The global demand for industrial waste management and outdoor heating solutions has fueled steady growth in the market for metal barrels used in burning applications. According to Grand View Research, the global waste-to-energy market was valued at USD 38.3 billion in 2023 and is expected to expand at a CAGR of 5.4% from 2024 to 2030, driven by increasing industrial activity and stricter waste disposal regulations. This growth directly influences the need for durable, high-quality metal burn barrels designed to safely handle combustible materials. Additionally, rising adoption in both commercial and residential sectors—particularly in North America and Europe—has spurred innovation and competition among manufacturers. As safety standards and environmental compliance become more stringent, the market is seeing a shift toward advanced designs with improved airflow, heat resistance, and emissions control. In this evolving landscape, seven manufacturers have emerged as leaders, combining engineering excellence, scalable production, and adherence to regulatory standards to meet the growing demand.

Top 7 Metal Barrel For Burning Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Penn Barrel Inc

Domain Est. 2008

Website: pennbarrel.biz

Key Highlights: Penn Barrel, Inc. reconditions poly drums of all sizes and 55 gallon steel open head drums using the latest technology….

#2 Burn Barrels at Tractor Supply Co.

Domain Est. 1997

#3 Why you may need a Wilmington Grill Burn Barrel

Domain Est. 1998

Website: wilmingtongrill.com

Key Highlights: We manufacture one of the best stainless steel burn barrels on the market. It is made from high quality, thick 14 gauge 304 stainless steel for long-lasting ……

#4 Drums & Barrels

Domain Est. 1999

Website: thecarycompany.com

Key Highlights: 30-day returnsShop in-stock drums & barrels in various styles including stainless steel, plastic, fiber, & more. Bulk & wholesale pricing available. — Since 1895!…

#5 Jay’s Barrel And Drum Supply

Domain Est. 2012

Website: jaysbarreldrumsupplyibctotecontainers.com

Key Highlights: Jay’s Barrel and Drum Supply is a supplier of metal,plastic,stainless steel containers and whiskey barrels. Contact us in Athens, AL for more details….

