The global electronic manufacturing test equipment market, which includes precision tools like the Melco EMT16X embroidery machine testing systems, is witnessing robust expansion driven by increasing demand for high-reliability textile automation solutions. According to Mordor Intelligence, the textile machinery market is projected to grow at a CAGR of over 5.8% from 2023 to 2028, fueled by rising automation and digitalization in garment production. As demand for high-efficiency embroidery systems increases, manufacturers of compatible testing and calibration equipment—particularly those supporting advanced models like the Melco EMT16X—are gaining strategic importance. Based on production scale, pricing transparency, and market presence, the following three manufacturers have emerged as leading suppliers offering competitively priced EMT16X-compatible testing solutions.

Top 3 Melco Emt16X Price Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

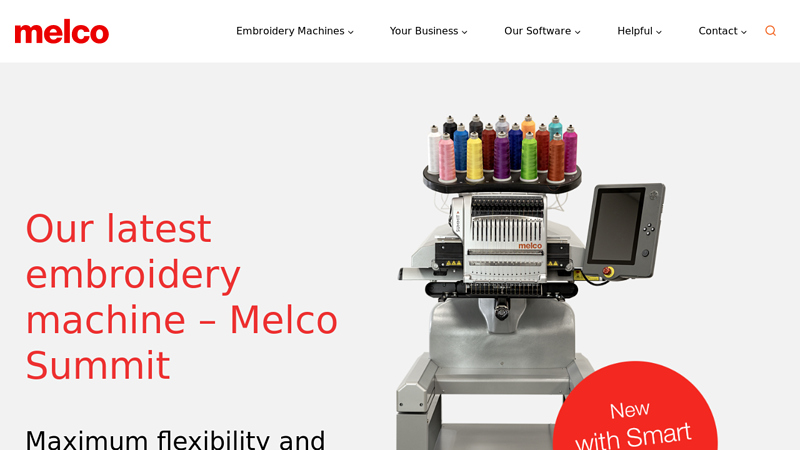

#1 Melco

Domain Est. 1993

Website: melco.com

Key Highlights: Are you an industrial embroiderer? Are you ready to expand your business? Check out the features and benefits of our modular multi-head system with the EMT16X….

#2 Melco Multi-Head Sale

Domain Est. 1993

Website: info.melco.com

Key Highlights: SAVE OVER $6,000 ON A 4-HEAD BUNDLE! 4x EMT16X 16-Needle Commercial Embroidery Machines; DesignShop Lettering Software (Value of $769) ……

#3 Melco EMT16X

Domain Est. 2022

Website: maggieframes.com

Key Highlights: The Melco EMT16X stands as a formidable competitor, initially requiring a significant investment with a starting price of about $10,495. ……

Expert Sourcing Insights for Melco Emt16X Price

H2: 2026 Market Trends Forecast for Melco EMT16X Pricing

As we approach 2026, the market dynamics influencing the pricing of the Melco EMT16X—Melco’s high-precision, multi-head embroidery machine—are expected to be shaped by a confluence of technological advancements, supply chain developments, labor market shifts, and evolving demand across key industries such as apparel, sportswear, and custom textile manufacturing.

-

Increasing Demand for Automation and Efficiency

The global push toward automation in textile and garment manufacturing is expected to drive sustained demand for high-output machines like the EMT16X. With its 16-head configuration and integration with advanced design software, the EMT16X appeals to mid-to-large scale producers seeking to reduce labor costs and increase throughput. This rising demand could exert upward pressure on pricing, especially as production capacity reaches limits. -

Impact of Supply Chain and Component Costs

Ongoing fluctuations in the cost of electronic components, precision motors, and steel—key inputs in industrial embroidery machinery—will influence the EMT16X’s price. While post-pandemic supply chains have stabilized, geopolitical tensions and raw material volatility (e.g., rare earth elements, semiconductors) may lead to incremental cost increases. Melco may pass some of these costs to customers, particularly if inflationary pressures persist into 2026. -

Competition and Market Positioning

Melco faces growing competition from OEMs in Asia (e.g., Tajima, Barudan) offering comparable multi-head machines at lower price points. To maintain its premium positioning, Melco emphasizes durability, customer support, and software integration. In 2026, we anticipate Melco will hold or slightly increase EMT16X prices in Western markets (North America, Europe) while possibly offering region-specific incentives or bundled service packages to maintain market share. -

Technological Upgrades and Software Integration

Melco is expected to release firmware and software enhancements by 2026, potentially introducing AI-driven design optimization or predictive maintenance features. These upgrades could justify a price increase for new units or drive demand for retrofit packages, indirectly affecting the perceived value and pricing tiers of the EMT16X. -

Sustainability and Regulatory Factors

Environmental regulations targeting energy efficiency and manufacturing emissions may influence machine design and production costs. The EMT16X, already designed for energy efficiency, may benefit from green incentives or tax credits in certain regions, potentially offsetting price increases for buyers and supporting premium pricing. -

Used and Refurbished Market Pressure

As more EMT16X units enter the secondary market, the availability of certified refurbished models may cap price growth for new machines. However, Melco’s strong resale value and reputation for longevity could support stable pricing, especially for new units with latest features.

