The industrial automation sector is experiencing robust expansion, driven by increasing demand for reliable communication protocols like Modbus in manufacturing, energy, and building management systems. According to a 2023 report by Mordor Intelligence, the global industrial communication market—of which Modbus remains a foundational protocol—is projected to grow at a CAGR of over 8.5% from 2023 to 2028. As legacy systems continue to interface with modern automation solutions, the need for high-performance, noise-resistant Modbus cables has become critical. This resurgence in demand has elevated the role of specialized cable manufacturers capable of delivering durable, shielded, and protocol-optimized solutions. Based on market presence, product reliability, and technical innovation, the following six manufacturers have emerged as leaders in supplying Modbus communication cables across industrial sectors worldwide.

Top 6 Modbus Cable Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Modbus Cable for Industrial Automation

Domain Est. 2021

Website: industrialautomationworld.com

Key Highlights: The Modbus Cable is a high-performance solution designed for industrial communication, specifically tailored for Modbus protocols. Featuring a durable black ……

#2 Modbus Cable

Domain Est. 1997

Website: belden.com

Key Highlights: You can interface quickly and easily with most existing plant control architectures by using Belden Modbus Cables. Multiple options are available….

#3 Modbus Organization

Domain Est. 1998

Website: modbus.org

Key Highlights: The Modbus Organization is a group of independent users and suppliers of automation devices. We seek to drive the adoption of the Modbus communication protocol ……

#4 Modbus Cable

Domain Est. 1998

Website: fscables.com

Key Highlights: Out of stockDeveloped by Modicon, Modbus provides a master/slave communication between intelligent automation devices. Based on Belden 9841, the Modbus cable has an ……

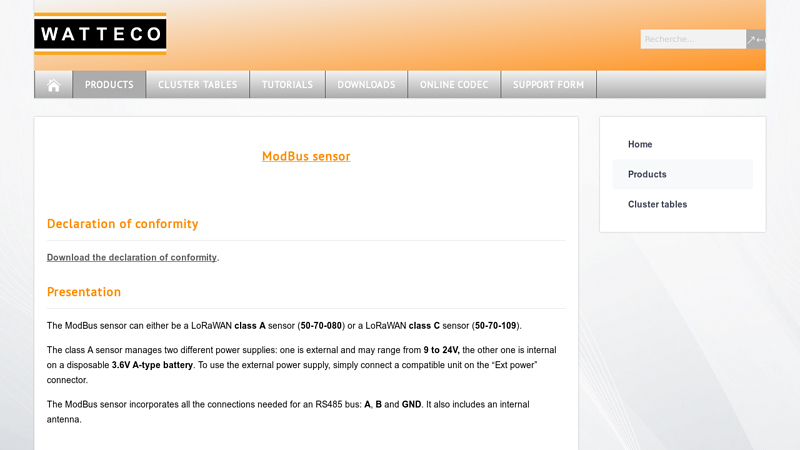

#5 ModBus

Domain Est. 2000

Website: support.watteco.com

Key Highlights: The ModBus sensor allows communication (via the LoRaWAN network) with any equipment that implements the ModBus protocol as slave. Thus, it works as a ModBus ……

#6 External Power and Modbus Communication Cable (25 Ft.)

Domain Est. 2004

Website: store.teledyneisco.com

Key Highlights: External power and Modbus communication cable (25 ft.). Used on the DuraTracker®. Includes a plug for easy connection to the front panel of the DuraTracker®….