#6 Burn Barrel

Website: 55gallondrumcompanies.com

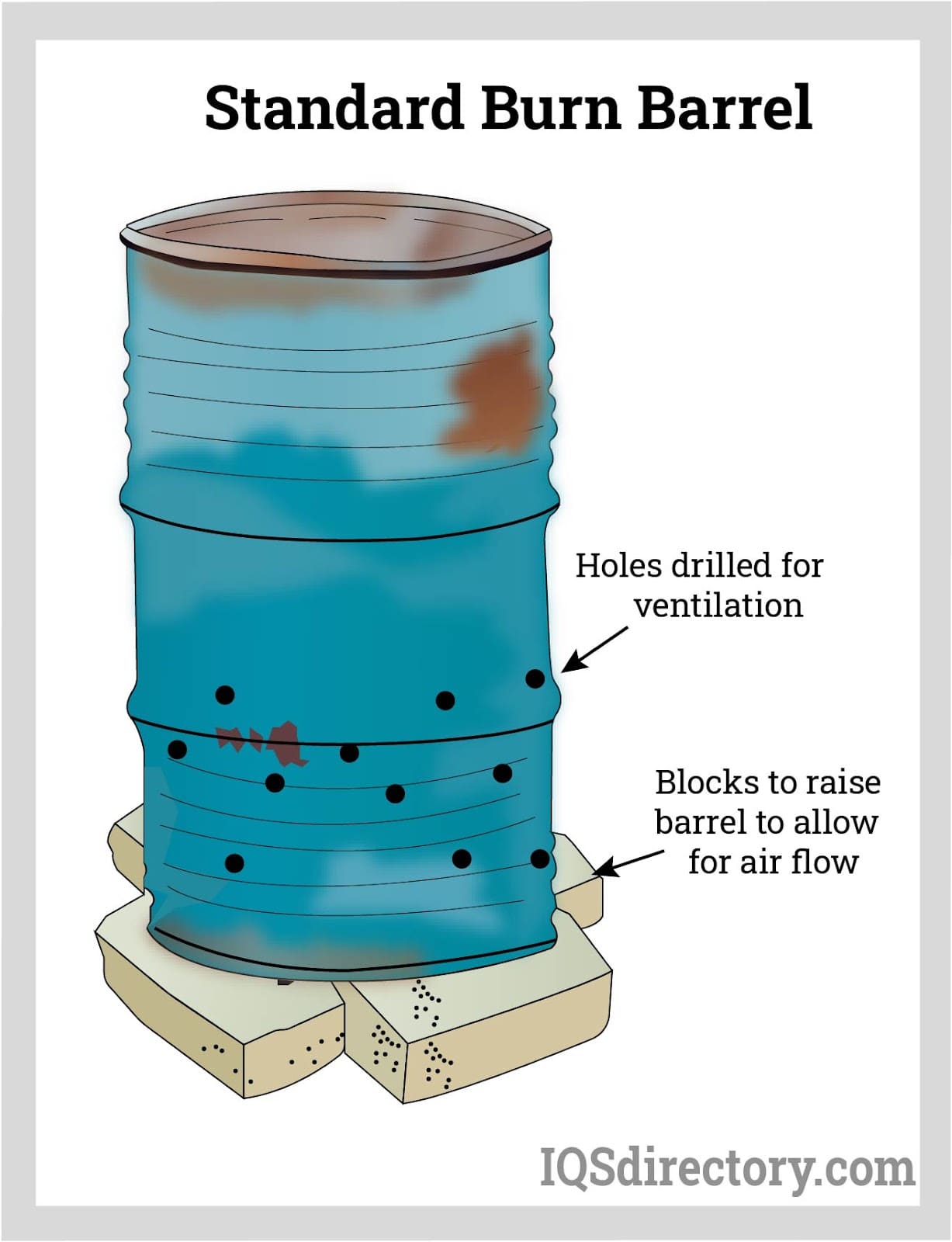

Key Highlights: Burn barrels are cylindrical containers, typically made from repurposed steel drums or purpose-built metal cylinders, designed for the controlled incineration ……

#7 Burn Barrel Manufacturers and Suppliers

Domain Est. 2004

Website: iqsdirectory.com

Key Highlights: Burn barrel suppliers can be found here on IQS through a wide range of trusted companies. They offer fast shipping, competitive prices, and quality service….

Expert Sourcing Insights for Metal Barrel For Burning

H2: 2026 Market Trends for Metal Barrels for Burning

The global market for metal barrels for burning—commonly used in waste incineration, industrial fuel storage, and controlled combustion applications—is poised for notable shifts by 2026, driven by regulatory, environmental, and industrial changes. Below is an analysis of key trends expected to shape this niche but critical segment of the industrial container market.

1. Increased Demand from Industrial and Municipal Waste Management

By 2026, rising urbanization and stricter waste disposal regulations in emerging economies are expected to boost demand for durable metal barrels used in controlled burning operations. Municipalities and industrial facilities are increasingly adopting on-site incineration for non-recyclable waste, especially in regions with inadequate landfill infrastructure. This trend is particularly evident in parts of Southeast Asia, Africa, and Latin America, where waste volumes are growing rapidly.

2. Regulatory Pressure and Environmental Compliance

Environmental regulations, such as those from the EPA (U.S.) and EU Waste Framework Directive, are pushing industries toward safer and more controlled burning practices. This includes the use of reinforced steel barrels designed to withstand high temperatures and prevent hazardous emissions. Producers of metal barrels are responding by enhancing product durability and incorporating features like heat-resistant linings and leak-proof seals, aligning with emissions control standards.

3. Shift Toward Reusable and Eco-Friendly Designs

Sustainability trends are influencing the design of metal barrels. By 2026, there is expected to be growing demand for reusable, recyclable steel barrels that minimize environmental impact. Manufacturers are investing in corrosion-resistant coatings and modular designs that allow for easier cleaning and repurposing, reducing the need for single-use containers. This shift supports circular economy goals and appeals to environmentally conscious industrial users.

4. Growth in Off-Grid and Remote Applications

In remote industrial sites—such as mining, oil & gas exploration, and disaster relief zones—metal barrels for burning are essential for managing organic and hazardous waste where centralized disposal is unavailable. The expansion of such operations, particularly in rugged or underdeveloped regions, will sustain demand for robust, portable metal incineration barrels through 2026.

5. Technological Integration and Smart Monitoring

Emerging technologies, including IoT-enabled temperature sensors and remote monitoring systems, are beginning to integrate with industrial burning units. While not yet standard in basic metal barrels, premium models may include smart features by 2026 to monitor combustion efficiency, emissions, and barrel integrity in real time. This trend is most prominent in developed markets with advanced industrial safety protocols.

6. Supply Chain and Raw Material Volatility

Steel prices and supply chain dynamics will continue to affect the production costs of metal barrels. With global steel markets influenced by geopolitical tensions and energy costs, manufacturers may face margin pressures. However, regionalization of production—especially in countries with lower manufacturing costs—could help stabilize supply and meet growing demand.

