The global motherboard packaging market is experiencing robust growth, driven by the expanding consumer electronics industry, rising demand for high-performance computing, and advancements in semiconductor packaging technologies. According to Grand View Research, the global semiconductor packaging market was valued at USD 45.7 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 7.2% from 2024 to 2030. This growth is directly tied to the increasing production of motherboards for applications in PCs, servers, data centers, and embedded systems. Mordor Intelligence further highlights that demand for advanced packaging solutions—such as system-in-package (SiP) and fan-out wafer-level packaging (FOWLP)—is accelerating due to the miniaturization of devices and the need for higher integration. As motherboard complexity increases, so does the need for reliable, innovative, and scalable packaging solutions. In this competitive landscape, leading manufacturers are differentiating through automation, thermal management, and sustainable packaging practices. Below, we spotlight the top 10 motherboard packaging manufacturers shaping the future of electronics manufacturing through technological excellence and operational scale.

Top 10 Motherboard Packaging Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Motherboards, HPC, Industrial Computers, Medical Panel …

Domain Est. 1995

Website: bcmcom.com

Key Highlights: BCM is your one-stop-shop and trusted supplier for all of your embedded computing requirements. From turn-key ODM/OEM design, both x86 and ARM, to quality & ISO ……

#2 BIOSTAR

Domain Est. 1985

Website: biostar.com.tw

Key Highlights: BIOSTAR is an experienced computer hardware accessories/PC/Gaming Motherboard manufacturer and supplier. We provide high-quality multinational products….

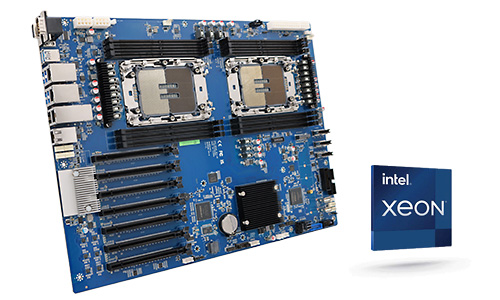

#3 System Manufacturers

Domain Est. 1986

Website: intel.com

Key Highlights: Process Technologies · Advanced Packaging & Test · Manufacturing · Accelerator Ecosystem Alliances · Software and Services. More +. Sign In My Intel. My Tools ?…

#4 Industrial Motherboard

Domain Est. 1991

Website: ipc.msi.com

Key Highlights: Free delivery 30-day returnsIndustrial motherboards are designed for demanding applications, characterized by stable long-term supply, high reliability, environmental resistance, ….

#5 Industrial Motherboards and SBCs

Domain Est. 1992

Website: contec.com

Key Highlights: Global Manufacturing and Prototyping: Motherboard and SBC prototyping and manufacturing capabilities in the United States, Taiwan and Japan….

#6 ASRock Industrial

Domain Est. 2018

Website: asrockind.com

Key Highlights: ASRock Industrial Computer was established as an independent company in July 2018, focusing on the fields of motherboards, edge computers and cameras, ……

#7 Plexus

Domain Est. 1990

Website: plexus.com

Key Highlights: Your trusted partner for designing, manufacturing and servicing. Plexus offers solutions for every stage of the product life cycle….

#8 Corporate Stable Model (CSM) Motherboard

Domain Est. 1995

Website: asus.com

Key Highlights: CSM motherboards offer flexible packaging: Bulk (stacks of up to 10, all accessories included*) or Standard Retail (no minimum order, easy identification)….

#9 Motherboards

Domain Est. 2002

Website: asrock.com

Key Highlights: + Category · AQUA · Phantom Gaming · Workstation · Creator · Taichi · Steel Legend · Extreme · PRO…

#10 Mini-Box.com – Mini-ITX

Domain Est. 2002

Website: mini-box.com

Key Highlights: Mini-Box.com design and manufacture a wide range of Mini-ITX products: Embedded Systems, Mini-ITX Power Supplies, Car PC Solution….

Expert Sourcing Insights for Motherboard Packaging

2026 Market Trends for Motherboard Packaging

Rising Demand for Compact and Efficient Packaging Solutions

As consumer electronics continue to trend toward smaller, more powerful devices, motherboard packaging in 2026 is expected to evolve in response. The demand for compact form factors such as Mini-ITX and smaller embedded motherboards is driving innovation in packaging design. Manufacturers are focusing on space-efficient, lightweight packaging that still provides adequate protection during shipping and handling. This trend is especially pronounced in markets for mini PCs, edge computing devices, and IoT infrastructure, where motherboard size and packaging footprint are critical.

Sustainability and Eco-Friendly Materials

Environmental regulations and consumer awareness are pushing motherboard manufacturers and packaging suppliers toward sustainable solutions. By 2026, the industry is anticipated to adopt biodegradable, recyclable, or compostable materials such as molded pulp, recycled cardboard, and plant-based foams. Major tech OEMs are likely to enforce green supply chain mandates, requiring packaging to meet specific environmental standards. This shift not only reduces environmental impact but also enhances brand image among eco-conscious consumers and B2B clients.