Expert Sourcing Insights for Modbus Cable

H2: 2026 Market Trends for Modbus Cable

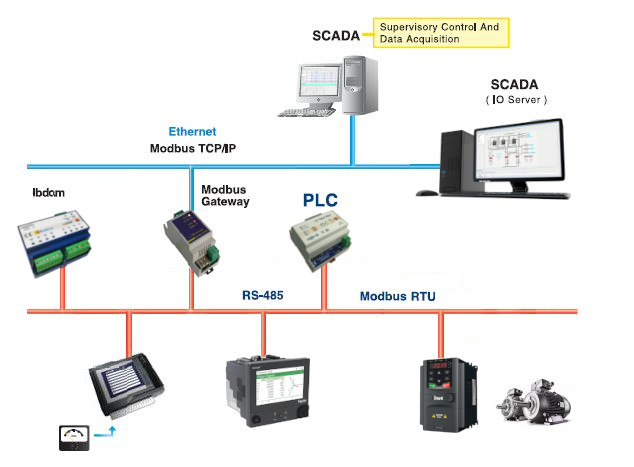

The Modbus cable market is poised for steady growth through 2026, driven by the ongoing expansion of industrial automation, the integration of legacy systems with modern control networks, and the rising demand for reliable, cost-effective communication solutions in industrial environments. As industries adopt Industry 4.0 principles and smart manufacturing technologies, the need for dependable serial communication infrastructure remains strong—particularly in applications where Modbus RTU and Modbus ASCII protocols are still widely used over RS-485 cabling.

A key trend shaping the 2026 landscape is the sustained demand for Modbus-compatible cabling in retrofitting older industrial systems. Many manufacturing facilities, energy plants, and building management systems continue to rely on Modbus for device communication due to its simplicity, low cost, and interoperability across vendors. This creates a consistent market for shielded twisted-pair Modbus cables, especially those designed for noise immunity and long-distance transmission in electrically noisy environments.

