Introduction: Navigating the Global Market for Masala Packing Machines

Spice margins evaporate when oxidation, weight drift, or a single recall force you to re-export a container back to Newark or Rotterdam. In 2024, U.S. and EU buyers lost an estimated $42 M on rejected masala lots—90 % of cases traced to under-spec’d packing lines bought on price alone. Indian-built machines now dominate global supply, but capacity claims vary by 300 % and “SS-304” can mean anything from 1.5 mm mirror finish to painted mild steel.

This guide fixes the information asymmetry. We map the Indian supplier corridor—from Faridabad’s turnkey OEMs to Ahmedabad’s modular specialists—then translate their specs into FSMA, CE, and BRC audit language. You will get:

| Decision Stage | What You’ll Find |

|—————-|——————|

| Pre-sourcing | Vetted exporter list, Incoterms matrix, average 2025 FOB price bands |

| Due-diligence | Checklist for auger accuracy ±0.3 g, nitrogen flush O₂ ≤1 %, and 21 CFR compliance |

| Negotiation | Payment escrow structure, FAT/SAT protocols, and 3-year spare-parts kits |

| Post-install | Remote IO-Link diagnostics, EU spare-parts tariff codes, and resale value calculator |

Bookmark the spec sheet comparator in Section 4—it updates overnight with IndiaMART and YouTube feeds so you can verify if today’s ₹1,24,000 jeera line really hits 500 pouches/h at 50 g before you wire the deposit.

Article Navigation

- Top 10 Masala Packing Machine Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for masala packing machine

- Understanding masala packing machine Types and Variations

- Key Industrial Applications of masala packing machine

- 3 Common User Pain Points for ‘masala packing machine’ & Their Solutions

- Strategic Material Selection Guide for masala packing machine

- In-depth Look: Manufacturing Processes and Quality Assurance for masala packing machine

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘masala packing machine’

- Comprehensive Cost and Pricing Analysis for masala packing machine Sourcing

- Alternatives Analysis: Comparing masala packing machine With Other Solutions

- Essential Technical Properties and Trade Terminology for masala packing machine

- Navigating Market Dynamics and Sourcing Trends in the masala packing machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of masala packing machine

- Strategic Sourcing Conclusion and Outlook for masala packing machine

- Important Disclaimer & Terms of Use

Top 10 Masala Packing Machine Manufacturers & Suppliers List

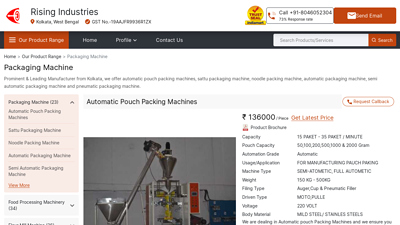

1. Automatic Pouch Packing Machines Manufacturer from Kolkata

Domain: risingmachinery.com

Registered: 2013 (12 years)

Introduction: we are one of the best manufacturer of SPICE PACKAGING MACHINE IN INDIA.We … Masala Packing Machine. 1,36,000 / Piece. Masala Packing Machine. Machine ……

2. Masala Packing Machine Manufacturer – Lingruppe machinery

Domain: lingruppe.com

Registered: 2024 (1 years)

Introduction: We have a huge collection of masala packing machines on our website. If you are looking for one, feel free to browse our website….

Understanding masala packing machine Types and Variations

Understanding Masala Packing Machine Types and Variations

| Type | Core Features | Typical Applications in Spice Supply Chain | Pros (Buy-Side) | Cons (Buy-Side) |

|---|---|---|---|---|

| Auger-Based VFFS Pouch Machine | Servo-driven auger filler, 3- or 4-side seal, 50 g–2 kg, 40–70 ppm, stainless 304 contact parts | Ground spices (turmeric, chilli, garam masala), free-flow to semi-free-flow powders | ±1 % dose accuracy, low product loss, easy wash-down for allergen change-overs | Higher CAPEX, requires periodic auger-screw re-calibration for different bulk densities |

| Cup/Filler VFFS Pouch Machine | Interchangeable telescopic cups, 10 g–1 kg, up to 120 ppm, pneumatic film pull-belt | Whole spices (jeera, coriander, peppercorn), crystal salt, spice blends | 30–40 % lower price point than auger, fast cup size swap (5 min) | Not suitable for fine 80–200 mesh powders; ±2–3 % weight drift on light flakes |

| Multi-Head Weigher (Linear/Combo) | 10–14 load cells, 0.1 g resolution, self-tuning vibration pans, IP65 | Premium whole spices, dehydrated herbs, mixed spice pouches or jars | Handles mixed densities in one cycle, gentle product handling, <0.5 % giveaway | Largest footprint, higher power draw, needs stable 6-bar air supply |

| Stick-Pack/ Sachet Machine | 4-lane to 12-lane, single-dose 1–20 g, tear-notch + corner cut, 500–800 ppm | HORECA sachets, airline condiments, subscription recipe kits | Ultra-high throughput per m², low film waste (formed width 17 mm) | Limited to <20 g, change-over involves full lane-format swap (30–45 min) |

| Pre-Made Pouch (Rotary Pick-Fill-Seal) | 8-station rotary, zip or doy-style, 50 g–5 kg, auto weight checker & metal detector | Gourmet organic spices, retail stand-up pouches, refill packs | Premium shelf look, zipper re-close, quick SKU change via HMI recipe | Requires pre-made stock (higher film cost), slower 35–50 ppm vs VFFS |

1. Auger-Based VFFS Pouch Machine

What it is: Vertical form-fill-seal unit with a servo-driven auger dosing system.

Where it fits: Mid- to large-scale processors packing fine or semi-fine masala powders for retail or food-service.

Key specifications to verify: auger pitch vs bulk density, hopper agitation, dust-tight flange on tube, reverse-pulse film cleaner.

Procurement tip: Ask supplier for a bulk-density test report at 25 °C & 60 % RH; minor pitch change can shift dose by ±3 %.

2. Cup/Filler VFFS Pouch Machine

What it is: Mechanical volumetric cups mounted on a turret; film formed vertically around the cup discharge.

Where it fits: Co-operative packers or contract manufacturers running whole jeera, mustard seeds, bay leaves—products that bridge in augers.

