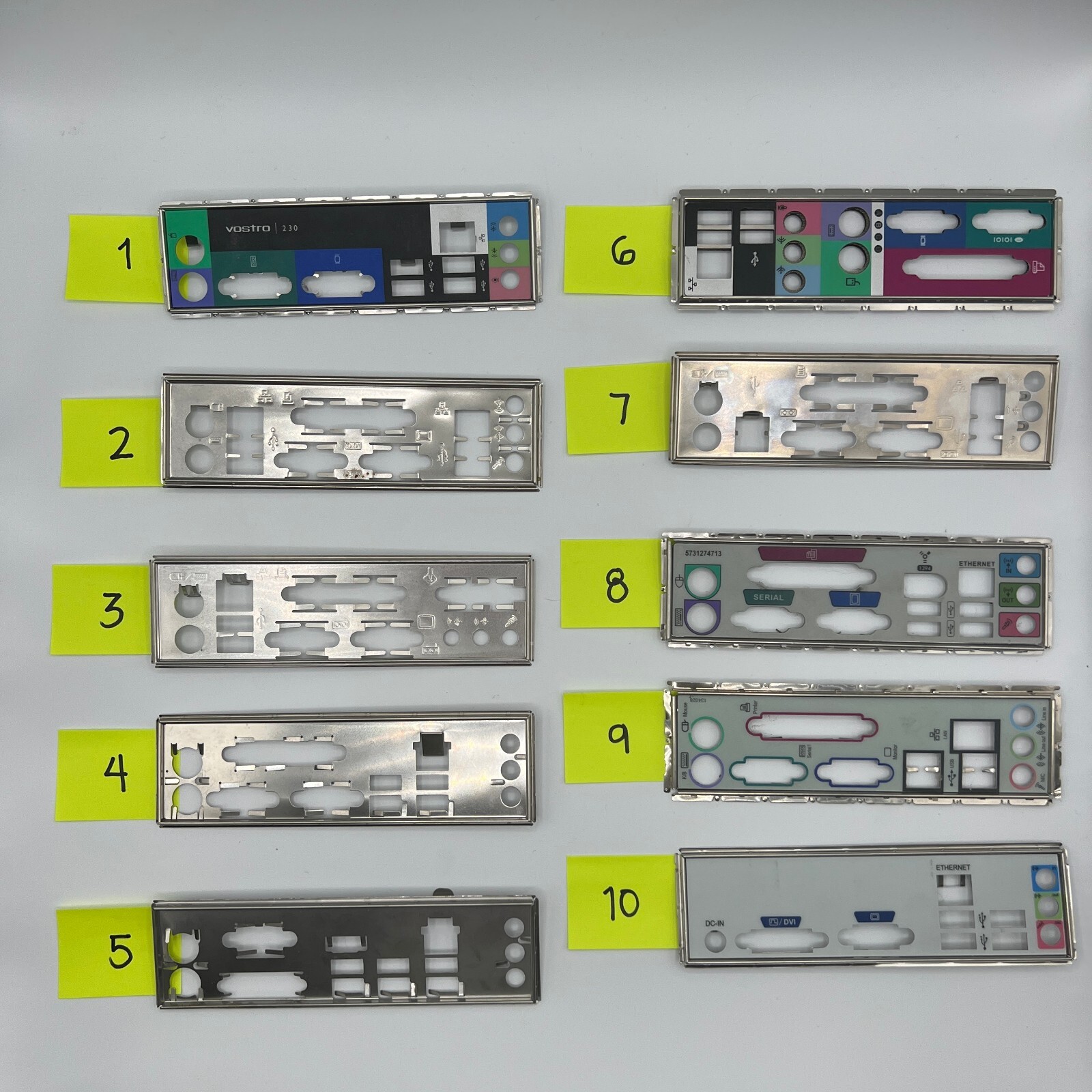

The motherboard I/O shield market has experienced steady growth, driven by increasing demand for high-performance computing, gaming PCs, and compact form-factor builds. According to a report by Mordor Intelligence, the global PC motherboard market is projected to grow at a CAGR of over 5.8% from 2023 to 2028, with a parallel uptick in demand for complementary components like custom I/O shields. These shields—essential for EMI shielding, grounding, and aesthetic finish—have evolved from basic metal pieces to precision-engineered, brand-integrated accessories. As OEMs and aftermarket manufacturers emphasize system customization and electromagnetic compatibility, companies specializing in I/O shields are scaling production and innovation. Driven by advancements in material technology and alignment with next-gen motherboards (including ATX, micro-ATX, and Mini-ITX), the market is seeing consolidation among key players offering both standard and customized shielding solutions. This growth trajectory underscores the rising importance of I/O shield manufacturers in the broader PC hardware ecosystem.