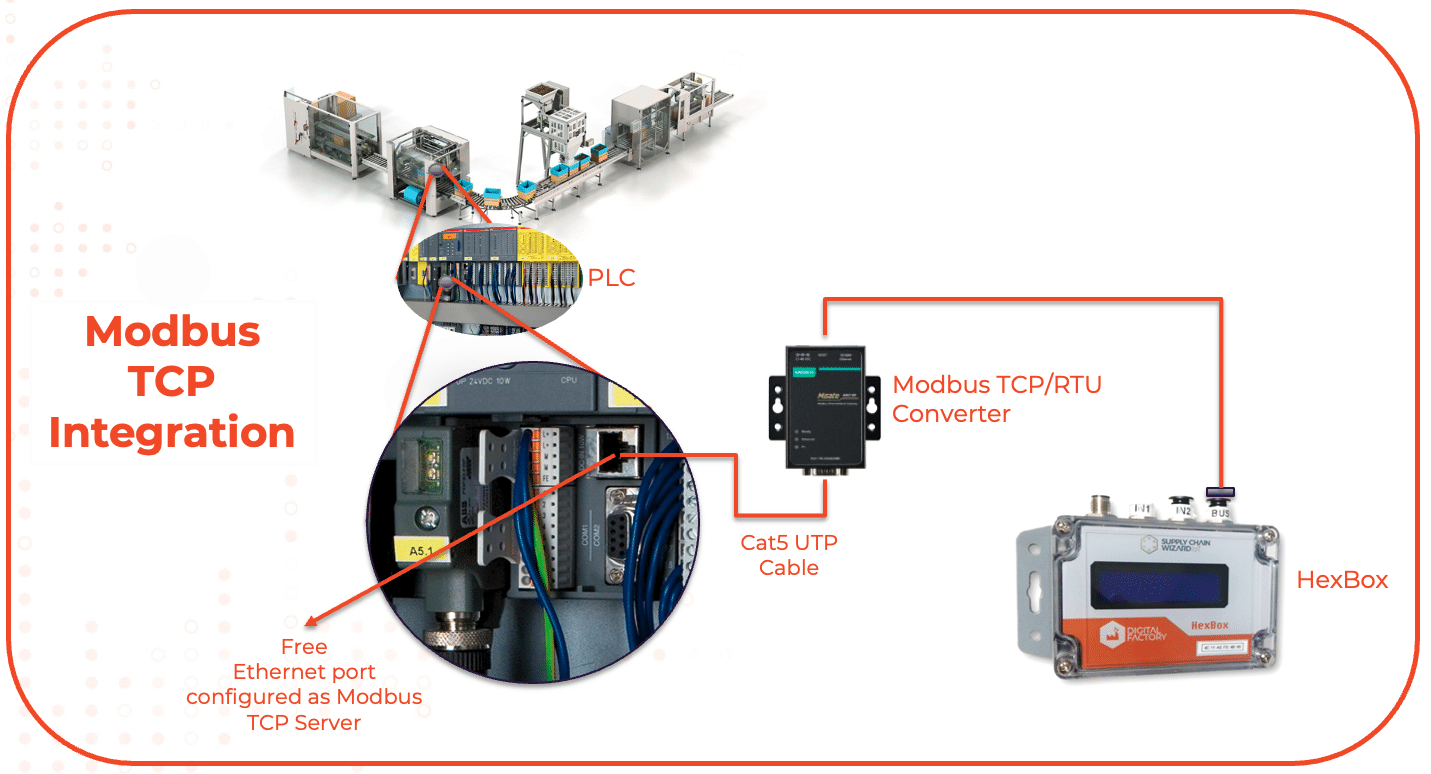

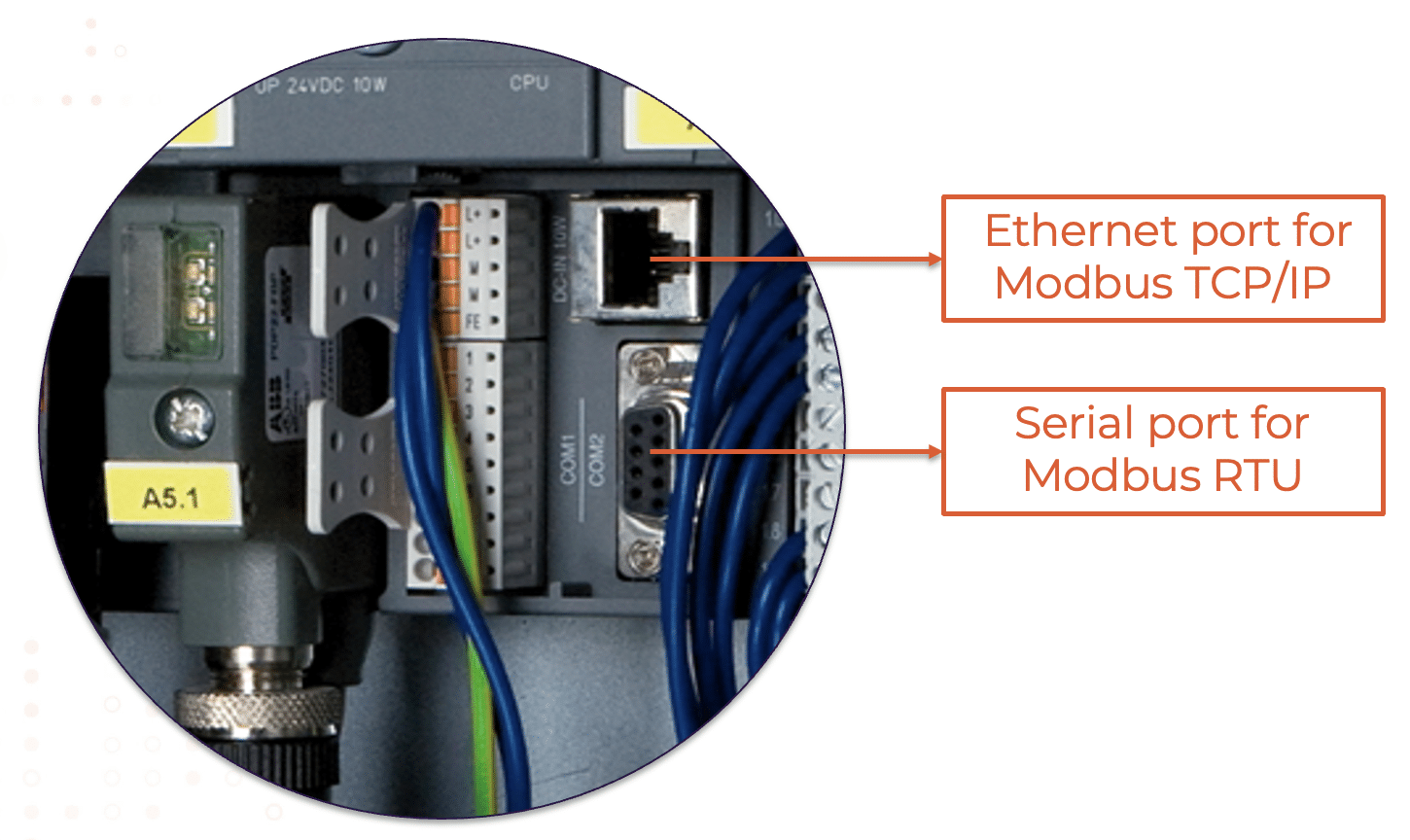

Another significant trend is the convergence of Modbus with modern communication gateways and IoT platforms. While Ethernet-based protocols like Modbus TCP are gaining ground, many edge devices still use RS-485-based Modbus, necessitating hybrid infrastructures. This drives demand for high-quality Modbus cables that ensure signal integrity between field devices and protocol converters.

Additionally, regional growth in emerging economies—particularly in Asia-Pacific and Latin America—where industrialization is accelerating, supports increased adoption of industrial control systems reliant on Modbus. Infrastructure investments in water treatment, oil & gas, and HVAC sectors further bolster demand for dependable cabling solutions.

By 2026, while newer digital communication technologies continue to emerge, the Modbus cable market is expected to maintain relevance due to its proven reliability, ease of implementation, and extensive installed base. Manufacturers are responding with enhanced cable designs featuring better shielding, UV and abrasion resistance, and compliance with industrial standards (e.g., CE, UL, TIA/EIA-485), ensuring longevity and performance in harsh environments.

In summary, the 2026 Modbus cable market reflects a blend of legacy support and modern adaptation, with steady demand anchored in industrial resilience, retrofit projects, and the enduring utility of serial communication in automated systems.

Common Pitfalls When Sourcing Modbus Cables (Quality and IP Rating)

When sourcing Modbus cables for industrial automation and communication systems, overlooking critical quality and environmental protection factors can lead to system failures, data loss, and costly downtime. Below are key pitfalls to avoid:

