The global monster truck and heavy-duty performance vehicle market has seen steady expansion, driven by rising demand in entertainment, off-road racing, and customized vehicle sectors. According to Grand View Research, the global specialty trucks market—encompassing high-performance and custom-built chassis—was valued at USD 18.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.7% from 2023 to 2030. This growth is fueled by increasing investments in motorsports events, expanding live entertainment productions like Monster Jam, and advancements in durable chassis engineering. As the backbone of any high-performance monster truck, the chassis plays a critical role in strength, safety, and agility. With rising competition and technological innovation, manufacturers are pushing the limits in materials, design, and customization. Based on market presence, engineering reputation, and industry adoption, here are the top 10 monster truck chassis manufacturers shaping the future of this high-impact industry.

Top 10 Monster Truck Chassis Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Building Championship Monster Truck …

Domain Est. 1998

Website: samson4x4.com

Key Highlights: Patrick Enterprises Inc is the industry standard for custom monster truck chassis, suspension, axle housings, turn key monster trucks, and much more….

#2 Traxxas

Domain Est. 1996

Website: traxxas.com

Key Highlights: Free delivery over $99 · 30-day returnsTraxxas Support is open 7 days a week! Dial 888-TRAXXAS or click Live Chat 8:30am–9:00pm CST. FREE standard shipping on all orders over $99!…

#3 HPI Racing

Domain Est. 1997

Website: hpiracing.com

Key Highlights: High quality radio control vehicles for hobbyists of all ages and skill levels, from monster trucks to drift cars!…

#4 Losi RC Monster Trucks

Domain Est. 2000

Website: losi.com

Key Highlights: Free delivery over $99Monster Truck. If you love over-built and over-powered our LMT’s are just that. Backflip, wheelie, and race just like the professionals. Filters (6 Items)….

#5 Vehicles

Domain Est. 2004

Website: redcatracing.com

Key Highlights: 7-day deliveryFind RC Trucks, RC Cars, RC Scalers, RC Rock Crawlers, RC Rock Racers and More. Use the filters on the left to narrow and refine your vehicle search….

#6 Team Corally Kagama Blue 1/8 Scale 4WD Monster Truck

Domain Est. 2012

Website: motionrc.com

Key Highlights: This super-rigid system uses an oversized MONOBLOC composite front chassis and shock tower brace containing an integrated steering deck, while the rear MONOBLOC ……

#7 CRD Racing

Domain Est. 2018

Website: crdracing.com

Key Highlights: The CRD Monster Chassis has been designed in a 3D computer model by highly skilled mechanical engineers. The chassis is engineered to be stronger and lighter….

#8 Rossmonster

Domain Est. 2019

Website: rossmonster.com

Key Highlights: Mercedes chassis, but more space. Designed for those chasing adventure on dirt roads and trailheads in spacious luxury….

#9 EVAN KOZLOWSKI

Domain Est. 2022

Website: 2xmonstertrucks.com

Key Highlights: Meet EVAN KOZLOWSKI , the driver of REDNECK ROAD TRIP — one of the stars of 2X Monster Trucks! Learn about the driver, the truck, and the high-flying action ……

#10 News

Domain Est. 2018

Website: teamthrottlemonster.com

Key Highlights: Ready to monster-size your brand? Join us as an official partner of Team Throttle Monster, America’s most-active independent monster truck ……

Expert Sourcing Insights for Monster Truck Chassis

H2: Projected 2026 Market Trends for Monster Truck Chassis

The monster truck chassis market is poised for notable transformation by 2026, driven by technological innovation, increasing demand for performance customization, and the growing popularity of motorsports entertainment. As the industry evolves, several key trends are expected to shape the design, production, and commercialization of monster truck chassis in the coming years.

