The global variable frequency drive (VFD) market, which includes Mitsubishi D700 series inverters, is experiencing robust growth driven by rising demand for energy-efficient motor control systems across industrial and commercial sectors. According to Grand View Research, the global VFD market size was valued at USD 14.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is fueled by increasing industrial automation, stringent energy efficiency regulations, and the integration of smart manufacturing technologies. As one of Mitsubishi Electric’s most widely adopted general-purpose inverters, the D700 series plays a critical role in HVAC, pump, and fan applications, making the selection of reliable manufacturers essential for performance and longevity. Based on market presence, production capabilities, and compliance with Mitsubishi’s technical standards, the following are the top five manufacturers producing the Mitsubishi D700 series and its compatible variants.

Top 5 Mitsubishi D700 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

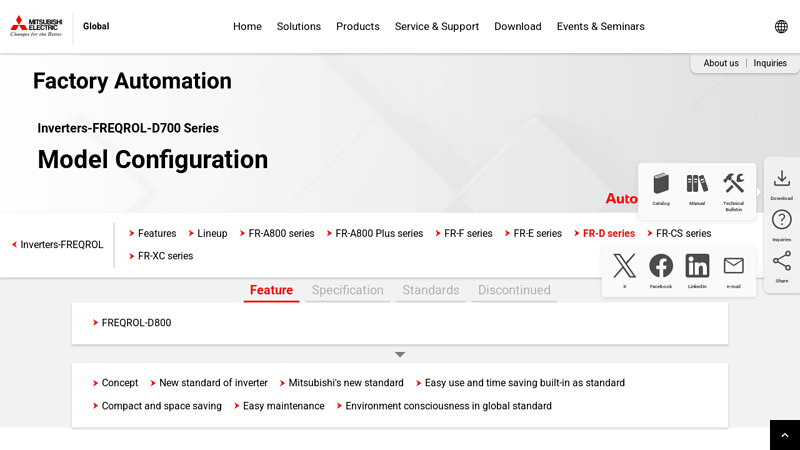

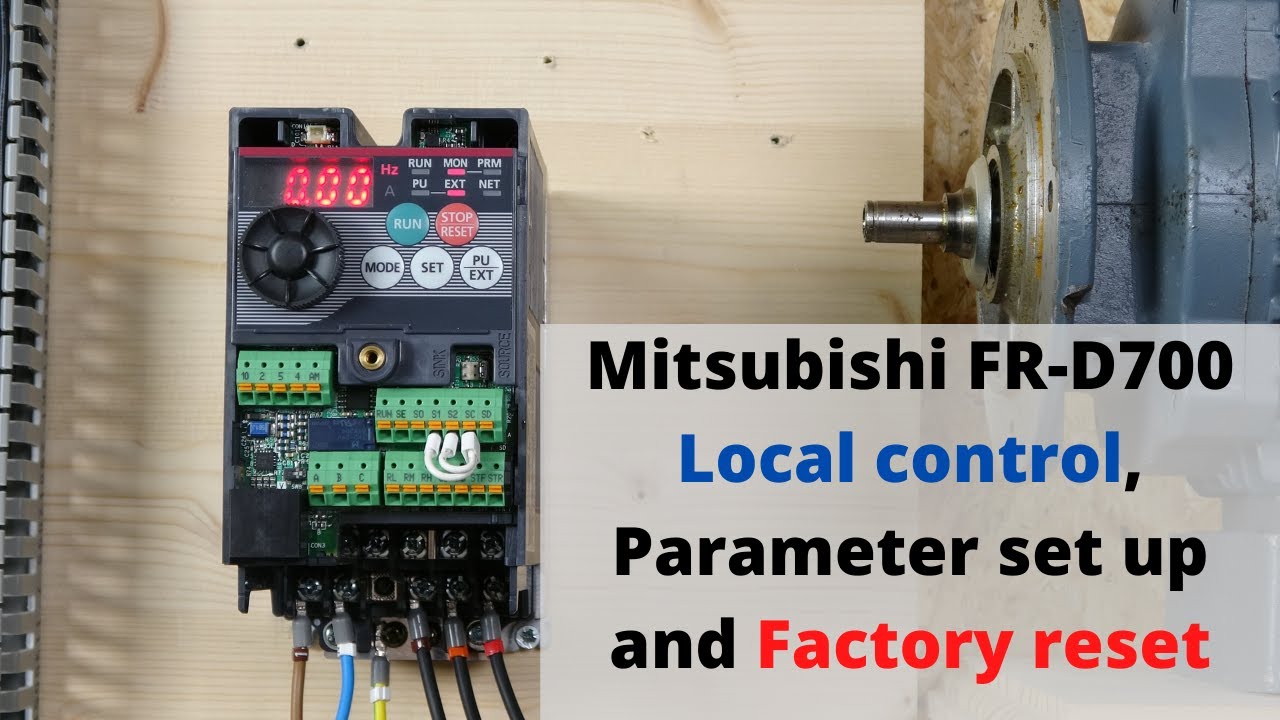

#1 FR-D700 Series Inverters

Domain Est. 1996

Website: us.mitsubishielectric.com

Key Highlights: Discover the compact FR‑D700 VFD series, designed for industrial automation with high torque, easy wiring via spring-clamp terminals, safety stop function, ……

#2 MITSUBISHI D700 SERIES 1HP, AC INVERTER 460V

Domain Est. 1996

Website: alliedelectronics.com

Key Highlights: MITSUBISHI D700 SERIES 1HP, AC INVERTER 460V Outright Purchase. Technical Specs. Manufacturer: Rebuilt Parts Brand: Mitsubishi Model: Variable Frequency Drive….

#3 Modbus RTU RS 485 communication with Mitsubishi VFD D700

Domain Est. 1994

Website: forums.ni.com

Key Highlights: I am having some serious problems when trying to communicate with with my Mitsubishi D700 VFD through serial port in LabVIEW using the NI VISA set of functions….

#4 Model Configuration

Domain Est. 1996

Website: mitsubishielectric.com

Key Highlights: Lineup. The lineup of three phase 200V/400V class goes to 15K. For a use in harsh environment, special unit with board coating is also available….

#5 Mitsubishi FR

Website: asb-drives.eu

Key Highlights: The Mitsubishi Electric FR-D700 frequency inverter series makes these units a particularly good choice for standard applications….

Expert Sourcing Insights for Mitsubishi D700

H2: Projected 2026 Market Trends for the Mitsubishi Fuso Canter (D700)

As of 2026, the Mitsubishi Fuso Canter, powered by the D700 series diesel engine, continues to play a significant role in the light and medium-duty commercial vehicle segment, particularly in emerging markets and urban logistics sectors. While the D700 engine itself—known for its 3.0L or 4.9L displacement depending on configuration (note: actual D700 refers to engine family variants in Fuso models)—is not a standalone product, its integration into the Canter lineup influences market dynamics. Below are key trends shaping the D700-powered Mitsubishi Fuso Canter in 2026:

