The global motherboard power switch connector market is experiencing steady growth, driven by rising demand for personal computers, servers, and industrial electronics. According to Mordor Intelligence, the global computer peripherals market—which includes critical internal components like power switch connectors—is projected to grow at a CAGR of over 5.8% from 2023 to 2028. This expansion is supported by increasing PC adoption in enterprise and consumer sectors, as well as advancements in modular and energy-efficient computing systems that require reliable, high-quality interconnect solutions. As motherboards become more complex and compact, the need for durable and precision-engineered power switch connectors has intensified, positioning key manufacturers at the forefront of innovation and supply chain integration. The following list identifies the top seven companies leading the market in terms of product quality, R&D investment, and global distribution reach.

Top 7 Motherboard Power Switch Connector Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 MEAN WELL Switching Power Supply Manufacturer

Domain Est. 1997

Website: meanwell.com

Key Highlights: MEAN WELL is one of the world’s few standard power supply mainly professional manufacturers, covering 0.5 to 25600W products are widely used in industrial ……

#2 Connectors, Cables, Optics, RF, Silicon to Silicon Solutions

Domain Est. 1995

Website: samtec.com

Key Highlights: Samtec is the service leader in the electronic interconnect industry and a global manufacturer of Connectors, Cables, Optics and RF Systems, ……

#3 Connectors

Domain Est. 1994

Website: molex.com

Key Highlights: Molex offers a wide variety of Board-to-Board Connectors for microminiature, high-speed, high-density, and high-power applications….

#4 PC Replacement Parts, Components & Accessories

Domain Est. 1995

Website: corsair.com

Key Highlights: Free delivery over $79In need of a key CORSAIR accessory to finish your build, or looking for a replacement part to keep your PC running smoothly? Look no further….

#5 motherboard power switch

Domain Est. 2000

Website: newegg.com

Key Highlights: 4–7 day delivery4pcs Computer Motherboard Power Cable Switch Push Button Switch On/Off/Reset Button Replacement Power Momentary Connector Cable. $11. Free Shipping. Compare….

#6 Power Supply Connectors and Pinouts

Domain Est. 2011

Website: moddiy.com

Key Highlights: Four of the pins on the 8 pin cable fit into the motherboard connector and the other four pins hang off the end. The 8 pin cable only fits into one end of the ……

#7 Amphenol Connectors

Domain Est. 2021

Website: amphenol-cs.com

Key Highlights: Amphenol Communications Solutions (ACS), a division of Amphenol Corporation, is a world leader in interconnect solutions for Communications, Mobile, RF, ……

