The North American plastics manufacturing industry continues to expand, driven by rising demand across automotive, healthcare, and consumer goods sectors. According to Grand View Research, the U.S. plastics manufacturing market was valued at USD 477.5 billion in 2022 and is expected to grow at a compound annual growth rate (CAGP) of 4.3% from 2023 to 2030. Within this competitive landscape, Plattsburgh, NY has emerged as a strategic hub for precision injection molding, bolstered by proximity to major supply chains and a skilled manufacturing workforce. Among local leaders, Mold Rite Plastics stands out for its consistent investment in automation, tight-tolerance molding capabilities, and rapid prototyping services. As demand for high-volume, high-quality plastic components increases—particularly in medical and technical applications—Mold Rite Plastics is well-positioned alongside three other top-tier manufacturers in the Plattsburgh area to meet evolving industry standards and drive regional growth.

Top 4 Mold Rite Plastics Plattsburgh Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

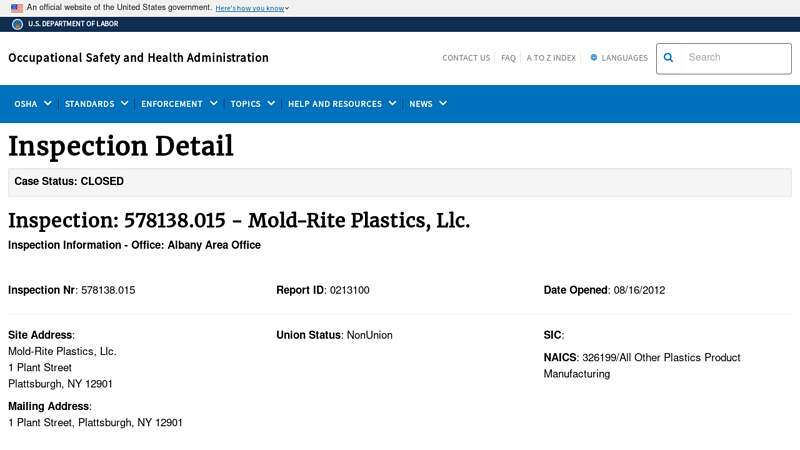

#1 Inspection Detail

Domain Est. 1997

Website: osha.gov

Key Highlights: Site Address: Mold-Rite Plastics, Llc. 1 Plant Street Plattsburgh, NY 12901. Mailing Address: 1 Plant Street, Plattsburgh, NY 12901. Union Status: NonUnion….

#2 MRP Solutions

Domain Est. 2013

Website: mrpsolutions.com

Key Highlights: MRP Solutions is a provider of high-quality, plastic packaging closures, caps and jars used every day by millions of consumers….

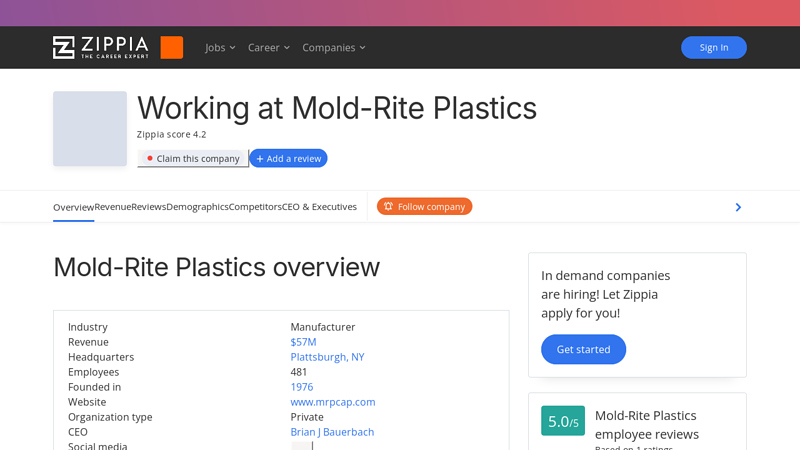

#3 Working At Mold

Domain Est. 2015

Website: zippia.com

Key Highlights: Rating 5.0 (1) Mold-Rite Plastics is a leading provider of high-quality, plastic packaging closures, caps, lids and jars used every day by millions of consumers around the ……

#4 Mold

Domain Est. 2014

Website: suncommunitynews.com

Key Highlights: PLATTSBURGH | In a Dec. 10 letter to employees, Mold-Rite Plastics announced that it will be changing its name to Mold-Rite Packaging….

Expert Sourcing Insights for Mold Rite Plastics Plattsburgh

H2: Projected 2026 Market Trends for Mold Rite Plastics – Plattsburgh Facility

As Mold Rite Plastics continues to operate its facility in Plattsburgh, NY, several key market trends are expected to shape the company’s strategic outlook in 2026. Drawing from broader industry dynamics, regional economic factors, and evolving customer demands, the following trends will likely influence operations, competitiveness, and growth opportunities for the Plattsburgh location.

