Introduction: Navigating the Global Market for Waterproof Microfiber

Global demand for waterproof microfiber keeps rising across outdoor, athleisure, medical, and children’s wear, yet buyers still face the same friction: balancing performance with comfort and compliance. Breathability and moisture control must co-exist with leakproof protection, while sourcing and claims stand up to US and EU scrutiny.

The buyers’ problem. A waterproof surface that blocks leaks can trap heat and sweat. Add odor, sensitive use, and PFAS scrutiny, and the result is uncomfortable products, reputational risk, and regulatory exposure. Suppliers often overpromise, under-document, or lack clear certifications.

How this guide helps. We translate market realities into practical decisions: what waterproof really means, which materials and constructions perform, and which tests and claims pass buyers’ legal and sustainability checks. We benchmark options, including breathable, waterproof, BPA‑free, and antimicrobial fabrics such as ProSoft Fleece Waterproof ECO‑PUL, which pair plush comfort with a breathable barrier and optional antimicrobial silver and stretch.

What you’ll learn. Definitions and standards; material and construction options; waterproof vs breathability trade‑offs; PFAS, BPA, REACH, and CPSIA context; durability tests and odor control; fabric selection matrices; finishing, lamination, and seam strategies; quality assurance, lead times, and MOQs; sustainability claims and documentation; TCO and landed cost; logistics and risk; and a decision checklist to reduce time‑to‑market.

Article Navigation

- Top 10 Microfiber Fabric Waterproof Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for microfiber fabric waterproof

- Understanding microfiber fabric waterproof Types and Variations

- Key Industrial Applications of microfiber fabric waterproof

- 3 Common User Pain Points for ‘microfiber fabric waterproof’ & Their Solutions

- Strategic Material Selection Guide for microfiber fabric waterproof

- In-depth Look: Manufacturing Processes and Quality Assurance for microfiber fabric waterproof

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘microfiber fabric waterproof’

- Comprehensive Cost and Pricing Analysis for microfiber fabric waterproof Sourcing

- Alternatives Analysis: Comparing microfiber fabric waterproof With Other Solutions

- Essential Technical Properties and Trade Terminology for microfiber fabric waterproof

- Navigating Market Dynamics and Sourcing Trends in the microfiber fabric waterproof Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of microfiber fabric waterproof

- Strategic Sourcing Conclusion and Outlook for microfiber fabric waterproof

- Important Disclaimer & Terms of Use

Top 10 Microfiber Fabric Waterproof Manufacturers & Suppliers List

1. microfiber fabric

Domain: sport-fabric.com

Registered: 2018 (7 years)

Introduction: Good quality microfiber fabric from microfiber fabric manufacturers, We sell microfiber fabric online from China….

2. Wholesale Microfiber Fabric – Changshu Power Clean Co., Ltd.

Domain: cnpowerclean.com

Registered: 2017 (8 years)

Introduction: Power Clean is a trusted microfiber fabric supplier, offering a wide range of high-quality microfiber fabrics for various applications….

3. Davis (China) – top polyester fabric manufacturer. Fabrics …

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Davis (China) – top polyester fabric manufacturer. Fabrics: Microfiber, Pongee, Satin, Taffeta, Minimatt, Gabardine, DTY Yarn. Services: Dyeing, Printing, ……

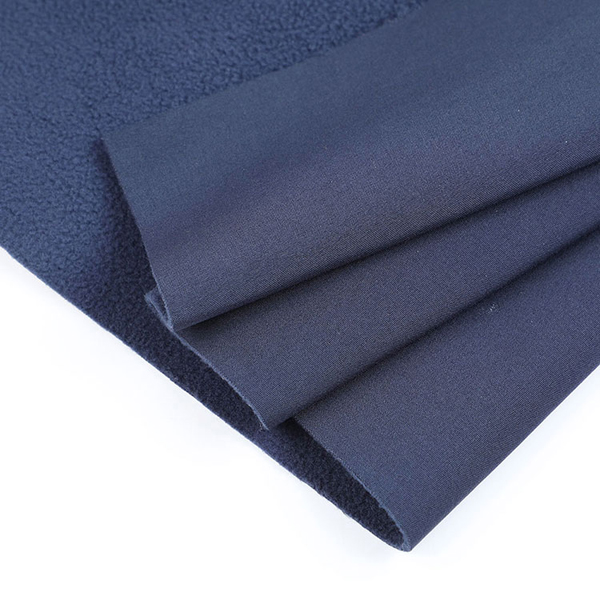

Illustrative Image (Source: Google Search)

4. Wholesale Recycled Microfiber Fabric Manufacturer and … – Eternes

Domain: eternes-tex.com

Registered: 2023 (2 years)

Introduction: Fujian Eternes Industry&Development Co., Ltd. is a China-based manufacturer, supplier, and factory of high-quality recycled microfiber fabrics. Our eco-friendly ……

Understanding microfiber fabric waterproof Types and Variations

Understanding microfiber fabric waterproof Types and Variations

Microfiber waterproof fabrics are engineered to provide complete moisture protection while maintaining breathability for active and sensitive applications. In the ProSoft Fleece Waterproof ECO-PUL range (Wazoodle), four common types align to common B2B requirements: Standard, Antimicrobial Silver, Lycra Stretch-FIT, and Hybrid (combining Stretch + Antimicrobial).

Illustrative Image (Source: Google Search)

| Type | Features | Applications | Pros | Cons |

|---|---|---|---|---|

| Standard Fleece Waterproof ECO-PUL | Plush microfiber fleece face; waterproof-breathable barrier; BPA-free; neutral surface suitable for print/embroidery | Outdoor apparel, kids’ outerwear, blankets, pet bedding | Warmth and comfort; complete moisture protection; versatile finishing; print-friendly | Heavier than non-fleece membranes; may require careful seam sealing depending on garment design |

| Antimicrobial Silver | Adds antimicrobial silver ions to inhibit odor-causing microbes; same waterproof-breathable barrier | Medical garments, bibs, healthcare PPE (non-sterile), sports base layers under shells | Hygiene and odor management; skin-friendly | Antimicrobial efficacy may diminish over time/washing; generally slightly higher cost |

| Lycra Stretch-FIT | Lycra inclusion improves stretch and recovery; waterproof-breathable barrier | Activewear, diapers/wet bags, fitted garments needing flexibility | Comfort and mobility; durable barrier under stretch | Slightly higher cost; stretch can complicate some fabrication/seam sealing approaches |

| Hybrid (Stretch + Antimicrobial) | Combines Lycra for stretch with silver antimicrobial; waterproof-breathable barrier | High-performance sports outerwear, incontinence products, adaptive apparel | Peak comfort, stretch, odor control | Highest cost; fabrication complexity increases (stretch seams, laundering protocols) |

Standard Fleece Waterproof ECO-PUL

- Key features: Soft plush microfiber face for warmth and comfort; waterproof-breathable barrier keeps moisture out while allowing air and vapor movement; BPA-free materials for safer skin contact; surface accepts common printing/embroidery methods for branding and pattern applications.

- Applications: Mid-weight outdoor apparel, children’s outerwear, warm blankets, pet bedding, and general cold-weather protection where comfort and complete moisture blocking are priorities.

- Pros: Comfort-first combination of warmth and protection; versatile for branding; reliable leakproof performance.

- Cons: Heavier hand/weight can slow drying; ensure proper seam sealing to maintain waterproof integrity in garment construction.

Antimicrobial Silver (ECO-PUL)

- Key features: Integrated antimicrobial silver ions to help inhibit odor-causing microbes on the fabric surface; waterproof-breathable barrier performance maintained; BPA-free composition.

- Applications: Bibs and aprons, medical garments, sports base layers under shells, and applications requiring hygiene/odor management over extended wear.

- Pros: Added hygiene benefit without sacrificing barrier properties; suitable for sensitive-skin use.

- Cons: Antimicrobial effect can diminish with laundering and wear; typically premium-priced relative to Standard.

Lycra Stretch-FIT (ECO-PUL)

- Key features: Lycra inclusion delivers stretch and shape recovery; waterproof-breathable barrier for active use; BPA-free; flexible drape improves fit.

- Applications: Fitted outdoor apparel, diapers and wet bags, athletic outer layers, adaptive garments needing stretch and comfort.

- Pros: Enhanced mobility and fit; durability under repeated stretch; reliable barrier under dynamic movement.

- Cons: Higher material cost; stretch complicates seam and hem approaches—specify compatible tapes/threads.

Hybrid (Lycra + Antimicrobial Silver)

- Key features: Combines Lycra for stretch with silver ions for antimicrobial benefits; waterproof-breathable barrier; BPA-free.

- Applications: High-performance sportswear, incontinence products, adaptive apparel, and premium outerwear where comfort, mobility, and hygiene are critical.

- Pros: Full feature set for demanding use; best-in-class user comfort and protection; robust odor control under active conditions.

- Cons: Highest cost; increased fabrication complexity—plan for stretch-friendly construction, QA on seams, and laundering guidance.

