The global material conveyor market is experiencing robust growth, driven by increasing automation across manufacturing, logistics, and mining sectors. According to Grand View Research, the global conveyor systems market size was valued at USD 8.4 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. This surge is fueled by the rising demand for efficient material handling solutions, labor cost reduction, and the expansion of e-commerce fulfillment centers requiring high-speed sorting and transport systems. As industries prioritize throughput and operational efficiency, investment in advanced conveyor technologies continues to rise. In this evolving landscape, leading manufacturers are differentiating themselves through innovation in durability, energy efficiency, and integration with Industry 4.0 systems. Based on market presence, technological capability, and global reach, here are the top 10 material conveyor manufacturers shaping the future of material handling.

Top 10 Material Conveyor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 QC Conveyors

Domain Est. 2013

Website: qcconveyors.com

Key Highlights: QC Conveyors is a trusted conveyor manufacturer providing custom systems for industrial and automation applications. Fast lead times and expert support….

#2 Dorner Conveyors

Domain Est. 2007

Website: dornerconveyors.com

Key Highlights: Dorner offers a wide variety of industrial, aluminum frame and sanitary, stainless steel frame conveyors. With fabric belt, modular belt, and flexible chain ……

#3 FMH Conveyors: Conveyor Manufacturer

Domain Est. 2014

Website: fmhconveyors.com

Key Highlights: FMH Conveyors is a leading conveyor company improving your truck loading and unloading efficiency, productivity, and safety in conveyance solutions….

#4 Span Tech Conveyors

Domain Est. 2017

Website: spantechconveyors.com

Key Highlights: Explore Span Tech’s custom conveyors for packaging, food, pharma, and more—built for efficiency, flexibility, and increased productivity….

#5 Shuttleworth

Domain Est. 1996

Website: shuttleworth.com

Key Highlights: Shuttleworth designs and manufactures conveyor systems & material handling systems for a variety of industries & applications….

#6 TKF Conveyors

Domain Est. 1996

Website: tkf.com

Key Highlights: TKF provides the industry a comprehensive range of conveyor based material handling services including initial engineering concepts, final system design, ……

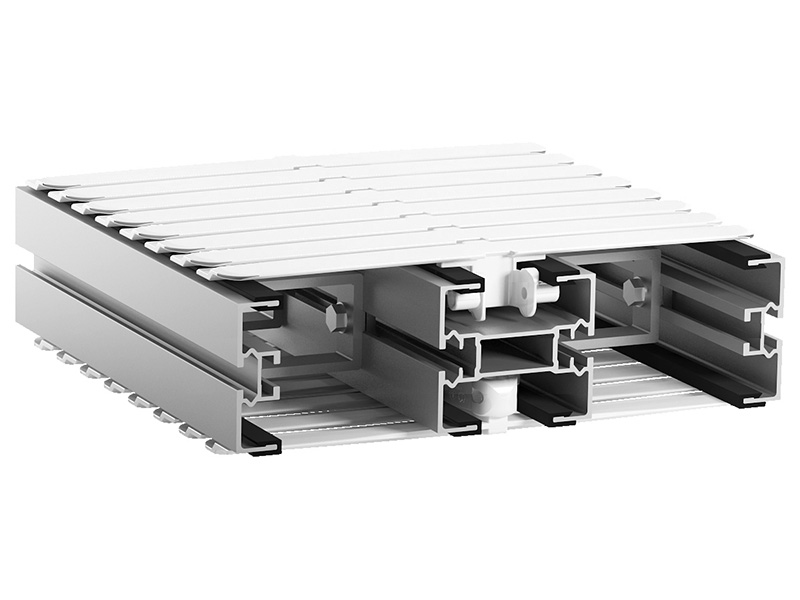

#7 Flexlink

Domain Est. 1997

Website: flexlink.com

Key Highlights: FlexLink is a leading company in the production of automated conveyors systems and robotic palletizing cells for several industries….

#8 Kornylak Corporation

Domain Est. 1998

Website: kornylak.com

Key Highlights: Kornylak manufactures conveyor systems, metal belt conveyors, rubber belt, steel slat conveyors, metal slat, roller conveyors, gravity flow and gravity powered ……

#9 Continental Conveyor

Domain Est. 2000

Website: cgmh.com

Key Highlights: Experience excellence with Continental™ – the most trusted name in conveyor equipment, setting the standard for quality and performance for decades….