-

Gradual Transition Toward Electrification

The 2026 landscape sees accelerated adoption of electric vehicles (EVs), with Mitsubishi Fuso leading through its eCanter model. As governments enforce stricter emissions standards (e.g., Euro 6d, Japan’s Post-New Long-Term Emissions Regulations), demand for diesel-powered D700 vehicles is declining in urban centers. However, the D700 engine remains relevant in regions with limited EV infrastructure or where high payload and range requirements favor internal combustion engines. -

Market Regionalization and Niche Demand

In Asia-Pacific (particularly Southeast Asia, India, and Oceania), Africa, and parts of Latin America, the D700-powered Canter maintains strong demand due to fuel availability, lower upfront costs, and proven durability. These regions continue to rely on diesel for commercial transport, supporting sustained aftermarket and service needs for the D700 platform. -

Aftermarket and Total Cost of Ownership (TCO) Focus

Fleet operators prioritize reliability and low maintenance costs. The D700 engine’s reputation for durability enhances residual value and supports a robust aftermarket ecosystem. By 2026, certified remanufactured D700 engines and components are in higher demand as cost-conscious buyers seek affordable, reliable options amid rising new vehicle prices. -

Regulatory Pressures and Retrofitting Trends

Emission regulations are pushing older D700 variants (pre-Euro 5) out of major cities. In response, some operators are retrofitting D700 engines with improved exhaust after-treatment systems (e.g., selective catalytic reduction or diesel particulate filters) to extend operational life and comply with local norms. This trend is especially notable in developing economies undergoing phased regulatory rollouts. -

Competition from Hybrid and Alternative Fuel Models

While Mitsubishi Fuso emphasizes full electrification, competitors are introducing hybrid light-duty trucks. The D700 engine may see integration into mild hybrid systems in select markets by 2026 as a transitional solution—though official Mitsubishi Fuso plans focus more on full EVs than hybridization of the D700 line. -

Fleet Digitization and Telematics Integration

Even diesel-powered Canter models with the D700 engine are being equipped with advanced telematics (e.g., Fuso Connect). This enables real-time monitoring of engine performance, fuel efficiency, and maintenance needs—improving operational efficiency and prolonging engine life in commercial fleets.

