The global motor cooling fan market is experiencing robust growth, driven by rising demand for thermal management solutions across automotive, industrial, and HVAC sectors. According to Grand View Research, the global cooling fan market size was valued at USD 28.6 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 6.3% from 2024 to 2030. Key factors fueling this expansion include increasing vehicle production, stricter emission standards requiring enhanced engine cooling, and the growing adoption of electric vehicles, which rely heavily on efficient thermal regulation systems. As industries prioritize performance and energy efficiency, leading motor cooling fan manufacturers are investing in innovative, high-efficiency designs and smart control technologies. In this evolving landscape, nine manufacturers have emerged as market leaders, combining technological expertise, global reach, and scalable production to meet rising demand.

Top 9 Motor Cooling Fan Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 ebm

Domain Est. 1998

Website: ebmpapst.com

Key Highlights: ebm‑papst Inc. is the world’s leading manufacturer of fans. As a technology company, we have continually set global industry standards since we were founded ……

#2 Twin City Fan & Blower

Domain Est. 1997

Website: tcf.com

Key Highlights: Twin City Fan & Blower is an industry-leading designer and manufacturer of high-quality custom, semi-custom and standard fans ranging from heavy-duty industrial ……

#3 GC Cooling

Domain Est. 2016

Website: gccooling.com

Key Highlights: We design and manufacture axial fans, centrifugal blowers, and DC electric motors (12V, 24V, 48V) for OEM and industrial applications….

#4 Fulltech Electric Co., Ltd

Domain Est. 2018 | Founded: 1990

Website: fulltechtw.com

Key Highlights: Fulltech Electric Co., Ltd are one of the professional cooling fans manufacturers based on Taiwan and have been selling fans worldwide since 1990….

#5 ZIEHL-ABEGG Fans & Ventilation Systems

Domain Est. 1997

Website: ziehl-abegg.com

Key Highlights: Welcome to ZIEHL-ABEGG US! We supply highly efficient ventilation, drive and control technology worldwide for more sustainable conservation of resources….

#6 Sunonwealth Electric Machine Industry Co., Ltd

Domain Est. 1998

Website: sunon.com

Key Highlights: SUNON has many years of experience in motor cooling fan, and our products have a wide range of applications in various fields. SUNON is recognized and trusted ……

#7 Industrial Fans, Air Knife Systems, Cooling Fans, Blowers, Ventilation

Domain Est. 2003

Website: aircontrolindustries.com

Key Highlights: Explore our wide range of industrial solutions – from fans and air knife blower systems to centrifugal fans. Enhance your operations with ACI….

#8 SPAL Automotive

Domain Est. 2004

Website: spalautomotive.com

Key Highlights: SPAL brushless axial fans are the latest development in cooling technology. Equipped with IP68 and IP6K9K sealed motors, these fans offer maximum protection ……

#9 Cooling Fans for Electronics

Domain Est. 1999

Website: nmbtc.com

Key Highlights: We design and engineer compact and quiet AC and DC cooling fans for electronic equipment. Browse part numbers or request a sample today….

Expert Sourcing Insights for Motor Cooling Fan

H2: 2026 Market Trends for Motor Cooling Fans

The global motor cooling fan market is poised for significant transformation by 2026, driven by technological advancements, evolving regulatory standards, and shifting industrial and automotive demands. Several key trends are expected to shape the trajectory of this market over the coming years.

-

Growing Demand from the Electric Vehicle (EV) Sector

The rapid expansion of the electric vehicle industry is one of the primary growth drivers for motor cooling fans. Unlike internal combustion engine vehicles, EVs require sophisticated thermal management systems to regulate battery, power electronics, and motor temperatures. Efficient motor cooling fans are critical to maintaining optimal performance and extending the lifespan of EV components. As governments worldwide implement stricter emissions regulations and incentivize EV adoption, the demand for advanced cooling solutions—including compact, high-efficiency motor cooling fans—is expected to surge by 2026. -

