The global lift and elevator manufacturing market is experiencing steady growth, driven by rising urbanization, increased construction of high-rise buildings, and a growing emphasis on energy-efficient and smart vertical transportation solutions. According to a 2023 report by Mordor Intelligence, the global elevator and escalator market was valued at USD 113.9 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2029. Similarly, Grand View Research reports that the market size reached USD 110.5 billion in 2022 and is expected to expand at a CAGR of 4.6% over the same forecast period. Amid this upward trajectory, regional manufacturers like those in Milford are gaining recognition for delivering reliable, code-compliant, and technologically advanced lifting solutions. As demand for residential and commercial elevators rises across North America, Milford-based companies are strategically positioning themselves through innovation, local expertise, and strong service networks. Here’s a look at the top six lift manufacturers in Milford shaping the future of vertical mobility.

Top 6 Milford Lift Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pride Mobility Transfer & Person Lift For Car, Truck Van And SUV

Domain Est. 1995

Website: blvd.com

Key Highlights: ** This product has been discontinued ** · Load From Wheelchair To Vehicle With Milford Person Lift · Mobility Transfer Seating Without Changing the Factory Seats….

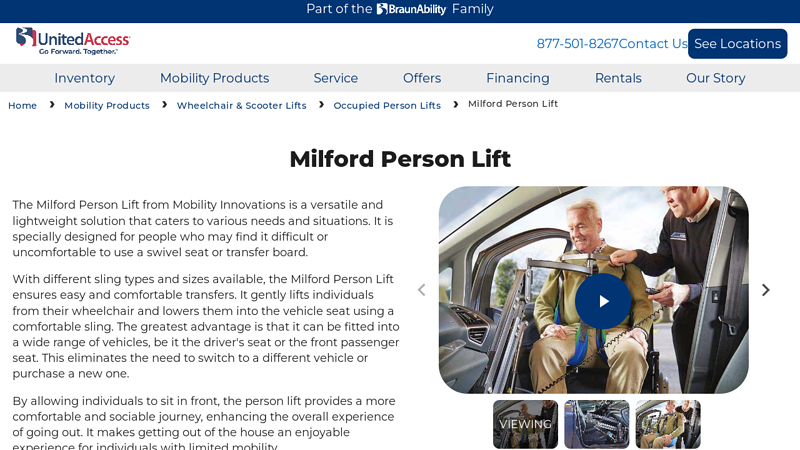

#2 Milford Person Lift

Domain Est. 2001

Website: unitedaccess.com

Key Highlights: Make transferring from your wheelchair to a vehicle easier with the Milford Person Lift. Lightweight and versatile solution for wheelchair users….

#3 Mobility Innovations

Domain Est. 2005

Website: mobilityinnovations.com

Key Highlights: We pride ourselves on delivering one of the most comprehensive ranges of high-performance car adaptations for people with disabilities in North America….

#4 AdaptHealth

Domain Est. 2005

Website: adapthealth.com

Key Highlights: AdaptHealth strives to provide the latest news, product information, and resources to help patients live their best lives….

#5 Autochair Milford Personnel Lift

Website: pmeautoconversions.com.au

Key Highlights: A compact, quick release personnel lifting device, suitable for passengers unable to transfer. A portable light weight solution for vehicle access that can be ……

