toward clean beauty, where ingredient transparency and brand honesty are prioritized. Nail polish boxes will increasingly feature ingredient lists, cruelty-free badges, and vegan certifications prominently. -

Regional Market Expansion and Localization

Emerging markets in Asia-Pacific, Latin America, and the Middle East will contribute to the growth of the nail polish boxes industry by 2026. Localized packaging—adapting designs, languages, and cultural motifs—will be crucial for brand success in these regions. Manufacturers will invest in agile supply chains to support regional customization and faster time-to-market. -

Increased Adoption of Digital and On-Demand Printing

Digital printing technologies will enable smaller print runs, rapid prototyping, and faster turnaround times. This flexibility allows nail polish brands—especially indie and niche players—to test new designs and enter the market with lower upfront costs. By 2026, on-demand packaging solutions will support trend-responsive product launches and seasonal collections.

Conclusion:

By 2026, the nail polish boxes market will be shaped by innovation, sustainability, and consumer-centric design. Brands that prioritize eco-conscious materials, digital engagement, and aesthetic appeal will gain a competitive edge. As the beauty industry continues to evolve, packaging will remain a powerful tool for brand storytelling, differentiation, and customer loyalty in the global nail care market.

Common Pitfalls When Sourcing Nail Polish Boxes: Quality and Intellectual Property Issues

Sourcing nail polish boxes, especially from overseas suppliers, can present several challenges that impact both product quality and brand integrity. Two of the most critical areas where businesses often encounter issues are quality consistency and intellectual property (IP) protection. Understanding these pitfalls can help brands avoid costly mistakes and maintain a professional image in the competitive beauty market.

1. Inconsistent Material and Print Quality

One of the most frequent quality-related pitfalls is receiving nail polish boxes that vary significantly in material thickness, color accuracy, or print finish. Common issues include:

- Low-grade cardboard or paperboard that bends or crushes easily, affecting shelf appeal and durability.

- Inaccurate color matching due to poor calibration in printing processes, leading to mismatched brand colors.

- Poor lamination or coating, resulting in smudging, peeling, or lack of moisture resistance—critical for products exposed to humidity.

To avoid this, request physical samples before mass production and establish clear quality specifications in your contract.

2. Lack of Durability and Functionality

Nail polish boxes must protect fragile glass bottles during shipping and handling. Pitfalls include:

- Boxes that are too flimsy to support the bottle, leading to breakage.

- Poor fit—either too tight, making it hard to insert/remove the bottle, or too loose, allowing movement.

- Inadequate structural design, such as weak creases or glue seams that come apart.

Ensure your packaging design includes proper internal supports (e.g., inserts or trays) and test prototypes under real-world conditions.

3. Hidden Costs from Minimum Order Quantities (MOQs) and Setup Fees

Suppliers may quote low per-unit prices but impose high MOQs or additional charges for:

- Custom molds or dies

- Printing plate setup

- Freight and import duties

This can inflate costs unexpectedly, especially for small or emerging brands. Always clarify all fees upfront and consider whether the supplier offers scalable options.

4. Intellectual Property Infringement Risks

Using designs, logos, or patented packaging elements without proper authorization can lead to legal trouble. Common IP pitfalls include:

- Unauthorized use of branded design elements, such as mimicking luxury packaging styles (e.g., similar to OPI or Essie), which could lead to trademark disputes.

- Supplier reusing your artwork for other clients, diluting your brand’s uniqueness.

- Lack of design ownership clauses in contracts, leaving you without legal rights to your packaging design.

Always sign NDAs, ensure contracts explicitly assign IP rights to your brand, and avoid designs too similar to established competitors.

5. Failure to Protect Custom Designs

If you invest in a unique nail polish box design, it’s essential to safeguard it. Suppliers in some regions may replicate and sell your design to others unless legally restricted. To prevent this:

- Register trademarks and design patents where applicable.

- Use watermark-protected proofs during the design phase.

- Include clauses in supplier agreements that prohibit reuse or resale of your design.

Conclusion

Sourcing nail polish boxes requires careful attention to both quality control and intellectual property protection. By vetting suppliers thoroughly, obtaining physical samples, securing legal rights to designs, and clearly defining specifications, brands can avoid common pitfalls and ensure their packaging reflects the premium nature of their products.

Logistics & Compliance Guide for Nail Polish Boxes

When shipping nail polish, proper packaging—not only the product container but also the outer box—is crucial for safety, regulatory compliance, and successful delivery. This guide outlines the key logistics and compliance considerations for nail polish boxes to ensure safe and legal transportation.

Regulatory Compliance: Hazardous Materials Classification

Nail polish typically contains flammable solvents such as ethyl acetate or butyl acetate, classifying it as a hazardous material (dangerous goods) under international and domestic shipping regulations. This classification directly impacts packaging requirements.