Expert Sourcing Insights for Motherboard Power Switch Connector

H2: 2026 Market Trends for Motherboard Power Switch Connector

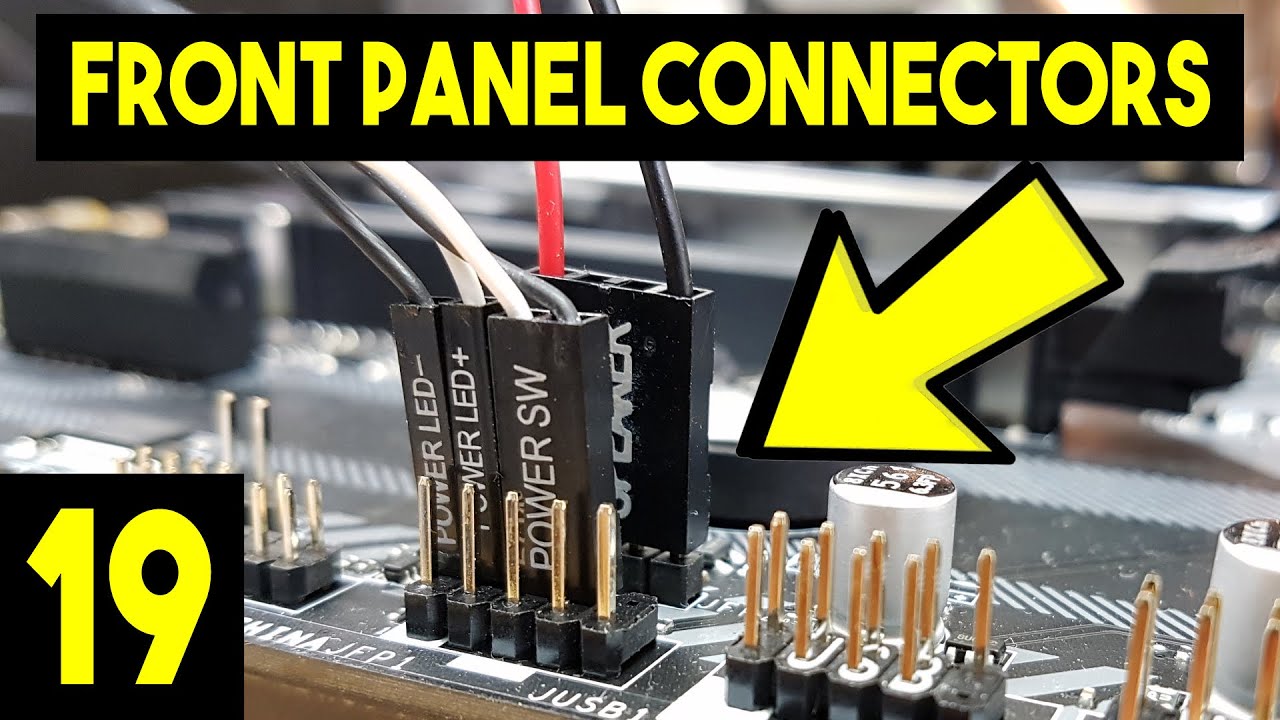

The motherboard power switch connector market is poised for notable transformation by 2026, driven by advancements in computing technology, evolving form factors, and increasing demand for energy efficiency and user-friendly system integration. While often overlooked as a minor component, the power switch connector plays a critical role in system initialization and user interaction with desktop and server-grade motherboards. The following trends are expected to shape the market landscape in 2026:

-

Miniaturization and Compact System Designs

As PC manufacturers continue to develop smaller form factor systems—such as mini-ITX, ultra-compact desktops, and edge computing devices—the demand for smaller, more efficient connectors is rising. By 2026, motherboard power switch connectors are expected to adopt more space-saving designs, potentially integrating with flex circuits or multi-function header systems to conserve board real estate. -

Increased Standardization Across Manufacturers

Despite the existence of general pinout standards (such as the 2×5 or 2×1 headers defined by Intel and AMD), variations in polarity and labeling persist. Industry-wide efforts toward standardization are expected to accelerate by 2026, especially with the rise of DIY and prebuilt ecosystem integration. This will improve user experience and reduce installation errors, supporting broader adoption in retail and industrial markets. -

Integration with Smart Power Management Systems

By 2026, motherboard power switch connectors may increasingly interface with advanced power management ICs (PMICs) and firmware-controlled boot systems. Features such as soft power-off, scheduled wake-ups, and remote power cycling (via IoT or enterprise management tools) will require smarter signaling between the physical switch and the motherboard. This shift may lead to hybrid digital-analog connectors or embedded logic within the switch circuitry. -

Growth in Industrial and Embedded Applications

Industrial PCs, medical devices, and ruggedized computing systems are adopting ATX and mini-ITX motherboards more frequently. These environments demand reliable, durable power switching mechanisms. As a result, the market will see increased demand for robust connectors capable of withstanding repeated cycles, extreme temperatures, and electromagnetic interference—driving innovation in materials and connector durability. -

Sustainability and RoHS Compliance

Environmental regulations and corporate sustainability goals will push manufacturers toward lead-free, recyclable materials in all motherboard components, including power switch connectors. By 2026, compliance with RoHS, REACH, and other environmental standards will be standard across the supply chain, influencing material selection and manufacturing processes. -

Rise of Modular and Tool-less Assembly

Consumer and enterprise PC assembly trends are shifting toward modular designs that simplify installation. Power switch connectors may evolve toward plug-and-play magnetic or snap-in solutions, reducing reliance on fragile pin headers and improving manufacturability. This trend will be particularly evident in prebuilt systems and OEM server configurations. -

Impact of Alternative Boot Technologies

While physical power switches remain essential, technologies such as Wake-on-LAN, voice-activated startup, and mobile app-based controls are gaining traction. However, these do not eliminate the need for physical connectors but may redefine their role—leading to dual-mode connectors that support both manual and digital triggering mechanisms.

In conclusion, the motherboard power switch connector market in 2026 will reflect broader trends in computing: miniaturization, smarter integration, and sustainability. Though a small component, its evolution will be critical to supporting next-generation system designs across consumer, industrial, and enterprise sectors.

Common Pitfalls When Sourcing Motherboard Power Switch Connectors (Quality and IP)

When integrating motherboard power switch connectors into electronic designs or sourcing replacements, several critical pitfalls related to quality and intellectual property (IP) must be carefully avoided. Overlooking these can lead to system failures, legal issues, or increased long-term costs.

Inconsistent Material Quality and Durability

One of the most frequent issues is sourcing connectors made from substandard materials. Low-cost connectors often use inferior plastics that become brittle over time or under thermal stress, leading to cracking or misalignment. Similarly, poor-grade metal contacts may oxidize or lose spring tension, resulting in intermittent connections or complete failure to power on the system. These quality inconsistencies are especially common with unbranded or counterfeit components.

Lack of Compliance with Industry Standards

Many low-quality power switch connectors fail to meet essential safety and performance standards such as UL, CE, or RoHS. Sourcing non-compliant parts can lead to regulatory issues, void certifications on end products, and pose safety risks including fire hazards or electrical shorts. Always verify that the connector meets required certifications for the target market.