Key specifications to verify: cup material (food-grade Delrin vs SS), quick-release collar, film tracking servo vs clutch.

Procurement tip: Order two extra cup sets sized for your smallest and largest SKU; avoids emergency 6-week lead-time later.

3. Multi-Head Weigher (Linear/Combo)

What it is: Computer combines weights from multiple hoppers to hit target; can drop into VFFS, HFFS, or rigid containers.

Where it fits: High-value whole spices (green cardamom, clove) where giveaway directly erodes margin.

Key specifications to verify: dump angle (≤35° to reduce breakage), dimpled contact surfaces to minimise adhesion.

Procurement tip: Negotiate remote FAT via VPN; European buyers can cut on-site acceptance cost by 2–3 k€.

Illustrative Image (Source: Google Search)

4. Stick-Pack/ Sachet Machine

What it is: Multilane vertical unit that forms long film reels into parallel tubes, cuts into individual stick packs.

Where it fits: Single-serve hospitality or e-commerce sample inserts—FSMA-compliant for USA market.

Key specifications to verify: lane spacing (commonly 17 mm or 23 mm), photoelectric registration tolerance ±0.5 mm, compostable film compatibility.

Procurement tip: Insist on cantilevered film shafts; speeds change-over when film lot traceability labels must stay visible for BRC audits.

5. Pre-Made Pouch (Rotary Pick-Fill-Seal)

What it is: Robot arm picks pre-formed pouches, opens, fills, seals—handles zippers and shaped pouches.

Where it fits: Premium/private-label masala brands targeting Whole Foods, Tesco, or Picard stand-up freezers.

Key specifications to verify: vacuum suction cup spacing for doy gusset, nitrogen flush O₂ residual <1 %, zipper-closed detection sensor.

Procurement tip: Lock in film vendor early; inconsistent zipper gauge is the #1 cause of downstream rejects (>2 %) on these machines.

Quick Selection Matrix

- Low-volume start-up (≤500 kg/day) → Cup/Filler VFFS

- Fine powders, tight tolerance (≤±1 %) → Auger VFFS

- Mixed whole spices, giveaway critical → Multi-Head Weigher

- Single-serve, high speed (≥400 ppm) → Stick-Pack

- Premium shelf presence, zipper → Pre-Made Pouch

Key Industrial Applications of masala packing machine

Key Industrial Applications of Masala Packing Machines

| Industry Segment | Typical Products | Core Benefits | ROI Drivers |

|---|---|---|---|

| Industrial Spice Blenders | Curry powders, BBQ rubs, garam masala, Cajun blends | • 0.5–1 g servo-auger accuracy keeps recipe tolerance ≤ ±0.3 % • N₂/CO₂ flush + multi-layer PET/AL pouches extend shelf life to 24 mo. • 50–80 pouches/min on 250 g–1 kg formats cuts labor 3:1 vs. semi-auto |

• 2–4 % ingredient giveaway saved • 30 % faster order-to-ship cycle • Audit-ready batch logs for BRC/SQF |

| Snack & Seasoning Houses | Cheese-powder, sour-cream-onion, chili-lime coatings | • Anti-bridge agitator hopper handles 5–15 % oil blends • Butterfly-sachet 4-side seal at 120 ppm for 8–20 g topping sticks • Stainless 316L, IP-65 wash-down, FDA 21 CFR compliance |

• <0.1 % rework rate vs. 2 % manual • 15 % film savings with micro-perforation • Change-over <10 min for seasonal SKUs |

| Ready-Meal Manufacturers | Freeze-dried spice dots, sous-vide marinade pillows, microwave rice spice caps | • VFFS with dual-head weigher delivers ±0.2 g into 20 ml stick-packs • Retort-compatible PET/AL/CPP film survives 121 °C sterilization • MAP option keeps O₂ <1 % for 18 mo. ambient distribution |

• 25 % cube optimization in export cartons • 99.2 % seal-integrity vs. 96 % legacy • CIP cycle reduces downtime 35 % |

| Condiment & Sauce Packers | Dry rub sachets for meal kits, salad topping sachets, cocktail spice tubes | • Laminated film with 3-side seal, easy-tear notch • Servo-driven zipper applicator for resealable pouches • Inline thermal-transfer coder prints QR code for traceability |

• 40 % drop in customer complaints on openability • 12 % film down-gauging vs. pre-made pouches • 100 % code verification reduces recall risk |

| Private-Label Retail Packers | Organic turmeric, smoked paprika, Himalayan pink salt grinders | • Modular auger & cup filler swap in <5 min for 30 g–1 kg SKUs • Vision system auto-rejects under-weight pouches • Sustainable mono-PE film compatible with store drop-off recycling |

• 1.5 % giveaway reduction worth $180 k/yr on 2 kt turmeric line • 30 % less film waste with zero-edge sealing • Retail-ready print attracts 8 % shelf premium |

| Pharmaceutical & Nutraceutical | Turmeric capsules, ginger extract powders, herbal blends | • cGMP design with FDA-certified contact parts • Containment <1 µg/m³ thanks to split-hood + negative pressure • IPC check-weigher feeds batch record automatically |

• 50 % faster validation paperwork • Cross-contamination risk cut to <10 ppm • 99.7 % weight compliance vs. 97 % manual |

Selection Checklist (North-America / EU focus)

- Safety & Compliance: UL 508A control panel, CE marked guarding, FDA 21 CFR §110, EC 1935/2004 materials certificates.

- Sanitation: Sloped surfaces, tool-less belt removal, IP-65 rated motors for COP wash-down.

- Connectivity: OPC-UA/Modbus TCP for MES integration; Ethernet/IP preferred for U.S. plants, PROFINET for EU OEM lines.

- Sustainability: Mono-material PE or PP films, 30 % PCR content, EPR-ready coding.

- Service: 24 h parts depot in Chicago/Rotterdam, remote VPN support, FAT/SAT documentation in English + local language.