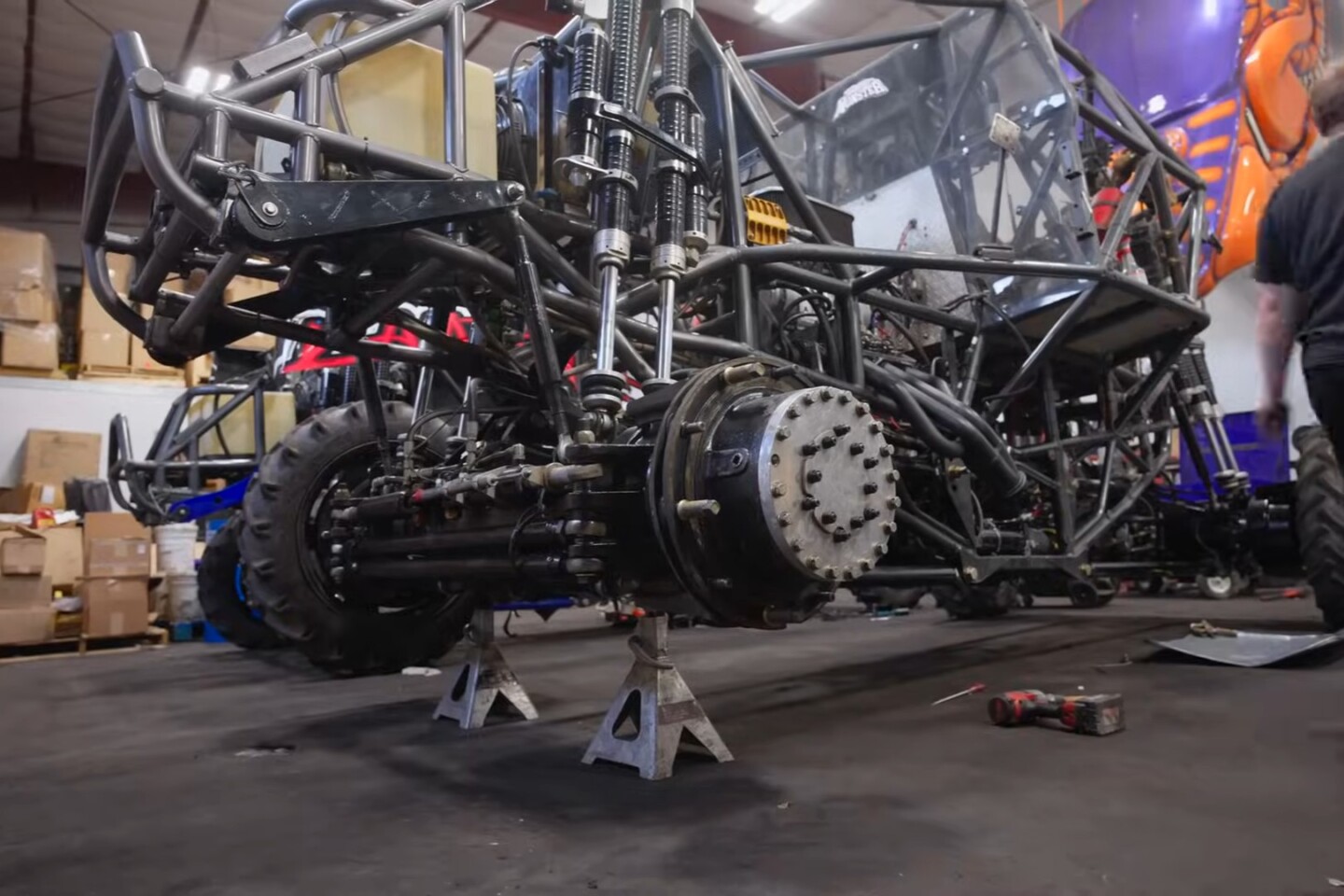

1. Advanced Materials and Lightweight Engineering

By 2026, manufacturers are anticipated to increasingly adopt high-strength, lightweight materials such as chromoly steel alloys, titanium components, and composite-reinforced frames. These materials improve durability while reducing overall vehicle weight, enhancing agility and fuel efficiency during high-impact stunts and competitions. The push for performance optimization will drive R&D in material science tailored specifically for extreme off-road stress.

2. Modular and Customizable Chassis Designs

Customization remains a dominant trend, with demand rising for modular chassis systems that allow teams to adapt configurations for different events—such as freestyle, racing, or truck pulls. In 2026, expect to see more plug-and-play chassis platforms that simplify upgrades and repairs, reducing downtime and maintenance costs for professional and amateur operators alike.