-

Growth in Medical and Life Sciences Manufacturing

The Plattsburgh region is increasingly becoming a hub for medical device and pharmaceutical manufacturing, supported by proximity to research institutions and a skilled technical workforce. Mold Rite Plastics, with its expertise in precision injection molding, is well-positioned to benefit from heightened demand for sterile, high-tolerance plastic components used in surgical tools, diagnostic devices, and drug delivery systems. The trend toward onshoring medical supply chains post-pandemic will further boost regional demand, creating steady contract opportunities. -

Emphasis on Sustainability and Circular Economy Practices

By 2026, regulatory and customer pressures for sustainable manufacturing will intensify. Mold Rite Plastics will likely face increased demand for recyclable resins, reduced material waste, and energy-efficient production processes. In response, the Plattsburgh facility may adopt closed-loop recycling systems, expand use of bio-based or PCR (post-consumer recycled) materials, and pursue certifications such as ISO 14001. These efforts could enhance competitiveness, especially with environmentally conscious OEM clients. -

Workforce Development and Automation Integration

Like many advanced manufacturing firms in upstate New York, Mold Rite Plastics may encounter persistent labor shortages in 2026. To maintain productivity and quality, the Plattsburgh plant is expected to increase investments in automation, robotics, and AI-driven process monitoring. Partnerships with local technical colleges—such as Clinton Community College or SUNY Plattsburgh’s engineering programs—will be critical to cultivating a pipeline of skilled technicians and engineers familiar with smart manufacturing technologies. -

Supply Chain Resilience and Regional Sourcing

The push for nearshoring and supply chain localization will continue to favor regional manufacturers like Mold Rite. With growing demand from clients seeking to reduce reliance on overseas suppliers, the Plattsburgh facility can leverage its Northeast U.S. location to offer faster turnaround, reduced logistics costs, and enhanced quality control. This trend supports long-term contracts with Northeast-based medical, packaging, and industrial equipment companies. -

Expansion of Custom and Low-Volume Production

Market demand is shifting toward customized, low-to-medium volume production runs, particularly in medical and specialty industrial sectors. Mold Rite’s agility in prototyping and rapid tooling positions it well in this niche. By 2026, the Plattsburgh plant may see increased utilization of modular tooling systems and digital twin technologies to shorten time-to-market and support clients in product development phases.

Conclusion

In 2026, Mold Rite Plastics’ Plattsburgh facility is expected to thrive by aligning with high-growth sectors like medical manufacturing, embracing sustainability, and investing in automation and workforce development. Strategic positioning within a resilient regional supply chain network will further solidify its role as a key player in Northeast precision plastics manufacturing.

Common Pitfalls Sourcing from Mold Rite Plastics Plattsburgh (Quality, IP)

Sourcing from Mold Rite Plastics in Plattsburgh can offer benefits such as domestic production and expertise in precision molding. However, partners should be aware of potential risks related to quality control and intellectual property (IP) protection to avoid costly setbacks.

Inconsistent Quality Control Standards

One major pitfall when sourcing from Mold Rite Plastics—or any molding supplier—is variability in quality control. Despite their ISO 9001 certification, inconsistencies may arise due to high production volumes, material batch variations, or inadequate in-line inspection processes. Without clearly defined quality benchmarks and third-party audits, defects such as flash, warping, or dimensional inaccuracies may go undetected until final assembly, leading to rework, delays, or product recalls.

Inadequate Intellectual Property Protection

Another significant risk involves intellectual property exposure. Mold Rite Plastics may have access to sensitive design files, proprietary tooling, and product specifications. If robust IP agreements—such as non-disclosure agreements (NDAs), clear ownership clauses in contracts, and controlled data sharing protocols—are not in place, there is a risk of design replication, unauthorized tooling use, or leakage to competitors. Additionally, ambiguity in who owns the molds or digital assets after production can lead to legal disputes or loss of competitive advantage.

Limited Transparency in Subcontracting Practices

Mold Rite Plastics may subcontract certain processes such as secondary operations, surface finishing, or assembly. If these subcontractors are not vetted or monitored, quality deviations and IP vulnerabilities can increase. Lack of visibility into the full supply chain complicates compliance tracking and exposes the buyer to risks if subcontractors do not adhere to the same standards.

Insufficient Documentation and Traceability

Poor documentation of material certifications, process validation, and lot traceability can undermine quality assurance efforts. Without rigorous records, it becomes difficult to conduct root cause analysis during failure investigations or to meet regulatory requirements in industries such as medical or aerospace. Buyers may find themselves without adequate support during audits or compliance reviews.