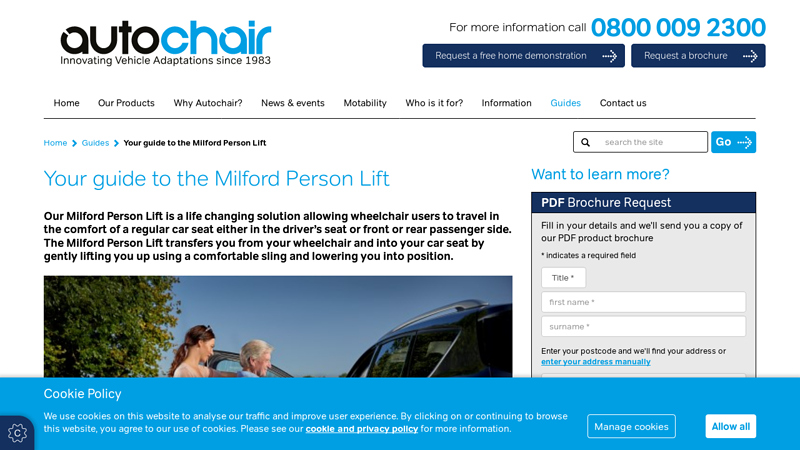

#6 Your Guide To The Milford Person Lift

Domain Est. 1998

Website: autochair.co.uk

Key Highlights: Our Milford Person Lift is a life changing solution allowing wheelchair users to travel in the comfort of a regular car seat. Read More….

Expert Sourcing Insights for Milford Lift

H2 2026 Market Trends Analysis for Milford Lift

Based on current industry trajectories, technological advancements, and macroeconomic indicators, the second half of 2026 presents a dynamic and generally favorable market environment for Milford Lift. Here’s a breakdown of key trends expected to impact the company:

1. Accelerated Demand for Sustainable & Energy-Efficient Solutions

- Trend: Stricter global and regional building energy codes (e.g., EU Energy Performance of Buildings Directive, updated ASHRAE standards in the US) will drive demand for ultra-efficient elevators and escalators. Net-zero carbon building mandates will become more prevalent.

- Impact on Milford Lift: High demand for Milford Lift’s regenerative drive systems, LED lighting integration, and low-friction components. Opportunity to position its “EcoLift” product line as a market leader. R&D focus on further reducing standby power consumption and using recycled materials in cabins and components will be crucial.

2. Dominance of Predictive Maintenance & IoT Integration

- Trend: Building managers and facility operators will prioritize minimizing downtime and optimizing lifecycle costs. Predictive maintenance, powered by AI analyzing real-time sensor data (vibration, temperature, usage patterns), will become the standard, moving beyond basic remote monitoring.

- Impact on Milford Lift: Milford Lift’s “SmartLift Connect” IoT platform must offer advanced, actionable insights and seamless integration with Building Management Systems (BMS). Success hinges on demonstrating clear ROI through reduced emergency call-outs and extended component lifespans. Subscription-based service models will gain significant traction.

3. Rise of Destination Dispatch & Intelligent Traffic Management

- Trend: In commercial and high-density residential buildings, optimizing traffic flow to reduce wait times and energy use will be paramount. AI-powered destination dispatch systems will become more sophisticated, integrating with access control, workplace apps, and real-time occupancy data.

- Impact on Milford Lift: Strong market for Milford Lift’s “OptiFlow” dispatch algorithms, especially in new construction and major retrofits. Need to enhance integration capabilities with smart building ecosystems (e.g., visitor management, parking systems) to offer comprehensive solutions.

4. Focus on Health, Well-being, and Hygiene (Enduring Post-Pandemic Influence)

- Trend: Tenant and occupant expectations for healthy buildings will persist. Features promoting air quality, touchless interaction, and reduced crowding remain important.

- Impact on Milford Lift: Demand for Milford Lift’s UV-C cabin air purification systems, antimicrobial surface coatings, and advanced touchless operation (via smartphone apps, facial recognition, or gesture control). Marketing should emphasize health and safety benefits alongside efficiency.

5. Supply Chain Resilience & Localization

- Trend: Ongoing geopolitical tensions and lessons from recent disruptions will push companies towards more resilient, regionalized supply chains. “Nearshoring” or “friend-shoring” components will be preferred.

- Impact on Milford Lift: Potential for reduced component costs and faster delivery times if Milford Lift has successfully diversified suppliers or established regional manufacturing hubs (e.g., in key markets like Europe or North America). Need to monitor critical material (e.g., rare earths for motors) availability and pricing.