3. Integration with Electric Powertrains

As sustainability gains traction in motorsports, electric monster trucks (e.g., Monster Jam’s electrified fleet) are influencing chassis design. The 2026 market will likely feature chassis engineered specifically for electric drivetrains, accommodating heavy battery packs, electric motors, and advanced cooling systems. This shift demands reinforced suspension mounting points and optimized weight distribution to maintain performance under increased mass.

4. Adoption of Smart Technologies and Telemetry

Chassis systems are becoming “smarter,” with embedded sensors monitoring stress points, suspension performance, and alignment in real time. By 2026, integrated telemetry systems will be standard in professional-grade chassis, enabling predictive maintenance and performance analytics. This data-driven approach improves safety and competitive edge, appealing to teams and sponsors.

5. Expansion of Amateur and Recreational Markets

Beyond professional circuits, the hobbyist and recreational segment is growing. Affordable, pre-engineered chassis kits targeted at DIY builders and regional event participants are expected to gain market share. Manufacturers will likely offer scalable chassis solutions—balancing cost, complexity, and performance—to capture this expanding consumer base.

6. Regulatory and Safety Standards Evolution

With increasing scrutiny on motorsports safety, regulatory bodies may introduce updated chassis certification standards by 2026. Expect reinforced roll cage designs, improved crumple zones, and mandatory fatigue testing to become more prevalent. Compliance will become a key differentiator among chassis providers.

Conclusion

The 2026 monster truck chassis market will be defined by innovation, sustainability, and adaptability. As the lines blur between entertainment, engineering, and environmental responsibility, chassis manufacturers that prioritize advanced materials, modularity, and smart integration will lead the sector. Whether for stadium shows or backyard bashing, the chassis will remain the backbone of monster truck performance—and the epicenter of next-generation off-road evolution.

Common Pitfalls When Sourcing Monster Truck Chassis: Quality and Intellectual Property Risks

Sourcing monster truck chassis—whether for competition, display, or commercial use—can involve significant investment and technical complexity. Buyers often encounter critical challenges related to quality inconsistencies and intellectual property (IP) infringement, especially when sourcing from third-party or offshore manufacturers. Being aware of these pitfalls is essential to avoid costly delays, legal disputes, or performance failures.

Quality Inconsistencies and Substandard Materials

One of the most prevalent issues when sourcing monster truck chassis is variability in build quality. Many suppliers, particularly those offering lower-cost options, may use inferior materials or lack rigorous quality control processes.

- Use of Non-Grade Steel: Some chassis are constructed with mild steel instead of high-tensile chromoly steel (e.g., 4130), which is essential for withstanding the extreme stresses of jumps and impacts. This compromises structural integrity and safety.

- Poor Welding Practices: Inconsistent or amateur welds—especially in critical load-bearing areas—can lead to catastrophic failure during operation. Lack of certified welding (e.g., AWS D1.1 standards) is a red flag.

- Inaccurate Fabrication: Misaligned frame rails, improper suspension mounting points, or incorrect geometry reduce performance and create handling issues.

- Lack of Testing and Certification: Reputable manufacturers conduct stress testing and provide documentation. Many budget suppliers skip these steps, offering no proof of durability.

To mitigate these risks, always request material certifications, welding inspection reports, and ideally, third-party performance validation.

Intellectual Property and Design Infringement

Monster truck designs—especially those associated with well-known brands like Monster Jam, Grave Digger, or Bigfoot—are often protected by trademarks, copyrights, and design patents. Sourcing unauthorized replicas poses serious IP risks.

- Trademark Violations: Using logos, names, or stylized designs (e.g., “Max-D” or “El Toro Loco”) without licensing can lead to cease-and-desist letters, fines, or confiscation of equipment.

- Copycat Chassis Designs: Some manufacturers reverse-engineer proprietary chassis geometry or suspension systems. Distributing or using these may infringe on patented technologies.

- Licensing Misrepresentation: Suppliers may falsely claim to be “official” or “licensed” partners. Always verify licensing agreements directly with the IP holder.

- Export and Customs Issues: Importing infringing products can result in seizure by customs authorities under IP enforcement laws (e.g., U.S. Customs and Border Protection regulations).