#10 Conveyor Systems

Domain Est. 2013

Website: nerconconveyors.com

Key Highlights: Nercon designs and manufactures conveyor systems to keep consumer packaged goods moving in ways that are faster, more reliable and more efficient. About Us….

Expert Sourcing Insights for Material Conveyor

H2: 2026 Market Trends for Material Conveyors

The material conveyor market in 2026 is poised for significant transformation, driven by technological advancements, shifting industrial priorities, and evolving global economic dynamics. Key trends shaping the industry include:

1. Accelerated Adoption of Automation and Smart Conveying Systems:

By 2026, the integration of Industry 4.0 technologies will be mainstream in conveyor systems. Conveyors will increasingly feature embedded sensors, real-time monitoring, predictive maintenance algorithms, and seamless connectivity with warehouse management systems (WMS) and enterprise resource planning (ERP) platforms. This shift enhances operational efficiency, reduces downtime, and enables data-driven decision-making, particularly in e-commerce fulfillment centers and smart factories.

2. Growth in E-Commerce and Omnichannel Logistics:

The continued expansion of online retail will drive demand for high-speed, flexible, and scalable conveyor solutions. Conveyors capable of handling diverse package sizes, supporting automated sortation, and integrating with robotics for order fulfillment will be in high demand. Modular conveyor designs that allow for rapid reconfiguration will be essential for adapting to fluctuating order volumes and seasonal peaks.

3. Emphasis on Sustainability and Energy Efficiency:

Environmental regulations and corporate sustainability goals will push manufacturers toward energy-efficient conveyor designs. In 2026, expect wider adoption of low-friction components, regenerative drives, and electric or hybrid-powered systems. Recyclable materials in conveyor construction and reduced lifecycle emissions will become key differentiators in procurement decisions.

4. Increased Demand in Emerging Markets:

Industrialization and infrastructure development in regions like Southeast Asia, India, and parts of Africa will fuel demand for material handling equipment. Localized manufacturing and logistics hubs will require robust conveyor systems for sectors such as food & beverage, automotive, and mining, presenting growth opportunities for global and regional suppliers.

5. Rise of Customization and Modular Solutions:

One-size-fits-all systems are becoming obsolete. By 2026, manufacturers will prioritize modular and customizable conveyor systems that can be easily expanded or reconfigured. This trend supports agile manufacturing, just-in-time logistics, and the need for rapid deployment in dynamic industrial environments.

6. Integration with Robotics and AI:

Material conveyors will increasingly serve as the backbone for automated guided vehicles (AGVs), autonomous mobile robots (AMRs), and robotic picking arms. AI-driven route optimization and load balancing will enhance throughput and minimize bottlenecks, especially in complex distribution networks.

In summary, the 2026 material conveyor market will be defined by intelligence, flexibility, sustainability, and deep integration with digital ecosystems. Companies that innovate in smart technology, energy efficiency, and modular design will lead the market, while traditional conveyor providers face pressure to modernize or risk obsolescence.

Common Pitfalls Sourcing Material Conveyors (Quality, IP)

Sourcing material conveyors involves significant technical and legal considerations, especially concerning quality and intellectual property (IP). Overlooking these aspects can lead to operational inefficiencies, safety risks, and legal exposure. Below are key pitfalls to avoid:

Poor Quality Control and Substandard Components

One of the most frequent issues is selecting suppliers who cut corners on materials or manufacturing processes. Low-quality rollers, belts, or drive systems can lead to frequent breakdowns, increased maintenance costs, and production downtime. Always verify supplier certifications (e.g., ISO 9001), request third-party inspection reports, and conduct factory audits when possible.

Inadequate Design for Intended Application

Conveyors must be engineered for specific load types, environmental conditions (e.g., temperature, humidity, corrosive agents), and throughput requirements. A common mistake is assuming a standard conveyor will suffice. Mismatched designs can degrade quickly or fail entirely, undermining long-term reliability and safety.

Lack of IP Due Diligence

Purchasing conveyors from suppliers who use patented technologies without proper licensing exposes your organization to IP infringement claims. This is especially critical when sourcing from low-cost regions where IP laws may not be strictly enforced. Ensure the supplier warrants that their design does not infringe on third-party patents and provide indemnification clauses in contracts.

