The global misting and fogging technology market is experiencing robust growth, driven by rising demand across agriculture, hospitality, industrial cooling, and healthcare sectors. According to Grand View Research, the global evaporative cooling systems market—of which misting and fogging systems are a key component—was valued at USD 4.2 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is fueled by increasing awareness of energy-efficient cooling solutions and the need for dust suppression and humidification in arid and urban environments. Mordor Intelligence further supports this trajectory, highlighting accelerated adoption in commercial landscaping, greenhouse farming, and outdoor comfort applications, especially in emerging markets across Asia-Pacific and the Middle East. As demand surges, innovation and scalability have become critical differentiators among manufacturers. Based on production capacity, geographic reach, product diversification, and technological advancements, the following ten companies have emerged as leading misting fog manufacturers shaping the future of this dynamic industry.

Top 10 Misting Fog Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Microcool

Domain Est. 1996

Website: microcool.com

Key Highlights: Commercial and industrial humidifier solutions, evaporative cooling fog systems, customized to fit your facility and unique application….

#2 Misting and Humidity Systems

Domain Est. 1999

Website: corriganmist.com

Key Highlights: A market leading manufacturer of humidification and water filtration technologies. Jack’s core principle of designing and manufacturing reliable solutions….

#3 Taizhou Fog Machine Co.,Ltd

Domain Est. 2018

Website: fog-mist.com

Key Highlights: We are the professional fog machine producer and leader in China. We product machine, nozzle, pipe, fitting, mist umbrella and so on….

#4 MISTEC

Domain Est. 2024

Website: mistec-group.com

Key Highlights: We are a leading Provider of High-Quality Misting Systems and Fogging Technologies for Indoor and Outdoor Cooling, Industrial Cooling, Dust Suppression, Odor ……

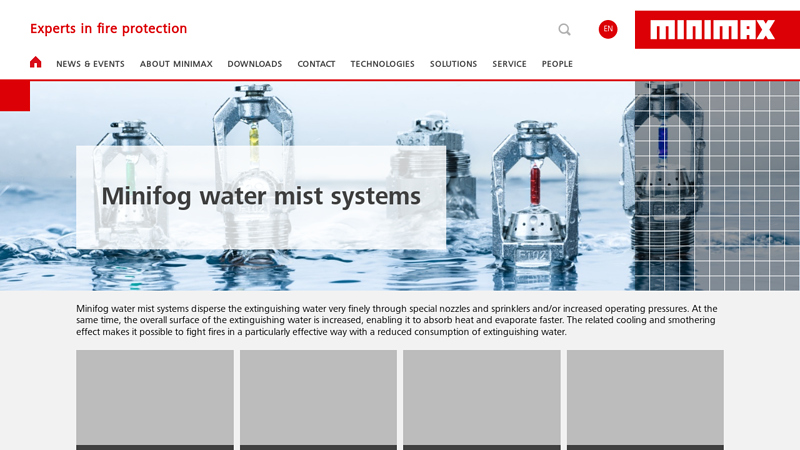

#5 Minifog water mist systems

Domain Est. 1995

Website: minimax.com

Key Highlights: Minifog water mist systems disperse the extinguishing water very finely through special nozzles and sprinklers and/or increased operating pressures….

#6 Koolfog: Misting Systems

Domain Est. 1998

Website: koolfog.com

Key Highlights: KOOLFOG designs and sells high quality misting systems and mist systems for outdoor cooling, hotel misting, dust control misting, animal cooling and more ……

#7 Fog and Misting Systems for Humidity, Dust & Odor Control

Domain Est. 2001

Website: fogco.com

Key Highlights: Fogco manufactures the industry’s most powerful high-pressure misting systems designed to solve your toughest environmental challenges….

#8 NATURAL FOG

Domain Est. 2004

Website: naturalfog.com

Key Highlights: The fog nozzles are used in both high pressure misting systems and low pressure fogging systems for various purposes to manage temperature and humidity, and ……

#9 VectorFog

Domain Est. 2011

Website: vectorfog.com

Key Highlights: VectorFog designs world-class ULV cold foggers and thermal foggers for disinfection, pest control, and sanitization. Trusted in over 100 countries….

#10 Misting Systems for Cooling

Website: mistafog.com.au

Key Highlights: The Mistafog misting system works at a 1000 PSI+ pressure level, which generates minute water droplets that eliminate the airborne heat and cool the air around ……

Expert Sourcing Insights for Misting Fog

H2: 2026 Market Trends for Misting and Fog Systems

As we approach 2026, the misting and fog system market is poised for significant evolution, driven by technological advancements, shifting consumer priorities, and broader environmental and economic trends. Here’s a breakdown of the key anticipated trends:

1. Sustainability and Water Efficiency as Core Drivers:

* Hyper-Focus on Conservation: With increasing water scarcity concerns globally, systems will prioritize ultra-efficient nozzles, smart sensors (humidity, temperature, occupancy), and closed-loop/recycling capabilities. “Water-wise” certification and low water consumption will be major selling points.

