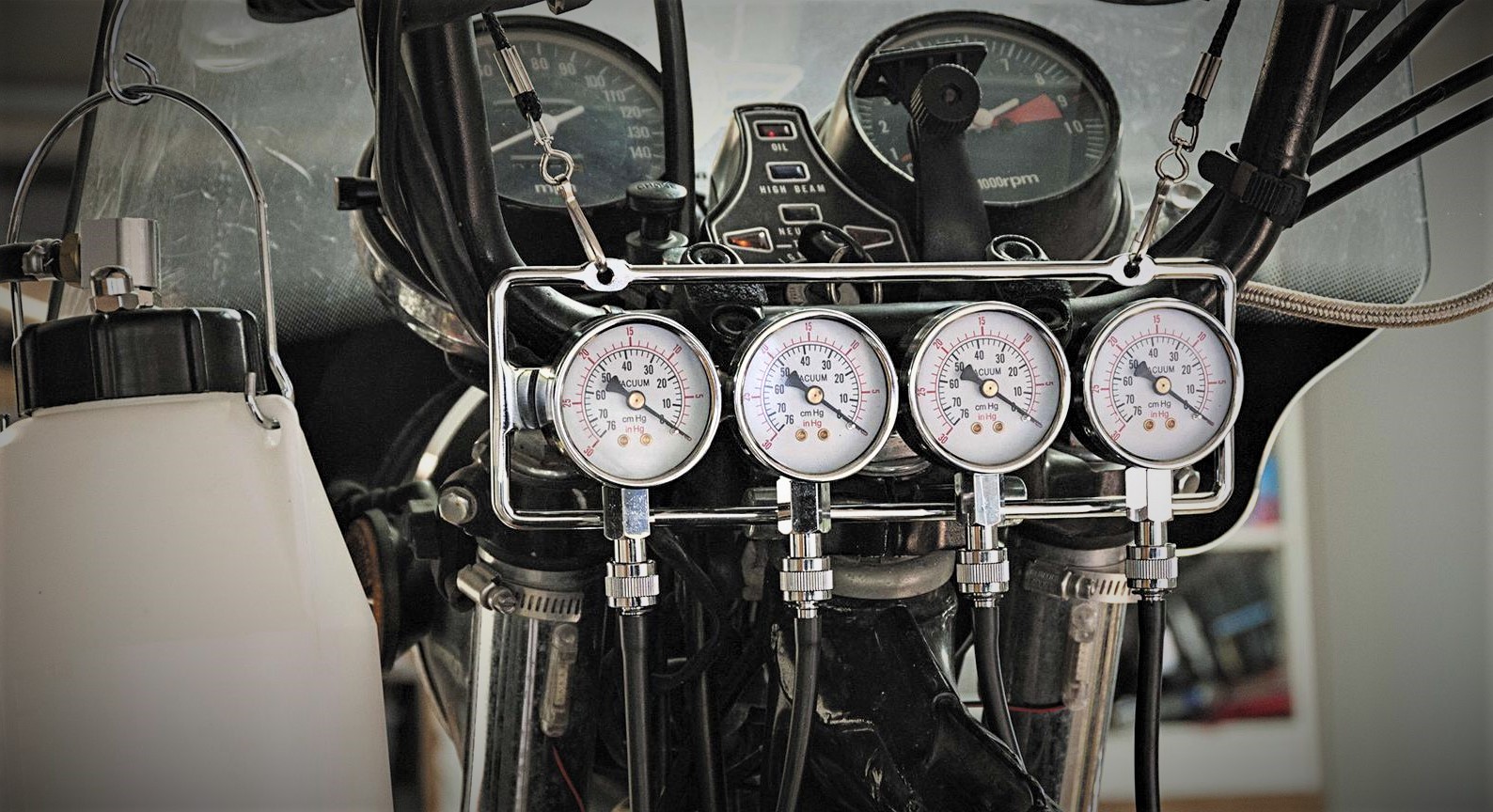

The global motorcycle aftermarket parts market is witnessing steady expansion, driven by rising motorcycle ownership, increasing customization trends, and a growing need for performance optimization and maintenance. According to a report by Mordor Intelligence, the global motorcycle aftermarket market was valued at USD 25.6 billion in 2023 and is projected to grow at a CAGR of over 6.8% from 2024 to 2029. A critical niche within this segment is motorcycle carburetor synchronization tools—essential for ensuring smooth engine performance, fuel efficiency, and emission control in carbureted motorcycles. As vintage bike restoration and dual-sport riding gain popularity, demand for precision carb synchronizers is on the rise. This growing technical demand has spurred innovation among manufacturers specializing in diagnostic and tuning equipment. Below, we highlight the top 9 motorcycle carb synchronizer manufacturers leading the charge with reliable, accurate, and user-friendly solutions, supported by market momentum and evolving rider needs.