- UN/DOT Regulations (USA): Nail polish is often classified under UN 1263, PAINT, or UN 1133, FLAMMABLE LIQUID, N.O.S. (Not Otherwise Specified), with Packing Group II or III depending on flash point.

- IATA/ICAO (Air Transport): The International Air Transport Association (IATA) Dangerous Goods Regulations strictly govern air shipping. Nail polish usually falls under Class 3 Flammable Liquids. Small quantities may qualify for Limited Quantity (LQ) or Excepted Quantity (EQ) exemptions, which affect packaging and labeling requirements.

- IMDG Code (Sea Transport): For ocean freight, compliance with the International Maritime Dangerous Goods (IMDG) Code is mandatory, with similar classifications and packaging standards.

Packaging Requirements for Nail Polish Boxes

The outer nail polish box must meet specific performance standards to qualify for hazardous materials shipping, especially under limited quantity provisions.

- Double Containment: The primary container (bottle) must be leak-proof and securely closed. It should be placed within a secondary leak-proof container (e.g., sealed plastic pouch). The outer box must be strong enough to contain both.

- Box Material & Strength: Use corrugated cardboard boxes with sufficient burst strength and edge crush test (ECT) ratings to withstand stacking and handling. Boxes must remain intact during vibration, drop, and compression tests.

- Absorbent Material: Include sufficient absorbent material (e.g., cushioning foam, paper) inside the box to contain any leaks from the primary container.

- Closure: Use strong, pressure-sensitive tape (e.g., 2-inch reinforced tape) applied in the “H-seal” or “H-taping” method to fully seal all seams. Avoid using staples or glue-only closures.

Labeling and Marking

Proper labeling is essential for compliance and safe handling during transit.

- Limited Quantity Mark: If shipping under Limited Quantity exemptions, apply the black-on-white Limited Quantity diamond mark to the box. No additional hazard labels are required for LQ shipments via ground or air (under specific conditions).

- Proper Shipping Name: Include the technical name (e.g., “FLAMMABLE LIQUID, N.O.S. (nail polish)”) and UN number (e.g., UN1133) on the outer packaging.

- Shipper/Consignee Information: Clearly display the full name, address, and contact details of both sender and recipient.

- Orientation Arrows: If bottles are not in child-resistant packaging or are prone to leakage, include “This Way Up” arrows to prevent leakage during handling.

Carrier-Specific Requirements

Different carriers (FedEx, UPS, DHL, USPS) have specific rules for shipping hazardous goods:

- Ground vs. Air: Air shipping has stricter rules. Many carriers allow ground shipment of limited quantity nail polish with proper packaging and documentation but may prohibit air shipment unless fully compliant with IATA.

- Documentation: A completed Shipper’s Declaration for Dangerous Goods may be required for non-exempt shipments. For LQ/EQ shipments, carriers often require a commercial invoice noting the hazardous nature.

- Training & Certification: Personnel preparing hazardous shipments must be trained and certified according to 49 CFR (U.S.) or IATA standards.

Storage and Handling Logistics

- Temperature Control: Avoid extreme temperatures during storage and transport. High heat can increase internal pressure and risk of leakage or combustion.

- Segregation: Store and ship nail polish away from oxidizers, strong acids, and foodstuffs. Do not stack heavy items on top of nail polish boxes.

- Inventory Rotation: Follow FIFO (First In, First Out) practices to ensure older stock is shipped first, reducing the risk of product degradation.

Sustainability and Branding Considerations

While compliance is mandatory, packaging can also support brand values.

- Eco-Friendly Materials: Use recyclable or biodegradable corrugated boxes and avoid plastic inserts when possible.

- Minimalist Design: Reduce excess packaging to lower shipping weight and environmental impact.

- Clear Brand Messaging: Include compliance symbols discreetly while showcasing branding elements on non-critical surfaces of the box.

Best Practices Summary

- Always verify the flash point and composition of your nail polish with the manufacturer to determine correct classification.

- Use tested, compliant packaging that meets UN certification standards when required.

- Train staff on hazardous materials handling and documentation.

- Consult with your carrier before shipping to confirm current policies.

- Perform periodic audits of packaging performance and compliance.

By following this logistics and compliance guide, businesses can ensure that their nail polish boxes meet safety standards, pass regulatory inspections, and reach customers intact and on time.

In conclusion, sourcing nail polish boxes requires a strategic approach that balances quality, cost, sustainability, and branding. Choosing the right packaging supplier is crucial for protecting the product, enhancing shelf appeal, and reflecting your brand identity. Considerations such as material durability, customization options, eco-friendliness, and minimum order quantities play a significant role in making an informed decision. By partnering with reliable manufacturers who offer innovative design capabilities and timely production, businesses can ensure their nail polish packaging not only meets industry standards but also stands out in a competitive market. Ultimately, well-sourced packaging contributes to customer satisfaction, brand loyalty, and long-term success in the beauty industry.