The global market for bio-based surfactants, including methylated seed oil surfactants, is experiencing robust growth driven by increasing demand for environmentally friendly and sustainable formulation solutions across agrochemicals, home care, and industrial applications. According to Mordor Intelligence, the bio-based surfactants market was valued at USD 9.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 6.4% through 2029, with methylated seed oil derivatives gaining traction due to their low toxicity, high biodegradability, and effective emulsifying properties. As regulatory pressure and consumer preferences shift toward green chemistry, manufacturers are scaling innovation in methyl ester sulfonates and methylated castor oil surfactants derived from renewable feedstocks such as palm, coconut, and soybean oil. This surge in demand has intensified competition and technological advancement among key players, paving the way for a new generation of high-performance, sustainable surfactants. In this evolving landscape, the following eight companies have emerged as leading manufacturers of methylated seed oil surfactants, combining strong R&D capabilities, global supply chains, and commitment to sustainable production.

Top 8 Methylated Seed Oil Surfactant Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 MSO Concentrate

Domain Est. 1997

Website: greenbook.net

Key Highlights: View the product label for MSO Concentrate from Loveland Products, Inc.. See active ingredients, product application, restrictions, and more at Greenbook….

#2 Adjuvants Product Catalog

Domain Est. 2004

Website: winfieldunited.com

Key Highlights: High surfactant methylated seed oil (HSOC-MSO) and drift reduction technology that helps cut through protective plant barriers, especially in extreme conditions ……

#3 MSO

Domain Est. 1997

Website: fertizona.com

Key Highlights: MSO is a multi-component spray adjuvant developed to maximize the performance of most post-emergent herbicides. This product may be be used as a replacement ……

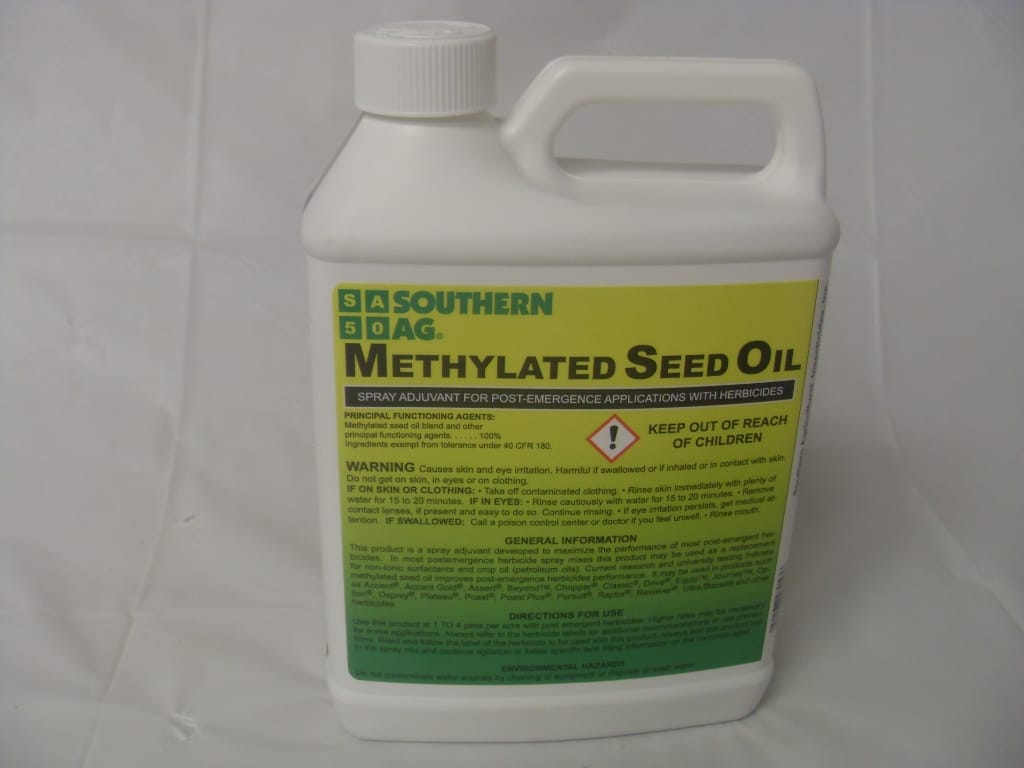

#4 Methylated Seed Oil

Domain Est. 1998

Website: kalo.com

Key Highlights: Nonionic Surfactant. • Antifoaming Agent. Methylated Seed Oil is a unique blend of highly refined and modified spray oil and superior nonionic surfactant….