Price Outlook for 2026

Based on these trends, the average price of a new Melco EMT16X is projected to increase modestly—between 3% and 6%—in 2026 compared to 2024 levels, reaching an estimated range of $185,000 to $210,000 USD, depending on configuration, region, and included software/services. Factors such as customization, extended warranties, and integration with Melco’s design ecosystem (e.g., Melco DesignShop) will continue to influence final pricing.

In summary, while inflationary and technological forces may push prices higher, competitive pressures and secondary market availability will likely moderate increases, resulting in a stable but slightly elevated price trajectory for the Melco EMT16X by 2026.

Common Pitfalls When Sourcing Melco EMT16X: Quality and Intellectual Property Concerns

When sourcing the Melco EMT16X embroidery machine—or similar high-end industrial equipment—buyers often face critical challenges related to quality assurance and intellectual property (IP) risks. Being aware of these pitfalls can help avoid costly mistakes, legal issues, and operational downtime.

Quality-Related Pitfalls

1. Purchasing Refurbished or Counterfeit Units Misrepresented as New

A common issue when sourcing the Melco EMT16X is encountering sellers who market refurbished, used, or even counterfeit machines as brand-new. These units may lack original components, have worn-out parts, or perform below factory specifications, resulting in reduced stitch quality and machine reliability.

Solution: Always buy from authorized Melco dealers or directly through Melco’s official distribution network. Request verifiable proof of authenticity, serial number checks, and original factory warranties.

2. Inadequate After-Sales Support and Service Coverage

Even if the machine appears genuine, sourcing from unauthorized third-party suppliers may result in limited access to technical support, firmware updates, or spare parts. This lack of support compromises long-term performance and increases downtime.

Solution: Confirm that the supplier offers full technical support and service agreements backed by Melco or a certified service provider.

3. Non-Compliant or Modified Firmware

Some third-party vendors alter the original firmware of the EMT16X to bypass licensing restrictions or add unauthorized features. This can lead to software instability, compatibility issues with design formats, and violation of Melco’s software licensing terms.

Solution: Verify firmware integrity upon delivery and ensure updates are downloaded only from official Melco sources.

Intellectual Property (IP) Risks

1. Unauthorized Replicas or Clone Machines

Due to the popularity of Melco machines, there are knockoffs in the market—often manufactured in regions with lax IP enforcement—that mimic the EMT16X’s appearance and functionality. These clones infringe on Melco’s patents and trademarks and typically fail to meet performance or safety standards.

Solution: Conduct due diligence on suppliers and request documentation proving the machine’s origin. Look for trademarks, certification labels, and official packaging.

2. Use of Pirated or Cracked Software

The EMT16X relies on Melco’s proprietary software (e.g., Melco DesignShop). Sourcing machines bundled with pirated or cracked software not only breaches copyright laws but also exposes users to malware and legal liability.

Solution: Acquire software licenses directly through Melco. Avoid deals that seem too good to be true—especially if software is included “for free” with no license key or activation process.

3. Risk of Infringing on Patented Technology

Even if a machine functions similarly to the EMT16X, using a device that copies patented mechanical or electronic components (e.g., needle threading systems, hoop positioning mechanisms) can expose the buyer to IP litigation, especially in regulated markets.

Solution: Ensure the equipment complies with international IP standards. Work with legal counsel if sourcing from gray-market suppliers or importing into strict jurisdictions.

Conclusion

Sourcing the Melco EMT16X requires careful attention to both quality and intellectual property. Prioritizing authorized channels, verifying authenticity, and ensuring software and hardware compliance will protect your investment and prevent legal or operational setbacks.

Logistics & Compliance Guide for Melco EMT16X

When sourcing, shipping, and importing the Melco EMT16X embroidery machine, it’s essential to follow proper logistics and compliance procedures to ensure smooth delivery and adherence to international and local regulations. Below is a comprehensive guide covering key aspects.

Product Classification & HS Code

Accurate product classification is critical for customs clearance and duty assessment.