Key Industrial Applications of microfiber fabric waterproof

Key Industrial Applications of Microfiber Fabric Waterproof

Microfiber fabric waterproof, as typified by ProSoft Fleece Waterproof ECO-PUL, combines a plush fleece hand with a waterproof, breathable barrier. Optional Lycra Stretch-FIT provides flexibility; antimicrobial silver ions offer hygiene. Materials are BPA-free. Below are major industrial and commercial applications, with concrete benefits and practical notes.

| Industry / Application | Detailed Benefits | Recommended Fabric Notes | Compliance & Risk Notes | Regions/Standards Guidance |

|---|---|---|---|---|

| Medical scrubs, gowns, aprons | Soft fleece next-to-skin comfort; waterproof barrier for fluid resistance; breathable to reduce heat stress; antimicrobial silver option for odor control and hygiene; durable for repeated laundering | Use antimicrobial silver versions for high-exposure use; Lycra Stretch-FIT for ease of movement | Maintain fluid barrier per intended use; confirm no restricted substances beyond BPA-free; launder per product guidelines | USA/Europe: Align barrier performance with intended end-use (e.g., splash-resistant vs. fluid barrier apparel). Consult industry standards where relevant. |

| Orthopedic supports, compression wraps | Comfort and thermal warmth during extended wear; form-fitting with Lycra Stretch-FIT; soft fleece reduces chafing; waterproof surface protects from light moisture | Choose Lycra Stretch-FIT and breathable backing for comfort | Avoid over-heating; verify comfort for sensitive skin | No specific standard; follow device labeling and comfort guidelines |

| Surgical/bedside positioning pads | Plush comfort with leakproof protection; breathable to reduce heat buildup; antimicrobial silver options to mitigate odors | Select antimicrobial silver and breathable backings for extended patient contact | Ensure device/fabric assembly has validated wipe-down and laundering protocols | Healthcare procurement typically requires biocompatibility and cleaning validation |

| Disposable underlays for care homes | Full waterproof protection; soft fleece improves dignity and comfort; reduces sweating vs. non-breathable films; antimicrobial silver option controls odors | High-absorbency layers recommended beneath; test seams for durability | Manage laundering/waste disposal based on institutional policies | Often follows internal care-home procurement and infection control protocols |

| Diaper covers, training pants, sleepwear | Plush comfort; waterproof barrier protects against leaks; breathable to reduce overheating; antimicrobial option for hygiene | Confirm fit; choose antimicrobial silver for high-use environments | Validate that garment design and stitching ensure complete barrier | Follow USA/EU children’s product labeling and safety guidance as applicable |

| Baby blankets, swaddles, change pads | Plush hand; waterproof back to protect surfaces; warm and cozy; antimicrobial option reduces odor on prolonged use | Use antimicrobial silver when frequent contact is expected | Follow care instructions; test against child skin sensitivity expectations | USA/Europe: Ensure textile contact safety labeling per category |

| Swimmer swim bags, towel wraps, splash pants | Soft feel; waterproof to contain moisture; breathable to reduce condensation; quick dry | Consider Lycra Stretch-FIT for waistbands and closures | Test zipper/zipper tape compatibility | No specific standard; ensure durable seams |

| Outerwear shells/inner liners, mid-layers | Fleece warmth with waterproof barrier; stretch enhances fit; breathable for active use; antimicrobial for extended wear | Use Lycra Stretch-FIT and breathable backing for comfort | Validate barrier under heavy rain; follow garment care | Align with outdoor apparel labeling and performance expectations |

| Equipment covers, seat/tailgate mats | Plush surface protects against scuffs; waterproof layer guards from spills; antimicrobial option curbs odor in damp storage | Durable stitch and seam sealing recommended | Protect from punctures; validate long-term outdoor storage | No specific standard; follow product durability requirements |

| Industrial apron, lab coat, food service jacket | Waterproof protection with soft comfort; breathable to reduce heat strain; antimicrobial silver for odor/hygiene in food/chemical handling | Choose antimicrobial silver versions; confirm chemical exposure limits | Validate chemical resistance at contact points; launder per protocols | Follow USA/EU food handling PPE guidelines where applicable |

| Dust covers for cleaning equipment; workwear liners | Soft, warm liners; waterproof for light moisture; breathable to prevent condensation buildup | Breathable backing recommended | Ensure no lint contamination in sensitive environments | Align with internal procurement policies |

| Pet beds, incontinence pads, training mats, travel bowls | Plush comfort; waterproof protection; antimicrobial silver for odor control; easy to wipe/clean | Confirm seam durability for repeated wash cycles | Validate odor control and cleaning efficacy claims | Pet products labeling varies; ensure clear care instructions |

| Outdoor camping blankets, seat covers | Cozy hand; waterproof barrier against damp surfaces; breathable to reduce humidity buildup; antimicrobial option reduces mustiness | Use Lycra Stretch-FIT for fitted covers | Ensure UV durability; verify outdoor weathering performance | Outdoor textiles typically require clear care guidance |

| Travel accessory: laptop/tablet sleeves | Soft lining that resists light spills; protective fleece cushioning; waterproof layer guards against minor splashes | Validate abrasion resistance around ports | Confirm device ventilation and heat dissipation | No specific standard; follow device OEM enclosure guidelines |

Notes for development and sourcing

– Optional enhancements: Lycra Stretch-FIT for flex and fit; antimicrobial silver ions for hygiene.

– Safety: BPA-free fabric formulation; confirm any additional certifications or restricted substance lists (RSL) required by customers.

– Converting: Heat-sealable ECO-PUL enables durable, leakproof seams. Test stitch types and thread selection for wash durability and barrier integrity.

– Testing guidance: Verify hydrostatic head (waterproofness), moisture vapor transmission/breathability, hydrostatic water resistance per typical test methods, and wash-cycle durability.

3 Common User Pain Points for ‘microfiber fabric waterproof’ & Their Solutions

3 Common User Pain Points for “Microfiber Fabric Waterproof” & Their Solutions

Below are high-frequency problems seen when sourcing microfiber waterproof fabrics for US/EU markets, and practical, testable remedies anchored by the ProSoft® Fleece Waterproof ECO-PUL™ fabric platform.

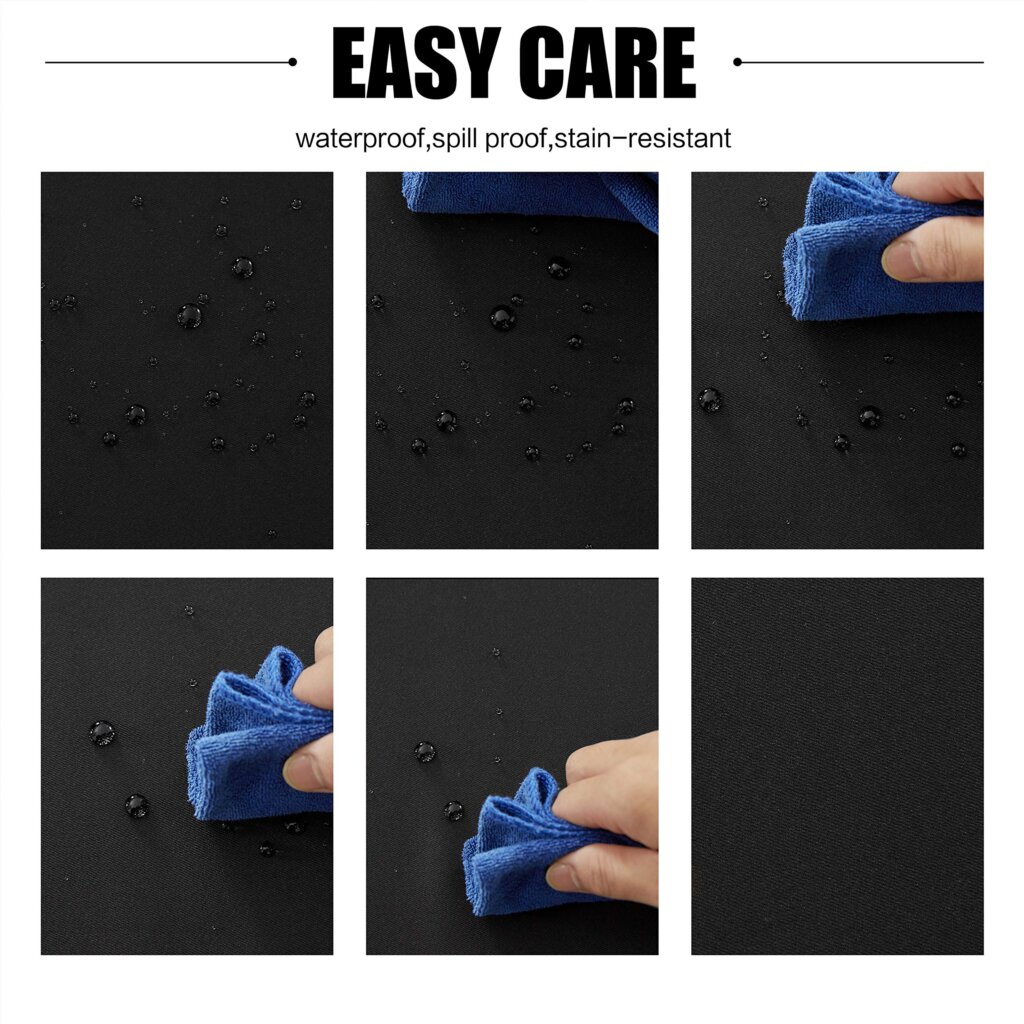

Pain Point 1 — Waterproof, leak-proof protection that must survive real-world use

- Scenario: Child’s rain jacket and medical bedding liners require reliable leak-proof performance, even after wear, washing, and flex cycles.

- Problem: Water intrusion and seam leakage cause dampness, cold spots, product returns, and compliance risks in regulated applications (e.g., healthcare).

Solution and how ProSoft helps:

– Design seams as sealed barriers:

– Use sealed seams (taped or welded) at critical zones (shoulders, cuffs, neck).

– Specify seam tape compatible with the laminate’s heat window; confirm bond via a 10-cycle flex and 24-hour pressure test.

– Use a continuous waterproof barrier:

– ProSoft fleece integrates a waterproof ECO-PUL barrier to block liquid water while retaining a plush fleece handfeel.

– Validate performance with repeatable tests:

– Fabric hydrostatic head (e.g., AATCC 42 or ISO 811) and leakage via ASTM D3393.

– Post-wash (AATCC 135 cycles) and flex (ASTM D3107) testing to monitor delamination and edge-wicking.

– Reduce edge and stitch ingress:

– Apply water-repellent edge coatings; use anti-wicking threads and tight stitch densities (e.g., 10–12 SPI).