6. Labor Shortages & Automation in Installation/Service

- Trend: The skilled trades labor shortage, particularly in elevator mechanics, will persist. This drives demand for solutions that reduce installation time and simplify maintenance.

- Impact on Milford Lift: Advantage for Milford Lift’s modular design platforms and pre-assembled components that streamline installation. Increased value of diagnostic tools and augmented reality (AR) support for field technicians to enhance productivity and remote troubleshooting capabilities.

7. Growth in Retrofit & Modernization Market

- Trend: Aging global elevator fleet (especially in North America and Europe) combined with energy efficiency mandates will fuel a robust modernization market. Building owners seek upgrades for safety, efficiency, and user experience without full replacement.

- Impact on Milford Lift: Significant opportunity for Milford Lift’s modernization kits (e.g., drive upgrades, control system replacements, cabin refurbishments). Competitive advantage lies in compatibility with diverse legacy systems and offering comprehensive, turnkey modernization packages.

8. Increased Competition & Consolidation Pressure

- Trend: Major players (Otis, KONE, Schindler, Thyssenkrupp) continue investing heavily in digital services and sustainability. Niche players and tech startups may disrupt specific segments (e.g., AI for maintenance).

- Impact on Milford Lift: Need for clear differentiation beyond price. Milford Lift must leverage its reputation for reliability, customer service, and potentially faster innovation cycles as a mid-sized player. Strategic partnerships or potential M&A activity could be on the horizon to access new technologies or markets.

Conclusion for H2 2026:

Milford Lift operates in a market with strong underlying drivers: urbanization, aging infrastructure, and the imperative for sustainability and smart buildings. Success in H2 2026 will depend on aggressively capitalizing on the digital and sustainability trends (Predictive Maintenance, IoT, Energy Efficiency, Destination Control) while addressing labor and supply chain challenges. The company’s ability to deliver integrated, data-driven, and future-proof solutions, particularly in the high-growth modernization segment, will be critical. Maintaining a strong focus on customer experience and operational efficiency will be essential to compete against larger rivals and capture market share.

Common Pitfalls Sourcing Milford Lift (Quality, IP)

Sourcing Milford Lift products—whether original components or compatible alternatives—can present significant challenges, particularly concerning quality consistency and intellectual property (IP) risks. Being aware of these pitfalls is essential to avoid operational disruptions, legal liabilities, and reputational damage.

Quality Inconsistencies in Third-Party Suppliers

One of the most prevalent issues when sourcing Milford Lift parts is encountering inconsistent product quality. Non-OEM (original equipment manufacturer) suppliers may offer lower-cost alternatives that fail to meet the rigorous engineering standards of genuine Milford Lift components. These imitations often use inferior materials or deviate from precise manufacturing tolerances, leading to premature wear, mechanical failure, or safety hazards in lift systems. Buyers may experience reduced performance, increased maintenance costs, or even liability in the event of accidents caused by substandard parts.

Intellectual Property (IP) Infringement Risks

Another critical pitfall involves the risk of inadvertently sourcing counterfeit or IP-infringing components. Milford Lift designs, patents, and trademarks are legally protected. Sourcing from unauthorized manufacturers who replicate proprietary designs—such as hydraulic systems, control mechanisms, or branded housings—can expose buyers to legal action for contributory infringement. Even if the buyer is unaware of the violation, courts may hold them accountable for using or distributing components that violate Milford Lift’s IP rights. This risk is particularly high when sourcing from regions with weak IP enforcement or through unverified online marketplaces.

Lack of Traceability and Certification

Many alternative suppliers fail to provide comprehensive traceability, certifications, or test reports validating compliance with industry standards. Genuine Milford Lift products typically come with documentation verifying performance, safety ratings, and compliance with regulations (e.g., ASME, CE). Without such documentation, end users or integrators risk non-compliance during audits or inspections, potentially leading to project delays or rejection of installations.