Enhanced Anti-Static and Protective Features

Motherboards are highly sensitive to electrostatic discharge (ESD) and physical damage. In 2026, packaging solutions will increasingly integrate advanced anti-static materials—such as metallized shielding bags, conductive foams, and static-dissipative coatings—to ensure product integrity. With the rise of high-performance motherboards for gaming, AI workstations, and data centers, even minor damage during transit can lead to costly returns. As a result, packaging will be engineered with multi-layer protection systems, combining cushioning, moisture resistance, and ESD safeguards.

Smart Packaging and Traceability

The integration of smart packaging technologies is expected to gain traction by 2026. RFID tags, QR codes, and NFC-enabled labels will allow for real-time tracking, authenticity verification, and supply chain transparency. This is particularly valuable in combating counterfeiting and ensuring product legitimacy in global distribution networks. Additionally, smart labels can provide end-users with installation guides, firmware update links, or recycling instructions, enhancing the overall customer experience.

Customization and Brand-Centric Design

As competition among motherboard brands intensifies, packaging will serve as a key differentiator. In 2026, expect to see more customized, visually striking packaging that reflects brand identity—especially in the gaming and enthusiast segments. Premium motherboards may come in themed boxes with augmented reality (AR) features, collectible elements, or reusable packaging containers. This trend aligns with the growing importance of unboxing experiences in digital marketing and social media sharing.

Regional Variations and Supply Chain Localization

Global disruptions have underscored the need for resilient supply chains. By 2026, motherboard packaging strategies will reflect regional logistics requirements, with localized production of packaging materials to reduce shipping costs and lead times. For example, Asian manufacturers may adopt compact, stackable designs optimized for high-volume exports, while North American and European markets may emphasize sustainability and compliance with regional environmental laws such as the EU’s Packaging and Packaging Waste Regulation (PPWR).

Conclusion

The motherboard packaging market in 2026 will be shaped by technological advances, environmental imperatives, and evolving consumer expectations. Innovations in materials, protection, and digital integration will define leading-edge packaging solutions, while sustainability and localization will remain central to operational strategies. As motherboards become more sophisticated, their packaging must evolve in parallel—offering protection, traceability, and brand value in an increasingly competitive and regulated global market.

Common Pitfalls in Sourcing Motherboard Packaging (Quality, IP)

Sourcing packaging for motherboards involves more than just aesthetics—it plays a critical role in product protection, brand perception, and legal compliance. However, manufacturers and OEMs often encounter significant challenges, particularly concerning quality and intellectual property (IP). Below are the most common pitfalls to avoid.

Poor Material Quality Leading to Product Damage

One of the most frequent issues in motherboard packaging is the use of substandard materials. Thin or low-density cardboard, inadequate ESD (electrostatic discharge) protection, and weak foam inserts can lead to physical damage during shipping and handling. Motherboards are sensitive to impacts, moisture, and static electricity, so insufficient packaging compromises product integrity, increases return rates, and damages brand reputation.

Inadequate ESD and Environmental Protection

Motherboards are highly susceptible to electrostatic discharge. Packaging that lacks proper ESD shielding—such as metallized shielding bags or conductive foam—can result in latent or catastrophic damage to components. Additionally, failure to account for humidity, temperature fluctuations, and contaminants during transit can degrade circuitry. Sourcing packaging without verifying ESD compliance (e.g., ANSI/ESD S20.20) is a significant technical oversight.

Lack of Brand Consistency and Customization

Generic or off-the-shelf packaging may reduce costs initially but can dilute brand identity. Poor print quality, incorrect color matching, or inconsistent design across product lines make the product appear low-end or counterfeit. Investing in customized, high-quality printing and structural design reinforces brand credibility and enhances customer unboxing experience.

Intellectual Property Infringement Risks

Using packaging designs, logos, or product imagery without proper authorization can lead to serious IP violations. This includes replicating design elements from competitors or using unlicensed graphics and fonts. Additionally, copying the structural design of well-known brands may infringe on design patents or trade dress rights. Such oversights can result in legal disputes, product seizures, and financial penalties.

Failure to Protect Proprietary Packaging Designs

On the flip side, companies often fail to safeguard their own packaging innovations. Not registering unique box designs, logos, or structural features through trademarks, copyrights, or design patents leaves them vulnerable to imitation by competitors. This undermines competitive advantage and can erode market share.

Overlooking Regulatory and Compliance Requirements

Motherboard packaging must comply with regional regulations, including RoHS labeling, WEEE directives, and country-specific import standards. Omitting required markings or using non-compliant materials can delay shipments or result in customs rejections. Additionally, misleading environmental claims (e.g., “recyclable” without proper certification) may lead to regulatory scrutiny.