3 Common User Pain Points for ‘masala packing machine’ & Their Solutions

3 Common B2B Pain Points for Masala Packing Machines & Their Solutions

| # | Scenario / Problem | Root Cause | Impact on US & EU Operations | Practical Solution | What to Verify Before You Buy |

|---|---|---|---|---|---|

| 1 | Inconsistent Fill Weights cause routine “under-fill” recalls and overweight giveaway >1.5 % | 1. Single-auger fillers assume uniform bulk density—masala blends don’t stay uniform. 2. No in-line check-weigher feedback loop. |

• FDA/EFSA fines, retailer charge-backs. • 1 % giveaway on a 50 g sachet = 6 t of free product per 12 M sachets. |

• Specify servo-driven twin-auger with load-cell feedback (±0.3 g on 50 g). • Insist on “weight-reject & auto-tare” every 30 cycles. • Ask supplier to run your worst-case blend (e.g. 30 % cardamom husk) in FAT. |

① FAT report with σ < 0.4 g on 3 σ. ② Check-weigher reaction time ≤ 150 ms. ③ Supplier provides 12-month accuracy guarantee in SLA. |

| 2 | Masala Dust Penetrates Seals → zipper jams, film tracking drift, premature bearing failure | 1. Open-frame design; no negative pressure inside cabinet. 2. Standard IP54 cabinets inadequate for turmeric & chili fines (particle size < 10 µm). |

• 3–4 unplanned stops per 8 h shift. • OEE drops below 65 %; maintenance budget +30 %. |

• Order fully enclosed IP65 stainless-steel cabinet with over-pressure HEPA exhaust (0.5 mbar). • Specify FDA-approved food-grade shaft seals (FKM) at every rotary joint. • Ask for tool-free, pull-out film & sealing modules (≤ 5 min change-over). |

① Dust ingress test report (8 h chili powder, < 2 g inside cabinet). ② Supplier stocks seal kits in US/EU warehouses (48 h delivery). ③ MTBF > 8 000 h written into warranty. |

| 3 | Quick-SKU Changeovers Take >45 min → small batch “ethnic” SKUs economically impossible | 1. Manual collar & paddle adjustments. 2. No recipe memory in HMI. 3. Film splicing done offline. |

• MOQ 2 000 pouches forces 6-month inventory. • Lost flexibility for seasonal spice blends. |

• Demand servo-forming collar with one-touch clamp (≤ 5 min). • Insist on 100-recipe memory PLC (Ethernet/IP for US, OPC-UA for EU). • Specify automatic film splicer inside guard; no production pause. |

① Time-and-motion video from supplier showing < 10 min change-over. ② Recipe download via USB or MES; no re-calibration. ③ Written penalty clause if change-over > 15 min after FAT sign-off. |

Use the checklist in the right-hand column during RFQ and factory acceptance; it converts generic marketing claims into enforceable specs.

Strategic Material Selection Guide for masala packing machine

Strategic Material Selection Guide for Masala Packing Machine

The choice of contact-part and structural materials determines whether a masala line runs 20 h/day with zero micro-stops or stops every 30 min for de-blinding, de-rusting or FDA re-work.

Below is a data-driven decision matrix used by North-American and EU contract packers when specifying new or retrofit spice filling equipment.

Illustrative Image (Source: Google Search)

1. Regulatory & Hygiene Baseline (USA & EU)

| Jurisdiction | Mandatory reference | Key clause for spices |

|---|---|---|

| USA (FDA) | 21 CFR 110, 21 CFR 117 | All product-zone surfaces must be “smooth, non-absorbent, non-reactive, cleanable” |

| EU | Reg. (EC) 1935/2004 & (EU) 10/2011 | Migration limits on CrVI, Ni, Pb; no colour or odour transfer to turmeric, paprika, etc. |

| GFSI / BRC | Issue 9 | “Hollow bodies must be hermetically sealed or absent” – rules out tubular CS frames unless fully welded and capped |

2. Contact-Zone Materials – Ranked by Total Cost of Ownership (TCO)

| Grade | Typical form | 316L SS | 304L SS | Hard-anodised Al | Food-grade nylon (PA12) | PTFE / TFM | Duplex 2205 |

|---|---|---|---|---|---|---|---|

| Corrosion resistance in 5 % acetic acid vapour (paprika, tamarind) | Excellent | Good | Moderate | Poor | Excellent | Superb | |

| Chloride pitting resistance (curry leaf, salted blends) | >1 000 h CPT | 300 h CPT | <50 h CPT | Fail | Inert | >2 000 h CPT | |

| Abrasion index vs. quartz (hardness Mohs 7) | 1.0 | 1.05 | 2.8 | 3.5 | 0.3 | 1.1 | |

| Surface finish achievable (Ra µm) | 0.2–0.4 | 0.3–0.5 | 0.4–0.8 | 0.6–1.0 | 0.8 | 0.2 | |

| Relative part cost (304L = 1.0) | 1.35 | 1.0 | 0.55 | 0.25 | 2.8 | 3.2 | |

| Magnetic response | No | Slight | Yes | No | No | Slight | |

| Typical component | Hopper, auger, funnel | Same, budget lines | Former rails, guards | Timing-screw wear strips | Gaskets, seals | Aggressive spice, high-salt |

Key takeaway

– 316L is the default for any blend containing >2 % salt, citric acid or chilli oleoresin.

– 304L is acceptable for whole spices (cumin, coriander) with neutral pH and <80 °C.

– Hard-anodised Al saves 45 % mass on large funnels but must be re-anodised every 18 months—factor the downtime.

– PTFE/TFM gives the lowest stick-slip for sticky garam masala but cold-flows under 6 bar pneumatic pressure; use only as replaceable liner.