#5 Activator Adjuvants

Domain Est. 1999

Website: exactoinc.com

Key Highlights: Oil-based adjuvants can be divided into three categories based on composition: crop oil concentrates (COCs), methylated seed oils (MSOs or MVOs), and crop oils….

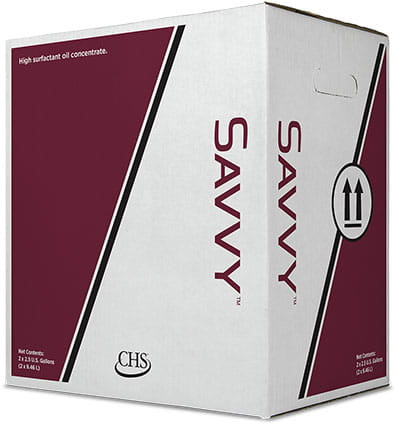

#6 Savvy enhances herbicide activity with methylated seed oil

Domain Est. 2003

Website: chsagronomy.com

Key Highlights: Savvy uses a high surfactant methylated seed oil concentrate to improve the activity of glyphosate tank mixes at nearly half the use rate of standard crop oil….

#7 Novita MSO methylated seed oil surfactant gallon (128 oz)

Domain Est. 2011

Website: intermountainturf.com

Key Highlights: In stock $13.75 deliveryNovita MSO is a premium methylated seed oil (MSO) surfactant made from 100% soybean oil, engineered to maximize the performance of post-emergent herbicides….

#8 MSO Premium

Domain Est. 2017

Website: helenaagri.com

Key Highlights: Premium MSO Methylated Spray Oil is designed as a replacement for non-ionic surfactants and crop oil concentrates in liquid spray mixtures. When used as ……

Expert Sourcing Insights for Methylated Seed Oil Surfactant

H2: 2026 Market Trends for Methylated Seed Oil Surfactant

The global market for methylated seed oil (MSO) surfactants is poised for significant evolution by 2026, driven by increasing demand for sustainable agrochemical adjuvants, regulatory shifts favoring bio-based products, and advancements in formulation technologies. As a biodegradable and effective crop oil concentrate (COC) alternative, methylated seed oil surfactants are gaining traction in agricultural spraying applications, particularly to enhance the performance of herbicides, insecticides, and fungicides.

Key market trends shaping the MSO surfactant landscape in 2026 include:

-

Growth in Sustainable Agriculture: With heightened emphasis on eco-friendly farming practices, bio-based surfactants like MSO are favored over petroleum-derived alternatives. Regulatory bodies in North America and Europe are incentivizing the use of non-toxic, renewable adjuvants, accelerating adoption in integrated pest management (IPM) systems.

-

Expansion in Emerging Markets: Regions such as Latin America, Southeast Asia, and parts of Africa are witnessing increased agricultural intensification. Rising awareness among farmers about spray efficiency and the cost-saving benefits of MSO surfactants is driving regional demand, supported by partnerships between local agrochemical distributors and global surfactant manufacturers.

-

Formulation Innovations: By 2026, manufacturers are increasingly tailoring MSO surfactants for compatibility with new-generation pesticides and genetically modified crops. Hybrid formulations combining MSO with silicone or ethylene oxide-propylene oxide (EO-PO) block copolymers are enhancing spreading, penetration, and rainfastness, improving overall field performance.

-

Regulatory and Environmental Pressures: Stricter regulations on volatile organic compounds (VOCs) and persistent chemical residues are pushing formulators to replace traditional surfactants. MSO, with its low VOC content and rapid biodegradability, is emerging as a preferred choice, especially under EPA and EU biocidal product regulations.

-

Supply Chain and Feedstock Dynamics: Fluctuations in seed oil prices (e.g., soybean, rapeseed, and castor) may impact MSO production costs. However, advancements in non-food feedstocks and waste-oil methylation are expected to improve cost-efficiency and reduce reliance on edible oils, supporting long-term scalability.

-

Competitive Landscape: Major chemical companies and specialty agrochemical adjuvant suppliers are investing in R&D and strategic acquisitions to strengthen their MSO portfolios. This competitive environment is fostering innovation and driving down prices, making MSO surfactants more accessible to smallholder farmers.

In summary, the methylated seed oil surfactant market in 2026 is characterized by strong growth potential, innovation in formulation, and alignment with global sustainability goals. As the agricultural sector continues to prioritize efficacy and environmental stewardship, MSO surfactants are well-positioned to capture a larger share of the adjuvant market.