– Inspect for stitch holes and pinholes; seal post-seam edges if needed.

– Quality controls and documentation:

– First-article inspection (FAI) for barrier integrity; include seam pull tests (ASTM D1683) and bonding checks.

– Maintain batch traceability and certificate of compliance for waterproof/leakproof claims.

Illustrative Image (Source: Google Search)

Pain Point 2 — Breathability and comfort in active use (or under pads)

- Scenario: Outerwear for outdoor activities and garments/pads that sit against skin must move moisture vapor to prevent clammy conditions and dermatitis.

- Problem: Low MVTR (Moisture Vapor Transmission Rate) leads to trapped moisture, sweat accumulation, and discomfort.

Solution and how ProSoft helps:

– Choose a breathable waterproof barrier:

– ProSoft’s ECO-PUL is engineered as a waterproof yet breathable barrier to allow moisture vapor passage while blocking liquid water.

– Use fleece on the body-facing side to trap warmth without trapping vapor when the breathable barrier is utilized as the outer barrier in garment construction.

– Engineer ventilation:

– Add micro-perforated zones, vents, or mesh-lined panels under arms, along sides, or in pad “dead zones.”

– Optimize insulation/air gaps; avoid vapor barriers on both sides of the layer.

– Use wicking linings and hydrophilic surfaces:

– Pair moisture-wicking inner layers with hydrophobic face fabrics for faster vapor exit.

– Test and target MVTR:

– Measure MVTR (e.g., ASTM E96, SW method) and target product-level performance that meets end-use needs.

– Calibrate with wearer trials under real conditions.

Pain Point 3 — Sustainability and chemical safety compliance across US/EU

- Scenario: Brands and manufacturers need compliant, responsibly sourced waterproof fabrics to meet market expectations and regulatory scrutiny.

- Problem: Inconsistent or unclear material sourcing, chemical content, and recycling claims trigger audits, delays, or rejections.

Solution and how ProSoft helps:

– Safety by design:

– ProSoft fleece incorporates BPA-free construction, aligning with safety standards and common procurement requirements.

– Material and sourcing transparency:

– Use supplier documentation including material disclosures, chemical inventories, and third-party certifications where applicable.

– Validate recycled content via standardized chain-of-custody documentation.

– End-of-life considerations:

– Engage in take-back or recycling programs; design modular components for easier separation of waterproof layers, face fabrics, and adhesives.

– Documentation for audits:

– Maintain Technical Data Sheets (TDS), material safety data (MSDS/SDS), Certificates of Analysis/Compliance, and test reports in a centralized quality management system.

– Quality management:

– Establish incoming inspection protocols, supplier scorecards, and periodic third-party testing to monitor performance and compliance over time.

Quick reference matrix

| Pain Point | Key Issue | Practical Solution | When to Consider |

|---|---|---|---|

| 1. Waterproof integrity | Leaks at seams, wicking edges | Sealed seams, post-seal edge protection, hydrostatic testing, post-wash flex checks | Jackets, ponchos, medical bedding liners, protective apparel |

| 2. Breathability | Clammy feel, moisture build-up | Breathable waterproof barrier, micro-vents, wicking inner layers, MVTR testing | Outerwear, sportswear, pads/diapers, healthcare garments |

| 3. Sustainability & compliance | Unclear materials/chemicals | BPA-free construction, material disclosures, verified recycled content, audit-ready documentation | US/EU brands and manufacturers with strict ESG requirements |

Notes

– Always validate performance claims with product-level testing under realistic end-use conditions (e.g., user trials for comfort, simulated use for durability).

– Confirm regulatory requirements by region (e.g., US FDA, EU REACH/PAH, consumer product standards) before making claims for specific end uses.

Illustrative Image (Source: Google Search)

Why ProSoft Fleece Waterproof ECO-PUL is a fit

– Combined comfort and protection: luxurious fleece feel plus a waterproof barrier for leak-proof performance.

– Breathability: engineered to allow moisture vapor transfer while blocking liquid water.

– Safety and sustainability: BPA-free construction; transparent sourcing and documentation to support compliance.

– Optional enhancements: Lycra stretch for flexibility; antimicrobial options for odor control in odor-prone environments.

This approach turns a soft microfiber fleece into a robust, waterproof solution that performs in the field—and clears audits on the business side.

Strategic Material Selection Guide for microfiber fabric waterproof

Strategic Material Selection Guide for Microfiber Fabric Waterproof

Purpose

Choose the right waterproof microfiber solution for your end-use by balancing performance, durability, sustainability, and compliance.

Decision criteria

- Use-case first

- Outerwear, kidswear, medical, bedding, diapers, sports, tents, or accessories.

- Must-haves: hydrostatic head (water column), MVTR (breathability), abrasion resistance, stretch, hygiene, and flammability behavior.

- Architecture

- Substrate (knit/woven microfiber), membrane/film (e.g., PU, TPU, ePTFE, bio-based PU), and finish (DWR, antimicrobial).

- Certification and compliance

- REACH (EU), Proposition 65 (CA, USA), CPSIA (USA), California SB-478 (Textile labeling). Confirm lab reports for claims like “waterproof,” “BPA-free,” and “antimicrobial.”

- Sustainability

- Recycled/bio-based content, film composition, solvent-free adhesives, and end-of-life options.

Key options at a glance

- ProSoft Fleece Waterproof ECO-PUL (Wazoodle)

- Soft plush fleece substrate bonded to a waterproof ECO-PUL film. Optional features: Lycra stretch and antimicrobial silver ions. Positions as BPA-free and breathable. Ideal for cozy, sensitive applications requiring warmth and leak protection.

- Conventional PUL (TPU or PU)

- Strong waterproofing, moderate breathability. Lower bio-content. Good for cost-driven and high-abrasion items.

- ePTFE (e.g., Gore) membranes

- High breathability and waterproofness, excellent durability. Typically premium-priced, and membrane care requirements may be strict. Check environmental compliance and sourcing availability.

- DWR + Durable Water Repellent (hydrophobic microfiber)

- Repels light water; not leakproof. Best for apparel where full waterproofing is not required.

- TPU extruded film lamination

- Consistent waterproofing; breathability varies by gauge and coating. Good for soft, flexible goods.

Fit by application

- Outerwear and sportswear

- Prefer breathable waterproof membranes. Consider stretch requirements (e.g., Lycra-containing composites).

- Kidswear and medical garments

- Prioritize softness, skin comfort, hygiene options, and validated waterproof/breathability. Ensure chemical compliance (CPSIA, REACH).

- Bedding and incontinence products

- Focus on leakproofness, wash durability, and dimensional stability. Antimicrobial options (e.g., silver) can reduce odors.

- Soft goods and accessories

- Balance cost, drape, and durability. Test seam integrity and tape adhesion in the intended construction.

How to validate performance (testing)

- Waterproof: Hydrostatic head (AATCC 42/ISO 811). Ask for minimum targets for your end-use.

- Breathability: MVTR/ASTM E96 orRET (ISO 11092). Align MVTR with activity level.

- Abrasion: Martindale/ASTM D4966 for rub resistance.

- Stretch/recovery: ASTM D2594 (knits) or ASTM D3107 (wovens).

- Seam and tape: Seam shear/peel strength; hydrostatic head of seam assemblies.

- Washing/shrinkage: ASTM D3597 or ISO 5077 dimensional change tests.

- Antimicrobial: AATCC 100 or ISO 20743 to substantiate silver-ion claims.

- Flammability: 16 CFR Part 1610 (USA) and relevant EN standards if applicable.

Construction and finishing notes

- Seam tape and adhesives must be compatible with the membrane/film to avoid delamination.

- If adding DWR, verify waterproof claims remain validated with the final composite and finish.

- For stretch, manage seam allowances and stress points to prevent seam failure.

- For skin-contact or hygiene uses, confirm hypoallergenic claims via appropriate lab tests.

Procurement in the USA and Europe

- Source: ProSoft Fleece Waterproof ECO-PUL is available through Wazoodle Fabrics; EU distributors include Milpoint (EU) and Cuddle Plush (UK).

- Lead time: Confirm stock vs. made-to-order. Provide target volumes and packaging needs.

- Quality documentation: Request test reports, TDS/SDS, REACH/CPSIA declarations, and Prop 65 statements.

- Sampling: Specify substrate, film type, and stretch requirements; evaluate drape, stitchability, and hand feel.

- MOQ: Clarify MOQs for custom colors, widths, or additional finishes.

Quick comparison table

| Option | Waterproof performance | Breathability | Durability (general) | Sustainability notes (per supplier) | Typical use-cases | Notable features (per supplier) | Certifications/notes |

|---|---|---|---|---|---|---|---|

| ProSoft Fleece Waterproof ECO-PUL | High (complete protection) | Moderate–High (breathable) | Moderate–High | ECO-PUL positioning; BPA-free; no plasticizers typical of BPA | Outerwear, kidswear, medical, bedding, diapers | Luxurious fleece hand; optional Lycra stretch; antimicrobial silver option | Confirm hydrostatic head/MVTR and antimicrobial data |

| Conventional PUL (PU/TPU film) | High | Low–Moderate | High | Varies by supplier | Diapers, soft goods, protective apparel | Versatile, cost-effective | Validate chemical and waterproof claims |

| ePTFE membrane composites | Very high | Very high | Very high | Environmental and regulatory compliance check (case by case) | High-performance outerwear, technical apparel | Premium performance | Care and membrane handling requirements |

| DWR-treated microfiber (non-laminate) | Low–Moderate | High | High | Depends on DWR chemistries | Light rain apparel, apparel linings | Lightweight, breathable | Not leakproof; validate DWR durability |

| TPU extruded film laminations | High | Varies (gauge dependent) | Moderate–High | Depends on formulation | Flexible waterproof goods | Soft hand, flexible | Validate film thickness, adhesion, and MVTR |

Notes

– ProSoft Fleece Waterproof ECO-PUL is a fleece–film composite marketed as waterproof and breathable, with optional antimicrobial silver ion treatment and stretch via Lycra. Confirm the hydrostatic head, MVTR, and wash durability required for your end-use.