Top 9 Motorcycle Carb Synchronizer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 How

Domain Est. 1996

Website: motionpro.com

Key Highlights: Motion Pro – High quality cables, tools and controls for motorcycles, ATVs, snowmobiles and personal watercraft….

#2 Motion Pro 08

Domain Est. 1998

Website: easternperformance.com

Key Highlights: Motion Pro 08-0411 Carb Sync Tool Vaccum Synchronizer Motorcycle Carburetor. Includes hoses, 5mm adapters, in-line restrictors and instructions….

#3 ZX

Domain Est. 1998

Website: themcdonalds.net

Key Highlights: Tools Required · Rear stand (recommended). · Phillips screwdrivers. · Hex keys. · Socket set. · Long-nose pliers. · Carburetor synchronization gauge. · Suitable ……

#4 CarbMate

Domain Est. 2003

Website: tecmate.com

Key Highlights: CarbMate displays the difference in vacuum intake settings of two separate carburetors (or fuel injection throttle valves) on the same engine very precisely….

#5 Kent Moore Tools J-23433

Domain Est. 2008

Website: autotoolworld.com

Key Highlights: 1–2 day delivery 90-day returnsThe Kent-Moore KM J-23433 Multi-Carb Synchronizer is designed for use on multi-carburetor engines. It is compatible with a variety of engines, includ…

#6 Twinmax: Fine

Domain Est. 2011

Website: motomachines.com

Key Highlights: Free delivery over $149 · 30-day returnsMotorcycle carburetors need consistent adjustment for the best performance. With the help of a Twinmax synchronizer, carb adjustment is eas…

#7 Digi Sync

Domain Est. 2015

Website: thedigisync.com

Key Highlights: Digi Sync is a high-performance digital carb synchronization and throttle body balancing tool, engineered for motorcycles, supercars, boats, and more….

#8 TWINMAX

Domain Est. 2019

Website: twinmax.us

Key Highlights: We sell the TWINMAX, a carb balance, Carb synchronization, and fuel injection synchronizer. The most accurate synchronizer on the market. Very easy to use!…

#9 synX – the carb synchronizer – x

Website: x-log.de

Key Highlights: Our teams know every single one of the finely tuned production steps. Automated quality controls ensure consistent quality even during the production process….

Expert Sourcing Insights for Motorcycle Carb Synchronizer

2026 Market Trends for Motorcycle Carb Synchronizer

The market for motorcycle carburetor synchronizers is navigating a period of gradual transformation in 2026, shaped by the enduring legacy of carbureted motorcycles, evolving rider demographics, and technological advancements. While fuel injection dominates new production, the carb synchronizer remains a vital tool within specific segments.

Declining New Vehicle Integration, Sustained Aftermarket Demand

By 2026, the penetration of carburetors in newly manufactured motorcycles continues its steep decline, limited almost exclusively to entry-level models in developing markets and niche retro-styled bikes. This significantly reduces the OEM demand for carb synchronizers. However, the aftermarket sector remains robust. A vast global fleet of older motorcycles, classic restorations, and performance-tuned bikes reliant on carburetors ensures consistent demand for maintenance and tuning tools. Enthusiasts and professional mechanics servicing this aging population drive the primary market for synchronizers.

Digitalization and Enhanced User Experience

The trend towards digital tools is reshaping the carb synchronizer landscape. Analog vacuum gauges, while still available, are increasingly supplemented or replaced by digital manometer-based synchronizers. These digital units offer greater precision, easier readability (especially in varying light), data logging capabilities, and often integrate with smartphone apps for diagnostics and record-keeping. In 2026, mid-to-high-end synchronizers feature intuitive interfaces, wireless connectivity, and compatibility with various adapter types, improving accessibility for both seasoned tuners and DIY riders.

Focus on Versatility and Multi-Functionality

Manufacturers are responding to a diverse user base by developing synchronizers with broader compatibility. Units capable of handling 2, 3, 4, or even 6 carburetor setups are common, appealing to owners of everything from twins to inline-fours. Some advanced models integrate additional functionalities, such as basic fuel pressure testing or simple vacuum leak detection, positioning the synchronizer as a more comprehensive engine diagnostic tool, enhancing its value proposition.