Top 5 Mobo Io Shield Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Innovation in I/O Shields for the PC Industry

Domain Est. 1999

Website: demandtechnology.com

Key Highlights: To address the varied demands of the PC industry, Demand Technology developed an extensive range of I/O shield designs, customised for different motherboard ……

#2 IO Shields

Domain Est. 1996

#3 io shield

Domain Est. 2000

Website: newegg.com

Key Highlights: 4–7 day deliveryIO I/O Shield BackPlate Baffle for RTX4060 8GB D6 Twin Cooler Graphics Card Holder Bezel Blocking Plate Panel. $21. Free Shipping. Compare. Add To Wish List….

#4 Removing the Pre-installed I/O Shield

Domain Est. 2003

Website: overclock.net

Key Highlights: Hi, Does anyone know how to safely remove the pre-installed I/O shield? I don’t need it….it’s in my way and it’s gotta go!…

#5 Design Your Own IO Shield

Domain Est. 2014

Website: makerworld.com

Key Highlights: Design Your Own … Open the 3mf project file to find an example of a custom IO shield that you can edit in Bambu Studio to customize to your motherboard’s needs….

Expert Sourcing Insights for Mobo Io Shield

H2: 2026 Market Trends for MOBO I/O Shields

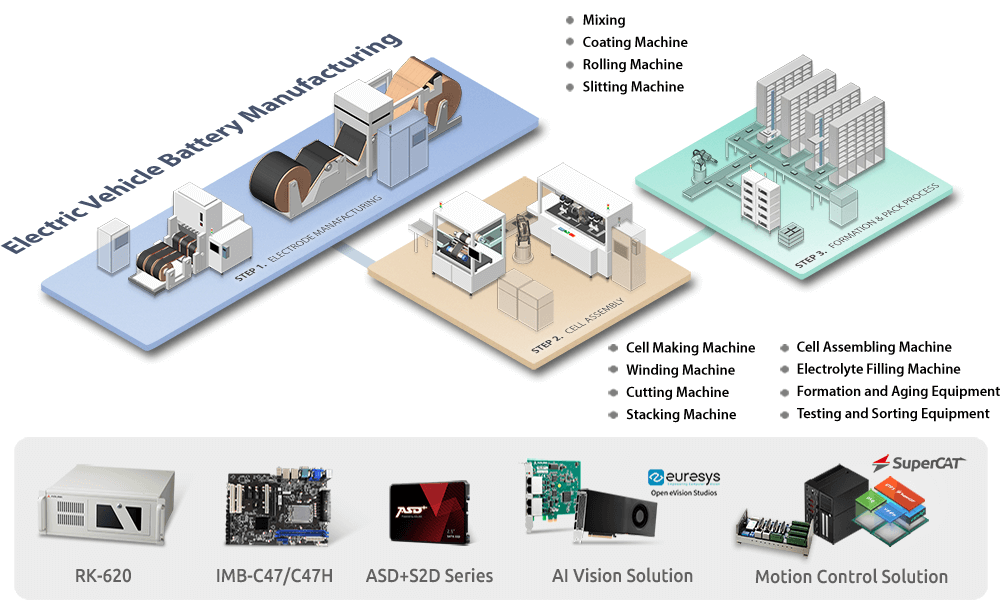

By 2026, the market for Motherboard Input/Output (I/O) Shields—also known as I/O plates or backplates—will evolve in response to broader trends in PC hardware, consumer preferences, and technological advancements. While I/O shields themselves are low-cost, passive components, their design, integration, and value proposition will be shaped by several key dynamics:

1. Increased Customization & Aesthetics as a Value Driver

The PC enthusiast and gaming markets will continue prioritizing visual appeal and personalization. As a result, I/O shields will transition from purely functional components to key aesthetic elements. Expect:

* Proliferation of Branded & Themed Shields: Manufacturers like ASUS (ROG), MSI (Mystic Light), Gigabyte (AORUS), and ASRock (Phantom Gaming) will offer shields with intricate laser-etched logos, RGB lighting integration (via motherboard headers or direct connection), and unique color finishes (brushed metal, anodized aluminum, matte black).