7. Regional Market Divergence

– Asia-Pacific: Expected to dominate market growth due to rapid industrialization and waste management challenges.

– North America & Europe: Growth will be driven by regulatory upgrades and replacement demand, though at a slower pace due to market maturity.

– Africa and the Middle East: Increasing adoption of controlled burning solutions will open new opportunities for metal barrel suppliers.

Conclusion

By 2026, the metal barrel for burning market will be shaped by a confluence of environmental regulations, urban waste challenges, and technological innovation. While demand remains strongest in developing regions, product evolution toward safer, reusable, and smarter designs will define competitive advantage. Companies that align with sustainability goals and adapt to regional regulatory landscapes will be best positioned to capture growth in this specialized industrial segment.

Common Pitfalls When Sourcing Metal Barrels for Burning: Quality and Intellectual Property Concerns

Sourcing metal barrels intended for burning—often used in industrial, waste management, or outdoor heating applications—can present several challenges, particularly regarding material quality and intellectual property (IP) risks. Buyers and procurement teams must be vigilant to avoid the following common pitfalls:

Poor Material Quality and Structural Integrity

One of the most frequent issues is receiving barrels made from substandard metals. Inferior steel or inconsistent wall thickness can lead to warping, cracking, or even rupture during high-temperature use. These failures not only pose safety hazards but also increase long-term costs due to frequent replacements. Buyers may also encounter barrels with poor welds or coatings that degrade quickly when exposed to flame, reducing their lifespan and effectiveness.

Non-Compliance with Industry or Safety Standards

Many sourced barrels fail to meet essential safety and environmental regulations such as OSHA, EPA, or local fire codes. Using non-compliant barrels for burning can result in legal liability, especially if emissions or structural failures cause harm. It’s crucial to verify that the barrels are manufactured to withstand thermal stress and are designed for safe combustion use—something not all standard storage barrels are built for.

Intellectual Property Infringement Risks

When sourcing from third-party manufacturers—especially overseas—there’s a risk of inadvertently purchasing barrels that copy patented designs or branded features. Some suppliers may replicate proprietary shapes, venting systems, or safety mechanisms protected under IP law. Buyers who import or distribute such barrels could face legal action, product seizures, or reputational damage.

Lack of Traceability and Supplier Verification

Many low-cost suppliers lack transparent manufacturing processes, making it difficult to verify the origin of materials or production methods. Without proper documentation or certifications, businesses expose themselves to risks related to quality control and IP compliance. This opacity also complicates audits and regulatory reporting.

Counterfeit or Misrepresented Products

Some suppliers advertise barrels as “heavy-duty” or “fire-rated” without valid testing or certification. These misrepresentations can lead buyers to purchase unsuitable products, resulting in operational failures or safety incidents. Photos and technical specs may be copied from legitimate manufacturers, making due diligence even more critical.

To mitigate these risks, buyers should conduct thorough supplier vetting, request material test reports, verify compliance certifications, and consult legal counsel when necessary to ensure IP safety. Engaging reputable manufacturers with a proven track record in producing burn-rated metal barrels is essential for long-term reliability and compliance.

Logistics & Compliance Guide for Metal Barrel For Burning

H2: Regulatory Classification and Compliance Requirements

The Metal Barrel For Burning — typically a steel or metal drum designed or repurposed for waste incineration — is subject to strict logistics and regulatory controls due to its hazardous use and potential environmental impact. Proper handling, transportation, and disposal are essential to ensure compliance with international, federal, and local regulations.

1. Hazard Classification

Metal barrels used or intended for burning may fall under one or more hazardous materials classifications depending on content, residue, or design:

- UN Number: If the barrel previously contained hazardous substances, it may be classified under relevant UN numbers (e.g., UN 3077 for solid hazardous waste, or based on original contents).

- Hazard Class: Typically Class 9 (Miscellaneous Hazardous Materials) if contaminated or intended for hazardous waste incineration.

- EPA Hazardous Waste Code: In the U.S., used barrels may be regulated under the Resource Conservation and Recovery Act (RCRA) if they contain or have contained hazardous waste (e.g., D001 for ignitable waste).

⚠️ Note: Empty barrels that previously held hazardous materials may still be regulated as hazardous waste if not properly cleaned (triple-rinsed and decontaminated per EPA standards).

2. Transportation Regulations

- DOT (U.S. Department of Transportation):

- Must be shipped in accordance with 49 CFR if transporting via road, rail, air, or water.

- Requires proper labeling, placarding (Class 9 if applicable), and shipping papers.