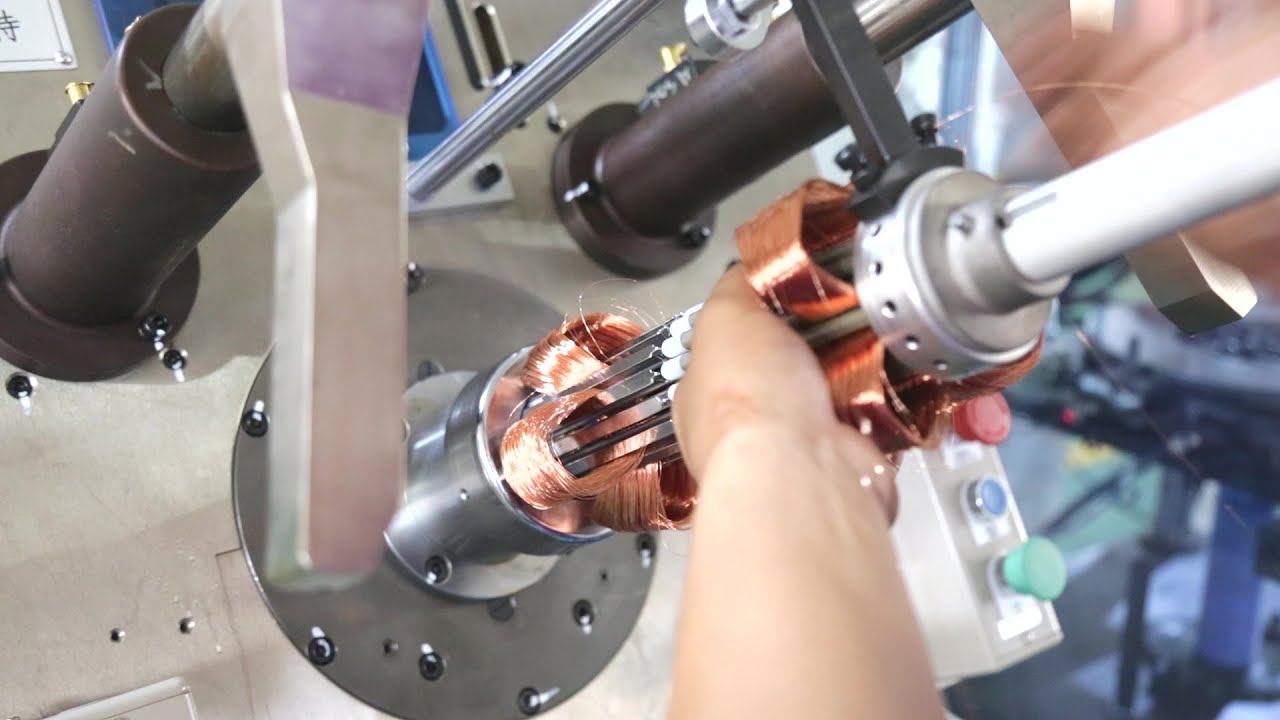

Advancements in Brushless DC (BLDC) Fan Technology

BLDC motor cooling fans are gaining prominence due to their energy efficiency, longer operational life, and quieter performance. By 2026, manufacturers are expected to increasingly adopt BLDC technology across automotive, industrial, and HVAC applications. Innovations in semiconductor materials and control algorithms will further enhance the precision and responsiveness of these fans, allowing for dynamic thermal management based on real-time load conditions. -

Integration with Smart and IoT-Enabled Systems

The trend toward smart manufacturing and connected devices is influencing the design of motor cooling fans. By 2026, a growing number of cooling fans will be equipped with embedded sensors and IoT connectivity, enabling remote monitoring, predictive maintenance, and adaptive cooling strategies. This shift is particularly evident in industrial automation and data center applications, where uptime and energy efficiency are critical. -

Stringent Energy Efficiency Regulations

Regulatory bodies in regions such as the European Union, North America, and parts of Asia are enforcing stricter energy efficiency standards for motors and cooling systems. These regulations are pushing manufacturers to develop high-efficiency motor cooling fans that comply with standards such as IE3 and IE4. Compliance not only avoids penalties but also appeals to environmentally conscious consumers and corporate sustainability goals. -