Niche Preservation and Premiumization

The classic and vintage motorcycle restoration market is a key growth area. Owners of these machines prioritize authenticity and precise tuning, creating demand for high-quality, reliable synchronizers. This segment supports a premium tier of products, featuring durable construction (e.g., metal casings), superior accuracy, and often bundled with specialized adapters for rare carburetor types. Brand reputation and precision are critical differentiators in this niche.

Challenges from Fuel Injection and Cost Sensitivity

The overwhelming shift to electronic fuel injection (EFI) in new motorcycles remains the fundamental long-term challenge. EFI systems self-balance and rarely require manual synchronization, reducing the need for these tools among owners of modern bikes. Additionally, economic pressures in 2026 make cost a significant factor. While premium digital tools gain traction, there’s persistent demand for affordable, reliable basic models (both analog and simple digital) from budget-conscious riders and small repair shops in price-sensitive regions.

Regional Market Variations

Market dynamics vary significantly by region. In North America and Europe, demand is heavily driven by the classic/vintage scene and performance tuning, favoring digital and premium tools. In parts of Asia, Africa, and Latin America, where carbureted motorcycles (especially scooters and small-displacement bikes) remain prevalent for daily transportation, there is sustained demand for durable, straightforward, and cost-effective synchronizers, often analog models.

In conclusion, the 2026 motorcycle carb synchronizer market is characterized by a stable but mature aftermarket, fueled by legacy vehicles and enthusiast culture. While facing existential pressure from fuel injection, the market adapts through digital innovation, enhanced functionality, and a focus on serving niche and restoration segments, ensuring its relevance for the foreseeable future.

Common Pitfalls When Sourcing a Motorcycle Carb Synchronizer (Quality and Intellectual Property)

Sourcing a motorcycle carb synchronizer—especially from overseas or third-party suppliers—can expose buyers to significant risks related to both product quality and intellectual property (IP). Being aware of these pitfalls is crucial for ensuring performance, safety, and legal compliance.

Poor Manufacturing Quality and Inaccurate Calibration

One of the most frequent issues with sourced carb synchronizers is substandard build quality. Many low-cost suppliers use inferior materials and imprecise manufacturing processes, resulting in tools that provide inaccurate or inconsistent readings. A poorly calibrated synchronizer can lead to improper carburetor balancing, which affects engine performance, fuel efficiency, and can even cause long-term engine damage. Always verify calibration standards and request certifications such as ISO or NIST traceability when available.

Lack of Durability and Component Reliability

Inexpensive synchronizers may feature fragile tubes, leak-prone connectors, or poorly machined fittings. These flaws reduce tool lifespan and compromise measurement integrity during use. Users often report cracked manometer tubes or seals that degrade after minimal exposure to fuel or oil vapors. Prioritize suppliers that use durable materials like borosilicate glass and chemical-resistant seals to ensure long-term reliability.

Inadequate Documentation and User Support

Many off-brand or generic carb synchronizers come with minimal or poorly translated instructions. This lack of clear documentation increases the risk of incorrect usage and misdiagnosis of engine issues. Reliable suppliers should provide comprehensive user manuals, application guides, and accessible technical support—especially for multi-cylinder or complex engine setups.

Intellectual Property Infringement Risks

Sourcing carb synchronizers from unverified manufacturers may involve IP violations. Many reputable brands (e.g., Motion Pro, OEM tools from Honda or Yamaha) hold design patents, trademarks, or copyrighted instruction materials. Clones or counterfeit tools that mimic these designs can expose buyers to legal risks, particularly in regulated markets. Always verify that the supplier holds proper licensing or produces tools under legitimate private-label agreements.

Misrepresentation of Compatibility and Specifications

Some suppliers exaggerate compatibility, claiming their tools work with a wide range of motorcycles without proper validation. This can lead to fitment issues or inaccurate synchronization on specific models. Confirm compatibility with your motorcycle’s make, model, and carburetor type before purchase, and cross-reference with independent reviews or technical forums.

No Warranty or After-Sales Service

Low-cost suppliers often offer little to no warranty or return policy. If the tool arrives damaged or fails prematurely, recourse may be limited. Choose suppliers with clear warranty terms and responsive customer service to protect your investment.

By being vigilant about quality control, supplier credibility, and IP compliance, buyers can avoid these common pitfalls and source a reliable, legally sound carb synchronizer that ensures optimal engine performance.

Logistics & Compliance Guide for Motorcycle Carb Synchronizer

This guide outlines key logistical considerations and compliance requirements for the distribution, sale, and use of a Motorcycle Carb Synchronizer. Adhering to these guidelines ensures safe handling, legal compliance, and customer satisfaction.

