The global mechanical filters market is experiencing robust growth, driven by rising demand for efficient filtration solutions across industries such as automotive, HVAC, water treatment, and manufacturing. According to Grand View Research, the global industrial filters market size was valued at USD 38.6 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. Mordor Intelligence further supports this trajectory, forecasting a CAGR of over 5.8% during the period 2023–2028, fueled by stringent environmental regulations and increasing focus on air and water quality. With expanding industrialization and infrastructure development—particularly in Asia-Pacific and Latin America—the need for reliable mechanical filtration systems has never been more critical. In this evolving landscape, a select group of manufacturers stands out for innovation, scalability, and performance. Based on market presence, technological advancement, and industry reputation, here are the top 10 mechanical filter manufacturers shaping the future of filtration.

Top 10 Mechanical Filter Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Engine and Industrial Air, Oil and Liquid Filtration

Domain Est. 1995

Website: donaldson.com

Key Highlights: Donaldson Company, Inc. is a global leader in providing engine and industrial air, oil and liquid filtration solutions….

#2 Hollingsworth & Vose in Massachusetts

Domain Est. 1996

Website: hollingsworth-vose.com

Key Highlights: Hollingsworth and Vose is a global manufacturer of advanced materials used in filtration, battery, and industrial applications….

#3 AAF International

Domain Est. 1997

Website: aafintl.com

Key Highlights: We design advanced air filtration systems and technology to give you more control over the air inside commercial, industrial, and residential living spaces….

#4 Filters

Domain Est. 1994

Website: murata.com

Key Highlights: Filters are components with a function that only extracts the required electrical signals, and removes the unnecessary electrical signals in electrical ……

#5 Hengst Filtration

Domain Est. 1996

Website: hengst.com

Key Highlights: Hengst Filtration develops filtration systems for Passenger cars and trucks, for plant and mechanical engineering, industrial filtration, hydraulics and Health ……

#6 Solberg MFG

Domain Est. 1996

Website: solbergmfg.com

Key Highlights: Solberg designs and manufactures filter silencers, vacuum filters, separators and oil mist eliminators for compressors, blowers, vacuum pumps and power ……

#7 Filtration Solutions for clean and pure products

Domain Est. 1996

Website: eaton.com

Key Highlights: Eaton is a leader in liquid filtration which helps its customers make clean and pure products spanning a range of industries….

#8 Mott Corporation

Domain Est. 1997

Website: mottcorp.com

Key Highlights: 60+ years innovating porous metal filtration for healthcare, aerospace, energy, manufacturing, and more. Engineered for peak efficiency and purity….

#9 Explore the MANN+HUMMEL brand landscape

Domain Est. 1998

Website: mann-hummel.com

Key Highlights: Rating 4.4 (100) As a globally recognized brand, MANN-FILTER offers filters in 100% OE quality for the automotive aftermarket. With precision-engineered filtration solutions, ……