Poor Mechanical Fit and Pin Compatibility

Even if a connector appears similar in form factor, dimensional inaccuracies in knock-off or reverse-engineered parts can prevent proper seating on the motherboard header. Mismatched pin pitch, incorrect polarization, or variations in housing depth may result in damaged pins or unreliable electrical contact. This is particularly problematic when sourcing from suppliers offering “compatible” alternatives without original design specifications.

Insufficient Current and Voltage Ratings

Some generic connectors are not rated for the inrush current typical during system startup. Using an under-specified connector can lead to overheating, contact welding, or premature failure. Always confirm that the connector’s electrical ratings (e.g., 3V/5V, 0.5A minimum) align with motherboard specifications and include sufficient safety margins.

Intellectual Property (IP) and Trademark Infringement

Sourcing counterfeit or imitation connectors that replicate branded designs (e.g., those resembling JST or Molex housings) can expose companies to IP infringement claims. Even if functional, using unlicensed copies may violate design patents or trademarks, leading to legal disputes, shipment seizures, or damage to brand reputation. Always source from authorized distributors or manufacturers with proper licensing.

Inadequate Traceability and Documentation

Low-tier suppliers may lack proper documentation, such as datasheets, material declarations, or batch traceability. This absence complicates quality audits, complicates failure analysis, and undermines compliance efforts—especially in regulated industries like medical or automotive electronics.

Overreliance on Online Marketplaces Without Vetting

Purchasing from unverified sellers on e-commerce platforms increases the risk of receiving counterfeit or out-of-spec components. These sellers often provide misleading product descriptions and lack the accountability of authorized channels. Implement a strict supplier qualification process to mitigate this risk.

Avoiding these pitfalls requires due diligence in supplier selection, rigorous component testing, and adherence to procurement best practices—ensuring both functional reliability and legal compliance.

Logistics & Compliance Guide for Motherboard Power Switch Connector

Overview

The motherboard power switch connector is a small but critical component in computer assembly, enabling user-initiated power management. Proper logistics handling and compliance adherence ensure product reliability, safety, and regulatory approval across global markets.

Packaging and Handling

Use anti-static packaging (e.g., static-shielded bags) to protect connectors from electrostatic discharge (ESD). Store in dry, temperature-controlled environments (10°C to 30°C; 30%–60% RH). Avoid mechanical stress during transit—use cushioned inner packaging and secure outer cartons to prevent pin deformation.

Transportation Requirements

Ship via ground or air freight compliant with IATA/IMDG regulations if applicable. Label packages with ESD-sensitive and fragile indicators. Maintain traceability with batch/lot numbers and barcodes. For international shipments, ensure proper export documentation and customs classification under HS Code 8536.90 (electrical apparatus for switching).

Regulatory Compliance

Comply with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization of Chemicals) directives for material safety. Ensure conformity with UL Recognized Component Program or IEC 60950-1 / IEC 62368-1 for electrical safety. Include CE marking for EU markets and FCC Part 15 compliance if integrated into radiated emission-sensitive systems.

Country-Specific Requirements

For the EU: Declare conformity via Declaration of Conformity (DoC) and maintain technical documentation per the EU RED and LVD. In the U.S.: Comply with UL standards and FTC labeling rules. In China: Adhere to CCC (China Compulsory Certification) if sold as part of a complete system. Japan requires adherence to PSE standards.

Documentation and Traceability

Maintain a Component Compliance Certificate (CoC) detailing material composition and test reports. Implement full supply chain traceability using serial numbers or batch tracking. Retain records for a minimum of 10 years to support audits and recalls.

End-of-Life and Recycling

Design for disassembly and recyclability. Comply with WEEE (Waste Electrical and Electronic Equipment) directives by providing take-back information. Label products with recycling symbols (e.g., crossed-out wheelie bin) where required.

Supplier and Quality Assurance

Source connectors from ISO 9001 and IATF 16949 certified manufacturers. Conduct periodic audits and incoming quality inspections (AQL sampling per ISO 2859-1). Require suppliers to provide IPC/WHMA-A-620 compliance for crimp and termination quality.

In conclusion, sourcing the correct motherboard power switch connector requires careful attention to compatibility, pin configuration, and physical specifications. It is essential to identify the exact form factor of the motherboard (e.g., ATX, micro-ATX, mini-ITX) and consult the manufacturer’s documentation to determine the required header type—typically a 2-pin or 3-pin connector with a specific pitch (commonly 2.54mm). Ensuring the connector is keyed correctly and matches the polarity (if applicable) prevents incorrect installation and potential damage. While many cases come with necessary front panel connectors, replacement or upgrade scenarios may require third-party sourcing from electronics suppliers or OEM parts. Compatibility, build quality, and correct pin labeling are critical factors in selecting a reliable power switch connector. Ultimately, verifying specifications and, when in doubt, consulting the motherboard manual or manufacturer support ensures a successful and safe integration into the system build.