Product Classification & Regulatory Compliance

Motorcycle Carb Synchronizers are typically classified as automotive diagnostic or tuning tools. They are not regulated as standalone emissions devices under major environmental agencies (e.g., EPA in the U.S., Euro emissions standards), but their use may impact compliance with emissions regulations depending on how they are applied.

- Emissions Regulations: While the tool itself is not emissions-certified, improper use leading to engine tuning that increases emissions may violate local or national emissions laws. Users should be advised to maintain emissions-compliant engine settings.

- CE Marking (Europe): If the synchronizer includes electronic components (e.g., digital manometers), it may require CE marking under directives such as:

- Low Voltage Directive (LVD) 2014/35/EU

- Electromagnetic Compatibility (EMC) Directive 2014/30/EU

Ensure conformity assessments are completed and technical documentation is maintained. - RoHS Compliance: Electronic versions must comply with Restriction of Hazardous Substances (RoHS) directives, limiting substances like lead, mercury, and cadmium.

- REACH Compliance (EU): Confirm that all materials used in the product comply with REACH regulations regarding chemical substances.

Packaging & Labeling Requirements

Proper packaging and labeling are essential for safe transport and regulatory compliance.

- Packaging: Use durable packaging to protect sensitive components (e.g., rubber hoses, gauges) from physical damage during shipping. Include cushioning materials and secure internal fastening.

- Labeling:

- Include product name, model number, and manufacturer/importer details.

- Add safety warnings (e.g., “Keep away from open flames,” “Do not ingest lubricants if included”).

- Display required regulatory marks (e.g., CE, RoHS).

- Provide multilingual labeling where required by target markets.

Import & Export Documentation

Ensure all necessary documentation is prepared for international shipments.

- Commercial Invoice: Must detail product description, value, quantity, country of origin, and Harmonized System (HS) code.

- HS Code Recommendation: Typically 9026.80 (Instruments and apparatus for measuring or checking pressure) or 8479.89 (Other machines and mechanical appliances). Confirm with local customs authorities.

- Certificate of Origin: May be required for preferential tariff treatment under trade agreements.

- Bill of Lading / Air Waybill: Accurate carrier documentation with proper handling instructions.

- Export Controls: Verify that the item is not subject to dual-use or technology export restrictions (e.g., under EAR in the U.S.).

Shipping & Handling Logistics

- Shipping Method: Suitable for standard ground or air freight. No hazardous materials classification under IATA/IMDG unless lubricants or pressurized components are included.

- Temperature & Environment: Store and ship in a dry environment. Avoid extreme temperatures that may degrade rubber or plastic components.

- Weight & Dimensions: Provide accurate specifications to carriers to avoid additional fees and ensure proper handling.

Safety & User Compliance

Educate end users on proper and compliant use.

- User Manual: Include detailed instructions for safe operation, calibration, and maintenance.

- Compliance Disclaimer: Advise users that modifying engine settings may affect emissions compliance and could void vehicle warranties or violate local laws.

- Professional Use Recommended: Recommend use by trained mechanics, especially when adjusting carburetors on emissions-controlled motorcycles.

Warranty & After-Sales Support

- Warranty Terms: Define warranty period and coverage (e.g., 1 year against manufacturing defects).

- Customer Support: Provide accessible technical support for troubleshooting and compliance-related questions.

- Recall Preparedness: Establish a process to address potential safety or compliance issues, including communication plans and return logistics if necessary.

Recordkeeping & Traceability

- Maintain records of:

- Regulatory certifications

- Manufacturing batches

- Import/export documentation

- Customer complaints and warranty claims

- Ensure serial number or batch traceability for quality control and recall management.

By following this guide, suppliers and distributors can ensure efficient logistics operations and full compliance with applicable regulations across major markets.

In conclusion, sourcing a motorcycle carburetor synchronizer is an essential step for maintaining optimal engine performance, fuel efficiency, and smooth throttle response—especially on multi-cylinder motorcycles with multiple carburetors. A properly synchronized carburetor system ensures balanced air-fuel delivery across all cylinders, minimizing vibration and engine wear. When sourcing a carb synchronizer, it’s important to consider factors such as accuracy, ease of use, compatibility with your motorcycle model, and durability. Whether opting for a basic vacuum gauge kit or a more advanced digital synchronizer, investing in a reliable tool not only simplifies maintenance but also contributes to the longevity and performance of your bike. Always purchase from reputable suppliers or manufacturers to ensure quality and support. Regular synchronization, facilitated by the right tool, is a cost-effective way to keep your motorcycle running smoothly and efficiently.