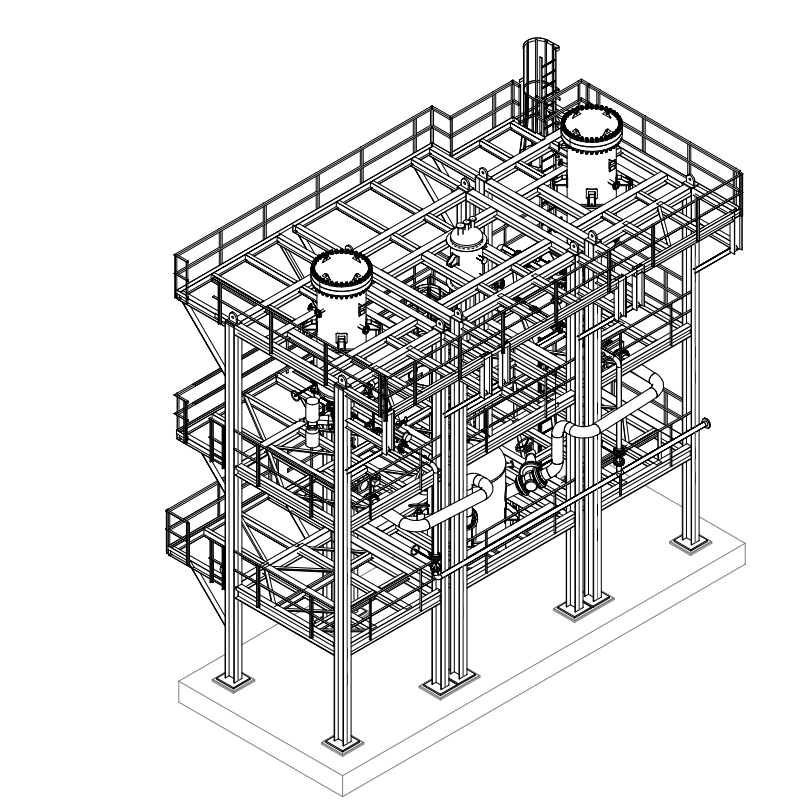

#10 Mechanical filtration systems for dust

Domain Est. 1999

Website: junker-group.com

Key Highlights: Our mechanical filtration systems for dust are individually adaptable and offer high performance. Convince yourself now!…

Expert Sourcing Insights for Mechanical Filter

H2: Emerging 2026 Market Trends for Mechanical Filters

The mechanical filter market is poised for significant transformation by 2026, driven by escalating environmental regulations, technological advancements, and shifting industrial demands. Key H2 (second half) 2026 trends are expected to reflect a maturation of current innovations and the acceleration of sustainability-driven solutions. Here’s an analysis of the dominant trends shaping the landscape:

-

Heightened Demand from Water & Wastewater Treatment:

- Trend: Stringent global regulations on water purity (e.g., PFAS removal, microplastic filtration) and increasing water scarcity will drive massive adoption of advanced mechanical filters (e.g., microfiltration, ultrafiltration membranes, high-efficiency backwashing sand filters).

- H2 2026 Impact: Municipalities and industrial facilities will prioritize upgrades to meet compliance deadlines, boosting demand for robust, low-maintenance mechanical filtration systems, particularly in emerging economies undergoing rapid urbanization.

-

Rise of Smart & Connected Filters:

- Trend: Integration of IoT sensors, predictive analytics, and remote monitoring into mechanical filters will become standard, moving beyond early adoption.

- H2 2026 Impact: Operators will leverage real-time data on pressure drops, flow rates, and filter life to optimize cleaning cycles (reducing energy/water waste), predict maintenance needs, and minimize downtime. This “smart filtration” will be a key differentiator, especially in critical processes (pharma, food & beverage, power generation).

-

Sustainability & Circular Economy Focus:

- Trend: Pressure to reduce energy consumption, waste, and environmental footprint will intensify. This includes demand for filters with lower pressure drops (energy savings), longer lifespans, and recyclable/reusable components.

- H2 2026 Impact: Manufacturers will innovate with sustainable materials (e.g., bio-based filter media, recycled housings) and designs facilitating easier recycling or regeneration. Closed-loop filtration systems minimizing waste discharge will gain prominence, particularly in manufacturing.

-

Advancements in Material Science:

- Trend: Development of next-generation filter media offering superior performance (higher flux, better rejection, fouling resistance) and durability.

- H2 2026 Impact: Wider commercialization of advanced materials like graphene-enhanced membranes, novel ceramic composites, and highly engineered synthetic polymers will enable filtration of challenging streams (high salinity, extreme temperatures, viscous fluids) and reduce operational costs.

-

Growth in Industrial Process Optimization:

- Trend: Industries (chemicals, petrochemicals, food processing, mining) will increasingly view mechanical filtration not just as a necessity, but as a critical tool for improving product quality, yield, and process efficiency.

- H2 2026 Impact: Demand will rise for specialized, high-precision filters capable of protecting sensitive equipment (e.g., catalysts, pumps), enabling higher purity standards, and facilitating process intensification. Customization will be key.