Conclusion:

While the Mitsubishi D700 engine platform is in a phase of managed decline due to electrification trends, it remains a critical asset in specific geographic and operational niches through 2026. Its market presence is being sustained by reliability, cost efficiency, and supportive aftermarket networks, even as Fuso’s strategic focus shifts toward electric mobility. The D700’s role is increasingly transitional, serving as a bridge technology in markets not yet ready for full electrification.

Common Pitfalls When Sourcing Mitsubishi D700 (Quality, IP)

1. Counterfeit or Substandard Units

One of the most significant risks when sourcing Mitsubishi D700 inverters is encountering counterfeit or refurbished units misrepresented as new. These may lack proper manufacturing standards, leading to early failure, inconsistent performance, or safety hazards. Always verify authenticity through authorized distributors and check for genuine Mitsubishi packaging, labels, and serial numbers traceable via Mitsubishi’s official database.

2. Lack of Genuine IP Protection

The Mitsubishi D700 series is designed with specific Ingress Protection (IP) ratings (e.g., IP20 for standard models). Sourcing from unreliable suppliers may result in units with compromised enclosures or incorrect IP ratings, especially if the device has been tampered with or repackaged. Using an inverter in an environment exceeding its IP rating can lead to dust, moisture, or particulate ingress, causing internal damage and voiding warranties.

3. Incomplete or Fake Documentation

Counterfeit or gray-market units often come with incomplete, inaccurate, or falsified technical documentation and compliance certificates. This includes missing CE, RoHS, or UL certifications, which are essential for regulatory compliance and safe integration. Always request and verify official product manuals, conformity statements, and test reports directly from Mitsubishi or authorized partners.

4. Absence of Firmware and Software Authenticity

Unauthorized sources may supply units with outdated, modified, or pirated firmware. This can impact performance, compatibility with control systems, and access to critical updates. Genuine Mitsubishi software tools (e.g., FR Configurator2) may not recognize or support non-authentic units, limiting configuration and diagnostics capabilities.

5. No Access to Warranty or Technical Support

Units sourced through unofficial channels typically do not qualify for Mitsubishi’s manufacturer warranty or technical support. If a quality issue arises, resolving it can become costly and time-consuming. Always confirm warranty eligibility by purchasing through certified distributors and registering the product with Mitsubishi.

6. Inconsistent Quality from Third-Party Sellers

Even on reputable marketplaces, third-party sellers may offer “compatible” or “branded” versions that mimic the D700 but lack Mitsubishi’s build quality and reliability. These units may use inferior components, leading to overheating, noise, or motor control inaccuracies. Stick to Mitsubishi-authorized resellers to ensure product integrity.

7. Misrepresentation of IP Rating for Harsh Environments

Some suppliers may claim higher IP ratings (e.g., IP55 or IP66) for standard D700 units that inherently have only IP20 protection. This misrepresentation can lead to equipment failure in industrial environments with dust or moisture. For harsh conditions, always use the correct model variant (e.g., D700 with optional enclosure) or consider Mitsubishi’s more rugged series.

Best Practice:

To avoid these pitfalls, source Mitsubishi D700 inverters exclusively through Mitsubishi Electric’s authorized distribution network. Validate supplier credentials, inspect units upon delivery, and verify serial numbers with Mitsubishi support to ensure authenticity, quality, and full IP compliance.

Logistics & Compliance Guide for Mitsubishi D700 Inverters

This guide provides essential information for the safe and compliant handling, transportation, storage, and regulatory adherence related to the Mitsubishi Electric D700 series inverters. Proper logistics and compliance procedures ensure product integrity, personnel safety, and regulatory conformity.

Product Overview and Handling

The Mitsubishi D700 series is a range of compact, general-purpose AC variable frequency drives (VFDs) designed for controlling three-phase induction motors. These inverters are sensitive electronic devices and require careful handling to prevent damage.

- Handling Precautions: Always handle units by the base or mounting flanges. Avoid gripping the front cover, keypad, or heat sink.

- Electrostatic Discharge (ESD): Use appropriate ESD-safe practices when handling, especially in dry environments. Ground personnel and work surfaces before touching the inverter.

- Physical Protection: Keep units in original packaging until ready for installation. Avoid dropping, tipping, or applying pressure to the enclosure.

Packaging and Transportation

Ensure proper packaging and shipping methods to prevent damage during transit.

- Original Packaging: Ship and store units in the manufacturer-supplied packaging, which includes protective foam and a moisture-resistant bag.

