The global motorcycle wheels and spokes market is experiencing steady growth, driven by rising demand for high-performance and aesthetically enhanced two-wheelers. According to Grand View Research, the global motorcycle market size was valued at USD 89.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth directly fuels demand for advanced wheel systems, including lightweight alloy wheels and durable spoked wheels, particularly in emerging markets across Asia-Pacific, Latin America, and Africa. Additionally, increasing motorcycle customization trends and the shift toward premium and off-road vehicles—which often rely on robust spoke wheel designs—are reshaping the component supply chain. As OEMs and aftermarket players alike prioritize strength, weight reduction, and design innovation, manufacturers specializing in wheels and spokes are positioning themselves at the forefront of this evolution. In this competitive landscape, nine key players stand out for their technological expertise, global reach, and commitment to quality—shaping the future of two-wheeled mobility.

Top 9 Motorcycle Wheels And Spokes Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Buchanan’s Spoke & Rim, Inc

Domain Est. 1998

Website: buchananspokes.com

Key Highlights: Motorcycle Spokes. Automobile Spokes. Airplane Spokes. Buchanans Spoke & Rim, Inc. Quality Spokes & Rims. Top Quality Wheel. Building Parts. and Labor ……

#2 Devon Rim Company

Domain Est. 2003 | Founded: 1990

Website: devonrimcompany.com

Key Highlights: Devon Rim Company Ltd was established in 1990 as a manufacturer of Motor Cycle Wheel Rims and Spokes for both Classic and Custom motorcycles….

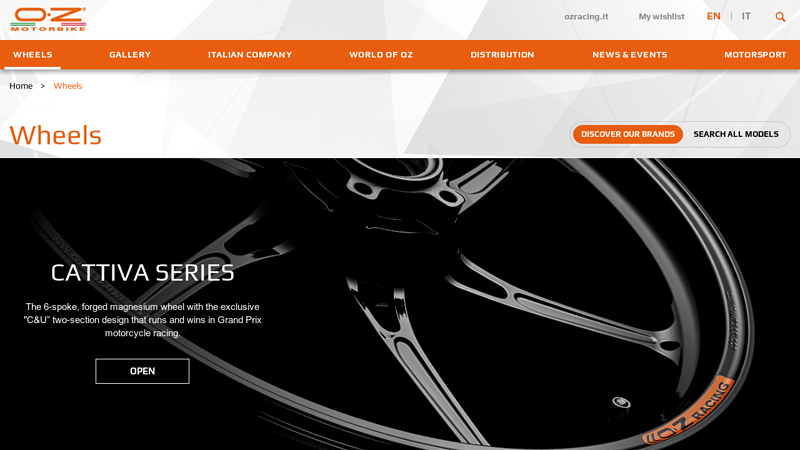

#3 Wheels

Domain Est. 2009

Website: ozmotorbike.com

Key Highlights: A series of wheels drawn straight from OZ racing experience that uses forged technology to achieve the utmost expression of wheel shape….

#4 Performance Machine

Domain Est. 1999

Website: performancemachine.com

Key Highlights: … Wheels · Off-Road · Bike Builds; Media. Videos … Wheels. Media / Info. Events Calendar · Blog · Clean And Care · Installation Instructions · Testing & TUV ……

#5 WanaRyd Motorcycle

Domain Est. 2004

#6 Metalsport Wheels

Domain Est. 2007

Website: metalsportwheels.com

Key Highlights: Our custom motorcycle wheels come in 2D and 3D styles and your choice of finishes and sizes. We offer stock sizes from 16″ to 21″ and the big wheels from 23″ to ……

#7 DUBYA USA / ALL THINGS WHEEL

Domain Est. 2011

Website: dubyausa.com

Key Highlights: Dubya USA offers the largest range of fully customizable wheel sets, allowing you to choose from a variety of hubs, spoke, nipple, and rim color options. CUSTOM ……

#8 Rotobox wheels

Domain Est. 2012

Website: rotobox-wheels.com

Key Highlights: Our revolutionary three-component composite, dry forging and racing design provide high torsional, lateral, radial stiffness and great impact resistance….