-

Supply Chain Resilience & Localization:

- Trend: Ongoing geopolitical tensions and lessons from recent disruptions will push companies to diversify suppliers and shorten supply chains.

- H2 2026 Impact: Increased investment in regional manufacturing hubs for mechanical filters and key components (especially membranes and media) is expected, reducing lead times and vulnerability to global shocks. “Nearshoring” or “friend-shoring” will influence sourcing decisions.

Conclusion for H2 2026:

The mechanical filter market in the latter half of 2026 will be characterized by smart, sustainable, and high-performance solutions driven by regulatory pressure and industrial efficiency demands. Success will depend on manufacturers’ ability to integrate digital technologies, innovate with advanced materials, offer demonstrable sustainability benefits, and ensure resilient supply chains. The focus will shift from basic filtration to integrated, data-driven systems that deliver tangible economic and environmental value.

Common Pitfalls Sourcing Mechanical Filters (Quality, IP)

Sourcing mechanical filters involves more than just selecting a part that fits; overlooking key quality and intellectual property (IP) aspects can lead to performance issues, legal risks, and supply chain disruptions. Below are common pitfalls to avoid:

Inadequate Quality Control Processes

One of the most frequent issues is partnering with suppliers lacking robust quality assurance systems. Without ISO certifications (e.g., ISO 9001) or documented inspection procedures, there’s a high risk of receiving filters with inconsistent pore sizes, material defects, or dimensional inaccuracies. These flaws can compromise filtration efficiency, reduce system lifespan, or cause failures in critical applications such as medical devices or aerospace systems.

Poor Material Traceability

Mechanical filters often require specific alloys, polymers, or composite materials to meet performance standards. Sourcing from suppliers that do not provide full material traceability—such as mill test reports or certificates of conformance—can result in undetected substandard materials. This is especially critical in regulated industries where compliance with standards like ASTM or ASME is mandatory.

Misunderstanding IP Ownership and Licensing

A significant but often overlooked pitfall is assuming that purchasing a mechanical filter transfers intellectual property rights. In many cases, especially with custom-designed filters, the design may be protected by patents or trade secrets. Without clear contractual agreements, buyers risk infringing on IP, facing litigation, or being unable to replicate or modify the design—even for internal use.

Failure to Verify Design Rights

When sourcing custom mechanical filters, buyers must confirm whether they are acquiring exclusive rights to the design or if the supplier retains the right to sell similar designs to competitors. Lack of clarity can lead to market competition with identical components and devaluation of proprietary systems.

Overlooking Counterfeit or Reverse-Engineered Components

In global supply chains, there’s a risk of receiving counterfeit filters that mimic genuine parts but use inferior materials or manufacturing processes. These components may pass initial inspections but fail prematurely under operational stress. Additionally, some suppliers may reverse-engineer patented designs, exposing the buyer to indirect IP infringement claims.

Insufficient Supplier Audits

Relying solely on product samples or datasheets without conducting on-site audits of manufacturing facilities increases exposure to quality and IP risks. Audits help assess the supplier’s production capabilities, adherence to quality standards, and respect for IP laws—critical for long-term reliability and compliance.

Incomplete Contracts and Specifications

Vague procurement contracts that omit detailed technical specifications, quality benchmarks, or IP clauses leave room for disputes. Clear documentation should define tolerances, testing requirements, warranty terms, and explicit statements on IP ownership and usage rights to protect both parties.

Avoiding these pitfalls requires due diligence, clear communication, and legal safeguards. Engaging qualified suppliers, conducting thorough audits, and formalizing IP terms in contracts are essential steps in sourcing reliable and legally compliant mechanical filters.

Logistics & Compliance Guide for Mechanical Filters

This guide outlines key logistics considerations and compliance requirements for the transportation, handling, and use of mechanical filters across various industries such as HVAC, automotive, industrial manufacturing, and water treatment.