H2: Common Pitfalls in Sourcing Methylated Seed Oil Surfactant – Quality and Intellectual Property Risks

Sourcing Methylated Seed Oil Surfactant (MSOS), a bio-based and environmentally friendly non-ionic surfactant derived from vegetable oils, presents several challenges related to quality consistency and intellectual property (IP) concerns. Procurement teams and formulators must navigate these pitfalls to ensure product performance, regulatory compliance, and freedom to operate.

1. Quality Inconsistencies

– Feedstock Variability: The quality of MSOS heavily depends on the source and purity of the seed oil (e.g., rapeseed, soybean, or sunflower). Variations in fatty acid profiles due to crop origin, season, or processing can lead to inconsistent surfactant performance (e.g., emulsification, wetting, foaming).

– Incomplete Methylation or Purity Issues: Poor process control during methylation can result in incomplete esterification, leaving residual free fatty acids or glycerides. These impurities reduce surfactant efficacy and may cause stability issues in end formulations.

– Lack of Standardized Specifications: Many suppliers do not adhere to industry-wide quality standards. Buyers may receive products with variable HLB values, color, odor, or viscosity, impacting formulation reproducibility.

– Oxidative Stability: Unsaturated bonds in certain seed oils make MSOS prone to oxidation, leading to rancidity and shortened shelf life if not properly stabilized or stored.

2. Intellectual Property (IP) Risks

– Patented Production Processes: Several MSOS manufacturing methods—especially those involving specific catalysts, green chemistry routes, or purification techniques—are protected by patents. Sourcing from suppliers using such processes may expose buyers to indirect IP infringement, particularly in regulated markets.

– Formulation-Level IP Conflicts: MSOS may be a critical component in patented formulations (e.g., agrochemical adjuvants, personal care products). Using a sourced surfactant in a way that replicates a patented blend could lead to legal exposure.

– Supplier Transparency Gaps: Some suppliers may not disclose whether their MSOS production or modification processes are covered under third-party IP. This lack of transparency increases the risk of unintentional infringement.

– Regional IP Variations: Patent protections vary by jurisdiction. A surfactant considered IP-free in one country may infringe on active patents in another, complicating global sourcing and distribution strategies.

Mitigation Strategies

– Require detailed Certificates of Analysis (CoA) and batch traceability.

– Conduct third-party testing for composition, HLB, and stability.

– Perform freedom-to-operate (FTO) analyses, especially when integrating MSOS into proprietary formulations.

– Engage suppliers in IP discussions and request documentation on process ownership and patent licensing status.

– Consider long-term supply agreements with technical collaboration to ensure quality alignment and IP safety.

In summary, while Methylated Seed Oil Surfactant offers sustainable advantages, careful due diligence in both quality assurance and IP landscape assessment is essential to avoid operational, legal, and reputational risks.

H2: Logistics & Compliance Guide for Methylated Seed Oil Surfactant

-

Product Overview

Methylated Seed Oil Surfactant (MSO) is a non-ionic surfactant derived from vegetable oils (e.g., soybean, rapeseed, or cottonseed) through esterification with methanol. It is commonly used in agricultural formulations to enhance the penetration and efficacy of pesticides and herbicides. Due to its biodegradable nature and low toxicity, it is classified as a relatively safe adjuvant; however, proper handling, storage, and regulatory compliance are essential. -

Regulatory Classification

- GHS Classification (Globally Harmonized System):

- Typically not classified as hazardous under GHS for health or environmental hazards.

- May carry label precautionary statements depending on formulation purity.

-

Always refer to the Safety Data Sheet (SDS) provided by the manufacturer.

-

EPA Regulation (USA):

- Regulated as an inert ingredient in pesticide formulations.

- Listed on EPA’s Inert Ingredient List (approved for use in pesticide products).

-

Registration required only when part of a formulated pesticide product.

-

REACH (EU):

- May require registration if produced or imported in quantities ≥ 1 tonne/year.

- Check ECHA database for specific substance registration status.

-

Classification under CLP Regulation should be verified per batch.

-

Other Jurisdictions:

- Canada (DSL): Listed as a low-risk substance; check Domestic Substances List status.

- Australia (AICIS): May require notification depending on import volume.

-

Always verify local chemical inventory status before import.

-

Transportation & Shipping

- UN Number: Generally not assigned (non-hazardous for transport).