#9 Custom Motorcycle Wheels Rims Parts

Domain Est. 2012

Website: smtwheels.com

Key Highlights: All of our custom motorcycle wheels and parts are made from aircraft-grade 6061-T6 billet aluminum alloy and machined right here in Glendale, AZ….

Expert Sourcing Insights for Motorcycle Wheels And Spokes

2026 Market Trends for Motorcycle Wheels and Spokes

Rising Demand for Lightweight and High-Performance Materials

The 2026 motorcycle wheels and spokes market is witnessing a significant shift toward lightweight composite and advanced alloy materials. Aluminum alloy wheels continue to dominate due to their strength-to-weight ratio, corrosion resistance, and improved fuel efficiency. Additionally, carbon fiber wheels are gaining traction in the premium and racing segments, offering unmatched performance benefits such as reduced unsprung weight and enhanced handling. Manufacturers are investing in R&D to make these high-performance materials more cost-effective for mass-market adoption.

Growth in Electric Motorcycle Integration

With the global push toward electrification, electric motorcycles are expected to account for a larger share of the two-wheeler market by 2026. This shift is directly influencing wheel and spoke design, as electric models often require stronger, heat-resistant components to handle increased torque and battery weight. As a result, wheel designs are being optimized for better load distribution and thermal management, with reinforced spoke patterns and specialized rim profiles tailored to electric platforms.

Customization and Aesthetic Appeal Driving Consumer Preference

Aesthetic customization remains a major trend, especially in developed markets such as North America and Europe. Riders are increasingly opting for aftermarket wheels and spoke kits that enhance the visual appeal of their motorcycles. Chrome finishes, multi-spoke designs, spoke covers, and color-matched rims are in high demand. The aftermarket segment is expanding rapidly, supported by online retail platforms and social media-influenced purchasing behavior.

Advancements in Spoke Technology and Maintenance-Free Designs

Traditional spoked wheels are evolving with innovations such as self-tensioning spokes and sealed spoke nipples that reduce maintenance needs. Tubeless spoked wheels are also emerging, combining the off-road durability of spoked wheels with the convenience of tubeless tire technology. These advancements are particularly appealing to adventure and dual-sport motorcycle enthusiasts, who prioritize reliability and ease of maintenance on long journeys.

Regional Market Dynamics and Manufacturing Shifts

Asia-Pacific remains the largest market and manufacturing hub for motorcycle wheels and spokes, driven by high motorcycle ownership in countries like India, Indonesia, and Vietnam. China and India are leading in both OEM and aftermarket production, benefiting from cost-effective labor and established supply chains. Meanwhile, North America and Europe show strong growth in the premium and custom segments, with local manufacturers focusing on high-value, niche products.

Sustainability and Circular Economy Initiatives

Environmental concerns are influencing material sourcing and production processes. By 2026, leading manufacturers are adopting sustainable practices such as recycling aluminum scrap, reducing energy consumption in casting processes, and using eco-friendly coatings. Some companies are exploring biodegradable composites and modular wheel designs to support repairability and reduce waste, aligning with global circular economy goals.

Impact of Supply Chain Resilience and Digitalization

The motorcycle wheels and spokes industry is increasingly leveraging digital tools such as AI-driven demand forecasting, IoT-enabled production monitoring, and blockchain for supply chain transparency. These technologies help mitigate disruptions and improve responsiveness to market changes. Regionalization of supply chains—especially in response to geopolitical tensions and post-pandemic logistics challenges—is also shaping sourcing and distribution strategies.

In conclusion, the 2026 motorcycle wheels and spokes market is characterized by innovation, electrification, and personalization. As consumer demands and technological capabilities evolve, manufacturers that adapt through material science, sustainable practices, and digital integration will lead the competitive landscape.