Supply Chain and Vendor Reliability Issues

Partnering with unreliable suppliers can result in inconsistent packaging quality, delayed deliveries, or unauthorized subcontracting. Some vendors may outsource production without approval, increasing the risk of IP leakage and quality deviations. Lack of transparency in the supply chain undermines control over both product protection and intellectual property.

Conclusion: Mitigating Risks Through Due Diligence

To avoid these pitfalls, companies should conduct thorough vetting of packaging suppliers, insist on material and ESD testing, secure IP rights for original designs, and ensure compliance with international standards. Legal review of packaging artwork and structural designs is essential to prevent infringement and protect innovation. Proactive management of both quality and IP aspects ensures that motherboard packaging supports—rather than undermines—product success.

Logistics & Compliance Guide for Motherboard Packaging

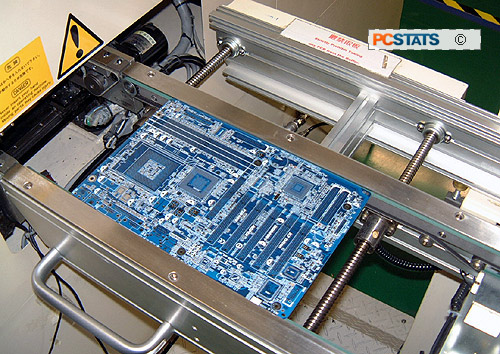

Packaging Specifications

Motherboards must be packaged in static-dissipative anti-static bags (pink or silver) that meet ANSI/ESD S20.20 or IEC 61340-5-1 standards. Each bagged motherboard should be enclosed in a rigid corrugated cardboard box with internal foam or molded pulp inserts to prevent movement during transit. The minimum box strength should be 32 ECT (Edge Crush Test) to withstand stacking and handling.

Labeling Requirements

All packages must display a clear barcode (GS1-128 or UPC-A), ESD sensitivity symbol (yellow hand-in-triangle), and product identification (model number, SKU, and revision). Hazard communication labels (e.g., “Fragile,” “This Side Up”) must be prominently displayed. For international shipments, labels must be in English and comply with destination country language requirements.

Environmental Compliance

Packaging materials must comply with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) directives. The use of heavy metals (lead, mercury, cadmium) and phthalates is prohibited. Packaging should be recyclable, and a recyclability symbol (e.g., Möbius loop) must be printed on the outer box.

Export Controls & Documentation

Motherboards containing controlled technologies (e.g., high-speed chipsets, encryption features) may be subject to export regulations such as the U.S. Export Administration Regulations (EAR) or EU Dual-Use Regulation. A commercial invoice, packing list, and, when required, an ECCN (Export Control Classification Number) must accompany each shipment. Validate destination country restrictions before dispatch.

Shipping & Handling

Use carriers certified for electronics logistics (e.g., FedEx, DHL, UPS) with temperature-controlled and shock-monitoring options for high-value shipments. Packages should not exceed 15 kg (33 lbs) to minimize handling risk. Implement a tracking system with real-time updates and delivery confirmation.

Import Regulations

Ensure compliance with local import laws, including duty classification (HS Code 8473.30 for motherboard components), safety certifications (e.g., CE, FCC, KC, CCC), and country-specific labeling (e.g., China’s CQC mark). Provide necessary documentation such as a Certificate of Origin and conformity assessment reports upon request.

Returns & Reverse Logistics

Establish a standardized return process with pre-authorized RMA (Return Merchandise Authorization) numbers. Returned motherboards must be repackaged using the same ESD-safe materials. Inspect all returns for damage and environmental exposure before processing refunds or replacements.

Audit & Recordkeeping

Maintain traceability through serialized packaging logs and batch records for a minimum of five years. Conduct annual compliance audits to verify adherence to logistics, environmental, and regulatory standards. Update packaging protocols in response to regulatory changes or audit findings.

Conclusion for Sourcing Motherboard Packaging:

Sourcing motherboard packaging requires a strategic approach that balances protection, cost-efficiency, sustainability, and brand representation. After evaluating various materials, design options, and supplier capabilities, it is clear that custom-designed packaging using durable, anti-static, and ESD-safe materials—such as corrugated cardboard with foam inserts or molded pulp—is essential to ensure the safe transport and storage of sensitive motherboard components. Additionally, partnering with reliable suppliers who adhere to international quality standards and offer scalability is crucial for long-term success.

Sustainability is increasingly important, and incorporating recyclable or biodegradable materials not only supports environmental goals but also enhances brand image. Furthermore, integrating branding elements into the packaging design can improve customer experience and product authenticity.

In conclusion, effective motherboard packaging sourcing should prioritize product safety, regulatory compliance, environmental responsibility, and cost management. A well-executed packaging solution ultimately reduces damage-related losses, strengthens brand reputation, and supports efficient logistics across the supply chain.