- Orientation: Maintain upright orientation (as indicated on the package) during all transport stages. Do not lay units on their side or invert.

- Environmental Conditions: Avoid exposure to extreme temperatures (below -20°C or above 60°C), high humidity, or direct sunlight during transport.

- Stacking: Do not stack more than the recommended number of cartons (refer to packaging label). Use pallets for bulk shipments and secure with straps.

Storage Conditions

Proper storage ensures long-term reliability and prevents internal component degradation.

- Environment: Store in a clean, dry, vibration-free indoor area with ambient temperatures between -20°C and +65°C and relative humidity below 90% (non-condensing).

- Shelf Life: If stored for more than one year before installation, perform an input power check and visual inspection for signs of moisture or corrosion.

- Moisture Control: In humid environments, use desiccants or climate-controlled storage. Avoid condensation by allowing units to acclimate before powering.

Regulatory Compliance and Certifications

Mitsubishi D700 inverters are designed and manufactured to meet international standards. Ensure compliance with local and regional regulations.

- CE Marking: Complies with EU directives including:

- Low Voltage Directive (LVD) 2014/35/EU

- Electromagnetic Compatibility (EMC) Directive 2014/30/EU

- RoHS Directive 2011/65/EU (Restriction of Hazardous Substances)

- UL/cUL Certification: Listed to UL 508C and CSA C22.2 No. 14 for use in the United States and Canada.

- RCM Mark (Australia/New Zealand): Complies with AS/NZS standards for electromagnetic compatibility and safety.

- KC Mark (South Korea): Certified under Korean EMC and safety regulations.

- EAC Mark (Eurasian Economic Union): Meets technical regulations for electromagnetic compatibility and low voltage safety.

Import/Export and Documentation

Ensure all required documentation is provided for international shipments to avoid customs delays.

- Commercial Invoice: Must include product description, model numbers (e.g., FR-D720-0.4K), quantity, value, country of origin (Japan), and Harmonized System (HS) code (typically 8504.40).

- Packing List: Details contents per package, weights, dimensions, and serial numbers if applicable.

- Certificate of Origin: May be required for tariff determination; issued by manufacturer or chamber of commerce.

- RoHS & REACH Compliance Declarations: Provide upon request to confirm absence of restricted substances.

Installation and Site Compliance

Prior to installation, verify local electrical codes and environmental conditions.

- Electrical Standards: Installation must comply with local regulations (e.g., NEC in the U.S., IEC 60364 internationally).

- EMC Installation Guidelines: Use shielded motor cables, proper grounding, and install optional noise filters if required to meet EMC limits.

- Environmental Protection: Ensure installation environment meets IP20 rating (indoor use, protected from dust and moisture).

Disposal and End-of-Life

Follow environmental regulations for end-of-life equipment.

- WEEE Directive (EU): Classifies inverters as electronic waste. Return to authorized collection points or Mitsubishi recycling programs.

- Proper Disposal: Do not dispose of in regular trash. Components contain metals and electronic parts requiring specialized recycling.

- Battery and Capacitors: Internal components may include electrolytic capacitors; handle in accordance with local hazardous waste rules.

By adhering to this logistics and compliance guide, users and distributors can ensure the Mitsubishi D700 inverters are handled, transported, stored, and disposed of in a manner that maintains safety, performance, and regulatory compliance. For model-specific details, consult the official Mitsubishi Electric technical manuals and regional compliance documentation.

Conclusion for Sourcing Mitsubishi D700 Inverters

In conclusion, sourcing the Mitsubishi D700 series inverters offers a reliable and efficient solution for a wide range of industrial motor control applications. Known for their robust performance, user-friendly operation, and advanced features such as energy savings mode, built-in PID control, and comprehensive protection functions, the D700 series remains a preferred choice across various industries.

When sourcing these drives, it is essential to consider factors such as authorized supplier credibility, product authenticity, technical support availability, and compliance with regional standards to ensure long-term reliability and system compatibility. Procuring from reputable distributors or directly through Mitsubishi Electric guarantees genuine products with full warranty and access to firmware updates and engineering support.

Furthermore, evaluating total cost of ownership—factoring in energy efficiency, maintenance needs, and scalability—confirms the D700’s value as a long-term investment. With proper sourcing and integration, the Mitsubishi D700 inverter provides a solid foundation for optimizing motor-driven systems, improving process control, and enhancing operational efficiency.

Therefore, a strategic sourcing approach focused on authenticity, support, and lifecycle benefits will ensure maximum performance and return on investment when implementing the Mitsubishi D700 series in industrial automation projects.