– “BPA-free” refers to the film/membrane being free of Bisphenol A. Verify that other components (adhesives, finishes) meet your target standards.

– For EU/USA, align material and claims with REACH and Proposition 65, and obtain 16 CFR Part 1610 flammability data for apparel when applicable.

Illustrative Image (Source: Google Search)

If you provide your hydrostatic head, MVTR, stretch, and compliance targets, I can narrow the selection and specify construction or finishing recommendations for your application.

In-depth Look: Manufacturing Processes and Quality Assurance for microfiber fabric waterproof

In-depth Look: Manufacturing Processes and Quality Assurance for Microfiber Fabric Waterproof

Overview

– Microfiber waterproof fabrics, such as ProSoft Fleece Waterproof ECO-PUL by Wazoodle, integrate a plush microfiber fleece face with a waterproof barrier that is typically a laminated breathable polymer film or a bonded film; the material can be specified with stretch (e.g., Lycra Stretch-FIT) or antimicrobial treatments (e.g., Silver antimicrobial).

– The goal for OEMs and technical converters is to ensure a stable, repeatable process that delivers a breathable yet waterproof assembly, consistent with claims such as BPA-free and suitable for sensitive applications including children’s wear and medical garments.

Manufacturing Flow

1) Prep

– Fibers and DTY: Select microfiber polymer type and denier as specified; prepare drawn textured yarn (DTY) and knitting feedstock; verify fiber quality certificates and lot traceability.

– Scouring/Sizing: Clean yarn and greige goods to remove oils, finishes, and contaminants that could compromise bonding; adjust sizing for knitting performance and runability.

– Antimicrobial Finish (optional): If an antimicrobial effect is desired, apply an approved agent such as silver-based antimicrobial with controlled add-on, ensuring uniform distribution and compliance with safety standards.

2) Forming

– Knitting: Knit the fleece face fabric to target GSM and pile/loop height; control tenter geometry to maintain dimensional stability and ensure uniform thickness for lamination/bonding.

– Barrier Laminate/Bond: Bond a waterproof breathable polymer film or membrane (e.g., ECO-PUL layer) to the fabric back using controlled heat/pressure; verify film type and specification, ensuring BPA-free composition and consistent thickness.

– Additional Backings (optional): Apply stretchable backings (e.g., Lycra Stretch-FIT) when extra flexibility is required, and manage bonding to avoid delamination risk.

Illustrative Image (Source: Google Search)

3) Assembly/Finishing

– Heat Setting: Set tenter conditions (temperature and dwell) to stabilize dimensions and enhance barrier adhesion; ensure even tenter tracking to avoid skew or tentering drift.

– Brushing/Napping: Brush/nap the fleece side to achieve specified softness and loft; maintain consistent pile density to achieve tactile targets.

– Dye/Color: Dye or color-match the microfiber face; control pH, liquor ratio, and temperature to maintain colorfastness while preserving barrier integrity.

– Sanitization/Seam Treatments: Conduct mild sanitation as required for sensitive applications; evaluate seam tape/ultrasonic sealing for final assemblies where seam leak-proofing is critical.

4) Conversion/Slitting/Packaging

– Slitting/Rewinding: Slit to roll widths with controlled edge quality; avoid nicks that could compromise hydrostatic head performance.

– Packaging: Pack with protective films or liners to prevent contamination; label with lot, width, GSM, and date to support traceability.

Manufacturing Steps Overview

| Step | Key Controls | Risks | Expected Outputs |

|---|---|---|---|

| Prep (Fiber/Yarn) | Fiber denier, lot traceability, moisture content | Batch variability; contaminants | Homogeneous feedstock; stable processing |

| Knitting | GSM, stitch density, tenter width | Weight drift; dimensional instability | Uniform fleece face; controlled pile/loft |

| Barrier Bonding | Temperature, pressure, dwell, film spec | Delamination; film pinholes | Consistent waterproof membrane adhesion |

| Heat Setting | Temperature profile, tenter speed | Shrinkage drift; barrier degradation | Stable dimensions; durable bonding |

| Brushing/Napping | Brush settings, pile uniformity | Thin spots; surface damage | Luxurious fleece texture; uniform hand |

| Dye/Color | pH, time, temperature; dye class | Color shift; reduced breathability | On-target color; preserved performance |

| Sanitization | Cleanliness, antimicrobial add-on | Over/under-dosing; uneven finish | Hygienic product; stable efficacy |

| Slitting/Packaging | Edge quality, cleanliness; lot labeling | Edge nicks; contamination | Ready-to-ship rolls; full traceability |

Quality Assurance and Test Plan

– QA operates under a certified QMS such as ISO 9001 and aligned environmental management (ISO 14001); where applicable, consider ISO 13485 for medical garments and ISO 13845 for protective clothing performance claims.

– Incoming Controls: Verify film (BPA-free) certifications, yarn lot traceability, and finish inventories; document chemical compliance and safety data.

– In-Process Controls: Online tenter tracking, bonding line checks for temperature/pressure, and periodic moisture control to avoid adhesion issues.

– Final QC:

– Waterproofness: ISO 811 (hydrostatic head), ISO 4920 (rain test).

– Breathability/Moisture Transport: ISO 9237 (air permeability); ISO 11092 (thermal manikin or sweating guarded hotplate where applicable).

– Mechanical Durability: ISO 4674 (tear resistance), ISO 1421 (tensile strength), ISO 9237 (breathability vs. membrane function), ISO 3175 (care performance tests, if relevant).

– Comfort/Thermal: ISO 11092 (thermo-physiological comfort).

– Colorfastness: ISO 105-B02 (light), ISO 105-C06 (wash), ISO 105-E04 (sweat), ISO 105-D01 (dry cleaning).

– Dimensional Change and Creasing: ISO 5077 and ISO 7768.

– Seam Integrity: Evaluate seam strength and leak risk using ISO methods (e.g., seam strength via ISO 13935-2; adjust per fabric construction).

– Safety and Compliance: BPA-free verification; consider REACH compliance where applicable for EU markets and CPSC/ASTM requirements for U.S. markets.

Illustrative Image (Source: Google Search)

Quality Test Matrix

| Property | Method | Typical Target/Claim Alignment |

|---|---|---|

| Waterproofness (Hydrostatic Head) | ISO 811 | Waterproof barrier as claimed by vendor |

| Rain/Spray Resistance | ISO 4920 | Meets protective apparel expectations |

| Breathability (Air Permeability) | ISO 9237 | Confirms breathable performance |

| Thermal/Physiological Comfort | ISO 11092 | Validates comfort under activity |

| Tensile Strength | ISO 1421 | Suitable durability for use cases |

| Tear Resistance | ISO 4674 | Adequate tear propagation resistance |

| Colorfastness (Light/Wash/Sweat) | ISO 105-B02/C06/E04 | Stable color under expected use |

| Dimensional Change | ISO 5077 | Low shrinkage post-processing |

| Creasing Performance | ISO 7768 | Maintains usability post-packaging |

| Seam Strength/Leak Integrity | ISO 13935-2 + local seam tests | Seams do not compromise waterproof claims |

Process Control Variables

| Variable | Spec/Target | Acceptance Criteria | Sampling |

|---|---|---|---|

| Knit Weight (GSM) | Within ±3% of spec | Meets dimensional target | Every 10 rolls |

| Membrane Thickness | As per film spec | Within ±5% | Start/end of run |

| Bond Temperature/Pressure | As per lamination curve | ±2% tolerance | Hourly |

| Tenter Dwell/Heat Profile | As per recipe | ±2°C tolerance | Hourly |

| Moisture Content | 2–5% typical | No condensation | Twice per shift |

| Antimicrobial Add-on | As per vendor certificate | Uniform distribution | Batch |

| Colorfastness (Light) | ISO 105-B02 ≥ X | Meets application need | Batch |

| Hydrostatic Head | ISO 811 ≥ Y | Maintains claim | First, middle, last roll |

Sustainability and Compliance Notes

– Materials such as ProSoft Fleece Waterproof ECO-PUL feature BPA-free materials; suppliers indicate antimicrobial options and stretch enhancements (e.g., Lycra Stretch-FIT), which can help tailor fabrics for medical or active-use garments.

– Where performance claims are made for protective or medical applications, align testing and documentation with ISO standards and applicable regional regulations; ensure traceability and batch records.

Why this process matters

– A disciplined approach—controlling bonding parameters, maintaining dimensional stability, and validating barrier/breathability through ISO methods—ensures that microfiber waterproof fabrics deliver the promised comfort, protection, and durability while meeting the rigorous compliance expectations of North American and European OEMs.

Illustrative Image (Source: Google Search)

Practical Sourcing Guide: A Step-by-Step Checklist for ‘microfiber fabric waterproof’

Practical Sourcing Guide: A Step-by-Step Checklist for Waterproof Microfiber Fabric

Use this checklist to select, qualify, and contract the right waterproof fabric for your product, with a clear path to launch in the USA and EU. Waterproof microfiber (tightly woven polyester/polyamide) and microfiber-backed waterproof breathable laminates are distinct from fleece-backed systems; choose the format that matches your application and testing requirements.

1) Define application and performance targets

- Map product use: outerwear, sportswear, medical textiles, reusable hygiene/pads, bedding/pillow protection, children’s sleepwear, etc.

- Set waterproof performance:

- Hydrostatic head: e.g., ≥1,500 mm for light rain to ≥5,000–10,000 mm for heavy rain or continuous exposure.

- Fabric waterproofness (AATCC 42): e.g., ≤1.0 g (low water resistance) for outerwear, or ≤0.2 g for heavy-duty.