Common Pitfalls When Sourcing Motorcycle Wheels and Spokes

Quality Inconsistencies in Materials and Manufacturing

One of the most frequent issues when sourcing motorcycle wheels and spokes—especially from low-cost or unverified suppliers—is inconsistent material quality. Wheels and spokes are critical safety components subject to high stress, vibration, and impact. Poor-grade aluminum alloys or low-tensile steel spokes can lead to premature fatigue, cracking, or failure. Additionally, inconsistent heat treatment, substandard welding, or improper spoke tensioning during manufacturing can compromise structural integrity and performance. Buyers often discover these issues only after installation or during use, leading to costly replacements and safety risks.

Lack of Compliance with Industry Standards

Many sourced wheels and spokes fail to meet recognized industry standards such as DOT (Department of Transportation), JWL (Japanese Wheel Standard), or ECE (Economic Commission for Europe) regulations. Non-compliant parts may not undergo proper load, impact, or fatigue testing, increasing the likelihood of failure under real-world conditions. This not only poses safety hazards but can also result in legal liability, voided warranties, or issues during vehicle inspections and insurance claims.

Intellectual Property (IP) Infringement Risks

Sourcing aftermarket or replica wheels and spokes carries a significant risk of IP infringement. Many suppliers produce designs that closely mimic branded OEM (Original Equipment Manufacturer) or premium aftermarket products—such as those from Excel, DID, or OZ—without proper licensing. Using or distributing these components can expose buyers to legal action, customs seizures (especially in regions with strict IP enforcement like the EU or U.S.), and reputational damage. Verifying design patents, trademarks, and legal documentation is essential to avoid unintentional infringement.

Inaccurate Fitment and Dimensional Tolerances

Motorcycle wheels and spokes must match precise specifications for diameter, width, bolt pattern, offset (hub centricity), and spoke pattern. Poorly manufactured or mislabeled products often have dimensional inaccuracies, leading to fitment issues, improper alignment, or interference with brakes, suspension, or chain/driveshaft systems. Even minor deviations can affect handling, increase wear on other components, or create unsafe riding conditions.

Inadequate Quality Control and Testing Procedures

Many suppliers—particularly smaller or offshore manufacturers—lack robust quality assurance systems. Without proper batch testing, X-ray inspection for weld integrity, or dynamic load testing, defects may go undetected. Buyers relying solely on visual inspections or supplier claims risk receiving subpar components. Requesting test reports, certifications, or third-party inspection services can mitigate this pitfall.

Misrepresentation of Product Specifications

Some suppliers exaggerate or falsify specifications, such as material grade, weight, or load capacity. For example, a wheel advertised as “aerospace-grade aluminum” may actually use a lower-grade alloy. Similarly, spoke tensile strength may be overstated. This misrepresentation can lead to incorrect component selection and performance shortfalls, especially in high-performance or heavy-duty applications.

Supply Chain and After-Sales Support Issues

Sourcing from unreliable suppliers can result in inconsistent lead times, lack of spare parts availability, or poor after-sales service. If a wheel fails or a spoke breaks, the inability to obtain replacements quickly—or receive technical support—can disrupt operations, especially for dealers or service centers. Establishing a relationship with reputable suppliers who offer warranties and responsive support is crucial for long-term reliability.

By addressing these pitfalls through due diligence, third-party verification, and adherence to safety and legal standards, businesses and individuals can ensure safer, more reliable sourcing of motorcycle wheels and spokes.

Logistics & Compliance Guide for Motorcycle Wheels and Spokes

Product Classification and HS Codes

Motorcycle wheels and spokes are typically classified under the Harmonized System (HS) for international trade. Key codes include:

– 8714.10: Wheels for motorcycles and cycles.

– 8714.91: Spokes and other parts and accessories of wheels.

Always verify the correct HS code with your destination country’s customs authority, as classifications may vary slightly by region. Accurate coding ensures proper duty assessment and avoids shipment delays.

Import/Export Regulations

Compliance with import and export regulations is essential:

– Export Controls: Check if any export licenses are required, especially when shipping high-performance or proprietary alloy components.

– Import Restrictions: Some countries impose restrictions on used or aftermarket parts. Confirm if wheels and spokes are subject to import bans or quotas.