* Integration with Smart Irrigation: Fog systems in agriculture and landscaping will increasingly integrate with broader smart irrigation platforms, using data analytics to optimize water use and minimize waste, aligning with precision agriculture demands.

2. Smart Technology and IoT Integration Dominance:

* AI-Powered Optimization: Systems will leverage AI algorithms to predict optimal misting schedules based on weather forecasts, real-time environmental data, and historical patterns, maximizing cooling efficiency and comfort.

* Seamless Home/Building Automation: Foggers will be standard components in smart homes and buildings, controllable via voice assistants, apps, and integrated into systems like HVAC and lighting for holistic environmental management.

* Predictive Maintenance: IoT sensors will monitor pump performance, filter status, and nozzle clogging, enabling predictive maintenance alerts, reducing downtime, and extending system lifespan.

3. Expansion Beyond Traditional Cooling:

* Health & Wellness Focus: Demand will surge for systems in wellness centers, spas, and homes emphasizing air purification (with nano-fog or integrated filters), humidity control for respiratory health, and creating “bio-philic” environments.

* Advanced Agricultural Applications: Fog systems will be crucial in vertical farming and controlled environment agriculture (CEA) for precise humidity control, nutrient delivery (fogponics), and disease prevention, boosting yields in compact spaces.

* Industrial & Process Cooling: Growth in data centers, manufacturing (especially semiconductor and food processing), and logistics (cool storage) will drive demand for highly reliable, scalable fog systems for spot cooling and humidity control.

4. Material Innovation and Design Aesthetics:

* Corrosion-Resistant & Sustainable Materials: Wider adoption of advanced polymers, ceramics, and recycled/recyclable materials to combat mineral buildup and reduce environmental footprint.

* Discreet & Architectural Integration: Design will shift towards ultra-slim, hidden, or architecturally integrated systems (e.g., built into pergolas, ceilings, or walls) prioritizing aesthetics, especially in residential and high-end commercial spaces.

5. Market Fragmentation and Niche Specialization:

* Rise of Niche Players: While major HVAC and irrigation companies compete, specialized firms will emerge focusing on specific applications (e.g., high-end residential luxury misting, industrial de-dusting, museum conservation fogging).

* Customization Demand: Increased demand for bespoke solutions tailored to unique architectural challenges, specific climate conditions, and exact client requirements.

6. Regulatory and Standardization Developments:

* Stricter Water Efficiency Standards: Governments and municipalities are likely to implement or tighten regulations on outdoor water use, potentially mandating smart controls or efficiency ratings for new installations.

* Focus on Air Quality & Safety: Regulations may evolve regarding microbial control in fog systems (preventing Legionella) and the potential inhalation of minerals or additives, driving safer system designs and maintenance protocols.

7. Supply Chain Resilience and Cost Pressures:

* Localization of Manufacturing: To mitigate global supply chain risks, there may be a trend towards regional manufacturing and sourcing of key components (pumps, nozzles).

* Material Cost Volatility: Fluctuations in prices for metals, plastics, and electronics will continue to pressure margins, potentially accelerating innovation in alternative materials and designs.

Conclusion:

By 2026, the misting and fog system market will transcend its traditional role as a simple outdoor cooler. It will be a sophisticated, data-driven, and sustainability-focused segment of environmental control technology. Success will hinge on innovation in water efficiency, seamless smart integration, expansion into high-value applications like wellness and precision agriculture, and responsive adaptation to regulatory and environmental pressures. Companies that embrace these H2 trends will lead the market.

Common Pitfalls Sourcing Misting Fog Systems (Quality, IP)

Sourcing misting fog systems can present several challenges, particularly when balancing performance expectations with quality and intellectual property (IP) considerations. Understanding these common pitfalls helps ensure reliable, long-term operation and legal compliance.

Poor Build Quality and Material Selection

Many low-cost misting fog systems use substandard materials such as non-stainless steel nozzles, low-grade plastics, or inadequate pump components. This leads to rapid clogging, corrosion, leaks, and inconsistent fog output. Over time, these issues increase maintenance costs and reduce system lifespan, especially in outdoor or high-humidity environments.

Inadequate Ingress Protection (IP) Ratings

A frequent oversight is selecting systems with insufficient IP ratings for the intended environment. For outdoor or industrial applications, misting systems must resist dust and water ingress. Units rated below IP65 may fail prematurely when exposed to rain, high-pressure cleaning, or dusty conditions, leading to electrical faults or component damage.

Misrepresentation of Performance Specifications

Some suppliers exaggerate fog output, droplet size, or coverage area. Without verified test data, buyers may receive systems that fail to achieve desired cooling, humidification, or aesthetic effects. Always request third-party performance validation or onsite testing before large-scale procurement.

Lack of Intellectual Property Due Diligence

Sourcing from manufacturers that infringe on patented designs, nozzle technologies, or control systems exposes buyers to legal risks. Using counterfeit or cloned components can lead to IP litigation, product recalls, or shipment seizures. Always verify that the supplier holds proper IP rights or licensing for their technology.