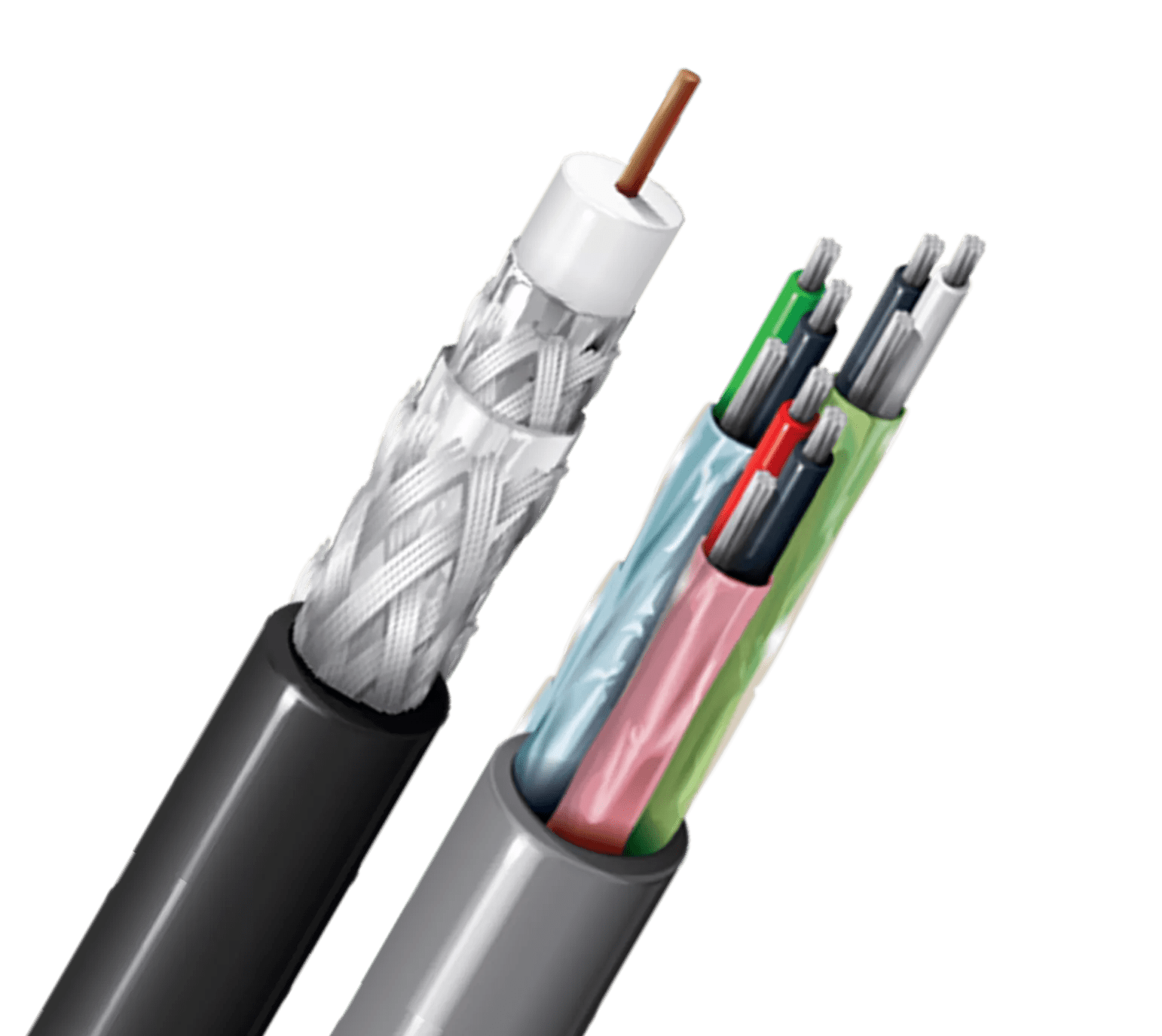

Poor Cable Quality and Construction

Using substandard Modbus cables often results in unreliable communication. Low-quality conductors, inadequate shielding, and improper insulation can lead to signal attenuation, electromagnetic interference (EMI), and crosstalk. These issues are especially problematic in environments with high electrical noise, such as near motors or VFDs. Always verify that the cable uses twisted-pair conductors with proper shielding (e.g., foil + braid) and is rated for industrial use (e.g.,符合RS-485 standards). Avoid cables with thin copper-clad aluminum (CCA) conductors, which increase resistance and reduce signal integrity.

Incorrect or Missing IP Rating for Environmental Conditions

A common oversight is selecting Modbus cables without appropriate Ingress Protection (IP) ratings for the installation environment. For example, using an indoor-rated cable (e.g., IP20) in outdoor or washdown areas exposes the cable to moisture, dust, and chemicals, leading to corrosion and short circuits. Always match the IP rating to the environment—use IP67 or IP68-rated cables for wet, dusty, or outdoor applications. Ensure connectors and junctions also maintain the required IP rating to preserve system integrity.

Logistics & Compliance Guide for Modbus Cable

Overview

This guide outlines the essential logistics and compliance considerations for the procurement, handling, transportation, and use of Modbus cables. These cables are commonly used in industrial automation for serial communication (typically RS-485 or RS-232) and must adhere to technical, safety, and regulatory standards.

Product Specifications

- Protocol: Modbus RTU or ASCII over RS-485/RS-232

- Conductor Type: Typically twisted-pair, shielded copper (18–24 AWG)

- Shielding: Foil and/or braid shield for EMI protection

- Jacket Material: PVC, PE, or LSZH (Low Smoke Zero Halogen)

- Connectors: DB9, terminal blocks, or screw terminals

- Operating Temperature: -20°C to +75°C (industrial grade)

- Compliance Standards: CE, RoHS, REACH, UL (where applicable)

Regulatory Compliance

CE Marking

- Required for distribution in the European Economic Area (EEA).