* Modular & Aftermarket Options: A growing niche aftermarket will provide customizable shields with swappable panels, enhanced materials (e.g., copper, brass, acrylic), and designs tailored for specific case windows or build themes.

2. Integration with Advanced Connectivity & Thermal Management

As motherboards pack more high-bandwidth ports (USB4, Thunderbolt 4, 10G/25G Ethernet, Wi-Fi 7 antennas), I/O shields will need to adapt:

* EMI/RFI Shielding Enhancement: With denser signal routing and higher frequencies, effective electromagnetic interference (EMI) and radio-frequency interference (RFI) shielding provided by the metal plate will become even more critical for signal integrity and regulatory compliance. Materials and grounding techniques will improve.

* Thermal & Airflow Optimization: Shields may incorporate subtle design features (e.g., optimized cutout shapes, thermal pads) to aid in heat dissipation from nearby VRMs or M.2 slots, especially in compact or high-performance systems. Ventilation patterns might be refined for better case airflow.

3. Standardization Pressures vs. Proprietary Designs

The tension between ATX standardization and OEM-specific features will persist:

* ATX 3.0 & Future Standards: Wider adoption of ATX 3.0 and potential future revisions may influence shield dimensions and grounding requirements, promoting some level of standardization for compatibility.

* Proprietary Lock-in: Major manufacturers will continue using unique shield designs (custom fit, integrated components) to ensure brand recognition and potentially lock users into their ecosystem for replacements or upgrades, despite minor standardization.

4. Sustainability and Material Innovation

Environmental concerns will influence material choices:

* Recyclable Materials: Increased use of recyclable aluminum and steel, with reduced plastic components.

* Durability Focus: Thicker gauge metals or corrosion-resistant coatings to extend product lifespan and reduce e-waste, aligning with broader sustainability trends in tech.

5. Automation and Supply Chain Efficiency

Manufacturing will see further optimization:

* Precision Stamping & Laser Cutting: Wider use of automated processes for tighter tolerances and complex designs at scale.

* Just-in-Time Integration: Closer coordination between motherboard assemblers and shield suppliers to reduce inventory and streamline logistics, especially for customized variants.

Conclusion:

By 2026, the MOBO I/O shield market will be characterized by a shift from pure functionality toward integrated design, enhanced performance support, and brand expression. While remaining a low-cost component, its role in system aesthetics, electromagnetic compliance, and thermal management will elevate its strategic importance for motherboard OEMs. Success will hinge on balancing standardization for compatibility with innovation in materials, customization, and integration to meet the demands of increasingly sophisticated and design-conscious consumers.

Common Pitfalls Sourcing Motherboard I/O Shields (Quality, IP)

Sourcing Motherboard I/O Shields (also known as backplates or rear shields) may seem straightforward, but several critical pitfalls can compromise product quality, brand integrity, and legal compliance—especially when dealing with generic or third-party suppliers. Here are key issues to watch for:

Poor Material and Build Quality

Many low-cost I/O shields are made from substandard materials such as thin, untempered steel or low-grade plastic. This can lead to sharp edges, warping during installation, poor EMI (electromagnetic interference) shielding, and inadequate grounding. Inferior plating (e.g., missing or thin conductive coatings) reduces shielding effectiveness and increases the risk of electrical interference or component damage.

Inaccurate Dimensions and Misalignment

Generic or reverse-engineered shields often suffer from dimensional inaccuracies. Even minor deviations can prevent proper fitment with the motherboard or chassis, leading to gaps that compromise EMI shielding, aesthetics, and structural integrity. Misaligned ports may hinder connector access or cause damage to cables and motherboard components during assembly.

Lack of Electromagnetic Interference (EMI) Shielding

A primary function of the I/O shield is to provide electromagnetic shielding. Poorly manufactured shields may lack proper contact fingers, grounding tabs, or continuous conductive surfaces, reducing their ability to contain EMI. This can lead to signal interference, reduced system stability, and non-compliance with regulatory standards (e.g., FCC, CE).

Intellectual Property (IP) Infringement Risks

Motherboard I/O shields are often protected by design patents, trademarks, and other intellectual property rights. Sourcing unlicensed replicas—especially those bearing branded logos or exact proprietary designs—exposes buyers and resellers to legal liability. Unauthorized duplication violates IP laws and can result in customs seizures, fines, or litigation, particularly in regions with strict IP enforcement.

