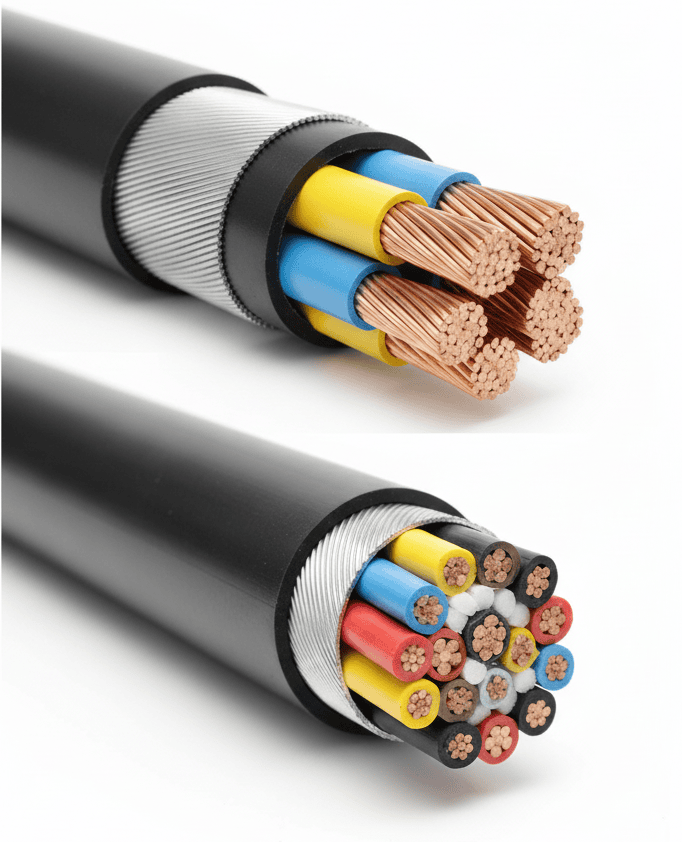

The global electrical cable market is experiencing robust growth, driven by rising demand for reliable power transmission, infrastructure development, and expanding renewable energy projects. According to a report by Mordor Intelligence, the market was valued at USD 158.37 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.4% from 2024 to 2029. This upward trajectory is further supported by urbanization, industrial modernization, and government initiatives to upgrade aging electrical grids worldwide. With such strong momentum, the role of Mc (Medium and Low Voltage Control) cable manufacturers has become increasingly critical in ensuring safe, efficient, and scalable electrical connectivity across sectors. In this dynamic landscape, nine key manufacturers have emerged as leaders, delivering innovative cable solutions backed by advanced engineering, stringent quality standards, and global supply capabilities.

Top 9 Mc Cable Electrical Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wire and Cable Manufacturers

Domain Est. 1996

Website: encorewire.com

Key Highlights: Encore Wire is the leading manufacturer of copper and aluminum for residential, commercial and industrial wire needs. We’re unlike any other wire company….

#2 Armored Cables • Grounded & Jacketed Cable Manufacturer

Domain Est. 1997

Website: conwire.com

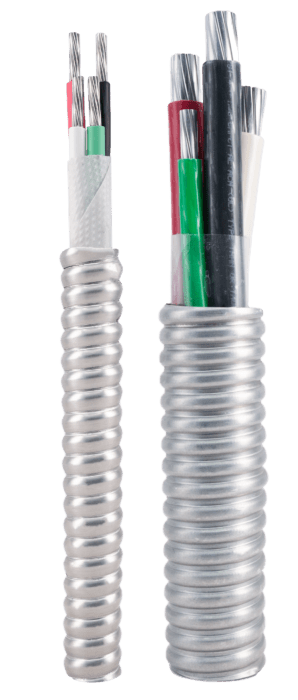

Key Highlights: Consolidated Electronic Wire & Cable is a trusted manufacturer of type MC (metal clad) and jacketed armored cables….