Conclusion

To mitigate these pitfalls, sourcing teams should implement strong supplier qualification processes, enforce detailed quality agreements, secure IP through legal contracts, and conduct regular on-site audits. Proactive engagement with Mold Rite Plastics on quality metrics and IP safeguards is essential for a successful, risk-managed partnership.

Logistics & Compliance Guide for Mold Rite Plastics – Plattsburgh Facility

This guide outlines the key logistics procedures and compliance requirements for operations at the Mold Rite Plastics facility in Plattsburgh, NY. Adherence to these standards ensures efficient operations, regulatory compliance, and product quality.

Transportation & Shipping Protocols

All inbound and outbound shipments must be coordinated through the Logistics Coordinator. Standard carriers include FedEx Freight, XPO Logistics, and J.B. Hunt for full truckload (FTL) and less-than-truckload (LTL) deliveries. Advance shipment notifications (ASNs) are required for all inbound materials 48 hours prior to arrival. Dock schedules must be confirmed in the warehouse management system (WMS) to prevent congestion. All outgoing shipments must be inspected for packaging integrity and labeled with proper customer PO numbers, part numbers, and barcodes.

Receiving & Inventory Management

Incoming materials are inspected upon arrival for damage, quantity accuracy, and conformance to purchase order specifications. Quality Control performs initial checks on resin batches and critical components. All items must be logged into the SAP ERP system within 2 hours of receipt. First-Expiration, First-Out (FEFO) and First-In, First-Out (FIFO) inventory practices are enforced for raw materials, especially hygroscopic resins requiring dry storage. Bin locations are updated in real time to maintain inventory accuracy.

Regulatory Compliance Standards

Mold Rite Plastics Plattsburgh complies with all federal, state, and local regulations, including OSHA, EPA, and DOT standards. Hazardous materials (e.g., certain mold release agents or cleaning solvents) are stored in designated, ventilated areas with secondary containment and are managed under a Hazardous Waste Program compliant with RCRA. SDS (Safety Data Sheets) are maintained electronically and accessible to all employees. DOT-compliant shipping papers are required for hazardous shipments, and all personnel handling hazardous materials must complete annual HAZMAT training.

Export Control & Trade Compliance

As a manufacturer serving international clients, Mold Rite Plastics adheres to U.S. export regulations administered by the Department of Commerce (BIS). All exports undergo an ECCN (Export Control Classification Number) review. Shipments requiring licenses are processed only after approval. Denied Party Screening is conducted for all international transactions using automated tools integrated with customer and supplier databases. End-use statements are maintained for high-risk destinations.

Packaging & Product Handling

Finished goods must be packaged according to customer-specific standards or internal packaging protocols. Anti-static packaging is used for electronic components. All skids are wrapped with UV-resistant stretch film and labeled with traceability information, including lot numbers and production dates. Handling equipment (e.g., forklifts, pallet jacks) operators are certified and conduct pre-shift inspections. Product segregation by project or customer is maintained throughout the warehouse.

Environmental, Health & Safety (EHS) Logistics

Waste streams are segregated into recyclables, general waste, and regulated hazardous waste. Spill response kits are stationed at loading docks and chemical storage areas. Emergency response plans are posted and reviewed quarterly. All logistics personnel complete annual EHS training, including forklift safety, hazardous material handling, and emergency procedures. Air emissions from facility operations are monitored and reported in compliance with NY State DEC regulations.

Documentation & Record Retention

All logistics and compliance records—including shipping manifests, receiving logs, training certifications, waste disposal manifests, and export documentation—are retained for a minimum of seven years in accordance with ISO 9001 and regulatory requirements. Digital records are backed up nightly, and hard copies are stored in fire-resistant cabinets. Audits are conducted quarterly to ensure documentation completeness and compliance.

Continuous Improvement & Audits

Internal logistics audits are conducted biannually to assess compliance, efficiency, and safety. Corrective actions are tracked via the non-conformance report (NCR) system. Feedback from carriers, customers, and suppliers is reviewed monthly to identify improvement opportunities. Mold Rite Plastics Plattsburgh is committed to lean logistics principles and ongoing compliance excellence.

In conclusion, sourcing from Mold Rite Plastics in Plattsburgh presents a strategic advantage for businesses requiring high-quality, precision plastic injection molding services. With a strong reputation for reliability, advanced manufacturing capabilities, and a commitment to quality control, Mold Rite Plastics demonstrates the expertise necessary to support diverse industry needs—from medical and automotive to consumer and industrial applications. Their local presence in Plattsburgh, NY, also offers benefits in logistics, responsiveness, and supply chain resilience, particularly for Northeast-based companies. By partnering with Mold Rite Plastics, organizations can leverage domestic manufacturing excellence, reduce lead times, and ensure greater oversight throughout the production process. Overall, Mold Rite Plastics stands out as a dependable and capable supplier for companies seeking consistent quality, innovation, and long-term collaborative relationships in plastic component manufacturing.