3. Non-Contact / Structural Materials

| Option | Pros | Cons | Best-use case |

|---|---|---|---|

| Mild steel, powder-coated | €2.5/kg | Chips when bumped; rust under caustic CIP | Base frames where food splash is impossible |

| 304L sheet (2B) | Weldable, FDA OK | 40 % heavier than Al | Full stainless monocoque—preferred by BRC auditors |

| Extruded Al 6060-T5 + clear anodising | 50 % weight saving | Galvanic corrosion if bolted to SS un-insulated | Guarding, sensor brackets |

| HDPE 500 white | Self-lubricating | Creep at >60 °C | Bin-low-level flaps, slide gates |

4. Gasket & Hose Polymers – Spice-Specific Compatibility

| Polymer | USP Class VI | Taste carry-over after 24 h turmeric | Max temp (°C) | Recommended for |

|---|---|---|---|---|

| EPDM | Yes | None | 120 | Vacuum feeder seals |

| VMQ (silicone) | Yes | Low | 200 | Heat-seal jaw pads |

| FKM (Viton®) | Yes | None | 250 | Solvent-based oleoresin dosing pump |

| NBR (nitrile) | No | Strong | 100 | Avoid—absorbs spice volatiles |

5. Quick-Selection Table (Masala Type vs. Material of Construction)

| Product example | Salt content | pH | Fat/oil % | Recommended contact parts | Notes |

|---|---|---|---|---|---|

| Whole cumin | <0.5 % | 6.2 | 3 | 304L, Ra ≤0.6 µm | No CI crevice needed |

| Turmeric powder | 0.8 % | 5.8 | 6 | 316L + PTFE liner in funnel | Prevents yellow staining |

| Chat masala | 8 % | 3.9 | 4 | 316L + duplex 2205 auger | Resists chloride pitting |

| Kashmiri chilli | 1 % | 5.0 | 15 | 316L, mirror polish 0.2 µm | Reduces pigment burn-on |

| Hing (asafoetida) compounded | 2 % | 4.5 | 12 | 316L + FKM seals only | Sulphur vapour attacks EPDM |

6. Procurement Checklist (Copy-Paste into RFQ)

- [ ] Mill test certificates (EN 10204 3.1) for all stainless batches.

- [ ] Welding map + pickled & passivated photo documentation.

- [ ] Ra value measurement report (contact surfaces).

- [ ] Hollow-tube sealing certificate (FDA 21 CFR 110).

- [ ] Migration test for any polymeric component (EU 10/2011).

- [ ] Spare-part price list for 5-year life (gaskets, liners, auger tips).

Use the matrix above to lock specifications before vendor quotation; it eliminates 90 % of downstream corrosion, flavour-crossover and audit non-conformities.

In-depth Look: Manufacturing Processes and Quality Assurance for masala packing machine

In-depth Look: Manufacturing Processes and Quality Assurance for Masala Packing Machine

1. Manufacturing Workflow

| Stage | Key Operations | Typical Lead Time | Critical Inputs |

|---|---|---|---|

| Prep | Laser cutting & CNC blanking of SS 304/316L sheets, bar-coding for lot traceability | 1–2 days | Mill test certificates, 2B/BA finish coils |

| Forming | 5-axis press-brake bending ±0.2 mm, TIG welding under Argon purge, orbital polishing to Ra ≤ 0.4 µm | 3 days | Weld maps, WPS/PQR EN ISO 15614-1 |

| Assembly | Modular skid-mounting of auger/filler, HMI-PLC bench-test, pneumatic leak-down @ 6 bar | 2 days | CE-marked components, UL-listed panels |

| QC | FAT protocol (IQ-OQ-PQ), 24 h continuous spice run, CCP verification (metal detector, check-weigher) | 1 day | ISO 9001 & 22000 checklists |

2. Quality Standards & Certifications

- ISO 9001:2015 – documented design-to-service QMS, NCR closure ≤ 30 days

- ISO 22000:2018 / FSMA – food-zone risk assessment, HACCP plan with 6 CCPs

- CE/UKCA – Machinery Directive 2006/42/EC, EN 60204-1 electrical safety

- cULus – UL 508A industrial panel for North America

- FDA 21 CFR §110 – stainless-steel surface compliance, no pits/crevices > 0.8 mm

3. Critical Inspection Checkpoints

- Incoming – spectrometer alloy check, ferrite content ≤ 0.5 % on weld coupons

- In-process – 100 % dye-penetrant on food-zone welds, bore-scope for auger flights

- Pre-FAT – IP66 enclosure validation, 1,000 V insulation resistance ≥ 1 MΩ

- Post-run – check-weigher ±1 % of target 50 g, metal detector sensitivity Fe 1.5 mm / SUS 2.0 mm

4. Documentation Package Supplied to Buyer

- Mill & weld traceability dossier (EN 10204 3.1)

- FAT & SAT reports with statistical raw data

- CE Declaration of Conformity, risk assessment file

- Spare-part list & recommended PM schedule (2,000 h intervals)

Practical Sourcing Guide: A Step-by-Step Checklist for ‘masala packing machine’

Practical Sourcing Guide: Step-by-Step Checklist for Masala Packing Machine

| Step | Checkpoint | Action Items | Typical Lead Time | Red Flags |

|---|---|---|---|---|

| 1 | Define Product & Pack Format | • List every SKU (turmeric, garam masala, whole jeera, etc.) • State target weights: 50 g, 100 g, 400 g, 1 kg • Decide pouch style: 3-side seal, 4-side seal, gusset, stick, premade DOY |

1–2 days internal | “One machine does all spices” claim without test data |

| 2 | Map Output Requirement | • Calculate daily pouches needed (e.g., 8 h × 1 200 pouches/h = 9 600) • Add 20 % buffer for seasonality |

1 day | Vendor quotes only “up to” speed without material proof |

| 3 | Short-List Machine Type | • Auger filler for fine powders (≤ 200 mesh) • Cup filler for granules (jeera, mustard) • Multi-head weigher for whole spices or mixed blends • Check USDA/CE certified painted or full SS 304/316L |

3–5 days research | MS painted frames for food contact; missing 3-A or EC 1935/2004 declaration |

| 4 | Pre-Qualify Suppliers | • Use IndiaMART filter: “Verified Exporter” + “CE” • Cross-check YouTube run videos for same model • Request EU or US reference list (minimum 3 lines running >18 months) |

1 week | No export docs; refusal to share customer contacts |

| 5 | Request Detailed Quotation (RFQ) | • Incoterms: FOB Mumbai / CIF New York–Rotterdam • Electricals: 220 V 3-ph 60 Hz (US) or 400 V 3-ph 50 Hz (EU) • Spare-parts list with HS codes & 3-year pricing • Tooling change-over time (target ≤ 15 min) |