- Ensures compliance with EMC Directive (2014/30/EU) and RoHS (2011/65/EU).

- Verify manufacturer’s Declaration of Conformity (DoC) is available.

RoHS Compliance

- Restricts the use of hazardous substances (e.g., lead, mercury, cadmium).

- Confirm cable materials meet RoHS limits (Pb < 0.1%, Cd < 0.01%, etc.).

REACH Regulation

- Requires disclosure of Substances of Very High Concern (SVHC).

- Suppliers must provide SVHC documentation upon request.

UL Listing (North America)

- Optional but recommended for industrial environments.

- Look for UL 2464 or UL 444 certification for wire and cable safety.

Other Regional Standards

- Canada: CSA C22.2 No. 210

- China: CCC Mark (if required for integrated devices)

- UK: UKCA marking post-Brexit (for UK market)

Packaging & Labeling Requirements

- Inner Packaging: Anti-static bags for connectors; spooled or cut-to-length with protective caps.

- Outer Packaging: Sturdy cardboard with moisture-resistant lining if needed.

- Labels Must Include:

- Product name and part number

- Length and gauge (e.g., 22 AWG)

- Compliance marks (CE, RoHS, etc.)

- Manufacturer name and contact

- Batch/lot number and date of manufacture

Storage & Handling

- Environment: Dry, temperature-controlled area (5°C to 40°C). Avoid direct sunlight and corrosive atmospheres.

- Shelf Life: Typically 3–5 years; inspect for jacket brittleness or conductor corrosion before use.

- Handling: Avoid sharp bends (minimum 6x cable diameter bend radius); prevent kinking or crushing.

Transportation Guidelines

- Mode of Transport: Suitable for air, sea, or ground freight.

- Hazard Classification: Non-hazardous (unless containing regulated materials).

- Documentation: Include packing list, commercial invoice, and compliance certificates.

- Special Handling: No specific requirements, but shielded cables should avoid high EMI exposure during transit.

Import/Export Considerations

- HS Code Example: 8544.42.00 (Insulated wires, cables for telecommunication)

- Customs Documentation: Bill of lading, commercial invoice, certificate of origin, compliance declarations.

- Restricted Destinations: Check for sanctions or import bans (e.g., certain countries under ITAR or EAR).

- Duty Rates: Vary by country; confirm with local customs broker.

Environmental & Disposal Compliance

- End-of-Life: Classify as electronic waste (WEEE).

- Disposal: Recycle through certified e-waste handlers. Do not landfill.

- Material Recovery: Copper and plastic components are recyclable.

Supplier & Quality Assurance

- Qualification: Source from ISO 9001-certified suppliers.

- Incoming Inspection: Verify length, continuity, shielding integrity, and labeling accuracy.

- Traceability: Maintain lot-level traceability for compliance audits.

Summary

Proper logistics and compliance management of Modbus cables ensures reliability, legal distribution, and environmental responsibility. Always verify certifications, maintain documentation, and follow handling best practices throughout the supply chain.

Conclusion for Sourcing Modbus Cable:

Sourcing the appropriate Modbus cable is a critical step in ensuring reliable and efficient communication within industrial automation and control systems. After evaluating factors such as cable type (RS-485 being the most common for Modbus RTU), shielding, wire gauge, connector types, and environmental durability, it is clear that selecting a high-quality, properly specified cable significantly enhances system performance and reduces the risk of data errors or communication failures.

It is recommended to source cables from reputable suppliers or manufacturers that comply with industry standards (such as TIA/EIA-485) and offer products designed for industrial environments. Additionally, considering future scalability, ease of installation, and compatibility with existing devices will contribute to long-term operational efficiency.

In summary, a well-informed sourcing decision—balancing cost, quality, and technical specifications—ensures robust Modbus communication, minimizes downtime, and supports the overall reliability of the control network.