- Seam leakage: specify “seams taped,” with seam hydrostatic head (AATCC 42 with seam) at 80–100% of face fabric.

- Select breathability:

- MVTR: e.g., ≥5,000 g/m²/24 h (comfort) or ≥10,000 g/m²/24 h (high-activity garments).

- Air permeability: ≤1.0 cfm for outerwear where windproofing matters.

- Set durability:

- Wash cycles: e.g., 25–50 home laundries; specify detergent (AATCC 1993) and water temperature.

- ABR (Abrasive-bruise) or Martindale abrasion: minimum cycles based on expected wear.

- Moisture barrier function:

- Absorbency: required for hygiene/medical pads; use DMP for fast testing (e.g., ≥0.3 g/s for immediate absorption), AATCC 195 for vertical wicking/absorption, and AATCC 79 for absorbency time.

- Mechanical requirements:

- Hand/handle and drape vs. fleece back; stretch/recovery if mobility is critical (e.g., Lycra Stretch-FIT).

- Antimicrobial option:

- Required for odor control in apparel or medical hygiene; confirm biocidal claims (silver ions) align with regulations and testing (AATCC 100).

2) Decide material format and construction

- Choose waterproof microfiber vs. fleece-backed ECO-PUL:

- Waterproof microfiber: woven microfiber face with DWR and a PU/TPU/PE layer for low-temperature lamination or low-melt adhesives.

- Fleece-backed ECO-PUL: waterproof breathable laminate with plush fleece interior (e.g., ProSoft Fleece Waterproof ECO-PUL), including optional Lycra stretch and antimicrobial silver ion options.

- Specify face fabric:

- Denier/yarn: e.g., 0.7–1.0 dpf microfiber; finish: brushed/napped; DWR grade as needed.

- Specify back/laminate:

- PU/TPU/PE laminate (microporous or monolithic), lamination GSM, seam tape type.

- Confirm hand/feel and insulation:

- Use fleece-backed ECO-PUL when soft hand and warmth are essential (e.g., children’s sleepwear, soft liners).

3) Specify compliance and safety

- USA:

- Prop 65 (CA), CPSIA for children’s items (heavy metals, pH).

- Azo dyes, formaldehyde restricted substances as applicable (AATCC 112, pH).

- EU (REACH):

- REACH SVHC compliance, biocidal product rules for antimicrobial claims.

- OEKO-TEX Standard 100 or bluesign for chemical assurance.

- Food/medical:

- Food-contact suitability where relevant; BPA-free is common for laminates and can be requested.

- Labeling:

- Care instructions aligned with laminate and seam tape specifications.

4) Set sustainability and traceability

- LCA and recycled content: ask for recycled fiber percentage (e.g., recycled polyester) and manufacturer disclosures.

- Chemically safer finishes: low-VOC resins, REACH-compliant dyes/finishes.

- Supplier transparency: request product safety data sheets (SDS) and chemical inventories.

5) Evaluate suppliers and channels

- Direct manufacturers vs. specialty laminate suppliers (for ECO-PUL technology, consider suppliers like Wazoodle with ProSoft Fleece Waterproof ECO-PUL).

- Distributor networks:

- USA/Canada via US distributors; verify local stock and technical support.

- Europe via regional warehouses (e.g., Milpoint – EU) for faster lead times and compliance support.

- Ask for:

- Technical datasheets, SDS, REACH/Prop 65 statements, OEKO-TEX listings, and laminate process description.

- Minimum order quantities (MOQs), lead times, dye-lot tolerances, and defect warranties.

6) Quality assurance and sampling

- Sampling plan:

- Request fabric swatches, construction samples, and a cut/sew kit (laminate and seam tape).

- Pre-production runs:

- Produce ≥3 pilot production units for field testing (comfort, breathability, seams).

- Quality agreements:

- Agree on AQL levels (fabric: 1.0–1.5), wash-test protocol, seam specifications, and defect SLAs.

- Test reports:

- Verify independent labs; perform comparative tests in-house before scale-up.

7) Define waterproof test methods and thresholds

- Waterproofing:

- ISO 811 (hydrostatic head)

- AATCC 42 (water resistance); specify face and seam tests

- Breathability:

- ASTM E96 (MVTR), JIS L 1099 A (MVTR), ASTM D737 (air permeability)

- Durability:

- AATCC 135 (care/laundering), ISO 6330; AATCC 135/1993 detergent; ASTM D3512/D3511 (abrasion)

- Absorption:

- AATCC 79 (time to absorb), AATCC 195 (vertical wicking/absorption), DMP (instant absorbency)

- Antimicrobial:

- AATCC 100 (antimicrobial efficacy)

- Seam integrity:

- Specify taped seam dimensions, tape grade, and edge sealing methods.

8) Contract terms and logistics

- Pricing:

- FOB/CIF; confirm currency and price protection for long projects.

- Lead times:

- Typical 2–4 weeks for stocked laminate; 6–10+ weeks for custom constructions.

- Payment:

- LC/TT terms; deposit for custom runs; milestone-based payments.

- Returns/claims:

- Clear cut-offs (laundering cycles, field trials), photo documentation, sampling retention for dispute resolution.

- Incoterms:

- DDP/DAP for USA; Incoterms 2020 terminology for EU shipments.

- Packaging:

- Roll lengths, width tolerance, core size; moisture-protected packaging.

9) Risk and change control

- Material change notification:

- 60–90 days for laminate chemistry or supplier changes.

- Chemical compliance monitoring:

- Annual REACH and Prop 65 updates; supplier change requests.

- Lifecycle data:

- Track wash durability and breathability performance over production lots.

10) Quick supplier scoring template

- Technical fit: 40 (waterproof, breathability, hand/feel)

- Compliance & sustainability: 25 (REACH/Prop 65, OEKO-TEX, recycled content)

- Quality and support: 20 (test data, sampling, documentation)

- Commercial terms: 15 (price, MOQs, lead time, Incoterms)

Example fit: ProSoft Fleece Waterproof ECO-PUL is waterproof, BPA-free, and breathable, and offers antimicrobial silver and Lycra stretch options—ideal for soft, warm products where comfort and leakproof performance matter. Use this to match against your performance targets and test plan.

Comprehensive Cost and Pricing Analysis for microfiber fabric waterproof Sourcing

Comprehensive Cost and Pricing Analysis for Waterproof Microfiber Fabric Sourcing

What matters to cost and pricing

- Total landed cost in the US/EU is a blend of materials, converting, labor to assemble final products, compliance/QC, and logistics to import and deliver.

- ECO-PUL waterproof systems carry a premium for safety (BPA-free), breathability, and durability compared with conventional TPU/PUL; however, they can reduce returns and warranty costs due to performance consistency.

- Breathability, softness, and antimicrobial options (e.g., Lycra Stretch-FIT; antimicrobial silver) influence material grade, converting complexity, and inventory choices (stock vs. custom runs).

Cost Structure Overview

| Category | What drives cost | Typical cost drivers | When costs spike | How to stabilize costs |

|---|---|---|---|---|

| Materials | Base fabric (microfiber), waterproof/breathable barrier (ECO-PUL/PUL), finishes (antimicrobial), stretch additives | Grade and GSM; barrier technology; antimicrobial; stretch content | Custom finishes, small lots, extended MOQs | Spec commonality across SKUs; negotiate annual needs; use stock widths/weights |

| Converting | Laminating, calendaring, backing, lamination quality checks | Breathability targets; uniformity; defect rate | Frequent rewinds due to pinholes/line defects; tighter hydrostatic head | Supplier QA gates; agree on acceptable defect limits; run consistent specs |

| Labor (cut-and-sew) | Garment assembly, seam sealing, edge finishing | Stitch types; seam tape cost/time; trimming | Complex patterns; reworking seam leaks | Standard seams; bundle designs; use thermal bonding where appropriate |

| Compliance & QC | BPA-free and chemical compliance, OEKO-TEX, REACH/SVHC, breathability testing | Number of SKUs and tests; repeat audits | New finishes and colorways | Batch release testing for critical SKUs only; reuse test data where possible |

| Packaging | Bags, boxes, labeling | Branding, size, inserts | Branded retail packaging | Use scalable packaging; consolidate SKUs into few box sizes |

| Logistics & Duties | Freight, insurance, customs, duties, VAT | L/C or NET terms; split billing vs. DDP; EU VAT registration | Small packages; cross-border B2C shipping | Use consolidated freight; clear HS codes; plan customs broker ahead |

Materials and Converting Costs

| Item | US | Europe | Notes |

|---|---|---|---|

| Base fabric (microfiber jersey/knit, 150–250 gsm) | ~$1.60–$3.00/yd | ~€1.50–€3.00/yd | Cheaper at volume; microfibers can stabilize at ~1.8–2.4 |

| ECO-PUL waterproofing (BPA-free, breathable) | ~$4.00–$8.00/yd | ~€4.00–€8.00/yd | Breathability and durability drive price; premium for antimicrobial silver |

| Finishing (soft-touch, antimicrobial silver) | +$0.50–$1.00/yd | +€0.50–€1.00/yd | Optional; impacts material cost and shelf-life |

| Stretch additive (Lycra Stretch-FIT option) | +$0.50–$1.00/yd | +€0.50–$1.00/yd | Adds recovery and comfort; affects cutting efficiency |

| Laminating/converting overhead | ~$0.80–$1.20/yd | ~€0.80–€1.20/yd | Includes rewind/QC; quality consistency reduces waste |

| Material total (mid-tier antimicrobial breathable) | ~$6.90–$13.60/yd | ~€6.90–€13.60/yd | Prices vary by grade; confirm lead times for specialty finishes |

- US prices shown as examples (range). EU shown with currency for clarity; treat ranges as indicative benchmarks.

- ECO-PUL systems (breathable, BPA-free) often command a higher base cost than standard PUL, but can deliver fewer seam failures and lower returns, improving margin per unit.