Expansion in Renewable Energy and Power Electronics Applications

The growth of renewable energy infrastructure—particularly solar inverters and wind turbine converters—requires reliable thermal management. Motor cooling fans play a vital role in dissipating heat from power electronics in these systems. As global investments in renewable energy continue to rise, the demand for durable and efficient cooling fans in this sector will expand significantly by 2026. -

Regional Market Shifts and Manufacturing Localization

Asia-Pacific, led by China, India, and Japan, is expected to dominate the motor cooling fan market by 2026 due to robust industrialization, automotive production, and government support for green technologies. However, trade dynamics and supply chain resilience are prompting some companies to localize production in North America and Europe, especially for high-value applications in EVs and aerospace. -

Material Innovation and Miniaturization

Ongoing R&D efforts are focused on lightweight materials—such as advanced composites and high-temperature plastics—that improve fan efficiency and reduce acoustic noise. Additionally, miniaturization trends, especially in consumer electronics and compact EV motors, are driving demand for smaller, yet powerful cooling fans capable of high thermal performance in constrained spaces.

In conclusion, the motor cooling fan market in 2026 will be characterized by innovation, sustainability, and integration. Companies that invest in smart technologies, energy-efficient designs, and strategic regional expansion will be best positioned to capitalize on these emerging trends.

Common Pitfalls Sourcing Motor Cooling Fans (Quality, IP)

Sourcing motor cooling fans involves critical considerations beyond basic specifications. Overlooking key aspects related to quality and Ingress Protection (IP) ratings can lead to premature failures, safety hazards, and increased operational costs. Here are the most common pitfalls:

1. Underestimating the Importance of IP Rating Accuracy

Many buyers assume a stated IP rating (e.g., IP54, IP65) guarantees protection, but discrepancies between claimed and actual performance are frequent. Suppliers may overstate ratings based on design rather than certified testing. Fans sourced without independent verification (e.g., third-party test reports) may fail in dusty or wet environments, leading to motor overheating and damage.

2. Prioritizing Low Cost Over Build Quality

Opting for the cheapest option often means compromised materials and construction. Low-quality fans may use undersized bearings, thin gauge steel, or substandard plastics that degrade quickly under thermal cycling and vibration. This results in increased noise, imbalance, reduced lifespan, and potential catastrophic failure affecting the entire motor system.

3. Ignoring Thermal and Environmental Compatibility

Fans must perform reliably across the full operating temperature range of the motor. Sourcing fans with inadequate thermal tolerance—especially for high-efficiency or high-load motors—can cause warping, material fatigue, or lubricant breakdown. Additionally, failure to account for exposure to chemicals, UV radiation, or high humidity accelerates corrosion and insulation degradation.

4. Overlooking Bearing Quality and Type

Bearings are a primary failure point. Sourcing fans with low-grade or inappropriate bearing types (e.g., sleeve bearings instead of ball bearings in high-vibration applications) drastically reduces service life. Poor lubrication or non-sealed bearings in contaminated environments lead to early wear and fan seizure.

5. Assuming Interchangeability Without Verification

Even with matching dimensions and voltage, fans are not always drop-in replacements. Differences in airflow (CFM), static pressure performance, blade design, or mounting tolerances can result in inadequate cooling or mechanical interference. Always verify performance curves and physical fit under real operating conditions.

6. Inadequate Supply Chain and Certification Transparency

Reputable suppliers provide clear documentation, including IP test certificates, material specifications, and RoHS/REACH compliance. Sourcing from vendors lacking transparency increases the risk of counterfeit or non-compliant components, posing safety and regulatory risks—especially in industrial or hazardous environments.

Avoiding these pitfalls requires due diligence: demand test reports, conduct sample validation, prioritize suppliers with proven quality management systems (e.g., ISO 9001), and match fan specifications precisely to the motor’s operational environment.

H2: Logistics & Compliance Guide for Motor Cooling Fans

Ensuring smooth international trade and regulatory adherence is critical for motor cooling fans. This guide outlines key logistics considerations and compliance requirements.