#3 Southwire

Domain Est. 1994

Website: southwire.com

Key Highlights: Choose Southwire for your wire and cable needs – we offer high-performance products that are built to last….

#4 Copper Wire Supplier

Domain Est. 1996

Website: cerrowire.com

Key Highlights: Cerrowire is a leading copper wire supplier offering MC cables, aluminum wire, and building cables for reliable electrical solutions….

#5 Armored Cables

Domain Est. 1996

Website: servicewire.com

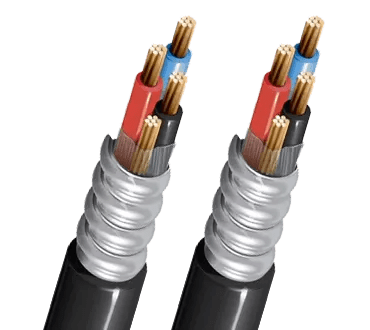

Key Highlights: Feeder MC armored cable offers cost-effective protection like conduit, with easy installation and versatile applications. Jacketed Type MC provides extra ……

#6 MC Cable

Domain Est. 1997

Website: belden.com

Key Highlights: Combine rugged durability, corrosion resistance, flexibility and easy handling with MC Cables from Belden. Cables are designed to meet the needs of demanding ……

#7 Type MC (Metal Clad) Cable Assemblies

Domain Est. 2002

Website: pducables.com

Key Highlights: Metal Clad cables are assemblies of one or more insulated circuit conductors with or without optical fiber members enclosed in an armor of interlocking metal ……

#8 Type MC & Jacketed Armored Cables

Domain Est. 2009

Website: classicwire.com

Key Highlights: Metal clad (MC) armored cables are versatile and provide comprehensive solutions for a wide range of wiring needs. Contact us for a quote!…

#9 AFC Cable Systems

Domain Est. 2010

Website: atkore.com

Key Highlights: We manufacture standard Type MC Cables, including MC Glide®, MC Tuff®, MC Lite® and other MC cables in various specialty configurations, most featuring the ……

Expert Sourcing Insights for Mc Cable Electrical

H2 2026 Market Trends Analysis for Mc Cable Electrical

As Mc Cable Electrical looks toward the second half of 2026, the electrical distribution and infrastructure market is poised for dynamic shifts driven by technological innovation, regulatory changes, and evolving customer demands. Understanding these H2 2026 trends is critical for strategic planning, product development, and market positioning. Key trends include:

1. Accelerated Adoption of Smart Grid and Energy Management Technologies

Utilities and commercial clients will increasingly invest in smart grid infrastructure to enhance reliability, integrate renewables, and manage peak loads. Mc Cable Electrical can expect rising demand for intelligent cabling solutions, including fiber-optic hybrid cables, sensors-ready conduits, and components compatible with IoT-enabled monitoring systems. Partnerships with tech providers and training in smart infrastructure installation will be essential.

2. Expansion of Renewable Energy Integration Projects

Solar, wind, and battery storage projects are projected to grow significantly in H2 2026, spurred by government incentives and corporate ESG commitments. This will drive demand for specialized cabling—such as photovoltaic (PV) wire, medium-voltage (MV) cables for interconnection, and fire-resistant cables for energy storage installations. Mc Cable should position itself as a solutions provider by offering bundled products and technical support for renewable energy developers.

3. Increased Focus on Resilience and Grid Hardening

With extreme weather events becoming more frequent, utilities are prioritizing infrastructure resilience. Mc Cable can capitalize on demand for underground cabling, moisture-resistant insulation, and fire-retardant materials. Products compliant with updated NEC codes (e.g., NEC 2026 updates emphasizing circuit integrity and arc-fault protection) will be in higher demand.

4. Growth in Electrification of Transportation and Buildings

Electric vehicle (EV) charging infrastructure deployment—especially Level 2 and DC fast-charging stations—will continue to expand in commercial, municipal, and multi-unit residential settings. Simultaneously, building electrification (e.g., heat pumps, induction cooking) will increase electrical load requirements. Mc Cable should expand offerings in EV charging cables, load centers, and high-capacity feeder cables, while promoting energy-efficient solutions.