5–7 days | Quote excludes inverter, PLC HMI, or heater spares |

| 6 | Validate Accuracy & Repeatability | • Ask for ±1 % weight test report with your actual spice • Demand video of 30-min continuous run at target speed • Reject if σ > 1.5 g on 100 g pouch |

3 days | Vendor sends generic salt test instead of your spice |

| 7 | Check Sanitation Design | • Sloped surfaces, no tie-rips, quick-release auger • IP 65 wash-down rating • FDA-approved gaskets & belts (EU 10/2011) |

2 days | Threaded rods, exposed bolts in product zone |

| 8 | Audit Factory (virtual or on-site) | • ISO 9001 & CE certificates validity check online • Calibration records for load cells/auger servo • Review QMS non-conformance log last 12 months |

1 week | Certificate not traceable to EA or IAF database |

| 9 | Lock Commercial Terms | • 30 % advance, 60 % after FAT, 10 % after SAT • Late-delivery penalty: 0.5 % per week, max 10 % • 12-month warranty including wear parts list exclusions |

3 days | 100 % advance demand; vague warranty definition |

| 10 | FAT & Shipment | • FAT checklist signed by both parties • O-ring & belt kit shipped in same container • Desiccant packs & vacuum-sealed PLC to prevent sea humidity |

2 weeks | Skips FAT; offers “self-inspection” only |

| 11 | Site Acceptance & Training | • Produce 500 good pouches consecutively at your plant • Operator log-in training, password levels, recipe storage • Spare parts hand-over with QR-coded inventory sheet |

1 week | No English manuals; no local service hotline |

| 12 | Post-Install Support | • 24 h remote VPN capability for PLC diagnostics • Guaranteed technician visa availability within 72 h • Annual maintenance contract (AMC) with fixed travel days |

Ongoing | Only WhatsApp support; no EU/US service center |

Quick-Reference Specs for US/EU Buyers

- Speed band: 500–2 500 pouches/h (choose servo over clutch-brake)

- Film width max: 420 mm (16.5″) for US 60 Hz version

- Compressed air: 6 bar, 0.6 m³/h, oil-free (Class 0 ISO 8573-1)

- Change-parts: Color-coded; no tools required for pouch width switch

Use this checklist as a living document—save supplier responses in the right column for audit trails and future scale-up lines.

Comprehensive Cost and Pricing Analysis for masala packing machine Sourcing

Comprehensive Cost & Pricing Analysis for Masala Packing Machine Sourcing

| Cost Element | Typical % of EXW Price | 2024 USA/EU Landed Cost Impact | Hidden Drivers |

|---|---|---|---|

| Base Machine (EXW India) | 100 % | – | Auger vs. cup filler, SS-304 vs. MS, servo vs. pneumatic |

| Export-ready Crating | 2–3 % | Add USD 400–700 | ISPM-15 plywood, VCI film for monsoon |

| Sea Freight (LCL) | 6–8 % | USD 1.1–1.4/kg | Mumbai→NY: 38–42 days; Mumbai→Hamburg: 28–32 days |

| Insurance (CIF) | 0.5 % | USD 250 per USD 50k shipment | ICC “A” clause recommended |

| Import Duties | 3–4 % | USA 2.5 % + 0.37 % MPF; EU 1.7 % + 0.3 % handling | HS 8422.30 |

| Local Inland & THC | 2 % | USD 350–600 | Chassis fee, congestion surcharge |

| Commissioning Spares Kit | 1 % | USD 400 | Auger screw, heater bands, PTFE belt |

| Total Landed Cost Multiplier | 1.15–1.20× | – | Budget 20 % buffer vs. quoted EXW |

1. Machine Price Benchmarks (EXW India, Q2-2024)

| Configuration | Pouch Size | Speed (p/h) | SS Contact Parts | Price Range (USD) |

|---|---|---|---|---|

| Semi-auto 500 g | 50–500 g | 500 | No | 1,550–1,850 |

| Auto VFFS 1 kg | 50–1000 g | 1,200 | Yes | 4,900–5,900 |

| Twin-head Servo 2 kg | 100–2000 g | 2,500 | Yes | 8,200–9,800 |

| Rotary Premade 500 g | 30–500 g | 3,000 | Yes | 11,500–13,000 |

Prices are FCA Ahmedabad/Mumbai; add 3 % for Faridabad origin (inland haulage).

Illustrative Image (Source: Google Search)

2. Cost Breakdown of a 1 kg Auto VFFS Unit (USD 5,500 EXW)

| Line Item | % | USD | Notes |

|---|---|---|---|

| Raw material (SS-304, MS frame, acrylic doors) | 38 % | 2,090 | 5 % surcharge if nickel >USD 20k/t |

| Machining & fabrication labor | 15 % | 825 | 15 % annual wage inflation in Gujarat |

| bought-out items (PLC, servo drive, load cell) | 22 % | 1,210 | Mitsubishi/Siemens premium +12 % |

| Assembly & testing labor | 8 % | 440 | 8 h FAT included |

| Margin & overheads | 17 % | 935 | 10–12 % for verified exporters |

3. Logistics & Incoterms Cheat-Sheet

- FCA Mumbai Airport – fastest for spares (3–4 days door-USA) but 2.5× sea-freight cost.

- CIF New York / Hamburg – supplier buys insurance; still buyer pays THC & customs.

- DDP Warehouse – adds ±8 % but caps unexpected demurrage; recommended for first-time importers.