Inconsistent Nozzle Quality and Compatibility

Nozzles are critical to fog quality, yet inconsistencies in manufacturing can result in uneven spray patterns or premature failure. Additionally, proprietary nozzle designs may limit replacement options, locking buyers into a single supplier. Ensure nozzle specifications are standardized or openly supported.

Absence of Certifications and Compliance

Reputable misting fog systems should meet electrical safety (e.g., CE, UL), RoHS, and IP standards. Systems lacking proper certification may not comply with local regulations, posing safety hazards and complicating installation approvals.

Poor After-Sales Support and Spare Parts Availability

Even high-quality systems require maintenance. Suppliers based in regions with weak support infrastructure may offer limited technical assistance or long lead times for spare parts. This undermines system reliability and increases downtime.

Hidden Costs from Incompatible Integration

Some systems are not designed for easy integration with building management systems (BMS) or existing plumbing. Proprietary controls or lack of communication protocols (e.g., Modbus, BACnet) can result in added engineering costs and delays during installation.

Avoiding these pitfalls requires thorough supplier vetting, demand for verified technical documentation, and attention to both physical durability and legal compliance. Prioritizing quality and IP integrity ensures a reliable, sustainable misting fog solution.

Logistics & Compliance Guide for Misting Fog Systems

Product Classification and Regulatory Overview

Misting fog systems, used for cooling, humidification, and pest control, are subject to various regulatory requirements depending on their application, components, and geographic market. These systems typically involve water pumps, nozzles, tubing, and sometimes chemical additives (e.g., biocides or insecticides). Understanding classification under environmental, electrical, and health regulations is essential for legal distribution and operation.

Environmental and Water Safety Compliance

Misting systems must comply with local and national water usage and conservation regulations, especially in drought-prone regions. In the U.S., systems discharging water or mist into open environments may fall under the Environmental Protection Agency (EPA) guidelines. If biocides or algaecides are used in the water supply, registration under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) is required. Ensure all chemical additives are EPA-registered and labeled for intended use.

Electrical and Equipment Safety Standards

Misting fog units with electrical components (pumps, timers, solenoids) must meet electrical safety standards such as UL (Underwriters Laboratories) in the U.S. or CE marking in the European Union. Equipment installed outdoors must be rated for wet/damp locations (e.g., IP65 or NEMA 4X). Always follow National Electrical Code (NEC) standards for wiring and grounding to prevent hazards.

International Shipping and Import Regulations

When shipping misting fog systems internationally, classify the product correctly under the Harmonized System (HS Code)—common codes include 8424.89 (spraying machinery) or 8509.80 (electrical appliances). Declare all components, especially if containing motors, electronics, or restricted materials. Comply with destination country requirements such as RoHS (EU), CCC (China), or SAA (Australia). Include technical specifications, user manuals, and compliance certificates with shipments.

Labeling and User Documentation Requirements

All misting fog systems must include permanent labeling with manufacturer name, model number, voltage, power rating, and safety warnings. User manuals must detail installation procedures, maintenance schedules, and safety precautions—especially regarding electrical safety, slip hazards from overspray, and proper use of additives. Multilingual documentation may be required for export markets.

Transportation and Handling Guidelines

Package misting systems to prevent damage during transit. Secure pumps, nozzles, and control units with protective padding. Clearly mark packages as “Fragile” and “This Side Up.” For large commercial systems, use palletized shipping with waterproof wrapping. Avoid exposure to extreme temperatures during storage and transit, which can damage seals and plastic components.

Installation and Operational Compliance

Ensure installations comply with local building, plumbing, and health codes. Overhead misting in public spaces may require permits or fall under occupational safety regulations (e.g., OSHA guidelines on slip hazards and air quality). In food service or healthcare environments, misting systems must adhere to hygiene standards to prevent microbial contamination (e.g., Legionella control under ASHRAE Standard 188).

Maintenance and Recordkeeping

Establish a maintenance protocol to inspect nozzles, filters, and water lines regularly. Document cleaning, part replacements, and system performance. For commercial or industrial users, maintain logs for regulatory audits—especially if chemicals are used. Proper maintenance ensures compliance with health, safety, and environmental standards over the system’s lifecycle.

Conclusion on Sourcing Misting Fog Systems

In conclusion, sourcing misting fog systems requires careful consideration of several key factors including system quality, supplier reliability, environmental suitability, and cost-effectiveness. Whether for agricultural cooling, dust suppression, humidification, or aesthetic purposes, selecting the right misting fog solution involves assessing nozzle type, pump pressure, water quality requirements, and energy efficiency. Partnering with reputable suppliers who offer technical support, warranties, and customizable options ensures long-term performance and durability. Additionally, evaluating sustainability aspects—such as water conservation and eco-friendly operation—can enhance both operational efficiency and environmental responsibility. By conducting thorough research and due diligence, businesses and organizations can successfully source misting fog systems that meet their specific needs and deliver reliable, consistent results.