Labor to Cut-and-Sew (per finished piece)

| Component | US | Europe | Notes |

|---|---|---|---|

| Base construction (assembly, hems) | $2.50–$6.00 | €2.50–€6.00 | Complexity and ergonomics drive hours |

| Sealing/edge finishing | $0.60–$1.20 | €0.60–€1.20 | Thermal tape or sewn + sealed seams |

| Quality inspection | $0.20–$0.40 | €0.20–€0.40 | Incoming + pre-pack checks |

| Trimming/packaging | $0.30–$0.60 | €0.30–€0.60 | Includes labeling and insert |

| Labor total | $3.60–$8.20 | €3.60–€8.20 | Standardizing patterns reduces rework and cost |

- Seam sealing is the biggest variable; designing simpler seam geometries can cut costs and defects.

Logistics & Duties (US vs. EU)

| Mode | US (domestic) | US (import) | Europe (intra-EU) | Europe (import from outside) |

|---|---|---|---|---|

| Freight | ~$0.04–$0.10/lb | Ocean 40′ ~$0.04–$0.08/lb; Air ~$1.50–$4.00/lb | ~€0.06–€0.12/kg | Ocean 40′ ~€0.04–€0.08/kg; Air ~€1.50–€4.00/kg |

| Lead time | 3–7 days | 7–28 days (ocean); 3–7 days (air) | 2–6 days | 7–28 days (ocean); 3–7 days (air) |

| Customs/clearance | Minimal | Broker + customs fees vary | Minimal | Broker + customs fees vary |

| Duties (fabric) | Typically 0% | Typically 0% | 0% intra-EU | Tariffs vary by HS code/country |

| VAT | N/A | N/A | VAT paid/recoverable on domestic flows | VAT on import; local VAT for sales |

| Notes | Optimize LTL vs. FTL | FOB/CIF impacts delivery risk | Use regional warehouses | Use IOR/EOR to simplify compliance |

- Clear HS codes upfront. Keep a single broker for US/EU to smooth customs and documentation.

- Domestic US and intra-EU shipments usually cost less and arrive faster than transatlantic moves.

Pricing Model (Mid-tier, Breathable, BPA-free)

| Element | Per yard | Per piece (250 g) |

|---|---|---|

| Material (mid-grade, antimicrobial) | $7.50 | $0.94 |

| Converting (lamination/QC) | $1.00 | $0.13 |

| Direct labor | – | $5.40 |

| Packaging | – | $0.40 |

| Compliance & testing | – | $0.20 |

| Overhead (utility, depreciation, G&A at 10%) | – | $0.72 |

| Logistics (domestic US) | – | $0.20 |

| Total manufacturing & logistics cost | – | $8.19 |

| Target margin (e.g., 55–65%) | – | $12.80–$13.65 |

| Suggested wholesale (per piece) | – | ~$12.80–$13.65 |

| Suggested retail (per piece) | – | ~$25.60–$27.30 |

- Per-piece material cost assumes 2.0 yards per piece; weight 250 g for shipping math.

- Use currency conversion for EU pricing; retain the same cost architecture.

Comparative Sourcing Options

| Supplier/Path | Strengths | Risks/Costs | Best for |

|---|---|---|---|

| Wazoodle (ProSoft Fleece ECO-PUL) | Waterproof, breathable, BPA-free; antimicrobial and stretch options; mature quality | Premium material price; inventory on specialty grades varies | Mid-volume runs needing consistent quality and certifications |

| EU local PUL converters | Faster intra-EU logistics; easier compliance (REACH/SVHC coverage) | Higher labor cost; potential higher material price | Mid-volume EU sales with strict regulatory timelines |

| Asian converters | Competitive material price; broad finish options | Longer lead times; air freight cost volatility; shipping from outside EU triggers duties/VAT | High-volume, cost-focused programs with tolerance for lead time |

How to Save Cost without Sacrificing Performance

| Action | Why it works | Impact (US/EU) |

|---|---|---|

| Standardize widths and weights across SKUs | Reduces setup time and scrap; simplifies cutting | Lower per-unit cost; faster lead times |

| Bundle designs with shared seam geometry | Simplifies seam sealing and training | Fewer defects; lower labor cost |

| Use stock finishes and colors first | Avoids custom dye/finish surcharges | Cuts material cost; improves availability |

| Negotiate annual needs and volume bands | Locks in pricing and allocation | Price stability; smoother supply |

| Plan freight mode by demand urgency | Uses ocean for steady runs; air for spikes | Balanced cost and service levels |

| Consolidate SKUs into larger batch orders | Amortizes logistics and conversion overhead | Lower cost per unit; better yield |

| Implement supplier QA gates (before lamination and post-lamination) | Catches defects early | Reduces waste and reworks |

| Keep compliance scope focused (test only critical SKUs) | Avoids redundant testing | Lower compliance cost |

Risk and Variability

| Driver | Impact | Mitigation |

|---|---|---|

| Lead time variance | Stockouts or expedited freight | Buffer stock + monthly top-up; dual-source critical grades |

| Freight spikes (air/ocean) | Cost overrun | Flexible mode choice; forward bookings during peak seasons |

| Customs/documentation errors | Delays, detention fees | Experienced broker; pre-clearance planning; correct HS codes |

| Finish performance inconsistency | Returns, warranty | Post-lamination checks; agree on QA thresholds; pilot runs |

| EU VAT/Importer of Record complexity | Cash flow friction | Appoint local IOR/EOR; register for VAT early; plan invoicing rules |

Bottom Line

- A credible price in the US/EU for breathable, BPA-free, antimicrobial ECO-PUL microfiber systems is built on: materials, converting quality, controlled labor, smart logistics, and tight compliance.

- In practice, most savings come from standardization, supplier QA, and logistics planning, not just chasing the lowest fabric price.

Alternatives Analysis: Comparing microfiber fabric waterproof With Other Solutions

Alternatives Analysis: Comparing Microfiber Fabric Waterproof With Other Solutions

At-a-Glance Comparison

| Criteria | Waterproof Microfiber Fabric (ECO‑PUL/Monolithic TPU on fleece) | ePTFE Microporous Membrane Laminate | TPU/Copolyester Microporous Laminate |

|---|---|---|---|

| Waterproof performance | Reliable waterproof barrier; hydrostatic head generally ≥10,000–20,000 mm (varies by construction) | High hydrostatic head; widely 10,000–28,000+ mm | Moderate to high; typically 5,000–15,000 mm |

| Breathability (MVTR) | Monolithic barrier—lower MVTR; suitable for lower-activity use | Higher MVTR via pores; better for active wear | Moderate MVTR; between monolithic and ePTFE |

| Breathability (RET) | Higher RET (tends to feel warmer); typically >6 | Lower RET (more breathable), 3–6 typical | Mid-range RET; 4–10 typical |

| Moisture handling vs climate | Insulating when layered; best for cold, static conditions | Better vapor transport for dynamic use | Balanced, varies by laminate |

| Softness, drape, hand | Soft fleece face/back; very comfortable | Membrane feel can be stiffer or crisper | Often stiffer than fleece; softer than some ePTFE |

| Stretch & flexibility | Often added Lycra for stretch; very flexible | Limited stretch unless engineered | Better stretch than ePTFE; depends on lamination |

| Abrasion & durability | High abrasion tolerance; fleece durable | Durable shells; membrane susceptible to contamination | Good durability; less seam stress than ePTFE |

| Wash/dry resilience | Stable; monolithic resists pore contamination | Sealed seams critical; performance drops if pores clog | Robust; pore clogging less critical than ePTFE |

| Seam sealing | Typically heat-laminated seams; lower complexity | Taped seams required; critical to waterproofness | Sealed or taped seams for waterproof ratings |

| Chemical/skin sensitivity | Choice of BPA-free films, hypoallergenic fleece | Contact surfaces vary by textile stack | Often PFAS-free choices; check resin specifics |

| Sustainability | Use of recycled backings; check TPU/PFAS status | Recyclable structures exist; PFAS often present | Recycled backings common; PFAS-free options available |

| Relative cost | Mid-range | Upper mid-range | Mid-range |

| Typical uses | Baby/kids layers, blankets, pet gear, mid-layers | High-performance outerwear, technical apparel | Everyday outerwear, gear needing water resistance |

Detailed Comparison

Waterproof Microfiber Fabric (ECO‑PUL/Monolithic TPU on fleece)

- Best for cold, dry, or semi-wet environments where comfort and warmth matter more than high vapor transport.

- Advantages: soft hand; added stretch options; fewer pore-related maintenance issues; strong abrasion resistance; hypoallergenic fleece backings often available.

- Limitations: lower breathability at higher activity levels; can feel warmer; seam sealing quality depends on heat bonding process.

- Typical applications: baby/kids garments, sleepwear, blankets, pet apparel, mid-layers, healthcare apparel.

ePTFE Microporous Membrane Laminate

- Designed for high breathability during active use; proven in technical outerwear.

- Advantages: very high hydrostatic head and MVTR; excellent vapor transport when clean; robust in rain protection.

- Limitations: pore contamination reduces breathability; requires meticulous seam sealing/taping; can feel stiffer; performance sensitive to detergents/residue.

- Typical applications: high-performance rainwear, alpine/mountain gear, athletic outerwear.

TPU/Copolyester Microporous Laminate

- Mid-ground between monolithic and ePTFE for breathability, cost, and processability.

- Advantages: good water resistance; moderate MVTR; easier to seam tape/heat seal; flexible for garment construction.

- Limitations: mid-range breathability; durability and performance vary with laminate stack; may not match ePTFE in sustained heavy rain/activity.

- Typical applications: everyday outerwear, workwear, school jackets, recreational apparel.