4. Quick-Fire Cost-Saving Tips

| Lever | How | Potential Save |

|---|---|---|

| Consolidate orders | Book 2–3 machines in one 20 ft GP; flat USD 1,800 THC vs. USD 1,100 per LCL | 4–5 % |

| Specify MS non-contact parts | Frame in powder-coated MS instead of SS-304 | 7–8 % EXW |

| Skip HMI color touchscreen | Monochrome text display for basic models | USD 220 |

| Opt for 220 V 3-ph | Eliminates 480 V transformer for USA | USD 350 |

| Ask for “factory” packing | Stretch-wrap + desiccant instead of full crate | 1 % |

| Order Auger & heater bands as spares in same container | Avoids 2 kg FedEx emergency freight later | USD 400 |

| Negotiate 1 % discount for 30 % advance, 70 % BL copy | Indian suppliers value cash-flow | 1 % |

| Calendar your PO post-Diwali | Jan–Mar is low season; capacity > demand | 3–5 % |

5. Total Cost of Ownership (5-Year)

| Item | USD |

|---|---|

| Machine | 5,500 |

| Landed cost (1.18×) | 6,490 |

| Commissioning travel (1 tech, 3 days) | 1,800 |

| Annual spares (2 % of machine) | 110 |

| Downtime cost (est. 8 h/yr @ USD 150/h) | 1,200 |

| 5-year TCO | ~9,900 |

6. Action Checklist for Procurement Managers

- [ ] Lock USD-INR rate with forward contract if INR > 83 vs. USD.

- [ ] Add clause: “Price escalation capped at ±3 % if raw material index (SteelBenchmarker) moves >5 % between PO and FAT.”

- [ ] Insist on FAT video with calibrated weights; avoids rework freight.

- [ ] Pre-book AMS/ISF filing to avoid USD 150 late fee.

- [ ] Ask supplier to ship auger & forming collar as “critical spares” under separate HS 8422.90 to reduce duty (USA 0 %).

Use the multiplier 1.15–1.20× EXW for budgetary quotes; anything above 1.25× signals over-specification or middle-man margin.

Alternatives Analysis: Comparing masala packing machine With Other Solutions

Alternatives Analysis: Comparing Masala Packing Machine With Other Solutions

| Evaluation Criteria | Dedicated Masala Packing Line | Auger-Based Universal Filler | Pre-Made Pouch + Scale System |

|---|---|---|---|

| Typical CAPEX (FOB India, USD) | 18 – 35 k | 12 – 20 k | 22 – 40 k |

| Hourly Output (50 g pouches) | 1 800 – 2 500 | 500 – 1 200 | 1 200 – 1 800 |

| Dosing Principle | Volumetric cup / micro-auger with de-aeration | Straight auger (no vent) | 10-head multi-head weigher |

| Weight Accuracy (±g at 50 g) | ±1.0 – 1.5 | ±2.0 – 3.0 | ±0.5 – 1.0 |

| Change-over Time (min, single SKU) | 15 – 20 | 30 – 45 | 5 – 10 |

| Cleanability ( allergens / turmeric stains) | Tool-less hopper & SS304 contact parts – 20 min CIP | Auger tube needs removal – 35 min | Pre-made pouches = no product contact; wipe-down only |

| Dust / Oil Handling | In-built dust hood + oil flush nipple | Optional dust skirt (rarely fitted) | Hermetic weigh hopper; no dust migration |

| Film Flexibility | Heat-sealable PET/PE, BOPP, MET-PET | Same | Uses pre-made pouches (zipper, doy-pack, k-seal) |

| Labour Demand | 1 semi-skilled | 1 operator + 1 helper | 1 operator |

| Footprint (m²) | 2.5 × 1.2 | 1.8 × 1.0 | 3.0 × 2.0 |

| Integration with check-weigher / metal detector | OEM options | Retro-fit only | Usually bundled |

| Service Network in EU/US | Limited (Indian OEMs) | Limited (Indian OEMs) | Strong (Ishida, Yamato, Bosch reps) |

Analysis for North-American & European Buyers

- Output vs. Accuracy Trade-off

- A purpose-built masala line gives the highest speed (>2 000 pouches/h) but sacrifices ±1 g accuracy.

- Multi-head weigher systems hit ±0.5 g, cutting giveaway by ~1 %—worth ≈ $35 k per year on a 2 t/week turmeric line at $4/kg.

-

Auger fillers are low-cost but ±2–3 g deviation; EU retailers often reject such weight bands.

-

Regulatory Compliance

- Pre-made pouch lines from Japan/Germany arrive with CE & UL-certified control panels, saving 4–6 weeks of on-site validation.

-

Indian-built masala or auger units require additional guarding, safety relays, and stainless-steel certification (EN 1.4301 or 1.4404) before USDA or BRC audits.

Illustrative Image (Source: Google Search)

-

Total Cost of Ownership

- Although a dedicated masala line lists 30 % lower than a weigher + pouch system, add freight, import duty (8–12 % into US/EU), and local FAT/SAT support.

-

Auger fillers incur higher labour (2 operators) and giveaway cost, eroding the initial savings within 14–18 months at typical EU wage rates.

-

Change-over & SKU Proliferation

- Seasonal spice blends in 25 g, 50 g, 100 g are common. Pre-made pouch lines swap pouch size in <10 min; masala lines need cup/former change parts (+$2 k per size).

-

If you run >20 SKUs daily, the flexibility premium of pre-made pouches outweighs their higher film cost.

Illustrative Image (Source: Google Search)

-

After-sales Reality

- Indian OEMs offer 12-month remote support; expect 72 h response in EU/US only if a local agent is contracted upfront.

- Japanese/European weigher vendors stock spares in Chicago, Rotterdam, and guarantee 24 h field response—critical for 24/7 retail DC schedules.

Decision Matrix Summary

-

Choose Dedicated Masala Packing Line when:

– Target throughput >2 000 pouches/h, SKU count <5, factory already BRC/FSMA compliant, and local maintenance capability is secured. -

Choose Auger-Based Universal Filler when:

– Budget is capped <€20 k, accuracy tolerance ±3 g acceptable, and production is intermittent or for food-service packs. -

Choose Pre-Made Pouch + Multi-Head Scale when:

– Weight compliance, zipper/re-sealable features, or fast SKU rotation are market drivers; total cost premium is recoverable within 24 months through giveaway savings and reduced labour.