H2: Regulatory Compliance

1. Safety & Electromagnetic Compatibility (EMC)

– IEC 60034-1 / IEC 60034-30: International standards for rotating electrical machines, covering performance, efficiency, and testing.

– UL 507 (USA): Standard for electric fans, required for sale in the United States. Certification by a Nationally Recognized Testing Laboratory (NRTL) is mandatory.

– EN 60335-1 & EN 60335-2-80 (EU): Covers safety of household and similar electrical appliances, including fan-specific requirements. CE marking required.

– FCC Part 15 (USA): Regulates electromagnetic interference; essential for fans with electronic speed controls.

– RoHS (EU & others): Restriction of Hazardous Substances. Ensure compliance with limits on lead, mercury, cadmium, etc.

2. Energy Efficiency

– Energy Star (USA/Canada): Voluntary program for high-efficiency products; applicable if marketed as energy-efficient.

– Ecodesign Directive (EU): Sets minimum energy performance standards (MEPS) for fans in certain applications. Verify applicability based on fan type and power.

– DoE 10 CFR Part 431 (USA): Efficiency standards for commercial and industrial fans; verify if your fan model falls under scope.

3. Environmental & Chemical Regulations

– REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals. Declare Substances of Very High Concern (SVHC) if present above thresholds.

– Proposition 65 (California, USA): Requires warnings for products containing chemicals known to cause cancer or reproductive harm.

H2: Logistics & Transportation

1. Packaging & Labeling

– Use robust packaging to prevent damage during transit (shock, vibration, moisture).

– Clearly label with:

– Product name, model, and part number

– Manufacturer/importer details

– Voltage, power, speed ratings

– Safety certifications (e.g., CE, UL, CCC)

– Handling symbols (e.g., “Fragile”, “This Way Up”)

– Country of origin

2. Shipping & Customs

– HS Code: Use correct Harmonized System code (e.g., 8414.59 – Fans of electric motor-driven, other). Confirm with local customs authority.

– Export Documentation: Prepare commercial invoice, packing list, bill of lading/air waybill, and certificate of origin.

– Import Requirements: Provide compliance documentation (test reports, certificates) to customs. Some countries (e.g., China, South Korea) require CCC, KC certification respectively.

3. Storage & Handling

– Store in dry, temperature-controlled environments to prevent corrosion or material degradation.

– Avoid stacking beyond recommended limits to prevent crushing.

– Follow first-in, first-out (FIFO) inventory practices.

H2: Market-Specific Requirements

- China (CCC): Mandatory China Compulsory Certification for listed electrical products. Apply via accredited body.

- UKCA (UK): Required for Great Britain (England, Scotland, Wales); self-declaration based on UK-adopted EU standards.

- PSE (Japan): Required for specified electrical products; check if fan falls under “Specified” or “Non-specified” category.

- KC (South Korea): Korea Certification for electrical safety and EMC; mandatory for most electrical equipment.

H2: Best Practices

- Maintain updated technical documentation (DoC, test reports, risk assessments).

- Partner with certified labs for testing and certification.

- Conduct regular compliance audits and stay updated on regulation changes.

- Use freight forwarders experienced in electrical goods for international shipments.

Note: Always verify requirements with local authorities or legal counsel, as regulations vary by product configuration and destination.

Conclusion for Sourcing Motor Cooling Fan

After a thorough evaluation of technical requirements, supply chain reliability, cost-efficiency, and performance specifications, sourcing the motor cooling fan from a qualified supplier is recommended. The selected fan meets critical parameters such as airflow capacity, thermal management efficiency, noise levels, power consumption, and durability under operational conditions. Engaging with a supplier that demonstrates proven quality certifications, consistent delivery timelines, and after-sales support ensures long-term reliability and reduces downtime risks. Additionally, a competitive pricing structure and scalability options provide strategic advantages for future production needs. Finalizing the sourcing decision with due diligence on contractual terms, warranty, and performance validation testing will ensure optimal integration into the motor system and overall product performance.