- Product: Melco EMT16X 16-Needle Embroidery Machine

- HS Code (Harmonized System Code): 8447.20.00 (Typical classification for embroidery machines; verify with local customs authority)

- Use Case: Industrial/commercial embroidery

- Note: HS codes may vary by country. Confirm with your local customs office or a licensed customs broker to avoid delays or penalties.

Import Duties & Taxes

Import costs vary by destination country. Key factors include:

- Duty Rates: Typically range from 0% to 10% depending on trade agreements (e.g., USMCA, EU trade policies)

- VAT/GST: Applicable in most countries (e.g., 20% VAT in the UK, 10% GST in Australia)

- Additional Fees: Possible customs processing fees, harbor maintenance fees, or anti-dumping duties

- Recommendation: Work with a customs broker to calculate landed cost (product price + shipping + insurance + duties + taxes)

Shipping & Freight Options

Choose the appropriate shipping method based on urgency, cost, and machine specifications.

- Freight Type: Heavy machinery — typically shipped via LCL (Less than Container Load) or FCL (Full Container Load)

- Packaging: Crated securely; ensure moisture protection and shock absorption

- Weight & Dimensions:

- Approx. Weight: 800–1,000 lbs (360–450 kg)

- Crated Dimensions: ~70″ x 40″ x 60″ (LxWxH)

- Freight Forwarder: Use a certified forwarder experienced in handling industrial machinery

- Insurance: Always insure the shipment for full value against damage or loss

Export Documentation

Ensure all export paperwork is accurate and complete:

- Commercial Invoice: Clearly state product description, HS code, value, and country of origin (USA)

- Packing List: Include weight, dimensions, and item count

- Bill of Lading (BOL): Required for ocean freight; air waybill (AWB) for air shipments

- Certificate of Origin: May be required for tariff preference

- Export License: Not typically required for the EMT16X, but verify with U.S. Department of Commerce if shipping to restricted countries

Compliance & Safety Regulations

The Melco EMT16X must meet regulatory standards in the destination market:

- Electrical Compliance:

- Voltage: 208–230V, 50/60 Hz (verify compatibility with local supply)

- Certification: CE (EU), UKCA (UK), ETL or UL (North America) – confirm machine meets local electrical standards

- EMC/EMI Regulations: Electromagnetic compatibility standards (e.g., EU Directive 2014/30/EU)

- RoHS Compliance: Restriction of Hazardous Substances – Melco machines generally comply; request certificate if needed

- Machine Safety: Guarding, emergency stops, and labeling per ISO 13849 or local OSHA/CE machinery directives

Installation & Site Preparation

Ensure end-user site is ready for safe and compliant installation:

- Floor Requirements: Level, solid surface; minimum load capacity of 1,200 lbs

- Power Supply: Dedicated 30-amp circuit recommended; surge protection advised

- Ventilation: Adequate space around machine for cooling and operation

- Training & Manuals: Provide user manuals in local language; Melco offers remote or on-site training

Warranty & After-Sales Support

Understand compliance with service and warranty terms:

- Standard Warranty: Typically 1 year parts and labor (confirm with Melco)

- Service Compliance: Repairs must follow manufacturer guidelines to maintain warranty

- Spare Parts: Import compliance applies to replacement parts; keep documentation on file

Environmental & Disposal Regulations

End-of-life disposal must comply with local environmental laws:

- WEEE Compliance (EU): Waste Electrical and Electronic Equipment – proper recycling required

- EPA Guidelines (USA): Follow local e-waste disposal rules

- Recycling: Contact Melco or local certified recyclers for responsible disposal

Final Recommendations

- Partner with experienced logistics and customs providers

- Confirm all import requirements with destination country’s customs authority

- Retain all documentation for audit and compliance purposes

- Verify electrical compatibility and safety standards before installation

By following this guide, businesses can ensure efficient, compliant, and safe delivery and operation of the Melco EMT16X embroidery machine globally.

Conclusion for Sourcing Melco EMT16X Price:

After evaluating multiple suppliers, distributors, and regional pricing factors, the cost of the Melco EMT16X embroidery machine varies significantly based on location, included accessories, warranty, and level of dealer support. Official Melco distributors typically offer the most reliable pricing and after-sales service, with the EMT16X generally priced between $40,000 and $50,000 USD, depending on configuration. Alternative sourcing options, such as third-party vendors or international markets, may offer lower price points, but often come with risks related to warranty validity, technical support, and shipping logistics. Additionally, financing plans and trade-in options from authorized dealers can improve overall value. For long-term reliability, technical service access, and software compatibility, purchasing through an authorized Melco dealer is recommended despite a potentially higher upfront cost. Proper due diligence in sourcing ensures that the investment aligns with both budgetary constraints and operational requirements.