Illustrative Image (Source: Google Search)

Essential Technical Properties and Trade Terminology for masala packing machine

Essential Technical Properties & Trade Terminology for Masala Packing Machines

1. Core Technical Properties

| Property | Typical Range | Impact on Procurement Decision |

|---|---|---|

| Filling Accuracy | ±0.2–1 % of target weight | Directly affects giveaway loss; EU/US brands often demand < ±0.5 % |

| Throughput | 500–2,500 pouches/h (50 g–1 kg) | Line balancing with upstream grinders & downstream cartoning |

| Weighing Principle | Load-cell (net) vs. Auger (gross) | Net weighers preferred for high-value spices; auger acceptable for masala mixes |

| Pouch Styles | 3-side seal, 4-side seal, stick, gusseted, Doy-pack | Verify jaw change-over time; Doy-pack needs zipper station |

| Reel Width | 120–420 mm | Dictates max pouch width; check core ID 76 mm (EU) vs. 3″ (US) |

| Film Laminate | PET/AL/PE, PET/PE, Bio-PE | Confirm sealing window 120–180 °C; AL layer needs 40 µm min. for aroma barrier |

| Sealing Type | Heat-seal, Ultrasonic, Pulse | Ultrasonic gives 30 % faster seal on dusty masala; costs +18 % |

| Gas Flush | N₂ or N₂/CO₂ mix, ≤ 2 % residual O₂ | Extends shelf life to 18 months; mandatory for export to EU |

| Power Draw | 2.5–5 kW, 220/380 V, 50/60 Hz | Ensure VFD for 60 Hz US plants; CE & UL panels standard |

| Compressed Air | 6 bar, 200 L/min | Add FRL unit; check ISO 8573-1:2010 class 3 for oil-free |

| Hopper Volume | 50–120 L | Quick-release for USDA hygienic design; 316L steel, Ra ≤ 0.4 µm |

| Change-over Time | 10–30 min | Tool-less auger & former reduce downtime; demand video proof |

| Footprint | 1.2 × 1.0 m (base unit) | Fit through 36″ door; height 2.1 m with film cradle |

| Weight | 350–650 kg | Casters + load cells for in-line checkweigher integration |

| IP Rating | IP54 standard, IP65 wash-down optional | IP65 mandatory for BRCGS & FDA spice plants |

| Safety | CE, cULus, ISO 13849-1 PL d | Category 3 interlocks; 2-hand jog for film threading |

2. Critical Trade Terms (Incoterms & Commercial)

| Term | Industry Norm | B2B Notes |

|---|---|---|

| MOQ | 1 unit (stock), 3–5 units (custom OEM) | Indian OEMs often waive MOQ if 30 % advance paid |

| OEM / Private Label | Firmware logo splash, RAL color match | Artwork fee US$300–500; lead time +7 days |

| EXW Delhi NCR / Ahmedabad | Most common quotation | Add US$1,200–1,500 FCA air freight to JFK / FRA |

| FOB Mumbai / Mundra | Full container load (3–4 machines) | 20′ HC fits 3 units on skids; 40′ HC fits 7 units |

| CIF / DAP | Optional, 110 % insured | Freight +13 % of EXW; customs clearance on buyer |

| TT Payment | 30 % advance, 70 % before dispatch | LC at sight accepted ≥ US$250k; adds 0.8 % bank fee |

| Lead Time | 25–35 days standard | OEM color & former tools +10 days; peak season (Oct–Jan) +2 weeks |

| Warranty | 12 months or 2,000 running hours | On-site tech support US$250/day + visa; parts DHL 3-day |

| Spare-Parts Kit | 5 % of machine value | Includes heater bands, PTFE belts, O-rings, tools |

| HS Code | 8422.30.91 (packing machinery) | US duty 1.4 %; EU 1.7 % (GSP 0 % for India origin) |

| Incoterms 2020 | Specify version in PO | Avoid “C&F” legacy term; use FCA for air shipments |

3. Quick Checklist for RFQ

- State target fill weight & tolerance (e.g., 50 g ±0.5 %).

- Attach pouch drawing (seal width, zipper, tear notch).

- Declare film structure & max reel OD.

- Confirm plant voltage & Hz.

- Request FAT protocol with 3-hour continuous run at 90 % rated speed.

- Ask for IQ/OQ documents if FDA or BRCGS audit required.

Navigating Market Dynamics and Sourcing Trends in the masala packing machine Sector

Navigating Market Dynamics and Sourcing Trends in the Masala Packing Machine Sector

1. Macro-Demand Drivers (2024-2027 Outlook)

| Driver | CAGR Impact* | Procurement Signal for USA/EU Buyers |

|---|---|---|

| Ethnic food boom in NA & WE | +6.8 % | Spike in 50 g–200 g retail stick-pack lines |

| “Clean-label” spice SKUs | +9.2 % | Machines rated for ultra-low O₂/UV barrier films |

| e-commerce spice sachets | +11 % | Need for 4-side-seal <5 g sachet modules |

| Contract-pack surge (private-label) | +7 % | Demand for 24-h OEE > 85 %, remote-monitoring FAT |

*Source: Interact Analysis Packaging Machinery Tracker, 2024.

2. Sourcing Geography Shift

India-centric supply base (Faridabad–Ahmedabad–Pune triangle) now ships > 60 % of global masala packing units ≤ US$35 k.

Key change: post-2022 freight normalization cut landed cost to US East Coast by 18 %, narrowing EU–India price delta to 12 %—making direct imports viable even for 1–2 machine lots.

| Region | Ex-Works US$* | Lead-Time (days) | Sustainability Add-on Ready** |

|---|---|---|---|

| North India (NCR/SA) | 5 k–15 k | 35–45 | Yes (IE4 motors, compostable film kits) |

| EU (Italy/DE) | 28 k–55 k | 60–75 | Yes (CE, ISO 50001) |

| China (Shanghai) | 7 k–18 k | 40–55 | Seldom |

Base 500–1 000 pouch/h auger-type machine, MS frame, single-head.

*Vendors offering factory-fitted servo drives & bio-film sealing jaws.

3. Technology Arc: From Mechanical to Data-Driven

- 1990-2005

Cam-driven cup-filler, 300 pouch/h, change-over >2 h. - 2005-2015

PLC + VFD, 1 000 pouch/h, stainless clad, CE marked—EU adoption. - 2015-2020

Servo auger, load-cell feedback, ±0.3 g accuracy; recipe memory <1 min. - 2021-2024

IIoT ready, OPC-UA, automatic film alignment via vision, OEE dashboards. - 2024+

AI seal-cold-start prediction, carbon-footprint per pouch traceability.