- Transport Classification: Not regulated as dangerous goods under ADR/RID (road/rail in Europe), IMDG (sea), or IATA (air) when shipped as a pure substance.

- Packaging:

- Use HDPE drums, intermediate bulk containers (IBCs), or flexitanks.

- Ensure containers are tightly sealed to prevent moisture absorption and contamination.

- Labeling:

- Label with product name, batch number, manufacturer details, and basic safety information.

-

Include “Keep away from food, drink, and animal feed” if recommended.

-

Storage Requirements

- Conditions:

- Store in a cool, dry, well-ventilated area away from direct sunlight.

- Maintain temperature between 10°C and 30°C to prevent solidification or degradation.

- Shelf Life: Typically 12–24 months when stored properly.

- Compatibility:

- Store away from strong oxidizing agents and acids.

- Compatible with most agricultural chemicals when used as an adjuvant.

-

Secondary Containment: Recommended for bulk storage to prevent environmental contamination.

-

Handling & Personal Protection

- Engineering Controls: Use local exhaust ventilation if handling in large volumes or heated conditions.

- Personal Protective Equipment (PPE):

- Wear chemical-resistant gloves (nitrile or neoprene).

- Safety goggles to prevent eye contact.

- Long-sleeved clothing and closed-toe shoes.

- Respiratory protection not typically required under normal conditions.

-

Hygiene Practices: Wash hands thoroughly after handling. Avoid ingestion and prolonged skin contact.

-

Environmental & Disposal Considerations

- Ecotoxicity: Generally low toxicity to aquatic life; however, large spills may cause oxygen depletion due to biodegradation.

- Spill Response:

- Contain with absorbent materials (e.g., vermiculite, sand).

- Prevent entry into waterways, sewers, or soil.

- Collect spill material and dispose of as non-hazardous waste.

- Waste Disposal:

- Dispose in accordance with local, state, and federal regulations.

- May be incinerated in licensed facilities or disposed of in authorized landfills if classified non-hazardous.

-

Consult waste contractor for proper classification.

-

Documentation & Compliance

- Safety Data Sheet (SDS): Ensure up-to-date SDS is available and compliant with local regulations (e.g., OSHA HazCom, EU REACH/CLP).

- Import/Export Documentation:

- Provide Certificate of Analysis (CoA), SDS, and commercial invoice.

- Verify import permits or notifications as required by country.

-

Recordkeeping: Maintain records of shipments, storage conditions, training, and incident reports.

-

Training & Emergency Procedures

- Train personnel on safe handling, storage, and spill response.

- Ensure emergency eyewash and safety showers are accessible in handling areas.

- In case of exposure:

- Inhalation: Move to fresh air.

- Skin Contact: Wash with soap and water.

- Eye Contact: Rinse thoroughly with water for at least 15 minutes.

-

Ingestion: Do not induce vomiting; seek medical attention.

-

Audit & Continuous Compliance

- Conduct periodic audits of storage and handling practices.

- Monitor regulatory updates in target markets (e.g., EPA, ECHA).

- Re-evaluate SDS and labeling at least annually or after formulation changes.

Note: This guide is general in nature. Always consult the manufacturer’s SDS and local regulatory authorities to ensure full compliance.

Conclusion on Sourcing Methylated Seed Oil Surfactant:

Sourcing methylated seed oil surfactant presents a promising, sustainable alternative to petroleum-based surfactants, aligning with the growing demand for bio-based and eco-friendly chemical solutions. Derived from renewable seed oils such as soybean, rapeseed, or castor oil, methylated surfactants offer favorable properties including biodegradability, low toxicity, and good performance in various applications such as agrochemicals, personal care products, and industrial cleaners.

However, successful sourcing requires careful consideration of several factors: consistent feedstock supply, scalability of production, cost-competitiveness with conventional surfactants, and adherence to quality standards. Partnering with reliable suppliers or manufacturers experienced in green chemistry and esterification/methylation processes is crucial. Additionally, evaluating regional availability, regulatory compliance (e.g., REACH, USDA BioPreferred), and life-cycle impacts will support responsible procurement.

In conclusion, while challenges in cost and supply chain maturity remain, the long-term benefits of using methylated seed oil surfactants—particularly in sustainability, branding, and regulatory alignment—make them a strategic choice for forward-thinking industries. Continued advancements in green chemistry and increased market demand are likely to enhance accessibility and affordability, reinforcing their viability as a mainstream surfactant solution.