– Documentation: Prepare commercial invoices, packing lists, bill of lading/airway bill, and certificates of origin. Include detailed product descriptions (material, size, application).

Safety and Technical Standards

Motorcycle wheels and spokes must meet safety and quality standards in both origin and destination markets:

– DOT (USA): While not directly certifying wheels, the Department of Transportation (DOT) requires compliance with FMVSS standards when installed on street-legal motorcycles. Aftermarket parts should not compromise safety.

– ECE Regulations (Europe): Wheels must comply with UN ECE Regulation 124 for motorcycle wheels. Certification via an EU-recognized test lab and CE marking is mandatory.

– JIS (Japan): Japanese Industrial Standards (e.g., JIS D 4311) apply to wheel strength and dimensions.

– INMETRO (Brazil), S-Mark (Southeast Asia), and other regional certifications may also apply—verify based on destination.

Packaging and Handling Requirements

Proper packaging ensures product integrity during transit:

– Use sturdy cardboard or wooden crates to prevent deformation.

– Individually wrap wheels to avoid scratches; use corner protectors for spoke edges.

– Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up”).

– Include product identifiers (model number, fitment) and batch/lot numbers for traceability.

Transportation and Freight Considerations

Motorcycle wheels and spokes are generally non-hazardous but require careful logistics planning:

– Mode of Transport: Air freight is suitable for small, high-value shipments; sea freight is cost-effective for bulk orders.

– Stacking & Weight Distribution: Avoid stacking heavy items on top of wheel shipments. Use pallets and secure with straps.

– Environmental Protection: Protect against moisture and extreme temperatures during ocean transit—consider moisture-absorbing desiccants.

Customs Clearance and Duties

Streamline customs processes by:

– Providing complete and accurate product valuation (including component costs).

– Declaring correct country of origin—this affects duty rates and eligibility for trade agreements (e.g., USMCA, ASEAN).

– Being aware of anti-dumping or countervailing duties that may apply to wheels/spokes from certain countries (e.g., China, India).

Aftermarket vs. OEM Compliance

Distinguish between Original Equipment Manufacturer (OEM) and aftermarket components:

– OEM parts may require coordination with vehicle manufacturers for warranty and fitment compliance.

– Aftermarket products must clearly state compatibility and performance ratings. Misleading claims can lead to customs rejection or legal liability.

Product Liability and Traceability

Maintain compliance with consumer protection laws:

– Register with relevant product safety authorities (e.g., CPSC in the U.S.).

– Implement a traceability system using serial or batch numbers to support recalls if necessary.

– Provide clear installation and torque specifications to prevent misuse.

Environmental and Disposal Regulations

Ensure compliance with environmental directives:

– REACH (EU): Verify that metals and coatings comply with restrictions on hazardous substances (e.g., lead, cadmium).

– RoHS: May apply if wheels include electronic components (e.g., sensor-equipped valve stems).

– End-of-Life Vehicle (ELV) Directive: Design for recyclability where applicable.

Conclusion

Successfully shipping motorcycle wheels and spokes globally requires attention to classification, regional compliance, packaging, and documentation. Proactive engagement with regulatory requirements minimizes delays, avoids penalties, and ensures product safety and market access. Always consult with local legal and customs experts when entering new markets.

In conclusion, sourcing high-quality motorcycle wheels and spokes requires careful consideration of material, design, compatibility, and supplier reliability. Whether replacing worn components or upgrading for performance and aesthetics, it’s essential to prioritize durability, safety, and adherence to manufacturer specifications. Opting for OEM parts ensures guaranteed fit and reliability, while aftermarket options can offer enhanced performance or customization at varying price points. Evaluating suppliers based on reputation, certifications, and customer reviews helps mitigate risks of counterfeit or substandard products. Additionally, understanding the specific needs of your motorcycle—such as riding style, terrain, and load capacity—guides informed decision-making. Ultimately, investing time and resources into sourcing the right wheels and spokes contributes to improved ride quality, safety, and long-term satisfaction with your motorcycle’s performance.