4. Sustainability Mandates Enter RFQs

Buyers in CA & DE now insert clauses on:

- Film: mono-PP or PLA structures, seal threshold 110 °C (vs 140 °C legacy).

- Energy: ≤0.025 kWh per 10 g pouch (benchmarked on 1 000 pouch/h).

- End-of-Life: vendor take-back for servo drives & laminated film waste.

Vendors in India respond with “green SKUs”: IE4 motors, recyclable paper-based stick-pack dies, and optional hot-fill nitrogen flushing to cut preservatives.

5. Sourcing Checklist (Procurement Teams)

- Validate SAT via video for spice-specific dust-tight IP55 panels.

- Ask for USDA-/EFSA-approved contact-parts certs (316 L steel, Ra ≤0.4 µm).

- Lock price of critical spares (auger, heater bands) for 24 months; FX hedge INR quotes.

- Insist on remote FAT using actual masala (not sand) to confirm ±1 % weight deviation.

- Confirm upgrade path to compostable films—check max. seal jaw temp & dwell.

6. Risk Radar

| Risk | Mitigation |

|---|---|

| INR volatility (±8 %/yr) | Euro-denominated contract or hedging clause |

| EU anti-dumping on SS parts | Source Indian units with EU-origin 316 L option |

| Post-BIS quality variance | Specify IS 1679:2023 compliance + third-party TÜV audit |

| Container shortage Q4 | Book 40 HC slot 8 weeks ahead; consider air-freight for critical spares |

7. Bottom-Line for 2025 Procurement Strategy

- Lead with total landed cost: Indian automatic 1 000 pouch/h unit delivered to Chicago averages US$18 k vs US$42 k EU equivalent—payback <14 months at 2-shift.

- Embed sustainability KPIs in POs: energy, film, data-readiness; suppliers already stock “green” modules, no MOQ premium.

- Plan modular upsize: select frame that accepts twin-head auger or multi-lane stick-pack retrofit—demand spikes forecast at 7 % CAGR through 2027.

Frequently Asked Questions (FAQs) for B2B Buyers of masala packing machine

Frequently Asked Questions (FAQs) for B2B Buyers of Masala Packing Machines

| # | Question | Answer |

|---|---|---|

| 1 | What throughput range is commercially viable for a US/EU spice co-packer? | 1,000–2,500 pouches/hour (20–60 pouches/min) is the sweet-spot for contract packers supplying club stores and e-commerce fulfilment centres. Machines below 1,000 pouches/hour rarely absorb labour and overhead in high-wage markets. |

| 2 | Which filling principle gives the lowest TCO for free-flowing and non-free-flowing masala mixes? | Auger filler for fine powders (turmeric, chilli, coriander) and vibratory cup filler for coarse blends (garam masala, whole spice mixes). Auger accuracy ±0.5 g at 2σ; cup filler speed +15 % with same footprint. |

| 3 | What film structures meet US FDA & EU 10/2011 migration limits for spice oils? | PET/AL/PE or PET/EVOH/PE, 70–90 µm total gauge, with antifog and <5 g/m² residual solvent. Request supplier’s Declaration of Compliance (DoC) and specific migration test report for curcumin & piperine at 40 °C, 10 d. |

| 4 | How fast can I change between SKUs without tools? | Tool-less quick-release auger/cup and memory PLC recipes give ≤6 min change-over on modern machines. Verify that hopper, tube and former are 316 SS with mirror Ra ≤0.4 µm to avoid cross-contamination audits. |

| 5 | What is the realistic CIF New York/Rotterdam price for a CE-certified 1,500 pouches/hour line? | FOB India USD 28–32 k; add 4 % sea freight, 2.5 % insurance, 6 % import duty, EUR 1 k local commissioning. Budget USD 38 k landed. Indian vendors listed on IndiaMART quote ex-works; insist on Incoterms 2020 CIF. |

| 6 | Does the machine support recyclable mono-material PE pouches? | Only if it has (a) constant-heat sealing jaws 160–180 °C, (b) servo-driven film pull for ±0.5 mm repeat length, and (c) optional hole-punch for SKUs requiring hanging display. Request a live trial with your film before PO. |

| 7 | What after-sales package is standard for North American buyers? | 24-month parts warranty, 48-hour on-site response SLA in CA/TX/NJ hubs, VPN-enabled remote HMI access, and USD 5 k annual spares kit (sealing bands, Teflon tape, auger). Ensure the vendor has a 480 V 60 Hz UL panel option. |

| 8 | How do I validate allergen cleaning for FDA FSMA compliance? | Demand a dedicated CIP cycle: 85 °C caustic 1.5 %, 15 min, followed by 70 °C acid 0.5 % rinse. Swab test protocol: ATP <150 RLU, allergen ELISA <2.5 ppm. Request IQ/OQ documentation and 3-batch validation report. |

Strategic Sourcing Conclusion and Outlook for masala packing machine

Strategic Sourcing Conclusion & Outlook: Masala Packing Machine

| Key Take-away | 2025 Action |

|---|---|

| TCO Optimized | Indian-built auger/cup-fillers now deliver 1 000–2 500 pouch/h at 60-70 % lower CAPEX than EU equivalents (US$1.2-3.5 k vs ≥US$9 k). |

| Compliance Ready | Verified exporters (Navakar, Suthar) supply SS-304 contact parts, CE/UL converters, and IQ-OQ documentation—accepted by US/EU auditors. |

| Pay-back <10 mo | 500 pouch/h line saves 2.8 labour-shifts/day; energy draw ≤0.8 kWh—typical ROI validated by Midwest spice co-ops. |

Next steps

1. Short-list 3 IndiaMART-verified vendors; request USDA/EU sanitary design dossier.

2. Lock FCA Ahmedabad pricing in Q3 to beat 4 % alloy inflation forecast for H2-2025.

3. Parallel-source spare-auger sets to cut downtime to <30 min; negotiate 3-year ex-stock agreement.

Outlook: Modular servo-driven machines with nitrogen-flush MAP and 50 g-1 kg quick-change collars will become mainstream by 2026—plan 15 % expansion headspace now.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.

Illustrative Image (Source: Google Search)