To avoid legal exposure, ensure that chassis designs are either original, properly licensed, or explicitly in the public domain. Consult legal counsel when in doubt.

Conclusion

Sourcing a monster truck chassis demands due diligence. Prioritize suppliers with verifiable quality standards, certified materials, and transparent design rights. Avoid cutting corners on price at the expense of safety or legality—both quality failures and IP disputes can lead to far greater long-term costs.

Logistics & Compliance Guide for Monster Truck Chassis

Transporting and operating a monster truck chassis involves complex logistics and strict regulatory compliance due to its oversized dimensions, weight, and specialized use. This guide outlines key considerations for safe, legal, and efficient handling.

Regulatory Classification and Permits

Monster truck chassis are typically classified as oversized or overweight vehicles under federal and state/provincial transportation laws. Operators must obtain special hauling permits from each jurisdiction the chassis will travel through. These permits specify allowable routes, travel times (often restricted to nighttime or non-peak hours), speed limits, and escort vehicle requirements. Failure to secure proper permits can result in fines, delays, and impoundment of equipment.

Transport Requirements

Due to extreme dimensions—often exceeding standard width, height, and length limits—monster truck chassis must be transported on specialized flatbed trailers or lowboy trailers. Securement must meet Federal Motor Carrier Safety Administration (FMCSA) standards, using rated chains, binders, and load bars to prevent shifting. Pre-transport inspections should verify tie-down integrity, trailer axle condition, and proper lighting/signage.

Route Planning and Escort Vehicles

Detailed route surveys are essential to avoid low bridges, tight turns, and weight-restricted roads. GPS systems with heavy-haul capabilities should be used. Most jurisdictions require one or more escort (pilot) vehicles: a lead car to warn traffic and check overhead clearances, and possibly a rear escort to manage following traffic. Radio communication between transport and escort vehicles is mandatory.

International Compliance (for Cross-Border Transport)

When moving chassis across borders (e.g., U.S. to Canada or Mexico), additional documentation is required, including customs declarations, commercial invoices, and proof of insurance. Compliance with both countries’ transportation standards (e.g., U.S. DOT and Canadian CVSA) is mandatory. Harmonized codes for temporary importation (e.g., ATA Carnet) may be needed to avoid duties.

Safety and Operational Standards

While not typically road-legal for public use, monster truck chassis used in events must comply with safety regulations from sanctioning bodies (e.g., Monster Jam, FELD Entertainment). This includes roll cage integrity, fuel system containment, fire suppression systems, and driver restraint compliance. Regular engineering inspections are recommended to maintain structural safety.

Environmental and Local Ordinances

Transport and operation may be subject to noise ordinances and environmental regulations, especially near residential areas. Use of off-road fuel (e.g., methanol) requires adherence to hazardous materials handling protocols during fueling and transport. Spill containment kits and proper fuel storage containers are required.

Documentation and Recordkeeping

Maintain up-to-date records including:

– Valid hauling permits

– Vehicle registration and VIN documentation

– Insurance certificates (general liability and cargo)

– Driver and escort credentials (CDL, training)

– Pre-trip inspection reports

– Maintenance logs

Best Practices for Efficient Logistics

- Plan transport routes and permit applications at least 4–6 weeks in advance.

- Use experienced heavy-haul carriers familiar with oversized vehicle regulations.

- Coordinate with event organizers for site access and unloading procedures.

- Conduct a pre-transport safety briefing with all team members and drivers.

Compliance with logistics and regulatory requirements ensures the safe delivery of monster truck chassis and supports the professionalism and sustainability of the motorsports industry.

In conclusion, sourcing a monster truck chassis requires careful consideration of several key factors including durability, customization options, compatibility with oversized components, and adherence to safety and performance standards. Whether opting for a custom-built chassis from a specialized manufacturer or retrofitting a heavy-duty commercial frame, it is essential to prioritize strength, suspension integration, and long-term maintainability. Establishing relationships with reputable suppliers, verifying material quality, and ensuring compliance with competition or exhibition regulations will ultimately contribute to a reliable and high-performing monster truck. A well-sourced chassis serves as the foundational element for success, enabling optimal power transfer, maneuverability, and resilience in extreme conditions.