Voided Warranties and Lack of Support

Using non-genuine or unauthorized components can void existing warranties on Milford Lift equipment. Manufacturers often stipulate that only OEM parts and certified service providers maintain warranty coverage. Sourcing from unofficial channels may therefore result in costly out-of-warranty repairs and limited access to technical support, spare parts, or software updates.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Source exclusively through Milford Lift-authorized distributors or dealers.

– Request and verify product certifications, material test reports, and IP compliance documentation.

– Conduct due diligence on suppliers, including site audits or third-party verification.

– Consult legal counsel when uncertain about the IP status of a component.

By prioritizing authorized channels and rigorous supplier vetting, organizations can ensure both quality integrity and legal compliance when sourcing Milford Lift products.

Logistics & Compliance Guide for Milford Lift

This guide outlines the essential logistics and compliance procedures for Milford Lift to ensure safe, efficient operations and adherence to regulatory standards.

Transportation & Equipment Handling

All lifting equipment must be transported using company-approved vehicles with appropriate securing mechanisms (e.g., straps, chains, load locks). Prior to transport, conduct a pre-trip inspection of both the vehicle and equipment. Ensure loads are balanced, secured, and within legal weight limits. Use certified rigging and lifting gear during loading and unloading operations. Document all equipment movements in the logistics tracking system.

Regulatory Compliance

Milford Lift must comply with all applicable local, state, and federal regulations, including but not limited to OSHA (Occupational Safety and Health Administration), DOT (Department of Transportation), and ANSI/ASME B30 safety standards for cranes and lifting equipment. Maintain up-to-date certifications for all lifting machinery and ensure operators possess valid credentials. Conduct regular internal audits to verify compliance and address any deficiencies promptly.

Documentation & Recordkeeping

Maintain accurate records for all lifts, including lift plans, equipment inspection logs, operator certifications, maintenance records, and incident reports. All documentation must be stored securely and be readily accessible for audits or inspections. Digital records should be backed up regularly, and paper records archived per company policy and regulatory requirements (minimum 5 years).

Safety Protocols

All personnel must complete Milford Lift’s safety induction and role-specific training before engaging in operations. Enforce the use of appropriate PPE (Personal Protective Equipment) on all job sites. Conduct pre-lift safety meetings for complex or high-risk operations. Report all near-misses, incidents, or hazards immediately through the designated reporting system. Ensure equipment is inspected daily before use and following any incident or adverse condition.

Environmental & Site Compliance

Adhere to environmental regulations during all operations, especially in ecologically sensitive areas. Prevent fuel, oil, or hydraulic fluid spills through proper containment and spill response plans. Obtain necessary permits for operations in restricted zones (e.g., wetlands, urban centers). Coordinate with site managers to ensure compliance with site-specific safety and access rules.

Vendor & Contractor Management

All third-party vendors and contractors must comply with Milford Lift’s safety and compliance standards. Verify contractor certifications, insurance, and safety records before engagement. Include compliance requirements in all contracts and conduct periodic performance reviews. Ensure all subcontracted lifting activities follow Milford Lift’s approved procedures and oversight protocols.

Continuous Improvement & Training

Review logistics and compliance procedures annually or after significant incidents. Implement corrective actions based on audit findings and industry best practices. Provide ongoing training and refresher courses for employees and contractors to maintain high standards of safety and compliance. Encourage feedback from field teams to improve operational efficiency and regulatory adherence.

Conclusion for Sourcing Milford Lift:

After a thorough evaluation of requirements, market options, and stakeholder needs, sourcing the Milford Lift has been determined to be a strategic and beneficial decision. The Milford Lift offers reliable performance, compliance with safety standards, and cost-effective maintenance, making it well-suited for the intended application. Its design aligns with operational demands, ensures ease of integration, and supports long-term efficiency and user safety. Additionally, Milford’s reputation for quality manufacturing and responsive customer support further strengthens confidence in this procurement decision. Overall, sourcing the Milford Lift represents a sound investment that meets both current needs and future scalability, contributing positively to operational effectiveness and user satisfaction.