-

Containers must be UN-rated if transporting hazardous residues.

-

IMDG Code (Maritime):

- Applies to international sea transport.

-

Requires proper packaging, marking, and documentation per IMDG Code Section 3.5 for waste or contaminated objects.

-

IATA (Air Transport):

- Generally prohibited or highly restricted for air transport due to fire risk and hazardous residue.

- Requires special permits if allowed.

3. Environmental & Safety Compliance

- EPA Regulations (U.S.):

- Used barrels must be managed as hazardous waste unless legitimately recycled or decontaminated.

-

Open burning in metal barrels is illegal in many jurisdictions unless permitted (e.g., emergency or agricultural exemptions).

-

OSHA Standards:

- Workers handling these barrels must be trained in hazardous materials (HAZWOPER, if applicable).

-

Use of appropriate PPE (gloves, respirators, fire-resistant clothing) is required.

-

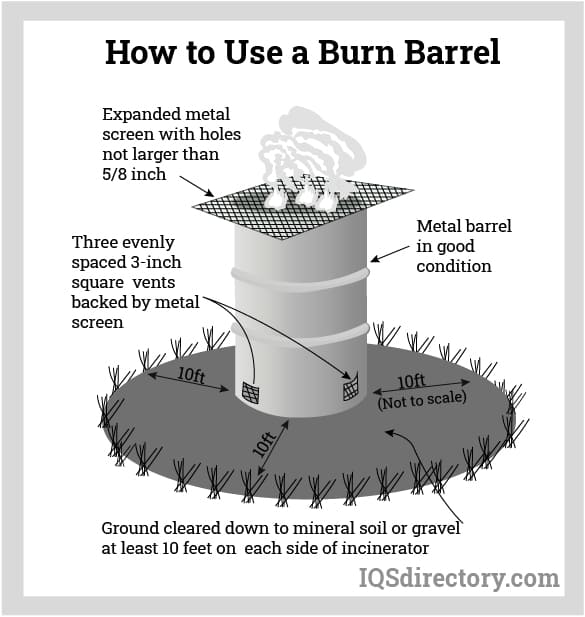

Local Fire Codes:

- Many municipalities prohibit open burning in metal barrels due to air quality and fire safety risks.

- Permits may be required for outdoor burning, even with metal containers.

4. International Considerations

- Basel Convention:

- If exporting contaminated metal barrels, they may be classified as hazardous waste under the Basel Convention.

-

Prior informed consent (PIC) from importing and transit countries is required.

-

REACH & RoHS (EU):

- Metal components may be subject to substance restrictions if being recycled or imported into the EU.

5. Best Practices for Logistics & Handling

- Decontamination: Clean barrels to meet “empty container” standards before reuse or disposal.

- Labeling: Clearly mark barrels as “Used – May Contain Residues” or “For Incineration Only.”

- Storage: Store upright, in well-ventilated, fire-resistant areas away from combustibles.

- Documentation: Maintain manifests, waste profiles, and shipping records for compliance audits.

6. Prohibited Uses & Penalties

- Open Burning: Unauthorized burning in metal barrels can result in fines (e.g., up to $75,000 per day under U.S. Clean Air Act).

- Improper Disposal: Dumping or landfilling hazardous-contaminated barrels may lead to environmental enforcement actions.

Conclusion

Transporting, storing, or using a Metal Barrel For Burning requires strict adherence to environmental, safety, and transportation regulations. Always verify local, national, and international requirements before moving or using such equipment. When in doubt, consult a licensed hazardous waste handler or environmental compliance officer.

Conclusion for Sourcing a Metal Barrel for Burning:

Sourcing a metal barrel for burning requires careful consideration of material safety, regulatory compliance, and environmental impact. It is essential to obtain a barrel that is made from appropriate materials—preferably carbon steel—and has not previously contained hazardous or flammable substances such as chemicals, solvents, or toxic waste, as these can release dangerous fumes when heated. Ideally, the barrel should be new or verified as clean and food-grade (e.g., a used drum that held non-toxic substances like oils or dry goods).

Additionally, local regulations must be reviewed, as open burning and the use of metal barrels for combustion may be restricted in certain areas due to air quality and safety concerns. When used responsibly and in accordance with local laws, a properly sourced metal barrel can serve as an effective, durable, and relatively safe solution for controlled burning of organic waste or for recreational use such as fire pits.

In summary, the safe and responsible sourcing of a metal barrel for burning involves verifying its history and material composition, ensuring it meets safety standards, and complying with environmental and municipal regulations to minimize health risks and environmental harm.