Performance by Scenario

| Use case | Best suited option | Rationale |

|---|---|---|

| Cold, low-intensity work (warehouse, winter commuting) | Waterproof Microfiber Fabric | Warmth and comfort; reliable waterproof barrier without high breathability demand |

| High-exertion activities (hiking, cycling in rain) | ePTFE Laminate | High vapor transport under load; proven weather protection |

| Everyday rainwear, moderate activity | TPU/Copolyester Laminate | Balanced water resistance and breathability; cost-effective |

| Baby/kids sleepwear, sensitive skin | Waterproof Microfiber Fabric | Soft, hypoallergenic feel; stable waterproofing |

| Pet apparel and blankets | Waterproof Microfiber Fabric | Abrasion tolerance and comfort; good for static use |

| Healthcare gowns (moderate wet exposure) | Waterproof Microfiber Fabric or TPU Laminate | Water barrier with manageable breathability for stationary use |

Decision Notes for B2B Procurement (USA, Europe)

- Validate regulatory status (BPA-free where applicable; confirm PFAS usage in membranes and DWR finishes).

- Confirm seam sealing method and warranty implications in garment specs.

- Consider end-of-life: recycled backings, material identification for circularity, and laminate recyclability pathways.

- Align breathability with target activity: choose monolithic for low-intensity wear, microporous membranes for dynamic use.

Bottom Line

- Choose waterproof microfiber fleece for comfort-forward, low-to-moderate activity products that need warmth and a reliable barrier.

- Choose ePTFE for high-exertion, long-duration weather protection where maximum breathability is critical.

- Choose TPU/copolyester microporous laminates for everyday outerwear needing balanced waterproofing, breathability, and processability.

Essential Technical Properties and Trade Terminology for microfiber fabric waterproof

Essential Technical Properties and Trade Terminology for Microfiber Fabric Waterproof

Why this matters

Microfiber waterproof fabrics combine fine polyester/polyamide fibers with coatings, laminates, or membranes to deliver superior moisture protection with user comfort. For USA and EU buyers, align specifications, testing, and commercial terms to avoid disputes and to meet regulatory expectations.

1) Material & Construction (Microfiber “Waterproof” context)

| Property | What to specify | Common options | Notes |

|---|---|---|---|

| Fiber type | Microdenier filament or spun polyester/polyamide microfibers | Polyester (e.g., DP 0.8–1.0 dtex), Polyamide (nylon), blends | Microfibers improve drape, softness, and high-surface-area backing for coatings. |

| Backing | Knitted/woven base + finish | Fleece, brushed knit, plain woven | Example: ProSoft Fleece Waterproof ECO-PUL integrates plush fleece with a breathable waterproof barrier. |

| Waterproof membrane/laminate | PU/TPU film or hydrophilic/hydrophobic membrane | PU/TPU laminated, PU-coated backer | PU/TPU often supports heat/weld sealing; hydrophilic systems rely on diffusion. |

| Optional enhancements | Stretch, antimicrobial | Lycra/Stretch-FIT, antimicrobial silver ions | Enhance flexibility and odor control where relevant. |

| Face fabric finishes | Durable Water Repellency (DWR) | C0–C6 DWR (C6 typical, C0 increasingly requested) | DWR aids water-beading and surface repellency; durability tracked via spray/impact tests. |

| Recycled content | Definition | Post-consumer PET (rPET) | Claimable when certified (e.g., GRS). |

| Safety claims | Example | BPA-free | Wazoodle highlights BPA-free for product safety assurance. |

2) Waterproof Performance

| Property | Target metric | Typical method | Buyer value |

|---|---|---|---|

| Waterproofness (hydrostatic head) | ≥ 5,000 mm; heavy-duty ≥ 10,000 mm | ISO 811 (AATCC 127) | Confirms rain/leak resistance under pressure. |

| Rain/splash resistance | Grade 4+ of 5 (ISO 5) | ISO 5 (AATCC 22 spray test) | Validates light rain repellency and surface dryness. |

| Water impact resistance | 60–80% water repellency | AATCC 42 (Impact Penetration) | Useful for vertical products exposed to splashes. |

| Seam integrity | Leak-free under stress | ASTM D751 (seam leakage); ISO 16603 (penetration under pressure) | Critical for assembled garments/coverings. |

| Fabric-to-coating adhesion | ≥ specified N/mm or wash-stability % | ISO 2411 or internal wash-cycling protocols | Ensures barrier durability after laundering. |

3) Breathability (Comfort)

| Property | Target metric | Typical method | Buyer value |

|---|---|---|---|

| MVTR (Moisture Vapor Transmission Rate) | 3,000–15,000 g/m²/24h (per design intent) | ASTM E96 (Proc B or UW), ISO 15496 | Confirms comfort during wear; higher values for active use. |

| Ret (evaporative resistance) | ≤ 6–13 m²·Pa/W (sport/outdoor target) | ISO 11092 (Sweating Guarded Hotplate) | Lower Ret indicates better heat/moisture transfer. |

| Air permeability | Product-dependent | ASTM D737 | Airproofing can be intentional (windproof designs). |

4) Durability & Care

| Property | Protocol | Typical spec | Buyer value |

|---|---|---|---|

| Abrasive durability | Martindale/Taber | Maintain waterproofness ≥ 80% of initial after cycle set | Shows wear resistance for apparel/backpacks. |

| Wash durability | 30–50 domestic cycles typical (product-specific) | Maintain hydrostatic head and MVTR within ±15–20% | Confirms performance retention after laundering. |

| Cold/heat stability | −20°C to +60°C (storage/use) | No delamination or stiffening | Ensures transport and seasonal use reliability. |

| UV and colorfastness | Lightfastness ≥ grade 4–5 (ISO 105-B02), washing ≥ grade 4 | ISO 105-B02/B06 | Protects appearance and barrier after sun exposure. |

5) Mechanical & Physical

| Property | Method | Typical target | Notes |

|---|---|---|---|

| Tear strength | ASTM D1424 or ASTM D2261 | Specified by end-use | Critical for snag resistance. |

| Burst strength | ASTM D3786 | Specified by end-use | Confirms integrity under pressure. |

| Tensile strength | ASTM D5034 | Specified by end-use | Baseline robustness for seams/edges. |

| Stretch & recovery | ASTM D2594 | Specified if stretch options included | Important for fitted garments/covers. |

| Softness/handle | Handle-O-Meter | Used for comfort characterization | Helps with subjective feel consistency. |

6) Safety & Compliance (USA/EU)

| Area | Typical requirement | Notes |

|---|---|---|

| Chemical compliance | BPA-free; SVHC screening; PFAS control | Example BPA-free claim visible in ProSoft product family; confirm PFAS-free via material declarations. |

| REACH/TSCA | RoHS/REACH compliance | Verify absence of restricted substances; request SDS. |

| Flammability | End-use specific | E.g., apparel vs. medical vs. accessories; require test reports. |

| OEKO-TEX | Standard 100/ECO PASSPORT | Optional certifications for chemicals/eco-profile. |

| Food contact (if applicable) | FDA/EU 1935/2004 | For reusable liners; request compliance proof. |

| Medical/biomedical | ISO 10993 series if applicable | For sensitive applications; validate cytotoxicity/skin contact. |

| Sustainability | Recycled content (GRS), transparency | Traceability via supplier documentation. |

7) Sustainability & Chemistry

- PFAS-free: Increasingly mandated; demand ZDHC/chemical disclosures.

- BPA-free: Useful for medical/child-use; keep verified in your compliance dossier.

- DWR chemistries: Document C0 vs C6 options and environmental profile.

- Recycled content: Claim only with GRS; require supplier certificates.

- VOC/chemicals: Align with US/EU regulations and buyer chemical policies.

8) Testing Standards to Request/Align

| Domain | Method | Reference |

|---|---|---|

| Waterproofness/hydrostatic head | ISO 811 (AATCC 127) | Water penetration resistance under pressure. |

| Spray rating | ISO 5 (AATCC 22) | Surface repellency (rain/splash). |

| Impact penetration | AATCC 42 | Resistance to water impact. |

| Seam leakage | ASTM D751; ISO 16603 | Seamed integrity under pressure. |

| Breathability MVTR | ASTM E96 Proc B/UW; ISO 15496 | Moisture vapor transmission. |

| Breathability RET | ISO 11092 | Evaporative resistance. |

| Air permeability | ASTM D737 | Optional for windproof designs. |

| Abrasive durability | Martindale (ISO 12947), Taber | Wear resistance. |

| Wash durability | AATCC 135/150 | Maintenance of performance after laundering. |

| Burst/tear/tensile | ASTM D3786 / D1424 / D5034 | Mechanical robustness. |

9) Trade Terms & Commercial Framework

| Term | Definition/Usage | Notes |

|---|---|---|

| MOQ (Minimum Order Quantity) | Smallest run per style/color | Confirm per colorway/width; 300–1,000 yds typical, product-dependent. |

| Lead time (LT) | Purchase Order to shipment | Usually 2–8 weeks depending on finish/dye/lamination capacity. |

| OEM/ODM/Customization | Custom finish, colors, weights | Specify hydro head, MVTR, finish, antimicrobial, stretch. |

| Custom colorways | Pantone/ISO/brand standards | Batch-to-batch color match; shade band agreements recommended. |

| Widths/roll lengths | Standard widths 54–60 in typical | Rolling on tubes, tube length per supplier. |

| Quality assurance (QA) | Inspections/testing protocols | AQL per buyer; pre-production sampling ( PPS ), pilot runs. |

| Lab dip/ strike-off | Color/finish approvals | Required for brand compliance before bulk. |

| Care labeling | Washing/care guidance | Impacts claims for wash durability; align with test protocols. |

| Claims management | Waterproof/breathable | Tie claims to specific methods and thresholds; avoid generic statements. |

| Incoterms | FOB/CIF/DAP/DDP typical for USA/EU | Define responsibilities for freight, insurance, duties. |

| Payment terms | e.g., 30–60 days NET, LC at sight | Negotiate with credit terms/insurance. |

| Liability/indemnity | Terms for claims | Align with QA and post-sale support. |

| Sampling | Stock samples vs. custom | Set sample fees and lead times; maintain consistency. |

| Documentation | SDS, compliance, test reports | Maintain technical file for audit. |

| Warranty | Performance over a defined period | Based on test-backed performance maintenance. |

10) How ProSoft Fleece Waterproof ECO-PUL Relates

- Integrated waterproof barrier with breathable membrane/laminate; offers soft fleece texture for warmth and comfort.