Hidden Costs from Non-Compliance

Conveyors that do not meet regional safety or electrical standards (e.g., CE, UL, OSHA) may require costly retrofits or fail inspections. Non-compliant equipment also poses liability risks. Confirm that the supplier provides fully compliant documentation and certifications relevant to your operational location.

Insufficient After-Sales Support and Spare Parts

Even high-quality conveyors need maintenance. Sourcing from vendors without reliable technical support or spare parts availability can result in prolonged downtimes. Evaluate the supplier’s service network and parts inventory before finalizing procurement.

Failure to Secure IP Rights for Custom Designs

If you commission a custom conveyor, ensure your contract explicitly transfers IP ownership or grants full usage rights. Otherwise, the supplier may retain rights, limiting your ability to modify, replicate, or service the equipment without permission or additional fees.

Avoiding these pitfalls requires thorough vetting of suppliers, clear contractual terms, and proactive risk management—particularly around quality assurance and intellectual property protection.

Logistics & Compliance Guide for Material Conveyor

This guide outlines the essential logistics considerations and compliance requirements for the safe, efficient, and legal transport, handling, and operation of material conveyor systems.

Transportation and Delivery

Ensure the conveyor system — including frames, rollers, belts, motors, and control panels — is securely packaged and labeled according to shipping standards. Coordinate with freight carriers experienced in handling industrial machinery. Verify delivery routes can accommodate oversized loads if applicable and confirm site access for unloading equipment (e.g., forklifts, cranes). Inspect all components upon arrival for shipping damage and document discrepancies immediately.

Site Preparation and Handling

Prepare the installation site in advance, ensuring a level, stable foundation and adequate space for assembly. Follow manufacturer guidelines for storage conditions (e.g., protection from moisture, extreme temperatures). Use proper lifting equipment and rigging techniques when moving conveyor sections to prevent injury and equipment damage. Adhere to site-specific safety protocols, including lockout/tagout (LOTO) if near energized systems.

Regulatory Compliance

Material conveyors must comply with relevant local, national, and international regulations. Key standards include:

– OSHA (Occupational Safety and Health Administration) – Ensure guarding on moving parts, emergency stop placement, and safe work practices per 29 CFR 1910.212 and 1910.147.

– ANSI/ASME B20.1 – Safety standards for conveyors and related equipment, covering guarding, controls, and maintenance.

– NEC (National Electrical Code) – Electrical installations must meet NEC Article 620 or equivalent for industrial machinery.

– CE Marking (EU) – Conveyors placed in the European market must comply with the Machinery Directive 2006/42/EC, including risk assessment and technical file documentation.

– ATEX/IECEx (if applicable) – Required for conveyors operating in explosive atmospheres; ensures equipment is designed for hazardous locations.

Installation and Commissioning

Installation must be performed by qualified personnel following manufacturer specifications and approved engineering drawings. Verify alignment, tension, and drive system integration. Conduct functional testing under controlled conditions, including emergency stop response and overload protection. Document all installation steps and test results for compliance audits.

Environmental and Safety Compliance

Implement dust control, noise mitigation, and spill containment measures as needed, especially in sensitive environments. Ensure conveyor design accounts for material characteristics (e.g., flammability, toxicity) and includes appropriate containment and ventilation. Train operators on safe use, maintenance procedures, and hazard awareness.

Documentation and Recordkeeping

Maintain comprehensive records including:

– Manufacturer manuals and drawings

– Risk assessments and safety certifications

– Inspection, maintenance, and repair logs

– Training records for operators and technicians

– Compliance documentation (e.g., CE Declaration of Conformity, OSHA inspections)

Regular audits should verify ongoing compliance and operational safety.

In conclusion, sourcing a material conveyor system requires a strategic and comprehensive approach that balances operational needs, budget constraints, and long-term efficiency goals. Key considerations such as the type of materials being transported, required capacity, available space, environmental conditions, and automation integration play a critical role in selecting the most suitable conveyor solution. Engaging with reliable suppliers, conducting thorough cost-benefit analyses, and evaluating maintenance and scalability options ensure that the chosen system delivers optimal performance and return on investment. By prioritizing quality, durability, and technical support during the sourcing process, organizations can enhance productivity, reduce material handling costs, and support sustainable growth within their operations.