5. Supply Chain Diversification and Local Sourcing

Ongoing geopolitical tensions and logistics volatility will push customers toward suppliers with resilient, regional supply chains. Mc Cable can strengthen its competitive advantage by emphasizing local inventory, shorter lead times, and partnerships with North American manufacturers. Transparency in sourcing and sustainability certifications (e.g., recycled copper content) will increasingly influence procurement decisions.

6. Workforce Development and Digital Integration

Labor shortages in skilled electrical trades persist. Mc Cable can differentiate by offering value-added services such as digital product catalogs, BIM integration, and training programs for contractors. Adoption of AR/VR tools for product visualization and project planning will enhance customer engagement and reduce installation errors.

Strategic Recommendations for Mc Cable Electrical:

– Invest in training and certification programs for emerging technologies (e.g., battery storage, EV infrastructure).

– Expand product lines focused on sustainability and resilience.

– Strengthen digital platforms for e-commerce and technical support.

– Forge strategic alliances with renewable energy developers and smart building integrators.

– Monitor regulatory updates closely, particularly around energy codes and safety standards.

By aligning with these H2 2026 market trends, Mc Cable Electrical can strengthen its market position, drive innovation, and deliver greater value to customers in an evolving energy landscape.

Common Pitfalls When Sourcing MC Cable Electrical (Quality, IP)

Poor Quality Control and Substandard Materials

One of the most frequent issues when sourcing MC (Metal Clad) cable is receiving products made with inferior materials. This includes undersized conductors, subpar insulation, or thin aluminum armor that doesn’t meet required mechanical protection standards. These deficiencies can lead to overheating, reduced lifespan, and potential safety hazards. Always verify compliance with recognized standards such as UL 1569 or NEC Article 330, and request third-party test reports or certifications.

Lack of Genuine IP (Ingress Protection) Certification

Many suppliers claim their MC cables offer specific IP ratings (e.g., IP66 for dust and water resistance), but these claims are often unverified or misleading. Without authentic IP certification from an accredited testing body, the cable may not perform reliably in harsh environments. Always demand official documentation, including test reports from independent labs, to confirm the stated IP rating.

Misrepresentation of Cable Specifications

Suppliers may exaggerate key electrical or mechanical properties—such as voltage rating, temperature tolerance, or fire resistance (e.g., claiming FT4 or Type TC-ER compliance without proof). This misrepresentation can result in non-compliant installations and failed inspections. Ensure datasheets are detailed and match actual product markings, and conduct random batch testing when feasible.

Inadequate Traceability and Documentation

Reputable MC cable suppliers should provide full traceability, including lot numbers, manufacturing dates, and material certifications. A lack of proper documentation makes it difficult to verify quality or respond to field failures. Insist on complete paperwork and audit trails to support compliance and liability protection.

Counterfeit or Non-UL Listed Products

In some supply chains, counterfeit or non-listed cables are sold as certified products. These can bypass safety evaluations and lack the required performance under fault conditions. Always source from authorized distributors and verify UL or ETL listing numbers directly through certification databases.

Inconsistent Manufacturing Standards Across Suppliers

When sourcing from multiple or low-cost manufacturers—especially overseas—there can be significant variation in build quality and adherence to specifications. Implement strict supplier qualification processes and conduct periodic on-site audits to ensure consistent quality and regulatory compliance.

Overlooking Environmental and Regulatory Compliance

Some MC cables may contain restricted substances (e.g., hazardous halogens) or fail to meet regional environmental regulations like RoHS or REACH. Confirm that the cable meets all applicable environmental standards, especially for use in sensitive or regulated facilities.