- Optional enhancements (e.g., stretch via Lycra; antimicrobial silver ions) suit apparel and sensitive applications.

- BPA-free positioning demonstrates proactive safety posture; buyers should still request full REACH/chemical documentation.

11) Buyer Checklist (USA/EU)

- Define waterproofness (ISO 811), seam integrity (ASTM D751), and breathability (ASTM E96 or ISO 11092).

- Request PFAS-free and BPA-free statements with documentation; specify DWR type (C0 vs C6).

- Align wash/abrasion protocols and acceptance criteria; agree on AQL levels.

- Define chemical compliance (REACH/TSCA), certifications (OEKO-TEX, GRS), and any medical testing (ISO 10993).

- Confirm MOQ/LT, payment terms, Incoterms, and sampling/approval process before bulk orders. ✅

This section gives you the technical baselines and commercial terminology to specify, procure, and qualify microfiber waterproof fabrics across USA/EU markets, while supporting product performance claims and regulatory alignment.

Illustrative Image (Source: Google Search)

Navigating Market Dynamics and Sourcing Trends in the microfiber fabric waterproof Sector

Navigating Market Dynamics and Sourcing Trends in the Microfiber Fabric Waterproof Sector

Market overview and drivers

– Demand growth is concentrated in outdoor/active apparel, children’s wear and school gear, medical/adaptive textiles, and textile rental/linen services. Buyers prioritize reliable waterproofing, comfort, and ease of care while meeting increasingly strict chemical safety regulations.

– US and EU buyers are converging on PFAS restrictions, circularity requirements, and documented performance claims. Microfiber waterproof fabrics that pair breathable laminates or membranes with soft, warm hand are gaining traction in premium midlayers and jackets.

– Brands are balancing waterproofness with breathability and noise control; hydrophilic/oleophobic membranes and water-based laminates are winning favor versus heavy fluorocarbon finishes.

Demand Drivers & End‑Uses

- Outdoor/Active: Lightweight waterproof midlayers and 2‑layer shells for hiking, cycling, and ski sports; breathability and packability matter.

- Children’s Wear/School Gear: Waterproof, soft-touch fleeces for jackets, snow pants, and bags; comfort and safety certifications are essential.

- Healthcare/Adaptive: Waterproof barriers under soft fleece for patient gowns and therapy wearables; hygiene, durability, and laundry performance matter.

- Rental/Commercial Laundry: Durable waterproof layers for workwear, spa and hospitality robes, and rental blankets; industrial washability and repairability are key.

Technology landscape (membranes, laminates, finishes)

| Technology | How it works | Strengths | Trade‑offs | Sustainability notes |

|---|---|---|---|---|

| ePTFE microporous membrane | Microporous barrier lets vapor out, blocks liquid | High hydrostatic head, proven breathability | Noise, can pick up oil contamination; seam taping critical | PFAS‑free ePTFE avoids C8 chemistry; long life cycle |

| TPU hydrophilic membrane | Active transport of moisture by diffusion | Soft hand, quiet, good stretch | MVTR varies; needs tuned face/laminate stack | Can be water‑based; BPA‑free claims relevant to PU systems |

| Laminate vs. bonding (e.g., ECO‑PUL) | Bonded or laminated barrier to fleece or woven backer | Microfiber tactility retained; simple care | MVTR depends on construction and glue pattern | Water‑based, breathable laminates align with chemical restrictions |

| Coatings (PU, silicone‑PU hybrids) | Direct coating on backer | Cost-effective, flexible constructions | Durability varies by wash cycles and abrasion | Water‑based and BPA‑free claims reduce hazard profile |

| DWR finishes (C0/C6 PFAS) | Surface repellency for hydro repellency | Improves initial hydrostatic head and rain shedding | C6 fading over time; C0 requires re‑finishing | Shift to PFAS‑free and durable mechanical solutions is accelerating |

Regulatory & compliance landscape

- US: Many states have enacted or proposed restrictions on PFAS in apparel and textiles (e.g., Maine; pending federal action under TSCA authorities). State regulations differ; a harmonized national approach is forming.

- EU: A European Union restriction on PFAS in textiles is being formalized with a transition window in the 2026–2028 timeframe. REACH and SVHC obligations persist; compliance is essential for market access.

- Product safety: Look for BPA‑free claims on PU systems, OEKO‑TEX Standard 100 or bluesign approval for chemical safety, and GRS for recycled content documentation.

Performance benchmarks (what to ask for)

| Metric | Typical target ranges | Test method | Buyer note |

|---|---|---|---|

| Hydrostatic head | 5,000–20,000 mm (end‑use dependent) | ISO 811 / AATCC 127 | Waterproof vs. water‑repellent cutoff commonly ~1,500–2,000 mm |

| MVTR (breathability) | 5,000–20,000 g/m²/day | ASTM E96, JIS L 1099B | Higher MVTR improves comfort; pair with seam sealing and venting |

| Air permeability | 0–5 cfm (outer shells) | ASTM D737 | Zero air permeability aids waterproofing; some breathability via MVTR |

| Seam strength/tape adhesion | ≥ 60 N (taped seams) | ISO 13936 / ASTM D751 | Critical in rainwear; use robust seam tape and qualified adhesives |

| Abrasion | 30k–80k rubs (face) | ASTM D4966 | Durable face fabrics extend garment life and service intervals |

| Wash durability | ≥ 50 cycles (medical use) | AATCC 135 / ISO 6330 | Maintain waterproofness, breathability, and hand after laundering |

| Chemical restrictions | Full PFAS disclosure; BPA‑free PU | Supplier declarations + third‑party testing | PFAS and BPA claims must be backed by certificates and test data |

Sourcing trends & risk management

- PFAS phase‑out is reshaping supply chains. Buyers are requesting PFAS‑free DWR, hydrophilic TPU membranes, and breathable, water‑based laminates to ensure compliance across US/EU jurisdictions.

- Traceability and certifications are increasingly mandatory: GRS for recycled inputs, OEKO‑TEX or bluesign for chemical management, REACH/SVHC declarations for EU access, and BPA‑free documentation for PU systems.

- Supplier rationalization and regionalization: Near‑shoring and dual‑sourcing reduce risk from single‑region disruptions. Verify capacity, lead times, and seam‑tape/lamination capability across vendors.

- Quality assurance: Require lot‑level testing for hydrostatic head and MVTR; validate seam strength post‑tape and after wash cycles; monitor abrasion performance for outerwear.

- Claims governance: Standardize vocabulary (waterproof vs. water‑repellent), test methods, and labeling; align advertising claims with regulatory guidance to avoid misinformation.

What makes microfiber waterproof different

Microfiber backings deliver a plush, warm hand feel, which is advantageous for midlayers and comfort‑driven garments. Achieving true waterproofness with microfiber requires:

– A continuous barrier (laminate or coating) that resists leaks at stitched seams.

– Proper seam sealing and tape selection for hydrophilic and microporous membranes.

– Care labeling to maintain DWR performance and membrane function over laundry cycles.

Illustrative Image (Source: Google Search)

ECO‑PUL and similar breathable laminates exemplify how soft fleece can be paired with a waterproof yet breathable barrier, often with water‑based systems and BPA‑free polyurethane claims that align with evolving chemical regulations.

Strategic actions for USA/EU buyers

- Align product claims to performance: Define waterproof vs. water‑repellent and set minimum hydrostatic head and MVTR targets for each end‑use.

- Secure compliance: Require PFAS‑free, BPA‑free PU and OEKO‑TEX/bluesign; obtain GRS where recycled content is used.

- Validate durability: Include wash cycle testing, seam strength verification, and abrasion checks before scale‑up.

- Build resilience: Dual‑source laminates/membranes, confirm seam‑tape partner capabilities, and establish MOQs and lead times that fit seasonality.

- Manage transition: As PFAS restrictions tighten, shift to water‑based laminates and hydrophilic membranes; document claims and retest every lot.

Market opportunities to watch

- Children’s waterproof fleece jackets and school apparel: Soft hand with breathable waterproofing, safety certifications, and easy care.

- Medical/adaptive textiles: Fleece with hygienic barriers for gowns and therapy wraps; wash durability and MRSA‑control treatments (e.g., silver) offer differentiation.

- Active‑to‑commute apparel: Quiet, comfortable waterproof midlayers for variable climates; stretch content and recycled face/backers support sustainability targets.

- Textile rental/linen services: Robust waterproof overlays that survive industrial laundering and repair, reducing total cost of ownership.

Conclusion

Sourcing waterproof microfiber fabrics in 2025 centers on compliance, performance, and comfort. US and EU buyers must prioritize PFAS‑free and BPA‑free systems, validate breathability and durability through rigorous testing, and prepare for tightening timelines on chemical restrictions. By adopting water‑based, breathable laminates such as ECO‑PUL and partnering with suppliers that can deliver full certifications and lot‑level testing, brands can achieve reliable waterproofness without sacrificing the soft, comfortable hand that makes microfiber fabrics compelling.

Illustrative Image (Source: Google Search)

Frequently Asked Questions (FAQs) for B2B Buyers of microfiber fabric waterproof

FAQs for B2B Buyers of Microfiber Fabric Waterproof (Wazoodle ProSoft Fleece Waterproof ECO-PUL)

1) What is ProSoft Fleece Waterproof ECO-PUL?