Product Classification and HS Codes

Mechanical filters are typically classified under the Harmonized System (HS) for international trade. Common HS codes include:

– 8421.39 – Air filtering or purifying machinery and apparatus

– 8421.93 – Filters for liquids

– 8409.91 – Parts of air filters for internal combustion engines

Accurate classification ensures correct duties, taxes, and regulatory compliance during import/export.

Packaging and Handling Requirements

Proper packaging is essential to prevent damage during transit:

– Use sturdy, moisture-resistant cartons or crates for bulk shipments.

– Secure filters with cushioning materials (e.g., foam, bubble wrap) to avoid deformation.

– Label packages with “Fragile,” “This Side Up,” and handling instructions.

– For large industrial filters, use pallets and stretch wrap; consider custom crating.

Storage Conditions

Store mechanical filters in a clean, dry, and temperature-controlled environment:

– Avoid exposure to dust, moisture, and extreme temperatures.

– Keep away from direct sunlight to prevent material degradation (especially for synthetic filter media).

– Store horizontally if specified by the manufacturer to prevent warping.

Transportation Regulations

- Domestic Shipping: Comply with carrier-specific regulations (e.g., FedEx, UPS, or specialized freight carriers). Use appropriate freight class for LTL (Less-Than-Truckload) shipments.

- International Shipping: Adhere to IMDG (for sea), IATA (for air), and ADR (for road in Europe) as applicable. While most mechanical filters are non-hazardous, verify content materials (e.g., oil-impregnated filters may have restrictions).

- Ensure proper documentation: commercial invoice, packing list, bill of lading, and certificate of origin.

Import/Export Compliance

- Verify export control classifications (e.g., EAR99 under U.S. Export Administration Regulations) – most mechanical filters are not controlled but check specific end-uses.

- Comply with destination country regulations (e.g., CE marking in the EU, UKCA in the UK, CCC in China).

- Obtain necessary import permits or licenses if required by the importing country.

Environmental and Safety Compliance

- Follow local, national, and international environmental regulations for disposal of used filters.

- Used filters may be classified as industrial waste; check for hazardous content (e.g., contaminated oils, heavy metals).

- Comply with OSHA (U.S.), WHMIS (Canada), or REACH/CLP (EU) for workplace handling and material safety data sheets (MSDS/SDS) if applicable.

Quality and Certification Standards

Ensure mechanical filters meet industry-specific standards:

– HVAC Filters: Comply with ASHRAE 52.2 (U.S.) or EN 779 / EN 1822 (EU) for efficiency ratings.

– Automotive Filters: Meet ISO 5011 or SAE J726 standards.

– Industrial Liquid Filters: Comply with ISO 16889 or ISO 4021.

– Retain certification documents for audits and customer requests.

Documentation and Traceability

Maintain records for full supply chain traceability:

– Batch/lot numbers

– Manufacturing and expiration dates (if applicable)

– Certificates of Conformance (CoC)

– Test reports and compliance documentation

Adhering to this logistics and compliance guide ensures safe, efficient distribution of mechanical filters and minimizes regulatory risks across global markets.

Conclusion for Sourcing a Mechanical Filter

In conclusion, sourcing a mechanical filter requires a comprehensive evaluation of technical specifications, application requirements, quality standards, and supplier reliability. Selecting the appropriate filter involves understanding key parameters such as filtration efficiency, flow rate, particle size retention, material compatibility, and durability under operating conditions. Additionally, considerations such as cost-effectiveness, lead times, regulatory compliance, and after-sales support play a crucial role in ensuring long-term performance and operational efficiency.

By conducting thorough supplier assessments, comparing multiple options, and aligning filter capabilities with system needs, organizations can secure a reliable and efficient filtration solution. Ultimately, a well-sourced mechanical filter not only enhances system protection and longevity but also contributes to reduced maintenance costs and improved overall performance. Continuous monitoring and feedback post-implementation will further support optimized sourcing decisions in the future.