Inconsistent Finish and Aesthetics

Low-quality shields may have inconsistent paint, poor anodization, or visible manufacturing defects (e.g., burrs, uneven edges). For OEMs or system integrators focused on premium build quality, such flaws can damage brand perception and customer satisfaction.

Supply Chain and Traceability Issues

Sourcing from unverified suppliers increases the risk of inconsistent batch quality and lack of traceability. Without proper documentation or compliance certifications (e.g., RoHS, REACH), businesses may face challenges in audits, product recalls, or environmental compliance.

Conclusion

To avoid these pitfalls, always source I/O shields from authorized suppliers or manufacturers with proven quality control and IP compliance. Verify material specifications, conduct fitment testing, and ensure all designs are either licensed or original to mitigate quality and legal risks.

Logistics & Compliance Guide for Mobo Io Shield

This guide outlines the logistics and compliance requirements for the Mobo Io Shield, ensuring smooth handling, transportation, and regulatory adherence throughout its lifecycle.

Product Overview

The Mobo Io Shield is an input/output (I/O) expansion module designed to interface with motherboard-based systems, providing additional connectivity options such as USB, Ethernet, audio, and GPIO. It is typically used in industrial automation, embedded computing, and custom PC builds.

Packaging & Labeling Requirements

All units must be packaged in anti-static bags and placed within rigid cardboard boxes with internal cushioning to prevent mechanical damage. Each package must include:

– Product name and model number (Mobo Io Shield v1.X)

– Manufacturer name and address

– CE, FCC, and RoHS compliance marks (as applicable)

– Serial number and batch code

– “Fragile” and “This Side Up” handling indicators

– Barcode for inventory tracking

Shipping & Handling

- Storage Conditions: Store in a dry, temperature-controlled environment (5°C to 40°C, humidity <60% RH).

- Transportation: Use certified carriers compliant with ISO 9001 and ISO 14001 standards. Avoid exposure to extreme temperatures, moisture, and direct sunlight during transit.

- Handling: Use ESD-safe practices when unpacking or installing. Personnel must wear grounded wrist straps in production or repair environments.

Regulatory Compliance

The Mobo Io Shield complies with the following international standards:

– CE Marking: Conforms to EMC Directive 2014/30/EU and RoHS Directive 2011/65/EU.

– FCC Part 15, Subpart B: Certified for Class B digital devices (domestic use).

– RoHS Compliance: Contains no restricted substances above permissible levels (Pb, Cd, Hg, etc.).

– REACH: Compliant with SVHC (Substances of Very High Concern) disclosure requirements.

– WEEE: Labeled for proper electronic waste disposal; recyclable through authorized facilities.

Import/Export Documentation

For international shipments, ensure the following documents are prepared:

– Commercial Invoice (with HS Code: 8537.10.90 – Control panels for electrical apparatus)

– Packing List

– Certificate of Origin

– FCC ID and CE Declaration of Conformity (available upon request)

– Export Control Classification Number (ECCN): 5A992.c (subject to EAR regulations)

Environmental & Safety Compliance

- Dispose of end-of-life units at certified e-waste recycling centers.

- Avoid incineration or landfill disposal to comply with WEEE and local environmental laws.

- Safety data sheets (SDS) available for component materials upon request.

Warranty & Support

- 24-month limited warranty against manufacturing defects.

- Support available via authorized distributors or manufacturer’s technical team.

- Return Material Authorization (RMA) required for all warranty claims.

For further information, contact [email protected] or visit www.moboioshield.com/compliance.

Conclusion for Sourcing Motherboard I/O Shields:

Sourcing motherboard I/O shields requires a strategic approach that balances cost, compatibility, quality, and supply chain reliability. After evaluating various options—including purchasing from OEMs, third-party suppliers, or manufacturing in-house—it is evident that the most effective solution depends on specific project requirements, scale of production, and customization needs. For most system integrators and PC builders, sourcing OEM-compatible or branded I/O shields ensures proper fit, EMI shielding, and aesthetic alignment with the motherboard design. However, for custom or niche builds, partnering with specialized manufacturers offers the flexibility to design unique shielding solutions.

Ultimately, establishing strong relationships with reliable suppliers, verifying material and EMI performance standards, and maintaining inventory flexibility are key to efficient sourcing. As motherboard designs continue to evolve, particularly with customizable backplates and modular I/O, staying informed and adaptable in the supply chain will remain crucial for long-term success.