Logistics & Compliance Guide for Mc Cable Electrical

Overview

This guide outlines the essential logistics and compliance procedures for Mc Cable Electrical to ensure efficient operations, regulatory adherence, and safe handling of electrical products and materials. All employees, contractors, and partners must follow these standards to maintain quality, safety, and legal compliance.

Shipping & Receiving Procedures

All incoming and outgoing shipments must be documented and inspected. Use standardized packing lists, bills of lading, and delivery notes. Verify quantities, part numbers, and product condition upon receipt. Report discrepancies immediately to the logistics manager. Shipments containing hazardous materials must be labeled and handled in compliance with DOT and OSHA standards.

Inventory Management

Maintain accurate inventory records using the company’s ERP system. Conduct regular cycle counts and scheduled physical inventories. Store items according to type, voltage rating, and flammability. Segregate obsolete or non-conforming materials. Ensure warehouse organization supports first-in, first-out (FIFO) practices where applicable.

Transportation & Carrier Compliance

Only work with certified carriers that meet federal and state transportation regulations. Ensure all vehicles used for transporting electrical cables and equipment are equipped to prevent damage (e.g., proper strapping, weather protection). Drivers must possess valid commercial licenses when required. Maintain records of carrier insurance and safety ratings.

Regulatory Compliance

Adhere to all relevant regulations, including but not limited to:

– OSHA – Workplace safety, handling of heavy reels, and electrical hazard protocols

– NFPA 70 (NEC) – Product standards and storage classifications

– DOT 49 CFR – Shipping of hazardous materials (e.g., insulating compounds)

– EPA – Proper disposal of packaging, oils, and non-recyclable components

– RoHS & REACH – Restrictions on hazardous substances in electrical products (especially for imported goods)

Import/Export Documentation

For international shipments, ensure all customs documentation is complete and accurate. This includes commercial invoices, certificates of origin, and Harmonized System (HS) code classifications. Verify export controls for dual-use electrical components. Retain records for a minimum of five years.

Product Certification & Labeling

All electrical cables and accessories must bear valid certification marks (e.g., UL, CSA, ETL) as required by jurisdiction. Labels must include specifications such as voltage rating, temperature range, and fire resistance. Never distribute products lacking proper certification.

Safety & Handling Protocols

Train staff on proper lifting techniques and use of material handling equipment (e.g., forklifts, cable carts). Wear appropriate PPE (gloves, safety shoes, eye protection) in warehouse and loading areas. Establish emergency procedures for fire, spills, or electrical exposure. Conduct quarterly safety drills.

Environmental Responsibility

Recycle packaging materials (wood reels, plastic wrap, cardboard) in accordance with local regulations. Partner with certified e-waste handlers for end-of-life product returns. Minimize carbon footprint by optimizing delivery routes and consolidating shipments.

Audit & Recordkeeping

Conduct internal compliance audits biannually. Maintain records of:

– Shipping and receiving logs

– Safety training certifications

– Equipment maintenance schedules

– Regulatory permits and licenses

– Product test reports and certificates

All documentation must be stored securely and be retrievable for inspection by authorities or auditors.

Continuous Improvement

Review logistics and compliance procedures annually or after significant regulatory changes. Solicit feedback from staff and partners to identify inefficiencies or risks. Implement corrective actions promptly and document all improvements.

Conclusion for Sourcing MC Cable (Electrical):

Sourcing MC (Metal-Clad) cable for electrical applications requires careful consideration of project specifications, compliance with electrical codes (such as the NEC in the U.S.), and the unique demands of the installation environment. By evaluating factors such as gauge size, conductor material (copper vs. aluminum), jacket type, and armor configuration, buyers can ensure optimal performance, safety, and longevity of the electrical system. Engaging reliable suppliers with proven quality certifications, competitive pricing, and timely delivery is crucial to maintaining project timelines and minimizing downtime. Additionally, staying informed about market trends and potential supply chain disruptions helps in making strategic procurement decisions. Ultimately, a well-structured sourcing strategy for MC cable supports reliable, code-compliant electrical installations across commercial, industrial, and residential applications.